How to use Labor Tracking Widget

Contents

Summary

Labor Tracking is a capability in Production Workbench created to collect the labor and know in an exact way the time that the employees of your company spent performing a process to build a product. In the following document, you will find a quick user guide for this widget.

How to access the Labor Tracking | Crews Widgets

These widgets are an addition to the Production Workbench portlet, to access them, enter to Production Workbench and select the Labor Tracking | Crews icon located at the left panel of the screen. A panel will be displayed with two tabs, one for Labor Tracking and the other for Crews. These tabs allow users to move from one widget to another.

Fig. 1: Labor Tracking Icon Figure. 2: Labor Tracking | Crews Tabs

Crews Tab

Users are able to log in as Regular Users or as Crew Users. In the following chart, you can see what users are able to do in the Crew Tab according to each log.

In any case, the authentication credentials will be required to log in. As Regular User, the employee number and password will be required; as Crew User, the crew name and password will be required.

Figure 3: User Login request to log as Regular or Crew User

Figure 4: User Login request to log as Regular or Crew User

How to Search a Crew

There are three different filter options to search a crew:

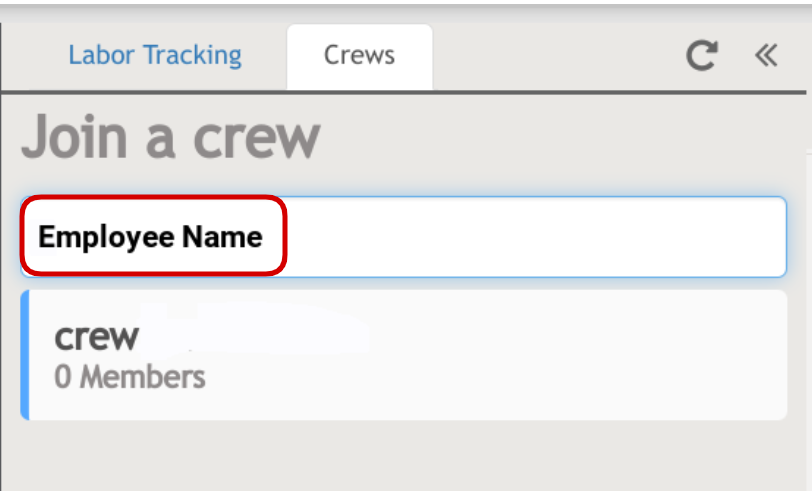

- Search by employee name: Type the employee name.

- Search by employee number: Type the employee number.

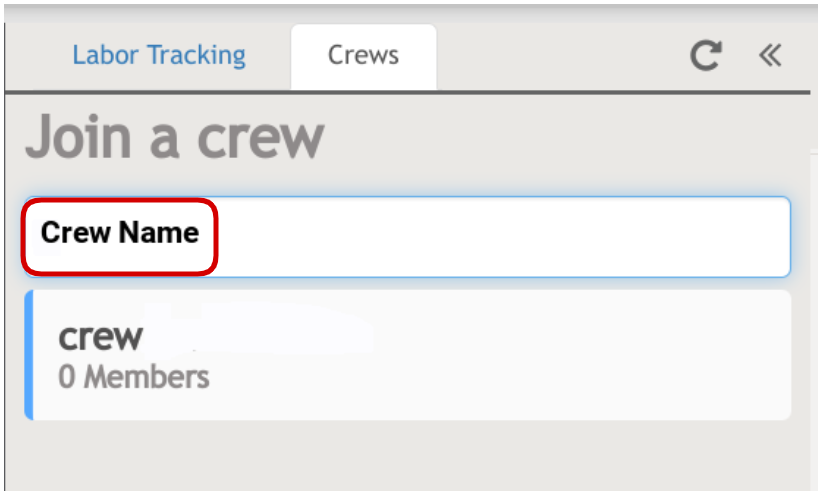

- Search by crew name: Type the crew name in the corresponding field.

Fig. 5: Search by Employee Name Fig. 6: Search by Employee Number Fig. 7: Search by Crew Name

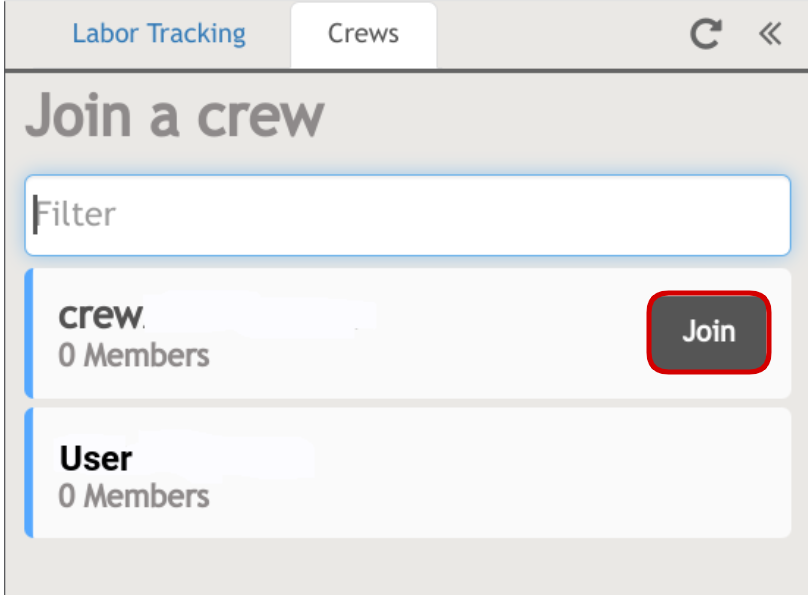

In all cases, users will see the list of all the crews where they can join. At the top, will appear the last crew where they were members, and below, the rest of the crews where they can join as members.

How to Join or Leave a Crew

- To join a crew, select a crew to join in, and then select the Join button at the right side of the crew information. A confirmation pop-up window will be displayed indicating the current opened direct units will be paused with the decision of joining the selected crew.

Figure 7: Join a Crew Button

Figure 8: Confirmation Pop-up for Pausing Regular User Labors at Joining A Crew

After a Regular User confirms the pause for labors, another pop-up window will be displayed asking to confirm the decision of joining the selected crew.

Figure 9: Confirmation Pop-up for Joining a Crew being a Regular User

Note: As a general rule a user cannot be part of two Crews at the same time.

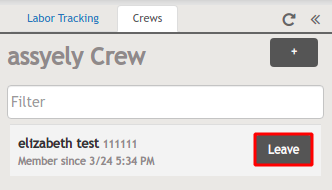

- To leave a crew just select the Leave button on the right side of the crew information. A confirmation pop-up window will appear asking if the decision of leaving is correct. Select Yes to confirm or No to cancel.

Figure 10: Leave a Crew Button Figure 11: Leave a Crew Confirmation Pop-up

Note: Once users are part of a Crew they won’t be able to scan themselves if they join a Crew, Conduit will block any request that comes with that employee.

Users are also able to log in as a Crew user, allowing them to see the crew members that belong to the logged Crew user, to join a Crew, and to use the Filter field to search crews by employee name and employee number.

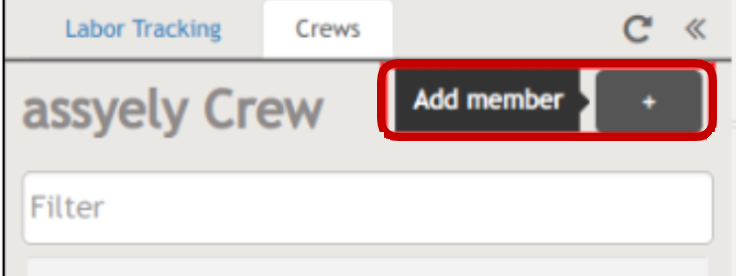

How to add another user to a Crew

If users have been logged in as Crew users, they will be able to add new crew members by selecting the + icon beside the crew name. The log-in window will pop-up to authenticate, and finally, be added as a new crew member.

Figure 12: Add Member Button

Labor Tracking Tab

In this tab, users will find two different types of labor, Direct and Indirect. In the following chart, you will find the principal features of each tab.

| DIRECT | INDIRECT |

| Activities related to the manufacturing process i.e machine setup, machine running, change over (list of jobs that an operator is working on, grouped by Shop Order). | Administrative activities non-related manufacturing i.e meetings, breaks, training, and cleaning. |

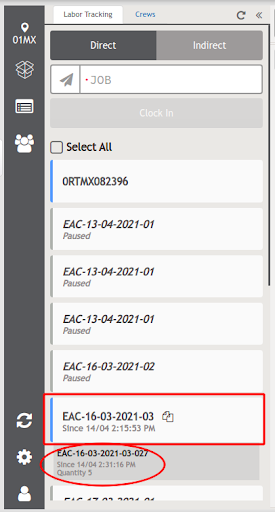

How to add direct labors to track

There are three ways to add Direct Labors to Labor Tracking. Scanned shop orders will be added to labor tracking with the serial numbers related to it, and they will be assigned to the user that scanned them.

- Selecting a Shop Order where the belonged serial numbers will be displayed to be scanned. These SN will appear automatically in the tracking panel.

Figure 13: Shop Order and Serial Numbers

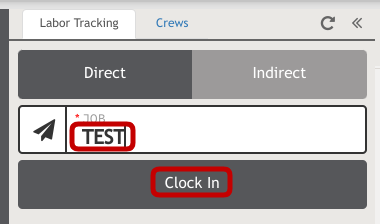

- Adding a Unique Serial Number and a Non-Serialized Batch directly in the JOB field and selecting the Clock In button. The Shop Order will appear automatically in the tracking panel.

Figure 14: Adding a Shop Order To Track

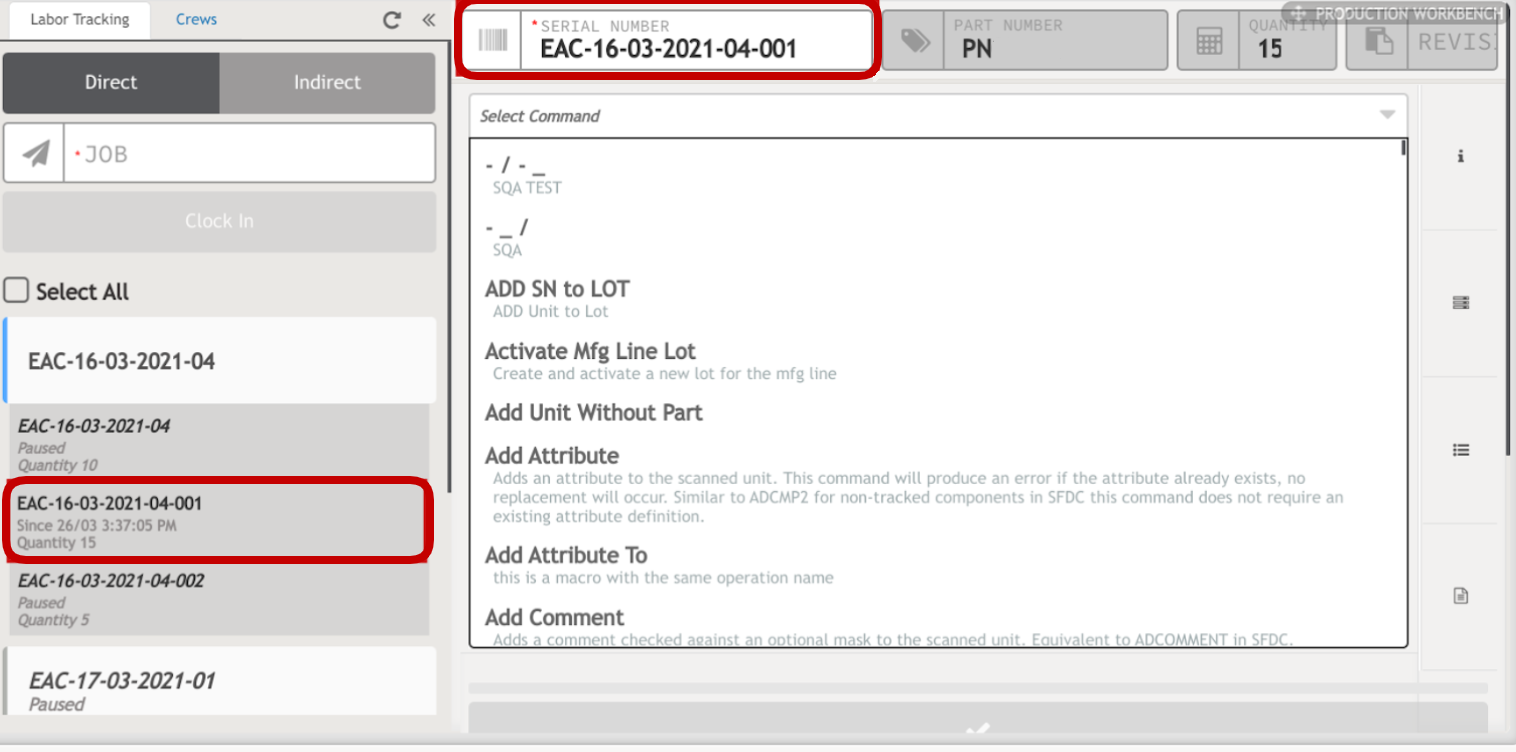

- Add a serial number directly to the corresponding field, and it will be scanned automatically and added to the list of direct labors.

Figure 15: Serial Number Scanned

How to pause, resume, or release Shop Orders and Serial Numbers

Users can perform any of the following activities to an individual Shop Order and Serial Number or to multiple Shop Orders and Serial Numbers:

Note: After users select any of those three activities, a pop-up confirmation message will be displayed, select Yes to proceed or No to cancel.

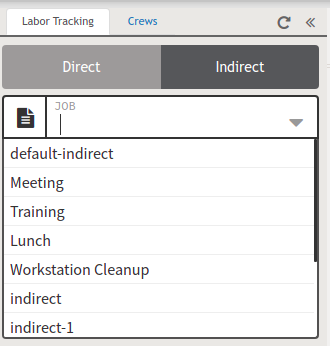

How to Add Indirect Labors to Track

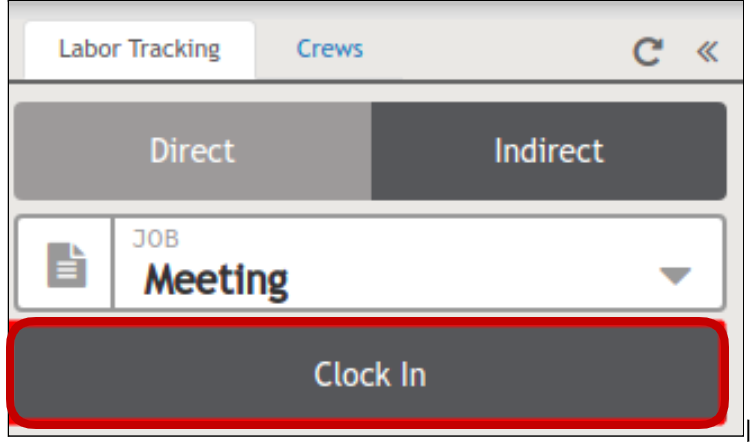

Select the Indirect tab. Then Select indirect labor from the displayed list of the JOB field. Finally, select the Clock In button. A confirmation pop-up window will appear if there is a work in progress (WIP). Select Yes to proceed or No to cancel.

Figure 16: Selecting Indirect Labor

Figure 17: Clock In Indirect Labors

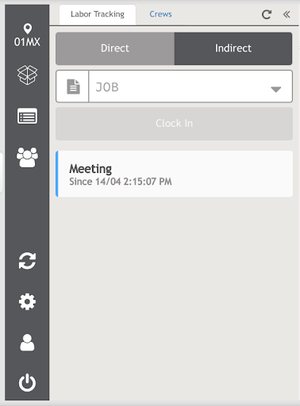

After confirming this action, a blue line will appear at the left side of the indirect labor information to indicate the current indirect labor, whereas a gray line will indicate that the indirect labor was recently clocked in.

Figure 18: Active Indirect Labor Figure 19: List of Indirect Labors Recently Clocked In

Note: For further information, please go to Production Workbench SOP.

-

How to Use Smart Insights Tool

Smart Insights describes the portal’s ability to assist users with simple automated tasks that could potentially save time and prevent users from the mistake of overlooking manual tasks that should be performed.

Note: Smart Insights can be configured in order to enable or disable as desired. Since labor entry is a manual process, the smart insight tool will help users to have the ability to start and/or resume labor records upon unit scanning by selecting one of the three deployed prompted choices:

- Clock In/Resume: this option will clock in/resume the Shop Order to Labor Tracking.

-

- Clock Out: this option is chosen when serial numbers of related Shop Orders are completed and the process has been reported.

- Dismiss: this option will not clock in or resume the Shop Order to Labor Tracking. Within the next case, the system will prompt the Smart Insights tool message again.

- Dismiss and Don’t Ask Again: this option will not clock in or resume the Shop Order to Labor Tracking. The system will also not prompt the user with the Smart Insights prompt message again unless it is re-enabled.

Figure 20: Smart Insights Message Prompt

Note: Operators will have the option to manage the Labor Tracking list in order to Clock in/ Pause/Resume/Stop a Shop Order Labor Tracking. There are two available options for users when the Smart Insights tool is enabled:

- If the user scans a serial and the system does not find a labor record for its Shop Order, the system will then prompt users to Clock In for that particular Shop Order (create a labor record).

- If the user scans a serial and the system does find a labor record for the Shop Order in the paused state, then the system will prompt if the user wants to resume that labor record.

Smart Insights can be and must be configured using one of two ways, by Generic Attributes or by Flex Fields.

-

Configuring Generic Attributes

To configure the Smart Insights - Labor Tracking Tool using the Generic Attributes option, users must navigate to 'Administration > Generic Attribute Maintenance. Here, users can search the attribute name ps_insights_enabled. '

Figure 21: Generic Attribute

https://lh6.googleusercontent.com/y8Jkbm8uJx6XC9Dawoufn-Do8enFhRwb_CWLXavAGrVL-syBBs1qtJiN67cqr9Kf5qGgZzwre-ZtBxwEI_YUmGX92AvkdSqNn1Y9qQvcC7_mM2BMh14HhhgzcMhuwuLCCYgYNMJ9XgZEcAzPSsJtCG8 Using this generic attribute will allow the user two options to: enable (true) or disable (false) this feature. This setting will take place within the Device and Process level.

Note: Users have the option to override it by Location or Process using a Flex Field.

-

Configuring Flex Fields

To configure the Smart Insights - Labor Tracking Tool using the Flex Field option, users must navigate toShop Floor Control > Configuration > SFDC Configuration. Here, users can search for the attribute nameps_labor_tracking_option.

- Click the Location icon option and begin searching for the Shop Floor ID. From there, select the check box and click edit and the FlexField Form tab will be available to then select.

Figure 22: FlexField Form - LT Figure 23: FlexField Value

https://lh6.googleusercontent.com/zX3o4wDy6_TSICrftG7G7H2S3bOdnTDUm2VOUhEAv8qnGd_zQrHKT2OM_UYczDqY6ps2SNkhjRNivp4LzY7j5OlYvLhjnRVjtK3ygUcNq0qxSnEJO-ubGYFYB2wUl-q3UpDxhJJjKdq-LZ233p64KVI https://lh4.googleusercontent.com/RDF-OTAwqf80OCqNr6_DmYQmkct2YEh6Wp8lyiwI6kEIQSCbmyh9Ge19IuRIAEOvMzJt7YM1ZLgEQUw-Fls3Bt9AFFUJX-nNWtHE0OerUCl0GWuRzHlNIAt64tp_7bGde_G9t2Cd9GogXrwkQaBzpFY In this case, there are three available options to use as the value for the Flex Field (ps_labor_tracking_option) :

- OFF: If the generic attribute is ON, but a specific location is not needed to track the time then Smart Insights can be turned off.

- AUTO: Auto value will allow automatic Clock-In and Clock-Out regardless if the generic attribute is ON or OFF.

- INSIGHTS: Even if the generic attribute is OFF, the plant still has the ability to track the time in a specific location or process by turning on the Smart Insights.

Note: Autotrack no longer exists within the configuration tool settings. Users must configure the flex field beforehand.