Difference between revisions of "SOP-42Q-MDS0029 CMMS Dashboard"

| Line 156: | Line 156: | ||

| | ||

| + | |||

=== E Panel Submodule === | === E Panel Submodule === | ||

| Line 178: | Line 179: | ||

2. Screens rotate to show all '''Open Repair W/Os'''; and all '''Open Preventive Maintenance W/Os''' according to the production line selected for view. | 2. Screens rotate to show all '''Open Repair W/Os'''; and all '''Open Preventive Maintenance W/Os''' according to the production line selected for view. | ||

| − | <br/> '''Figure 8a: E Panel Display: Open Repair Work Orders'''<br/> [[File:Open Repair Work Orders.png|RTENOTITLE]] | + | <br/> '''Figure 8a: E Panel Display: Open Repair Work Orders'''<br/> [[File:Open Repair Work Orders.png|1200px|RTENOTITLE]] |

| − | <br/> '''Figure 8b: E Panel Display: Open PM WOs'''<br/> [[File:E Panel Display Open PM WOs.png|RTENOTITLE]] | + | <br/> '''Figure 8b: E Panel Display: Open PM WOs'''<br/> [[File:E Panel Display Open PM WOs.png|1200px|RTENOTITLE]] |

<br/> 3. To '''change the production lines''' displayed on Dashboard, select the gear icon on the bottom right hand corner of the page.<br/> 4. The user is directed to a new window, similar to the Production Line Selection screen within the [[#Machine_Status_Submodule|Machine Status Submodule]] submodule of this Dashboard’s work instruction.<br/> 5. Check the lines for desired viewing on the Dashboard. | <br/> 3. To '''change the production lines''' displayed on Dashboard, select the gear icon on the bottom right hand corner of the page.<br/> 4. The user is directed to a new window, similar to the Production Line Selection screen within the [[#Machine_Status_Submodule|Machine Status Submodule]] submodule of this Dashboard’s work instruction.<br/> 5. Check the lines for desired viewing on the Dashboard. | ||

| Line 186: | Line 187: | ||

<br/> '''Figure 8c: E Panel Production Line Selection''' | <br/> '''Figure 8c: E Panel Production Line Selection''' | ||

| − | '''[[File:E Panel Production Line Selection.png|RTENOTITLE]]'''<br/> | + | '''[[File:E Panel Production Line Selection.png|1200px|RTENOTITLE]]'''<br/> |

| | ||

Revision as of 20:57, 18 March 2019

42Q Home > Reporting > CMMS Dashboard

This edition applies to MES 15 Portal1.0 and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

CMMS Dashboard

CMMS Dashboard provides a dynamic visual overview of the production floor. Managers can view machine status, and repair and preventive maintenance work order details in real time according to production line and asset. Typically, Dashboard is viewed on a large screen situated directly on the shop floor.

CMMS Dashboard conveys information in a visually-pleasing, simple format. Assets are color coded according to their status. Dashboard screens are accessible via URL, thus eliminating extra steps navigating the CMMS portal. Work Orders may also be created and/or modified from the CMMS Dashboard submodule when accessed via a personal laptop or mobile device.

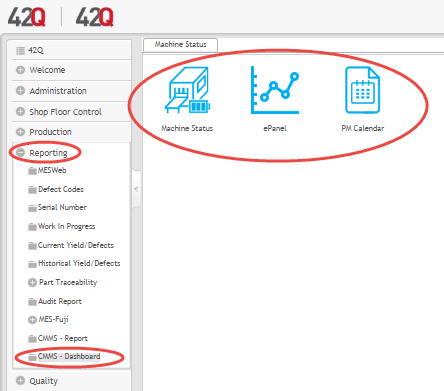

CMMS Dashboard is located in 42Q’s Reporting section (Navigate to Reporting > CMMS Dashboard) and is comprised of three submodules: Machine Status; ePanel; and PM Calendar.

Figure 1: Dashboard Submodules

Machine Status Submodule

The Machine Status submodule displays the status of all assets on a production line. Asset status is color coded for quick information retrieval. The following machine status types are available for view:

- In Use: Asset is running.

- Rejected: The Preventive Maintenance Work Order for this asset has been rejected.

- Spare: Asset is running, but not manufacturing product.

- PM (Maintenance): Preventive Maintenance tasks are being performed on this asset.

- Stop Down: Asset has been reported as down; production is stopped.

- Non-Stop Down: Asset has been reported down; production continues.

- WFP: (Waiting for Parts): The Preventive Maintenance Work Order has been placed on hold by the assigned technician due to unavailable parts. The Requestor must move the status back to assigned when part availability is confirmed. The up/down status of this asset is dependant upon whether Non-Stop was selected for the asset’s preventive maintenance. (See CMMS Work Order for more details about asset status, permissions, and steps in a Work Order.)

- WFB: (Waiting for Buy Off): The Preventive Maintenance Work Order for this asset has been completed and is awaiting manager (Requestor) approval.

NOTE: Plants predefine status types to reflect their company’s work flow. Configuration of machine assets is completed in the CMMS Asset portal: Shop Floor Control > Configuration > CMMS Asset.

Asset Type Display

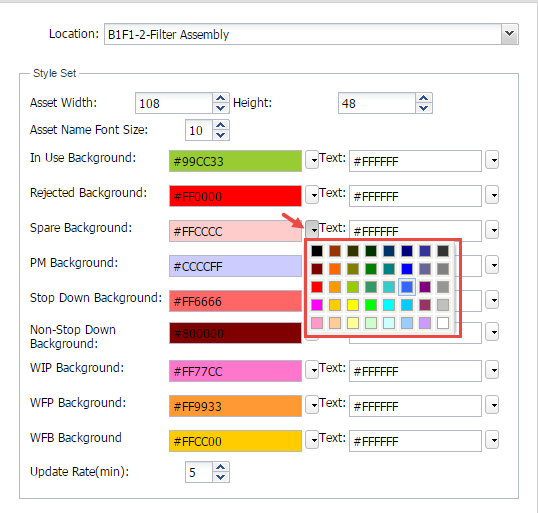

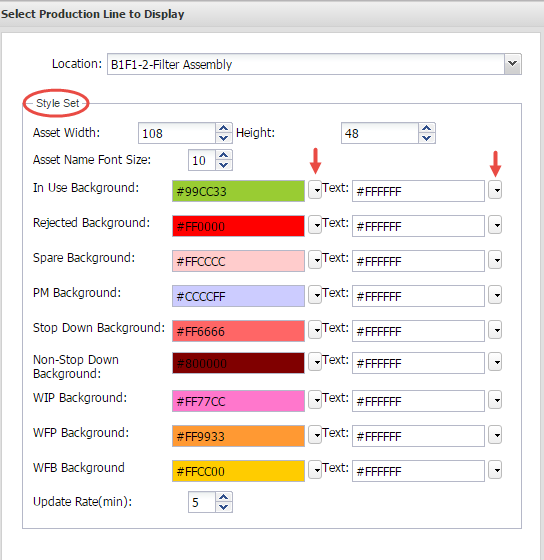

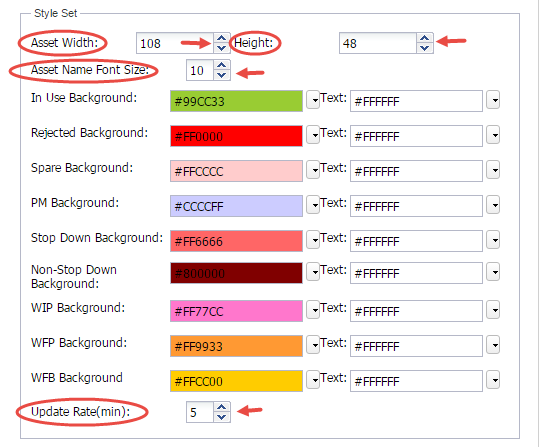

Icons in the Dashboard portal display brilliant, contrasting colors; coordinating color schemes and icon sizes are selected by default. If desired, users may adjust the appearance of the dashboard. Users may changecolor; text box width and height; asset name font size; and the update rate of the dashboard screen. To change any elements of the screen’s appearance, navigate to the Style Set panel. (NOTE: Style Set Panel automatically displays after the Machine Status icon is selected. See Figure 2, below.)

Change Asset Type Color/Text Color

- Select the drop-down boxes to the right of the default colors in the Style Set panel.

Figure 2: Change Asset Type Color and Font

2. A color palette will display:

Figure 3: Choose Color

3. Select the desired color for the asset type from the palette.

4. Text color can similarly be adjusted by selecting the drop down available. NOTE: Default text color is white.

Figure 4: Change Sizes and Update Rate

Change Asset Icon Size

- Adjust the width and height of the Asset’s icon with the drop-down available. NOTE: Default is 108 wide by 48 high.

Change Asset Name Font Size

- Adjust the Asset Name Font Size with the drop-down available. NOTE: Default font size is 10.

Change Update Rate

- Change the screen refresh time with the drop-down available next to Update Rate (min).Time increments are by minutes. NOTE: Default time is 5 minutes.

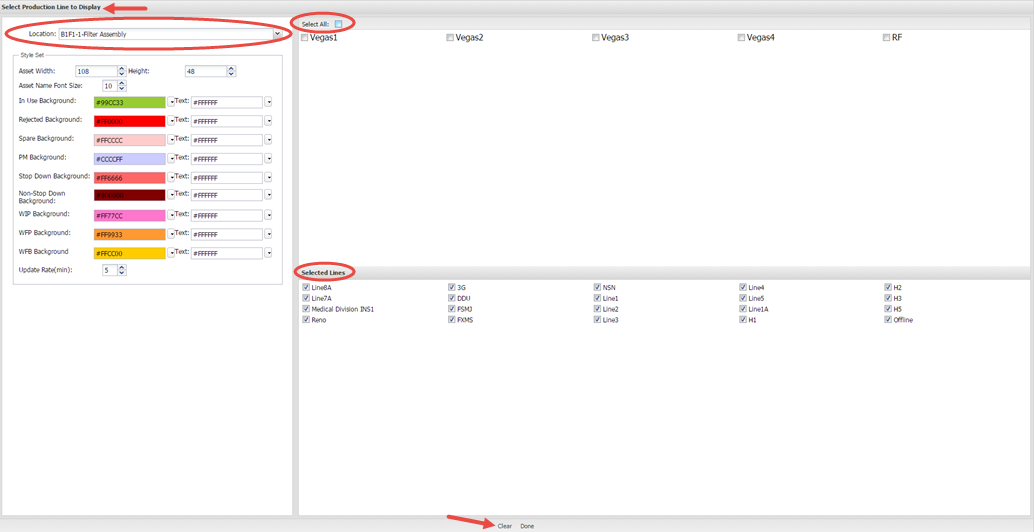

Add Assets to Dashboard

To view asset activity in live time on the Dashboard:

- Select a location from the drop down menu provided.

- Production lines from the selected location will now display in the panel on the right-hand side of the page.

- Select the production line by activating the checkbox next to its name.

- Selected lines will populate onto the bottom portion of the page.

- Users may select individual lines or Select All. NOTE: If a production line is not selected, the dashboard will display all the assets at this certain location by default.

- Select Done on the bottom right of the screen; or Clear to refresh the page information.

- Selecting Done releases the asset information onto the dashboard and the user is automatically directed to the Dashboard screen. NOTE: The coordinating URL address becomes available in the search bar.

Figure 5: Select Production Line

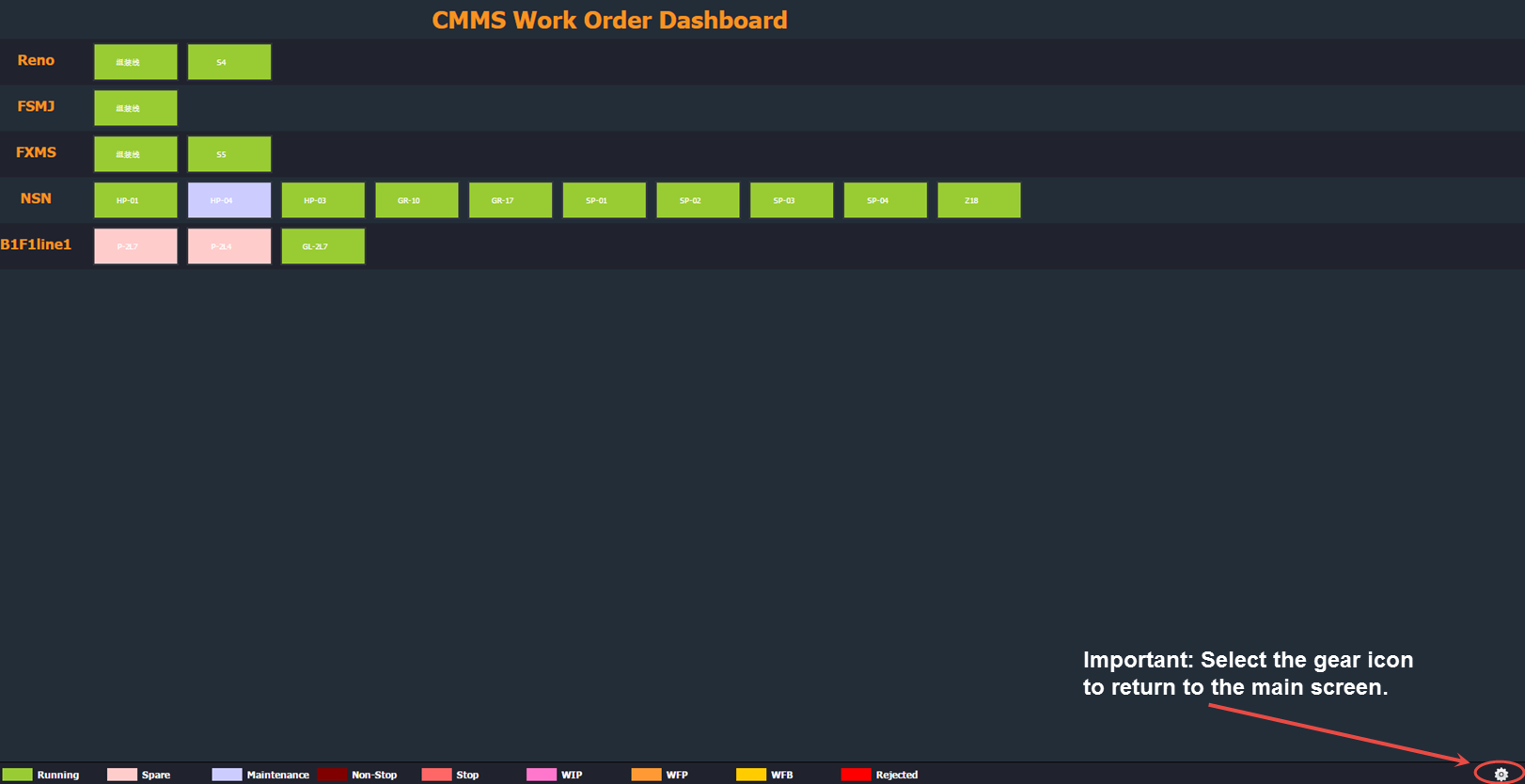

Machine Status Dashboard

The Machine Status Dashboard displays the status of all the machines on selected production lines. On the bottom of the screen, a helpful key is available for color-coding reference. This information can be displayed on a large monitor located on the shop floor and within the portal.

NOTE: To return to the main menu, select the gear icon on the right-hand corner of the page.

Figure 6: CMMS Work Order Dashboard

Create Work Order/View Work Order List

Users may create a work order to schedule a repair or view a work order list associated with a given asset directly from the Dashboard screen, thus eliminating the need to navigate back through the system (Production > CMMS Work Order).

To Create a Work Order for a machine asset:

- Select the machine’s icon.

- Right click on the icon.

- A message screen displays, offering the option to create a work order or view the work order list.

Figure 7a: Create Work Order/View Work Order List

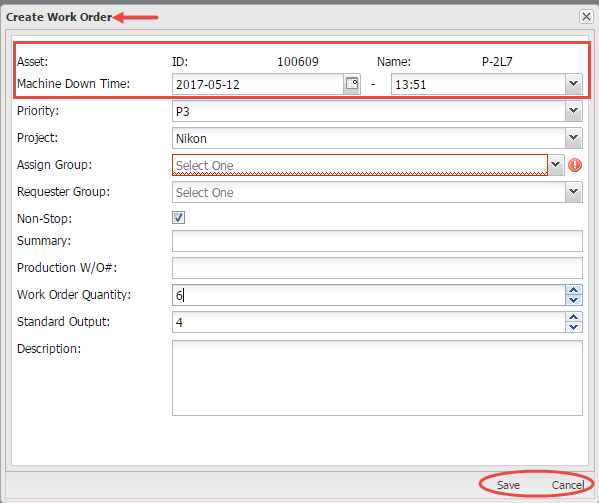

4. Select Create Work Order.

5. The Create Work Order pop-up window displays.

6. The top portion of the field (Asset ID; Name; Machine Down Time) automatically populates based on the asset selected and the current date and time.

7. The following additional fields are available for completion:

Priority: Select the urgency of the repair from the drop-down menu. Choices include: P1, P2, or P3.

- Select the name of the project from the drop-down menu.

- Select the group assigned to the work order (Mandatory).

- Select the name of the group requesting the repair.

- Mark whether the repair is non-stop by activating the checkmark. Default status is unchecked. NOTE: Non-stop signifies that the production line should continue even though the machine is down. An unchecked box alerts the operators that both the line and the machine are down.

Figure 7b: Create Work Order Window

To View a Work Order List for a machine asset:

- Select the asset’s icon.

- Right click on the icon.

- A message screen displays, offering the option to create a work order or view the work order list.

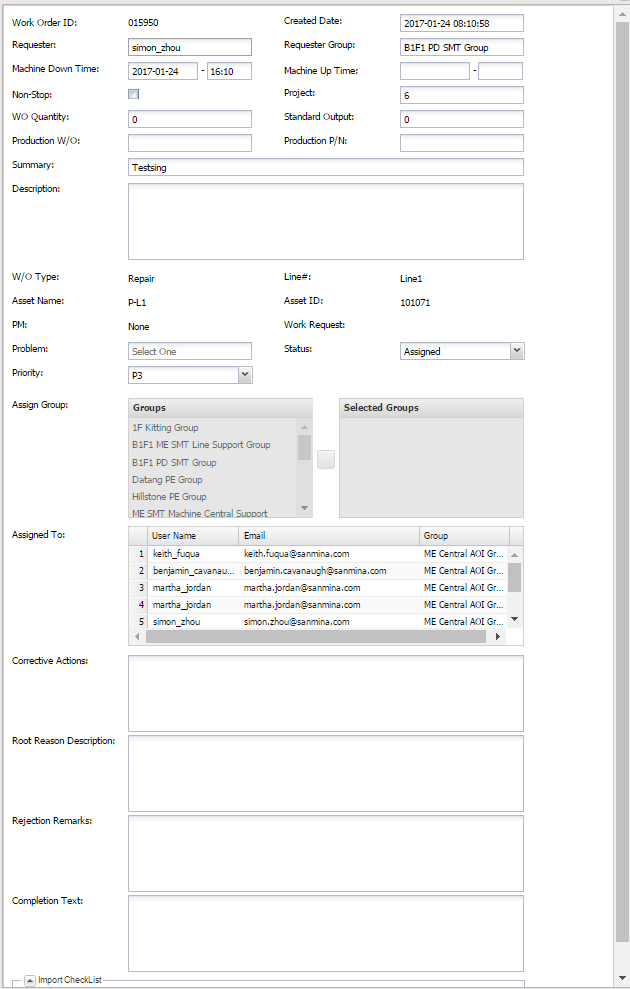

Figure 7c: View Work Order List Pop-up Window

- Users may view all details of a work order from the pop-up window.

- NOTE: The work order within the Dashboard portal is view only. Work orders are available for edit in various portals, depending on their purpose: Preventive Maintenance (Production > CMMS Preventive Maintenance) or Work Order (Production > CMMS Work Order). Checklists can be imported, exported and edited within the CMMS Asset portal (Shop Floor Control > Configuration > CMMS Asset > Check List).

'

Figure 7d: View Work Order List

E Panel Submodule

CMMS E Panel allows managers and employees on the shop floor to view machine (asset) status on a large screen according to production line. Asset status remains on the screen for the programmed amount of time. Then the next asset status automatically displays. The amount of seconds remaining before the next screen displays is noted in live time on the top left corner of the dashboard. Dashboard’s familiar color scheme (orange lettering on black background) is featured by default.

- The following information pertaining to the Work Orders selected will display:

- WO#

- Summary

- Line#

- Asset

- Priority

- Assigned Group

- Assignees

- Reason

- Requester

- Requester Group

- Status

- Down Time

2. Screens rotate to show all Open Repair W/Os; and all Open Preventive Maintenance W/Os according to the production line selected for view.

Figure 8a: E Panel Display: Open Repair Work Orders

Figure 8b: E Panel Display: Open PM WOs

3. To change the production lines displayed on Dashboard, select the gear icon on the bottom right hand corner of the page.

4. The user is directed to a new window, similar to the Production Line Selection screen within the Machine Status Submodule submodule of this Dashboard’s work instruction.

5. Check the lines for desired viewing on the Dashboard.

Figure 8c: E Panel Production Line Selection

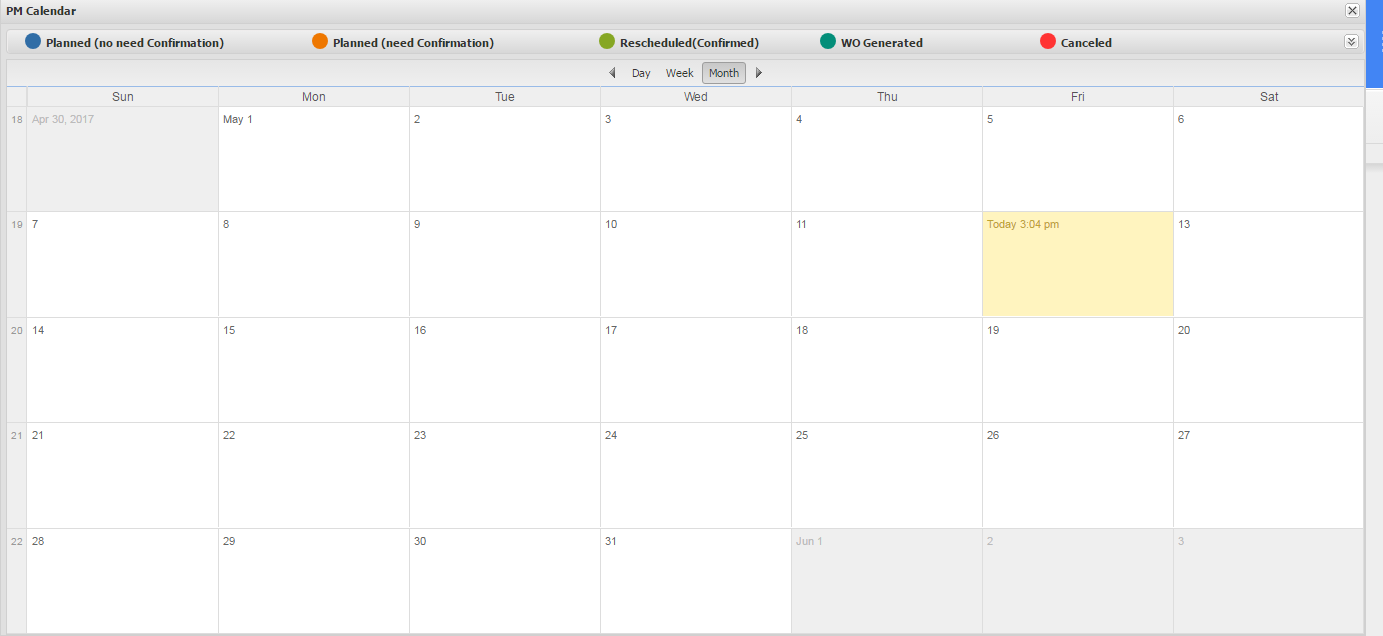

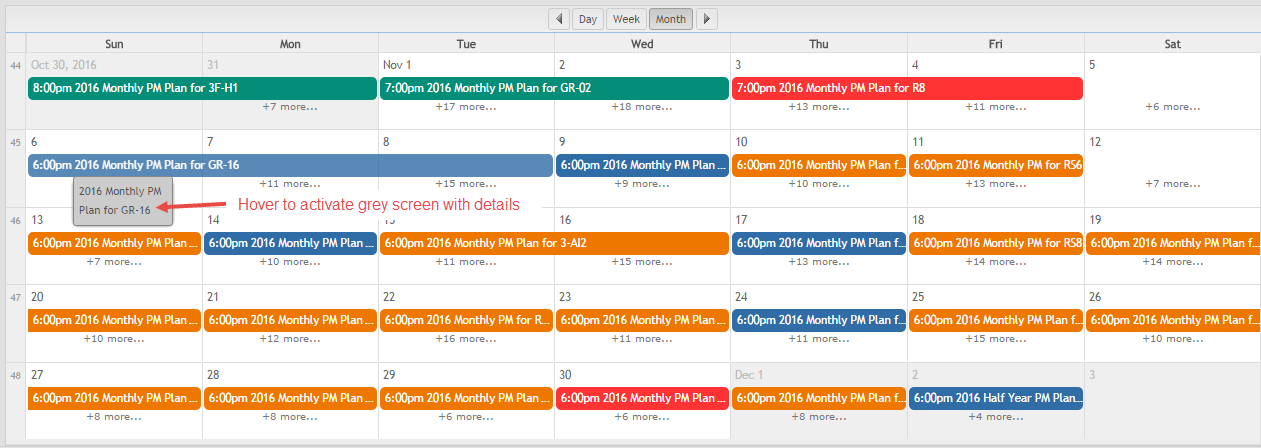

PM Calendar Submodule

- The PM Calendar view of CMMS Dashboard provides live time updates of all repairs and maintenance according to Planned and Confirmed Work Orders ; Planned but Unconfirmed Work Orders; Rescheduled (Confirmed) Work Orders; Generated Work Orders; and Canceled Work Orders.

- Categories are color-coded for easy understanding. NOTE: The same calendar features are also available in the Preventive Maintenance portal of CMMS Asset Management: Production > CMMS Preventive Maintenance > PM Calendar.

- Calendar view is available to view according to Month, Week, or Day.

Figure 9a: Color-Coded Dashboard Calendar View

Figure 9b: Scheduled PM WOs for the Month of November, 2016

Figure 9c: Scheduled PM WOs for the Week of November 17, 2016

Figure 9d: Scheduled PM WOs for November 17, 2016

4. Users may hover across an entry to view more details; or right click to reschedule work orders.

5. See the SOP-5-I-42Q-MES0076-C CMMS Work Order & Preventive Maintenance Work Instruction of 42Q’s CMMS Asset Management for more detailed description of Calendar.

Document Revision History

| Date | Author | Title | Version | Change Reference | Approved by |

| 05/30/14 | Ashley Martin | Tech Writer | 2.0 | This is the first revision of CMMS Dashboard | |

| 02/01/17 | Martha Jordan | Tech Writer | 1.10 | Recreated document as 42Q. Edited document to match new functions in 42Q portal. Replaced all images. | |

| 05/12/17 | Martha Jordan | Tech Writer | 1.10 | Added E Panel/Calendar instructions. Updated screenshots. Added introduction. | |

| 04/04/18 | Elaine Fonaro | Tech Writer | 1.0 | Applied new template for format | |

| 04/18/19 | Martha Jordan | Tech Writer | 1.0 | Added new feature in Create Work Order/View Work Order List. Added Figure 7c. Adjusted Figure numbers for Figures 7a - 7d. |