42Q Production Scheduling Whitepaper

Production Scheduling

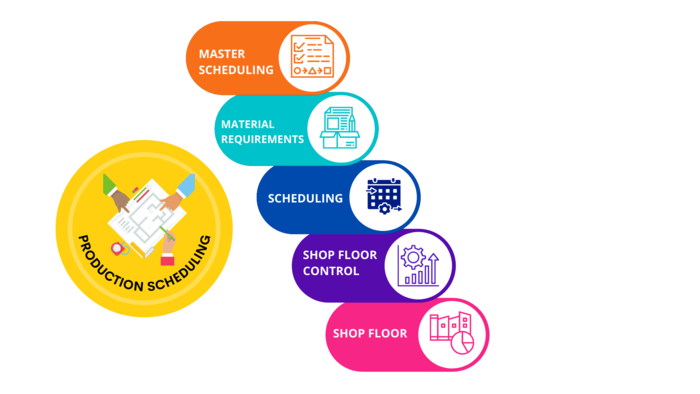

How Production Scheduling works

When this tool is integrated into the same cloud-based MES where work instructions and operations are configured, tracked, analyzed and managed, Production Scheduling helps to create processes where all the production activities are planned on a timescale.

This accessory is equipped with color-coding highlights to display changes to shop order demands, quantities or times. It also permits you to review supply, demand, availability and the running balance of an item following the current sales order, forecast, or dependent demand.

Users are able to schedule and display the production status of each Shop Order on each MFG line, see in the calendar what has been completed, what is in the current shift and needs to be completed, and even see the changes done to the scheduled Shop Orders. All that involves Shop Order completion percentage, start and end time, estimated end time, and target TPHR and allows planners to adjust the schedules in advance because they have visibility of the completed or delayed Shop Orders, as well as quickly find Shop Orders of the same part family.

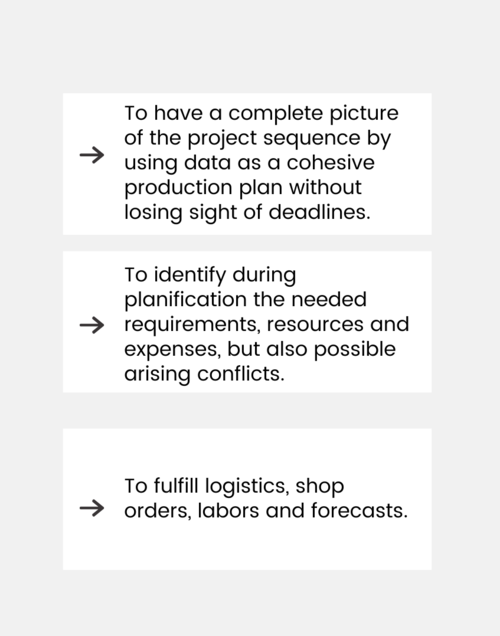

Why Production Scheduling must be considered

In short, to keep up the high demand from the manufacturing industry.

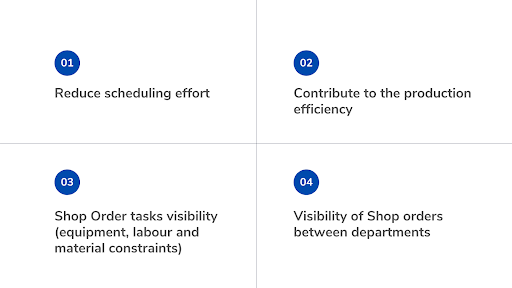

What benefits brings the use of Production Scheduling

Different areas of a company will be able to see what the priorities are and remain focused on the priority tasks. All that contributes to a significant reduction of time usually spent to create a production schedule and perform what-if analysis.