How to integrate Conduit-PTS Scanning

Conduit-PTS Scanning Integration

Contents

Introduction

This guide shows you how to configure and activate Conduit-PTS functions.

Conduit Admin and PTS Admin are required to complete the configuration on both systems.

Required to verify (upgrade if needed) the correct version before implementing Conduit-PTS Integration.

Configuration

To activate the function, setup needs to be done in Shop Floor ID and PTS.

Shop Floor Configuration

- Click the Data Editor under the Shop Floor Control -> Configuration -> Shop Floor Configuration menu.

Figure 1: Data Editor Menu

- Select one Shop Floor ID, then click the Edit button.

Figure 2: Select Shop Floor

- Add this below line into the setup data editor.

OPTIONS URL_WEB_SERVICE NAME=PTS VALUE=http://pts-uat.sanmina.com:8080/pts

Figure 3: Data Editor Options Example

#Conduit -PTS Service (For example)

OPTIONS URL_WEB_SERVICE NAME=PTS VALUE=http://pts-uat.sanmina.com:8080/pts

Note: Please replace http://pts-uat.sanmina.com:8080/pts with your Conduit-PTS service URL.

Save the changes before exit.

Server information Configuration

Make sure you have Conduit_shopFloorID & Conduit program configured from Administration-->Server information

- Click Server information under the Administration menu

- Add the Server information for the Conduit_ShopFloorID and Conduit program.

Figure 4: Add Server Information

Figure 5: Server Information List

PTS Configuration

There are 2 places that need to set up in PTS portlets

- Add MDS Net User in PTS Administrator(System setting)

- Location Mapping in Workstation Setup(PTS)

Add MDS Net User

Raise P3 Service Request to the MES Support team to request add MDS Net User in Traceability Administrator ->System setting.

Please include the below details in your TT

For Example:

Plant Name: E83 Penang

MES Portal Server:143.116.xxx.xxx

NetUser ID: P99LDC1H,P99LDC168, P99TESTDC1

Support team to add the MDS Net User refer to the picture as follows.

Note: The MDS Net Users separated by commas.

Figure 6: MDS Net User

Workstation Setup (PTS )

- Login to MES15 and from the pull-down menu(Shop Floor Control->Production Control->Traceability Setup.

- Select “Production Line” and “Workstation”

- Right, Click on “Workstation” to show the right menu then click on “Location Mapping” as below screenshot.

Figure 7: Location Mapping Menu

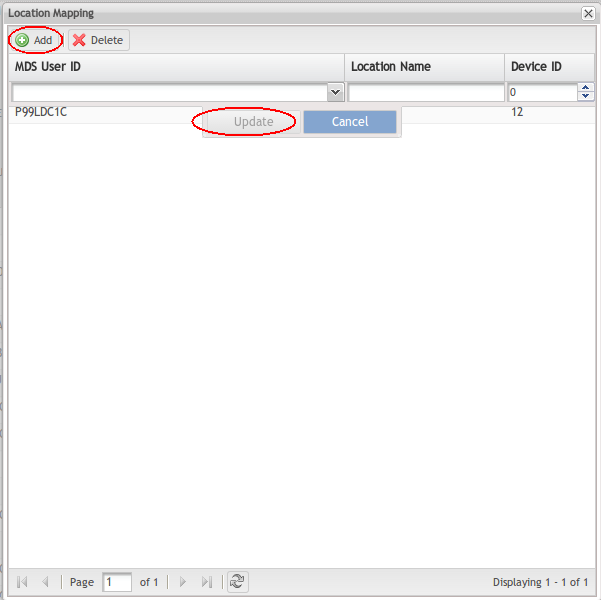

Location mapping page prompt up.

Click the Add button to add a mapping.

- MDS User ID (Compulsory)

Figure 8: Location Mapping

- This is referring to MDS Net User(Defined at system setting).

- All MDS NetUser ID added in system settings will appear in the pull-down menu.

- Select the correct SFDC NetUser ID.

- Location Name (Compulsory)

- Location name created in jMDS Location Maintenance (example S002 SMT Insp Bot or A002

SMT Insp Top or SMTT SMT Top)

- Value must be the first 4 characters from the location name (S002, A002, or SMTT)

- Device ID

- Device ID that associate to location name in Data Collector Maintenance

-

- - Example 1 or 401 or 508

Click the Update button to save the configuration in PTS for the selected production line and workstation.

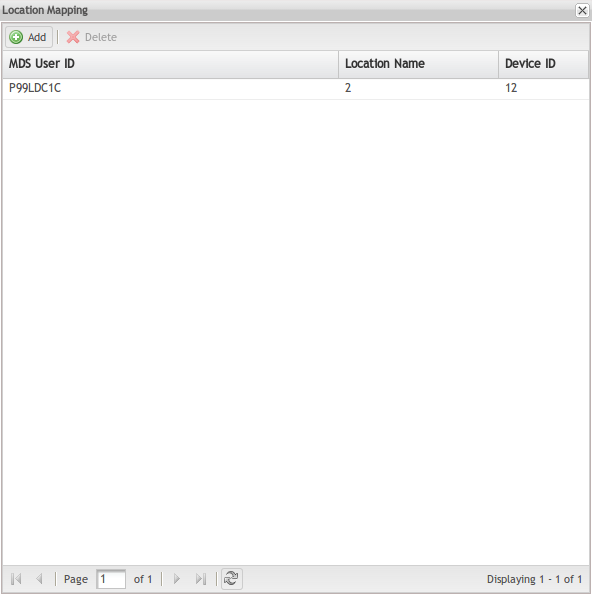

Once the mapping save in PTS, a list of location mapping show below

Figure 9: Location Mapping Example

Turn on the production line as usual and Conduit-PTS ready for action.

Conduit-Scanning Operation

By using NetDC or emulator, users can scan serial numbers and update to both Conduit and PTS.

Conduit Commands

- ScanPtsBoard

- CheckPtsComponent

- ptssplitpanel

- UpdatePtsComponent

- Validateboard

- LoadPtsMaterial

Scan Scenario

Conduit-PTS call

Macro: LoadPtsMaterialMacro

Load the material to the slot

Figure 10: Load Material to Slot

Figure 11: Load the Material Successfully

Tried to load the same material to the slot.

Figure 12: Load the Duplicated Material Failed

Conduit Macro: CheckPtsComponentMacro

Verified the material has been loaded

Figure 13: Check Material loaded

Note:

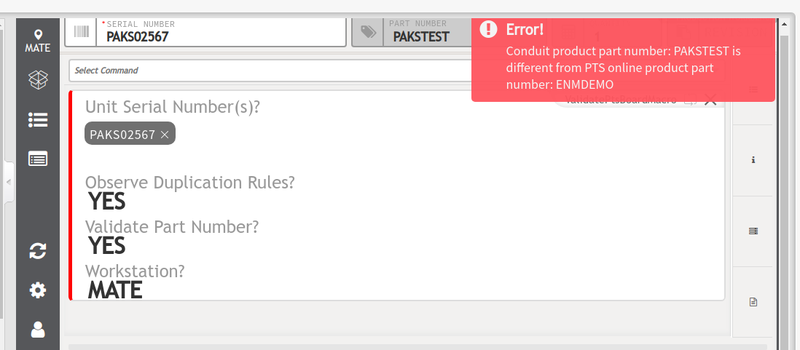

Before scanning, we need to make sure the location mapping to the workstation, otherwise we will have the following error.

Figure 14: Location not Mapping

Macro: ScanPtsBoardMacro

After loading the material and we are able to scan the serial number

Scanned serial: PAKS02567, PAKS02568, PAKS02569

Figure 15: Scan PTS Board

Material runs out:

Figure 16: Check Material Runout

Loaded the material After a material runout

Figure 17: Load More Material when Runout

Macro: UpdatePtsComponentMacro

Material splicing to the slot

Figure 18: Material Splicing to Slot

Conduit macro: validate board

Figure 19: Validate Board

Reporting

PTS scan board in production

Figure 20: PTS scan board in production

Board history report

Figure 21: Board History Report

Material onboard report:

Figure 22: Material on Board Report

Further assistance

For further assistance on Conduit-PTS Integration, please do not hesitate to contact the MES Support team.

Document Revision History

| Date | Author | Title | Version | Change Reference | Approved By |

|---|---|---|---|---|---|

| 11/04/2020 | Helena Wang | Technical Writer | A | The first version. | |

| 11/05/2020 | Marisol Vargas | Technical Writer | A1 | Peer Review, structure, and grammar | Simon Zhou |