SOP-42Q-MES0014 Revision Change Maintenance

42Q Home > Shop Floor Control > Configuration > Revision Change Maintenance

Contents

Introduction

The main function of the Revision Change module is that it enables the user to change a unit revision. The module also provides the following portlets: User-Defined, User Revision, Add a Comment and add MEO (Manufacturing Engineering Order, i.e. ECO or Deviation number).

The user defines the unit serial numbers to be updated by selecting from three different Rule Options:

- Part Number – Updates unit serial numbers by Part Number

- Serial Number – Updates unit serial numbers by Serial Number

- Shop Order – Updates unit serial numbers by Shop Order

The Revision Change portlet can be used with any rules; however, the user cannot add the same part number, serial number or shop order more than once. Users may add a shop order rule and then add the part number to the previously added shop order; this also applies to serial numbers. Revision Change will merge the part and serial numbers in order to avoid duplications.

Note: This portlet has the following limitations:

- Revision changes are not allowed for ERP-Interface Shop Orders or for unit serial numbers tied to them.

- Revision changes are not allowed for WIP units with a finished status.

To access the Revision Change Maintenance, navigate to Shop Floor Control > Configuration > Shop Floor Configuration > Revision Change.

Note: A user only has access to the modules assigned to his/her profile.

Revision Change

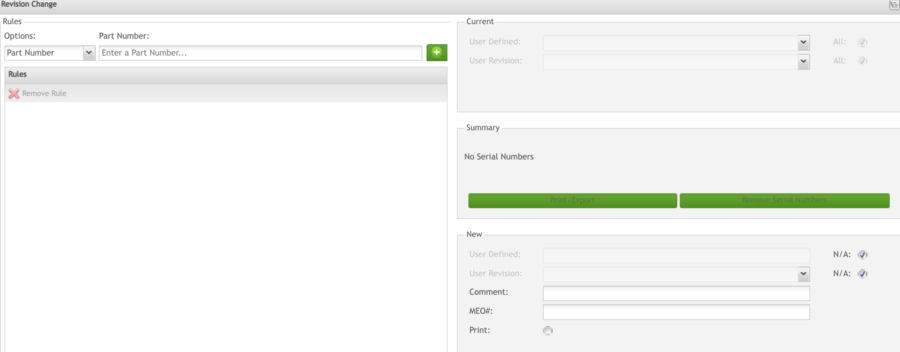

The main Revision Change page is display:

Figure 1: Revision Change Main Page

Adding Rules

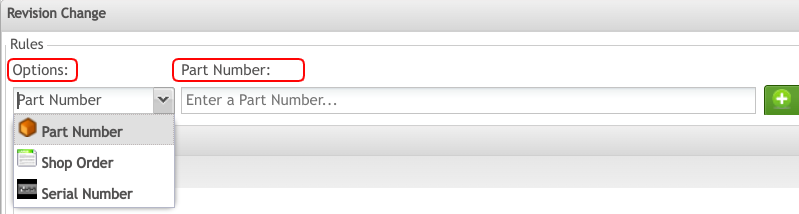

Select the desired rule option from the Options drop-down box:

- Part Number: After selecting the Part Number Option, the Browse button is enabled.

- Serial Number: Enter a valid WIP serial number in the space provided.

- Shop Order Number: After selecting the Shop Order Option, the Browse button is enabled.

Figure 2: Part Number Browser

1. Enter the desired part number. Or, enter at least three characters to enable the shop order search.

Note: If invalid information is provided in any of the above rules, an error message is displayed.

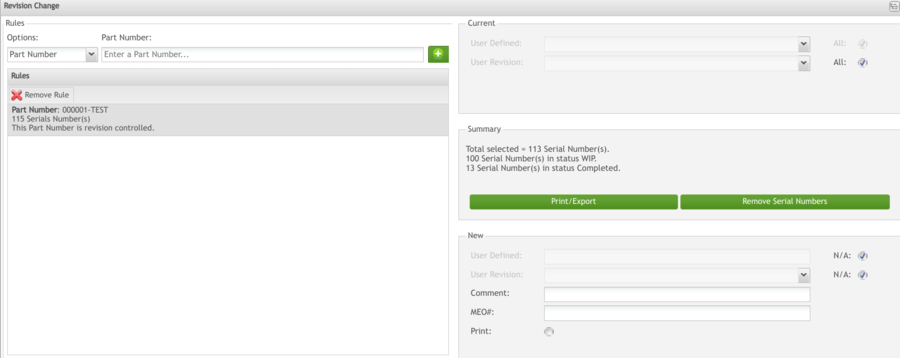

2. After selecting the desired Rule Option(s), select the Add button

Figure 3: Shop Floor Revision Change –Add Rules

3. The Option is added to the Rules and Summary section for easy verification.

Note: A Print/ Export is displayed in order to verify details in the Part Number's Serial Number

4. The user may add as many Rules as desired, as long as they do not conflict with the limitations defined in this guide.

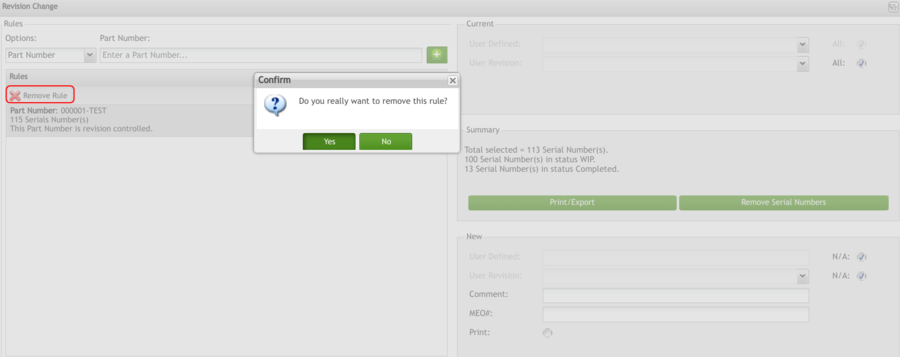

Removing a Rule

To remove a rule, select the desired Rule and select the Remove Rule button.

Figure 4: Remove Rule

A confirmation message is displayed, click Yes to confirm, or No to cancel.

Current User Defined/Revision

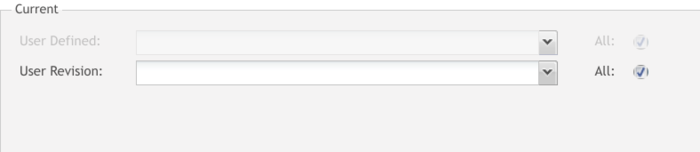

Current User-Defined and Current User Revision (optional): These fields are used to enter record search criteria (filter and view values). The default ALL value indicates all values.

Note: A blank value is valid for the undefined field in the serial record.

After adding the desired rules, the serial numbers can be filtered in the Current form:

Filter the serial numbers by User Defined or by User Revision fields or choose the option All to update all serial numbers selected.

Figure 5: Current User Defined/Revision

- Current User-Defined: When the user selects Update, the User-Defined field is updated with a new user-defined value of up to 20 characters.

- Current User-Revision: When the user selects Update, the User-Revision field is updated with a new revision value of up to 10 characters.

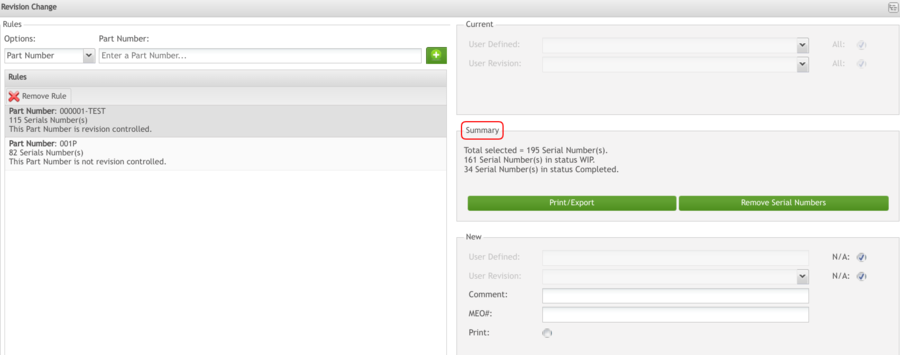

Summary – Viewing and Removing Serial Numbers Affected by Rules

After rules have been added, it is possible to view serial numbers affected by the rules and to remove them.

To view serial numbers affected by the Rules, Select Print/Export. A pdf report is generated listing the serial numbers and automatically downloaded to the user’s desktop.

Figure 6: Serial Numbers Summary

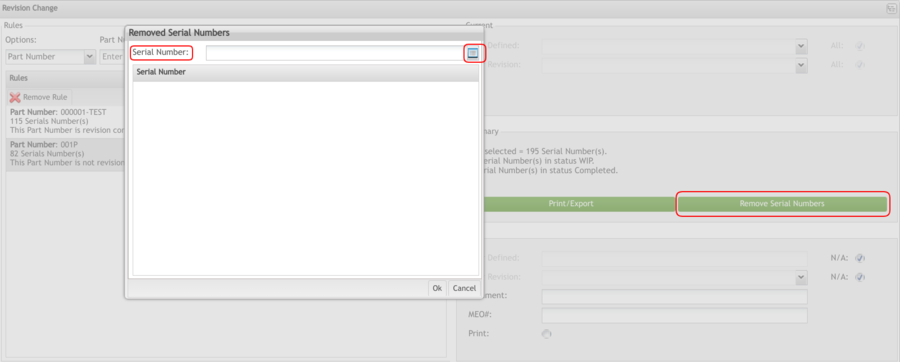

- To remove a Serial Number from the Selected Serial Numbers section, select the Remove Serial Numbers. A pop-up window will appear. Enter the Serial Number to be removed. Select the Add Serial Number button.

Figure 7: Remove Serial Numbers

- A pop-up window will appear. The user will be able to add one or multiple serial numbers to remove them from the Part Number Rule. When the desired serial number (s) have been entered, select OK to confirm or, select Cancel to abort.

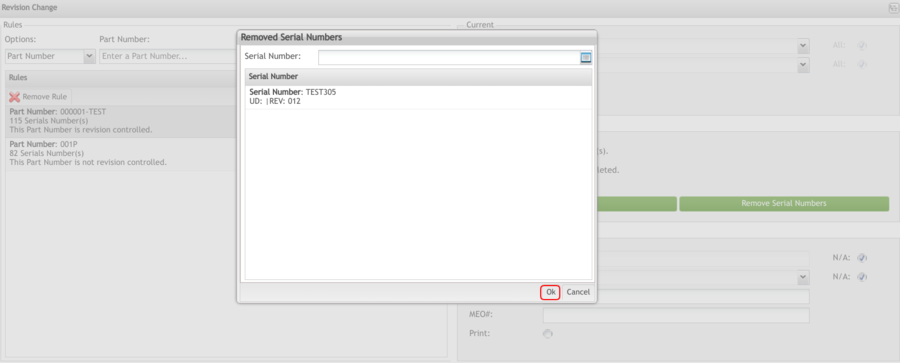

Figure 8: Add Multiple Serial Number

- When the desired serial number (s) have been entered, select OK to confirm (or select Cancel to confirm). The selected serial numbers will be display in the Remove Serial Number window Select OK to confirm or Cancel to abort. The Serial Number selected will be removed from the Revision Change upon final Update.

Figure 9: Removed Serial Number

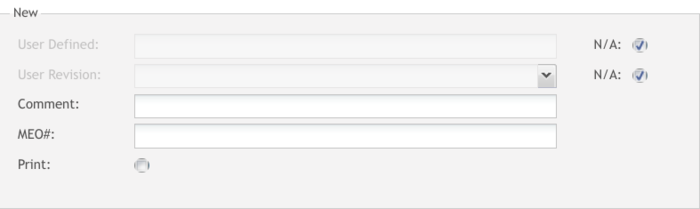

New – User Defined/Revision/Comment/MEO#

This section defines the new updates that will be performed to the serial numbers affected by the rules added in the previous sections.

1. Define New updates to be performed:

Figure 10: New User Defined/Revision/Comment/MEO#

Note: Either the User Defined or User Revision update is required, yet both can be updated if desired. If the boxes for both User Defined and User Revision are checked, the Update button is disabled.

- User Defined: Data to replace the current data for the affected serial numbers. 20 character limit.

- N/A: Check only if update to the User Defined field is not desired.

- User Revision: Enter the desired Revision, or double-click the field to select the desired value for Revision Controlled Part Numbers.

- N/A: Check only if update to the User Revision field is not desired.

- Comment: The comment entered will be attached to all serial numbers affected by the Rules.

- MEO#: Manufacturing Engineering Order (ADMEO) activity records will be added to the serial numbers affected by the rules.

As a general rule, any/all Revision changes performed are to be defined in an ECO, ECN, Deviation, or other traceable document. The document number should be included in the MEO# field as to add the activity records to the serial number for tracking the serial numbers affected by the documented change.

- Print: Check to print the affected serial numbers.

Appendix

Acronyms

MDS (Manufacturing Data System (JAVA Technology))

GLAD (Global Administration)

LDAP (Lightweight Directory Access Protocol)

MFG (Manufacturing Data Systems)

MES (Manufacturing Execution System)

PRAC (Process Access)

SPC (Statistical Process Control)