42Q-MES0135-C Rapid IIoT Work Instruction

This edition applies to MES 15 Portal 1.0 and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

42Q Rapid IIoT

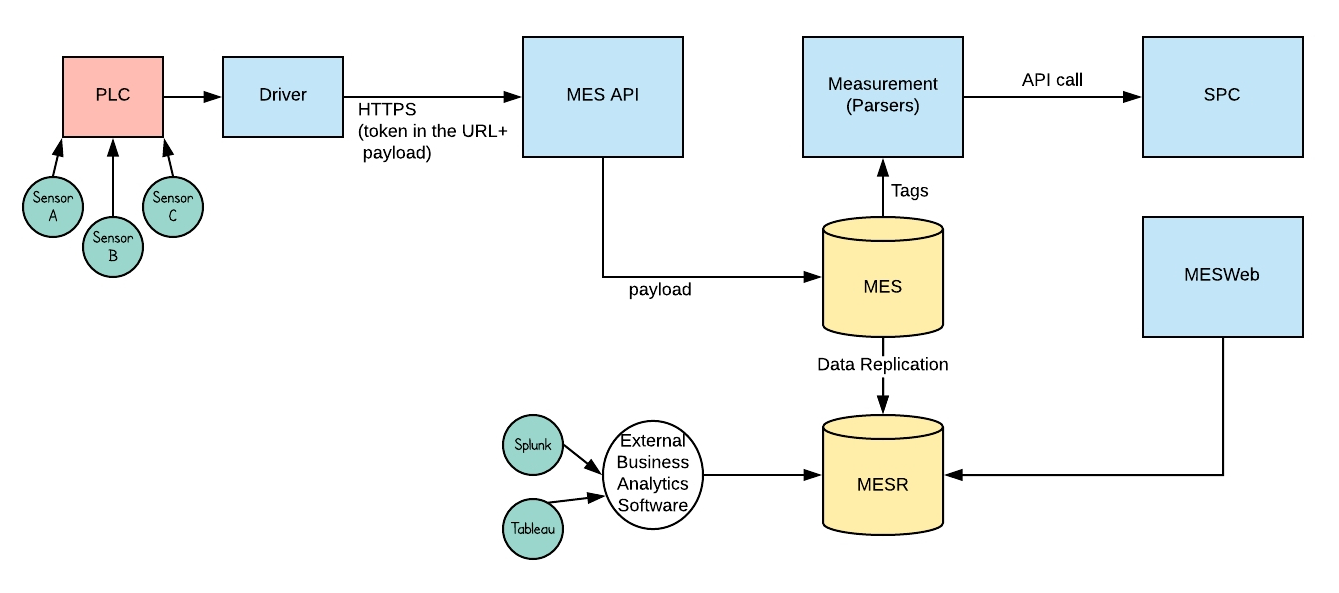

42Q's Rapid IIoT solution accurately captures raw data from the shop floor (sensor devices and machinery), and inserts that data into business intelligence software, MESWeb, or 42Q SPC, where reports such as unit history, defect and repair, and SPC charts are generated for self service analytics.

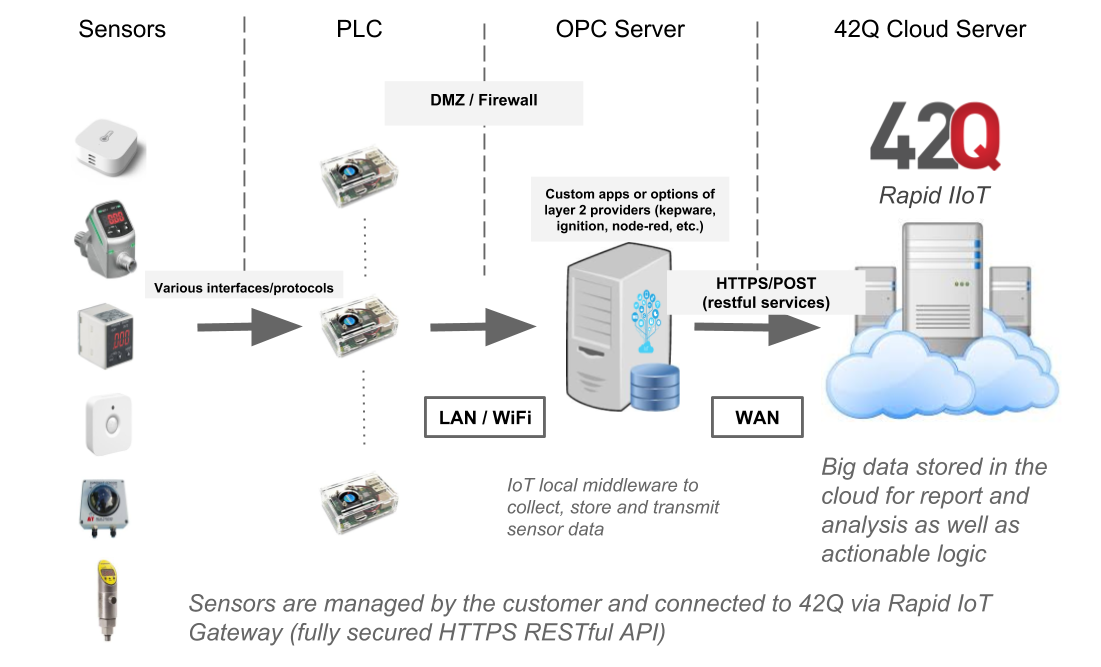

Connectivity

Sensor data from the Shop Floor moves to the 42Q Cloud through a designated path. The following architectural diagram illustrates the equipment and protocol used to exchange information.

42Q Rapid IIoT System Architecture Diagram

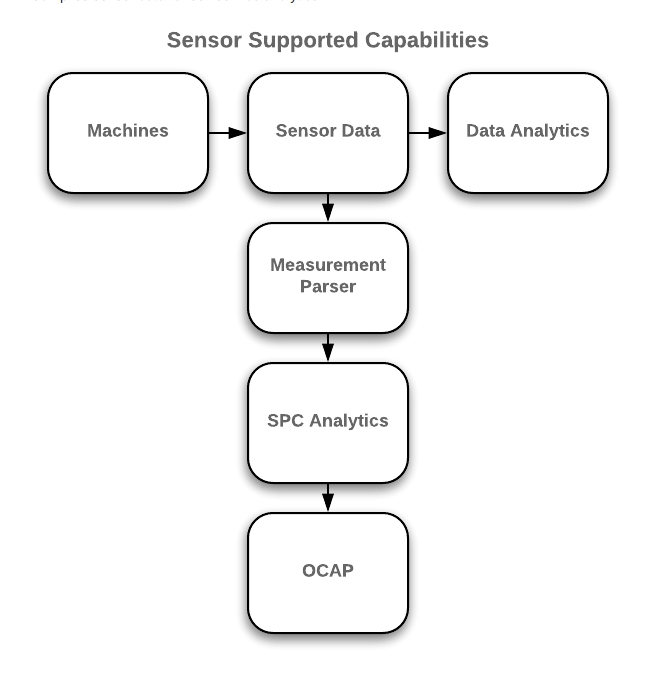

Sensor Supported Capabilities

Rapid IIoT enables factories to quickly capture sensor data, and analyze that data to improve productivity and performance. The following sensor-related capabilities are possible through Rapid IIoT's dynamic data exchange.

- Collects sensor data from machines (e.g. temperature, pressure, tension).

- Performs SPC analytics on sensor data.

- Generates Out of Control Action Plans (OCAPs) for sensor behavior outside of lower and upper control limits.

- Compiles sensor data for self service analytics.

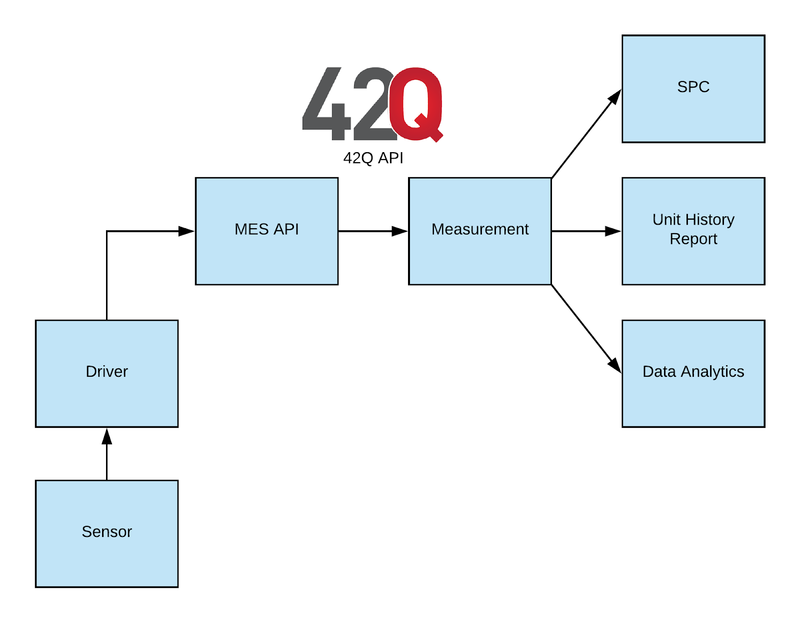

Sensor Data Flow

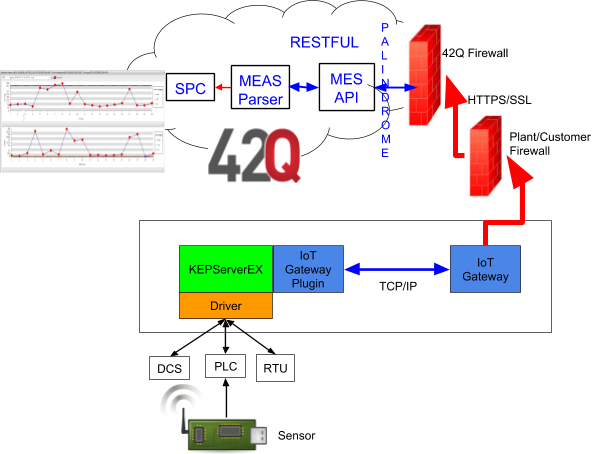

IIot Connectivity

- Sensors capture sensitive measurement data (such as temperature, and humidity).

- Plants can use a variety of systems to release data from controlled machinery (e.g. reflow ovens).

- Some standard hardware solutions include: PLCs, DCS, and RTU (see drawing).

- Sensor data is then transferred to the system’s driver via an OPC (KepServer is one OPC software used by many manufacturers).

- OPC then sends the information to an IoT plugin that communicates with 42Q’s API.

- 42Q’s API utilizes a Measurement parser to process and store the data.

- Measurement pushes data to the data analytic tool (SPC, MESWeb, or other third party data analytic tool such as Tableau or Splunk).

- Data is analyzed by SPC and/or MESWeb, where reports are generated.

Configuration Prerequisites

The following configurations are required:

- A Generic Part Number (PN) See Part Number Maintenance.

- An Attribute by Process. See Attribute Definition.

- SPC Monitor (described in this document).

- Sensor Capture Measurement Parser (described in this document).

NOTE: The Process serves an important function by creating a context for the data being captured. The Process aids technical engineers and administrators in analyzing reports and diagnosing root causes. See also: SPC and Test Integration.

Introduction

This document provides complete instruction on how to configure a sensor capture parser that captures data from sensors. Instructions also include how to send that data to other systems, such as SPC or CMMS.

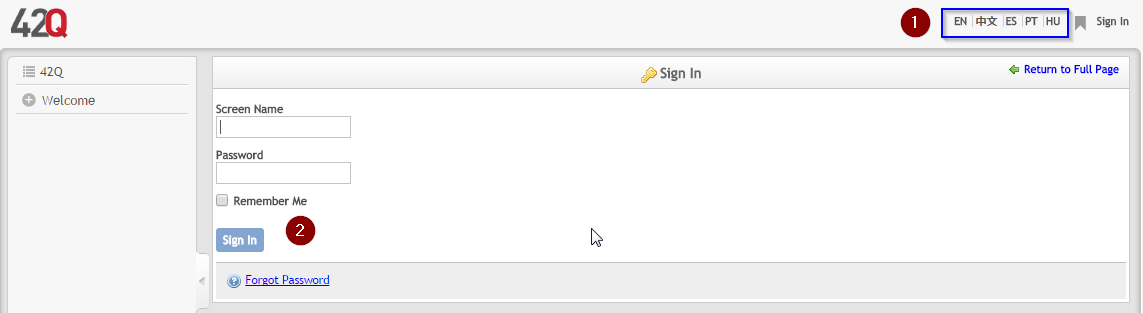

Home: Log in/Log out

Measurement can be accessed from the 42Q Welcome page. To log in, select a language, enter a valid screen name and password, and click the Sign In button.

Figure 1: Log In

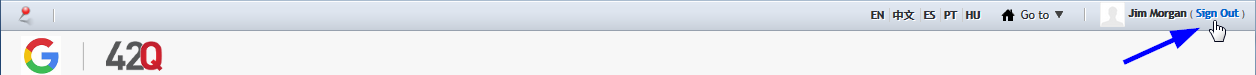

To switch users or log out of the application, click the Sign Out link located at the top right of the screen next to the username.

Figure 2: Sign Out

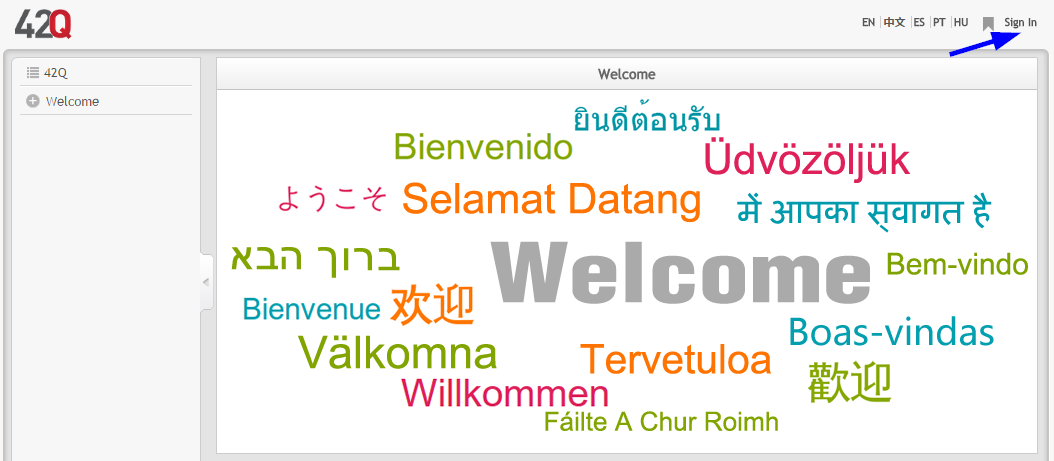

To log back in, click the Sign In link at the top right and repeat the login process.

Figure 3: Sign In

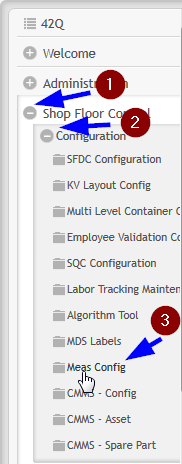

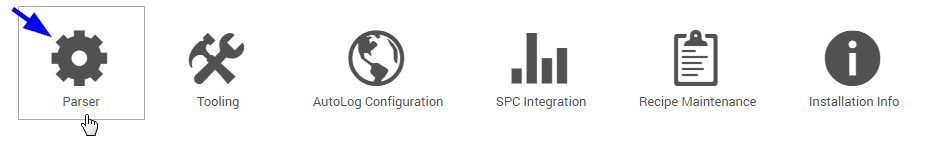

The Parser, Tooling, AutoLog Configuration, SPC Integration and Recipe Maintenance modules are located in the Shop Floor Control menu, within Meas Config. To access, navigate to: Shop Floor Control > Configuration > Meas Config.

Figure 4: Navigation

Select the Meas Config menu item to display the available modules.

Figure 5: Meas Config Modules

Note: To return to the menu of the current application suite, click the Return to Menu button.

Figure 6: Return to Menu Icon

Instance Selection

The Measurement Configuration web application is instance based. All parsers, stations, and any Measurement automated line production related information constitutes an instance and is stored in a Measurement database. Each instance is set to view one Measurement database. This produces one instance per Measurement installation. Generally, Measurement is configured to have one installation per site. It is also common to have a separate instance in the same site when there are medical operations.

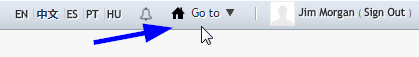

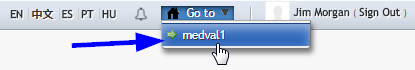

To view available instances in the Measurement application, select the Instances drop down list.

Figure 7: Instance Menu Bar Location

A list of instances will display. Instances can be selected in order to update information.

Figure 8: Select a new Instance

The instance set displays as the screen’s title to help the user identify the current instance.

Figure 9: Instance in Screen Title

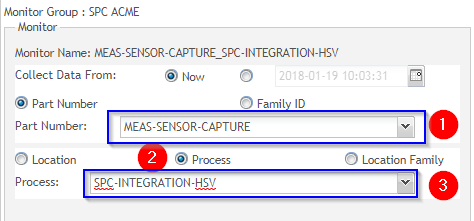

SPC Monitor

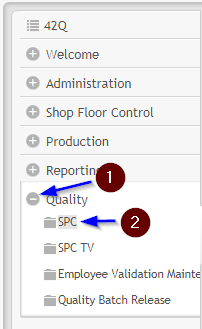

In order for measurement to send data to SPC, engineers must first assign an SPC monitor to receive the data. To configure an SPC Monitor:

- Navigate to: Quality > Reporting > SPC.

- From the system menu, click the Expand button (+) on the left of Quality to show the menu options.

- Select the SPC icon.

- Select Enter to access the SPC monitor list.

Figure 10: SPC Monitor Location

Figure 11: Enter SPC Portal

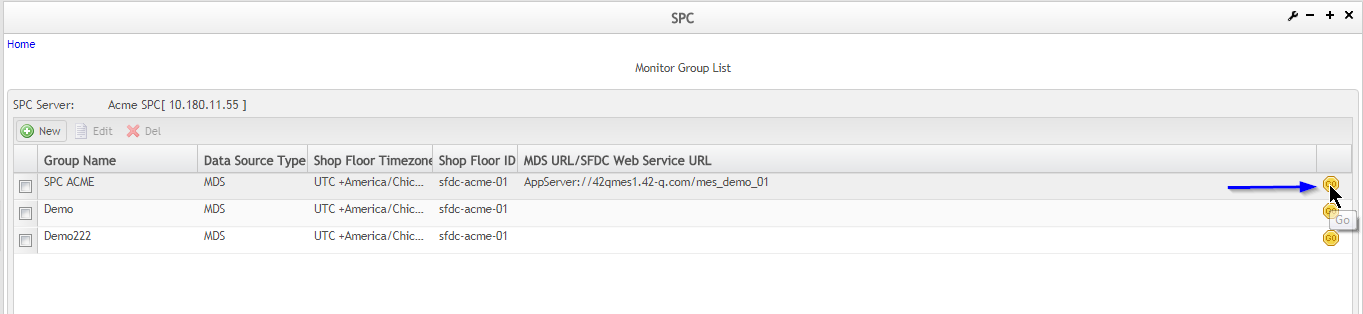

A list of all available Monitors displays on the SPC Home page.

Figure 12: Select Monitor Group List

Create a New Monitor

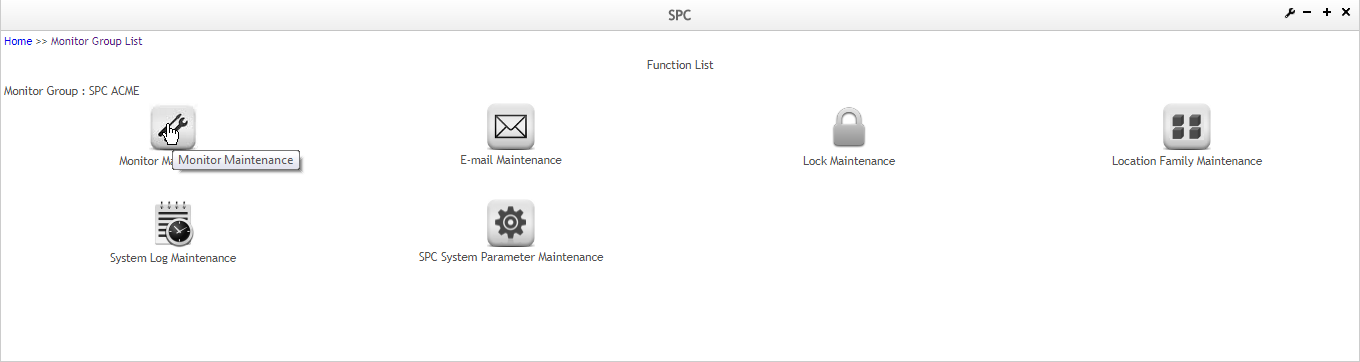

- The Function List displays in icon format.

- Select Monitor Maintenance to open a list of all Monitors available.

Figure 13: Select Monitor Maintenance from the Function List

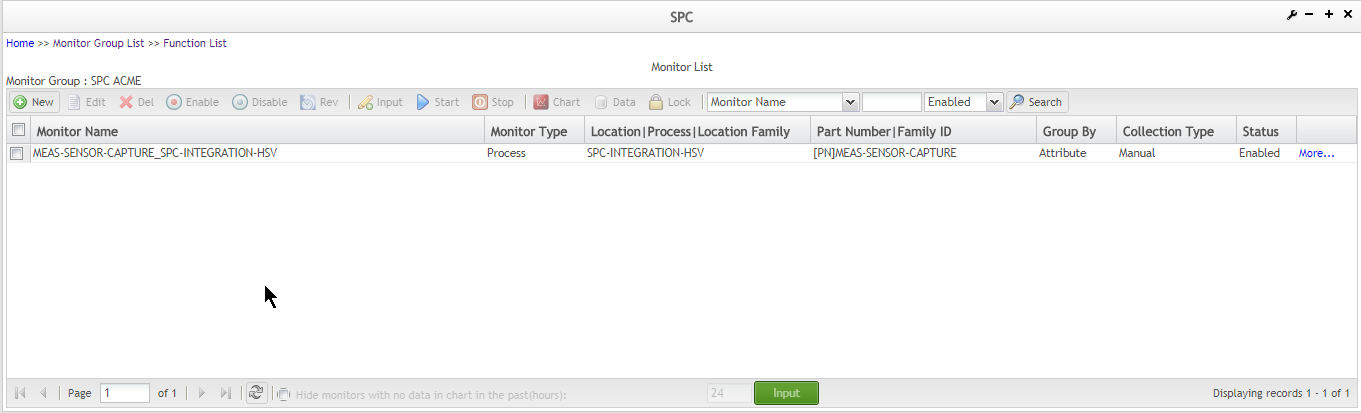

Figure 14: Monitor List

- To create a new Monitor, click on the green +New icon. The following form displays:

Figure 15: New Monitor Form

Complete the Monitor Form

- Select a Part Number from the drop down, or type it in the Part Number field (value is case sensitive).

- Select Process.

- Select the predefined process from the drop-down menu.

- NOTE: Part Number and Process are Configuration Prerequisites.

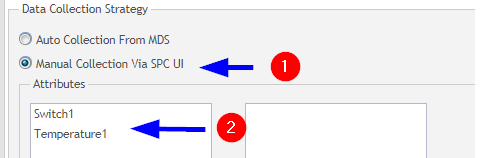

- Important Note: To create an SPC Monitor fed from sensor data, select Manual Collection via SPC UI.

Figure 16: Manual Data Collection Strategy

- Choose an Attribute to Monitor.

- NOTE: Attributes are Configuration Prerequisites.

- Configure chart parameters as desired:

- Control Chart Type

- Chart Rules

- Notification Actions

- After all configuration fields are complete, select Save.

- The new Monitor is now available in the Monitor List and ready to receive sensor data.

Measurement Configuration

Parser

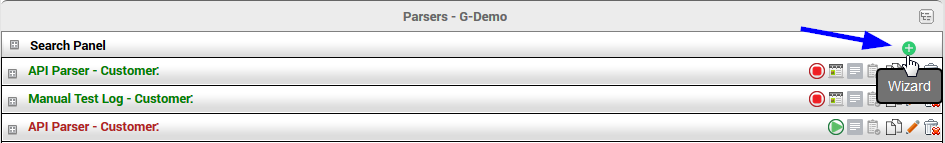

Create a New Parser

To access the Parser module from the main menu, go to: Shop Floor Control > Configuration > Meas Config and select the Parser icon.

Figure 17: Create New Parser

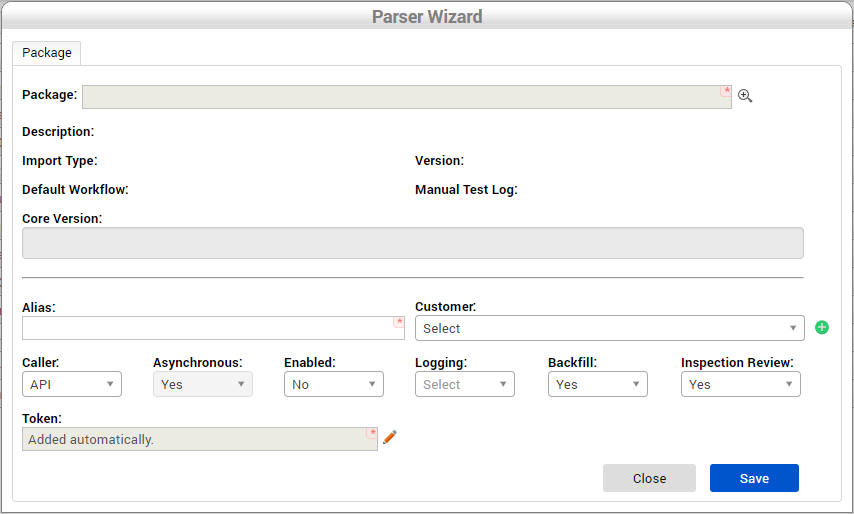

To create a new sensor capture Parser, click the green +New icon for the Parser Wizard, located at the top right of the menu bar. This action opens the Parser Wizard.

Figure 18: Parser Wizard

Package Tab Fields

- Package: This field populates the Assembly Name field on the Parsers screen, and is the fully qualified name from the parser file, including its extension.

- Alias: An alias to the parser, this will help identify this parser instance on the parser screen.If no text is entered, the system will automatically fill the field with the Parser Name.

- Customer: Used to identify from which customer the automated line is processing their products.

- Caller: Set how the parser will run.

- API: Set the parser to be run from Measurement Core.

- Service: Set the parser to be loaded from another parser.

- Asynchronous: Identify if the parser will process multiple serial number in parallel on SFDC.

- Enabled: Set the parser to run or stop.

- Logging: The user can set logging to all, info, or debug information.

- Backfill: Select whether or not to load historical data.

- Inspection Review: Toggle inspection review on or off.

- Token: A unique identifier string associated to a parser instance.

Install the Package

- Complete the Mandatory fields (denoted by a red *).

- Complete other fields as needed.

- Select Save.

- Select Choose Package by activating the magnifying glass icon.

- Select the Sensor from the drop-down menu.

- The following fields are automatically populated:

- Core Version: The 4 digits version from Measurement application this parser was deployed to run.

- Parser Version: 4-digit version number from this parser assembly file.

- Import Type: Informative data to identify the import mechanism the parser uses.

- Default Workflow: Technical option set by the developer to identify the parser to run in a default workflow (Import data, Parse to measurement data, send unit information to SFDC, store parametric data, release the file to out folder).

- Select Install or Back to exit to the Parser Wizard

Figure 19: Select Package Wizard

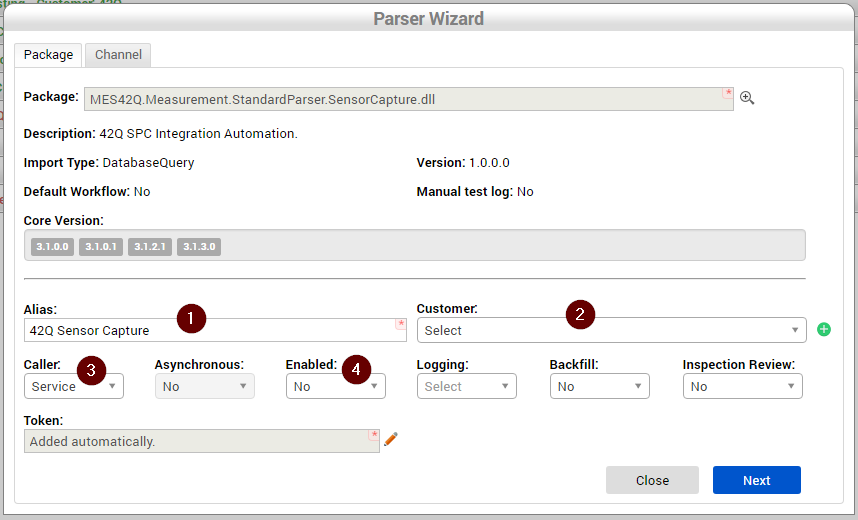

The following instructions detail the configuration requirements for a Sensor Capture Parser. Refer to Figure 20 for Sensor Capture configuration example.

Figure 20: Sensor Capture Parser Package

To configure a Sensor Capture, complete the fields according to the following:

- Alias: User can choose a meaningful name for the parser or use the one suggested.

- Customer: User can choose a specific customer this parser is tied to, or create a new one.

- Caller: Defines if this parser will be called via service or API. For sensor capture, Service must be selected.

- Enabled: Defines if this parser will be initially created enabled or not. There are more configurations to set before enabling it, it should remain No.

- Backfill: Select whether or not to load historical data. It should remain No.

- Inspection Review: Toggle inspection review on or off. It should remain No.

Click the Next button to go to the next screen, or click Close to abandon changes.

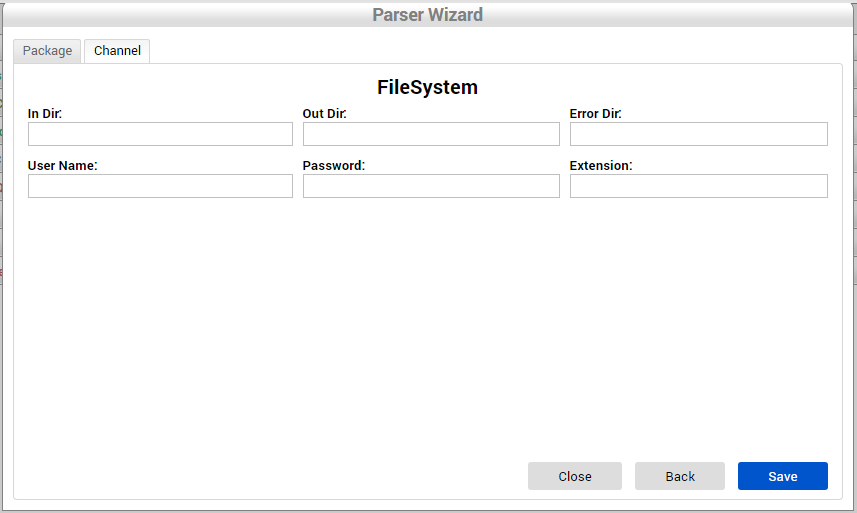

Figure 21: Channel Tab

- None of the fields in the Channel tab should be filled in, they are not required for Sensor Capture parser.

- Select Save to save the parser and reload the parser list screen. Select Close to abandon changes

- Select Back to return to the Package tab.

Rapid IIoT Workflow

A parser has a well-defined workflow structure based on inbound processing and outbound information.

Configuration Groups allow plants to customize workflows to accomodate production line variances and technical integration requirements.

Group configurations dictate where payload data will be stored & transferred.

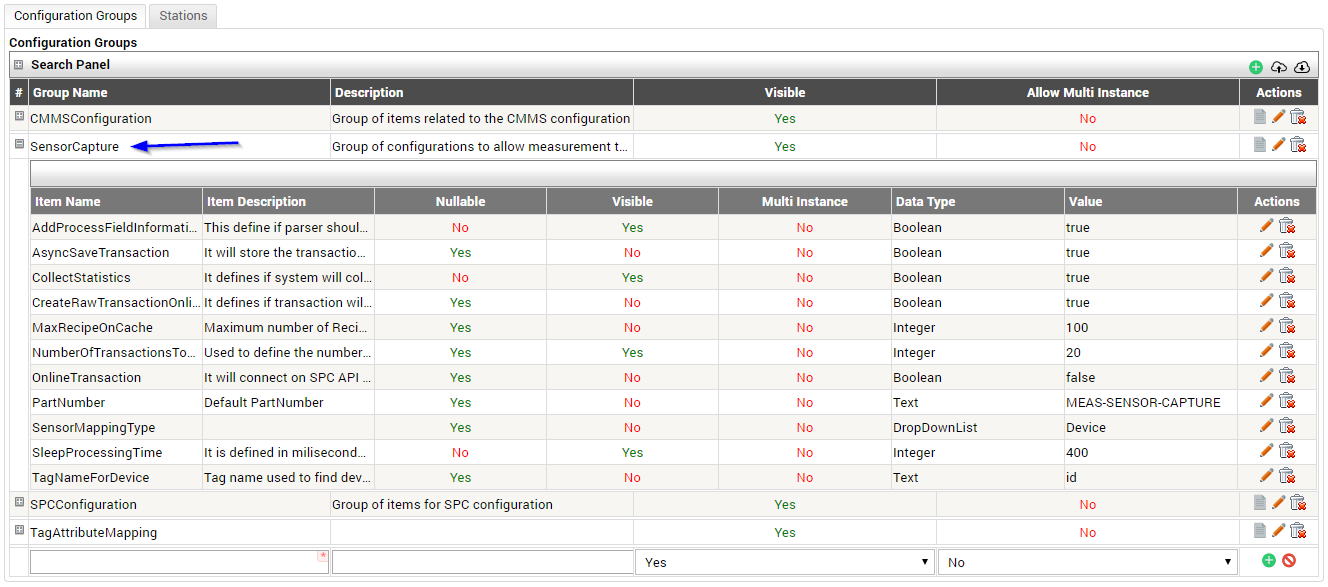

Parser Configuration Groups

The following 4 groups must be configured for sensor parsers to capture data:

- CMMS Configuration

- Sensor Capture

- SPC Configuration

- Tag Attribute Mapping

- Select the + icon to the left of the Sensor name.

- Select the notepad icon in the Configuration Groups tab (see Figure 22, below).

Figure 22: Parser Configuration Groups

- To add a configuration to each dynamic configuration group/item, expand the group by selecting the + icon to the left of the group name.

Figure 23: Expand To Configure Item

Figure 24: Select Edit Icon

Figure 25: Save, Cancel, and Delete Icons

CMMS Configuration

CMMS configuration defines how the parser will send data to CMMS.

Figure 26: CMMS Configuration Group

The following items are available for selection:

- AddDataToCMMS: Define if data will be sent to CMMS or not.

- SendAllTagsToCMMS: Define if Sensor Capture parser will send all tags received via payload to CMMS or only the ones configured in the TagAttribute item. Select False to specify a TagAttribute (see NOTE, below).

- SiteId: Site identification at CMMS.

- TagAttribute: Define which tag from the payload will be sent to CMMS. NOTE: When TagAttribute mapping is selected, SendAllTagsToCMMS value must be FALSE.

- URL: Define the CMMS URL the API will call.

Sensor Capture Configuration

The Sensor Capture Group defines how the Sensor Capture parser handles data.

- Select Edit.

- Complete the fields per plant requirements.

- AddProcessFieldInformation: Defines if parser will send information to the FlexFields attached to the process or not. Select True to utilize Flex Field configuration options.

- AsyncSaveTransaction: Select True to store the transaction in parallel to the rest of the processing.

- CollectStatistics: Defines if system will collect growth statistics related to the database and transaction tables. Default value is FALSE.

- CreateRawTransactionOnLine: Defines if transactions entering via MES-API sync method (online transaction) are saved. Select TRUE to save MES-API transactions.

- MaxRecipeOnCache: Defines the Maximum number of Recipes that can be cached.

- NumberOfTransactionsToProcess: Defines the number of transactions to be retrieved for processing. Default value is 50.

- OnLineTransaction: Defines if parser will send values to CMMS and SPC synchronously or not.

- PartNumber: Defines the generic part number the parser will use.

- SensorMappingType: Defines the Tag Sensor Capture parser should look for in the station mapping configuration.

- SleepProcessingType: Defines the amount of tiem (milliseconds) the parser will wait to start processing the next set of data.

- TagNameForDevice: Tag name used to locate device information.

Figure 27: Sensor Capture Configuration Group

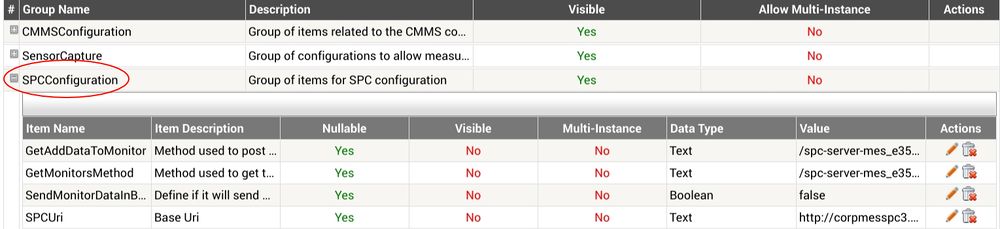

SPC Configuration

This configuration section defines how the parser integrates with the API to send data to SPC.

Figure 28: SPC Configuration Items

Select Edit to define the items:

- GetAddDataToMonitor: Define the Method used to post data to a given SPC monitor.

- GetMonitorsMethod: Define the Method used to get the list of monitors available.

- SendMonitorDataInBatches: Define whether the parser will send data to monitors in batches or not.

- SPCUri: Define the Base SPC Uri

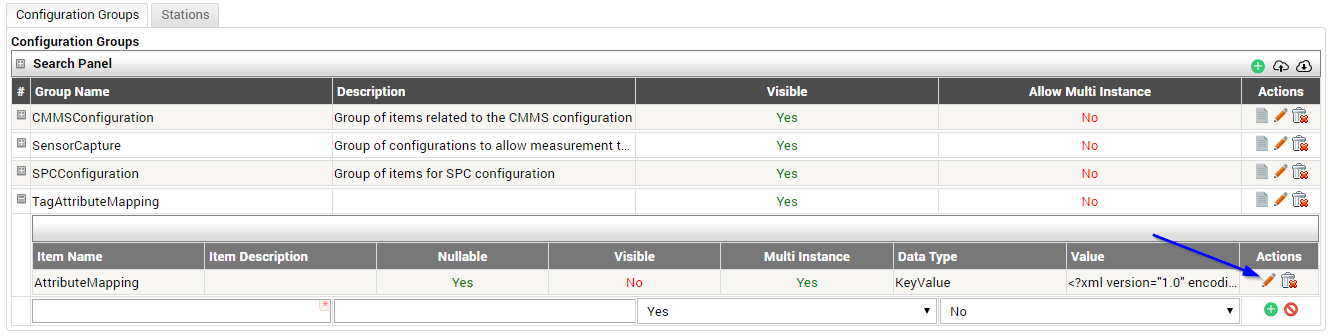

Tag Attribute Mapping

Tag Attribute Mapping defines the relationship between tags (sent within payloads) and attributes (configured in MES). The Sensor Capture parser uses this configuration to send data to SPC.

Tag Attribute Mapping Format Requirements

Sensor data from PLCs (Programmed Logic Controls) is sent to 42Q’s API via HTTPS. During original configuration, the Measurement parser generates a token that includes the URL (instance), the process, and the software’s payload. Payload is written in JSON format Text (see below). In this way, the parser is able to locate the information according to the token, URL, and process, then send the data to 42Q’s SPC via 42Q's API. See also IIoT Connectivity for broader illustration of how 42Q's Rappid IIoT transfers data.

JSON Format

{

"agent_id": "PLC_1",

"data_acquisition_ts": “123213213132” ,

"measurements": [

{

"id": "sensor_pi.office.temp",

"value": “74”,

"quality": "true",

"timestamp": "213132132132"

}

]

}

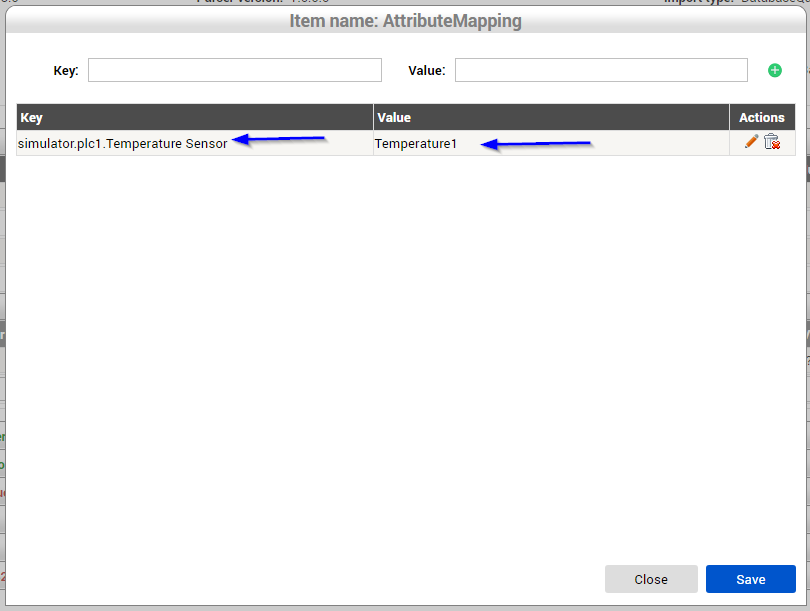

Create an Attribute Mapping

- Select AttributeMapping.

- Select Edit.

Figure 29: Create Attribute Mapping

- A new form displays: Item Name: Attribute Mapping.

Figure 30: Item Name: Attribute Mapping Form

- Complete the fields:

- Key Field: Enter the Tag Id (from the payload)

- Value Field: Enter the Attribute (from MES).

- Save.

Figure 31: Tag Attribute Mapping Configuration Example (Completed)

Station

The Station Mapping module links test stations to an SFDC device number and process. Within the IIoT framework, a Device is noted on the payload’s Tag. (See Tag Attribute Mapping Requirements for more details).

The Station mapping feature provides plants the ability to dynamically connect multiple customers, brands, and/or test stations to SFDC/MES locations and workstations. By placing similar data into the same subset, administrators can view overall measurement patterns to analyze and improve production.

For Sensor Capture parsers, station mapping is used to hook up data coming from specific sensors to a process, and allows measurement to send data to different SPC monitors.

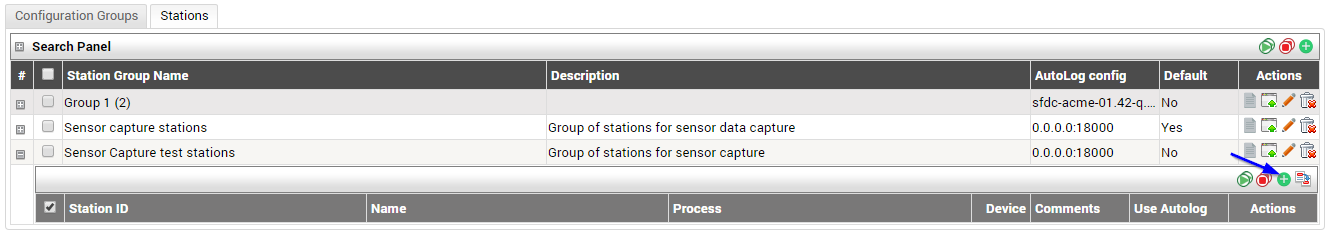

Add Station

To add a new station, select the New + icon.

Figure 32: Add Station

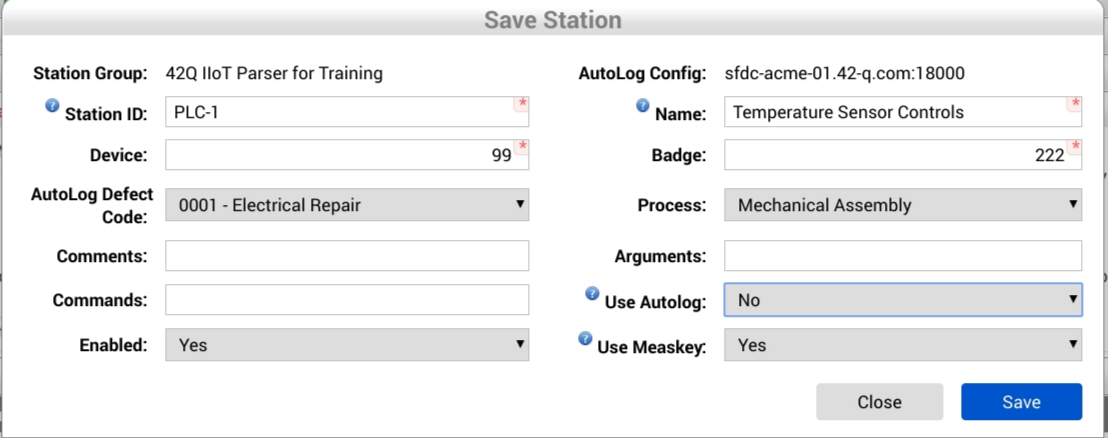

The Station Form will display.

Figure 33: Save Station Form

Station Form Fields

- Station Group: Name of the group to which the station will belong.

- *Station ID: This is the station identification. Measurement parsers use this field to match a station and device mapping from a tag in the payload sent by the sensors.

- *Device: The SFDC device number which Measurement will use to communicate to SFDC when using this Station mapping.

- AutoLog Defect Code: If there is no defect mapping found for the defect being recorded, Measurement uses this default defect code on SFDC to fail a unit. This field will automatically populate.

- Comments: This is a generic field to provide additional information on the parser. Optional.

- Commands: This is a generic field to provide additional information on parser. If this sensor parser is being configured to send data to an SPC monitor, then this field must contain the monitor name the parser will send data to.

- Enabled: Set the station to be used, or not, while processing a test result data. For sensor parsers, select YES.

- AutoLog Config: The SFDC PC which this parser uses to send data.

- *Name: A station name identification, like an alias, to be used on a station. .

- *Badge: The default operator to be used to login on SFDC in case this information is not provided in the test result data.

- Process: The MES process to which the test station belongs. This is used for recipe creation. It is part of the Checklist module that identifies the recipe, and sends sensor data to SPC monitors. NOTE: SPC monitors are configured in Quality > SPC.

- Arguments: This is a generic field that is used on a parser.

- Use Autolog: C<a href="#cmnt21" id="cmnt_ref21">[u]</a>onfigure station to not perform any SFDC communication. No.

- Use Measkey: This sets the parser to send/not send the MEASKEY command to SFDC. When set to Yes, Measurement sends the MEASKEY command to SFDC and links this MES Activity to Measurement parametric data generated by this test. Doing so makes Parametric data viewable inside the Unit History report on MESWeb. For Sensor Parsers, select No.

- Fill out all mandatory fields (denoted with*).

- Select Save.

- Measurement will validate the data and insert the new station into the group.

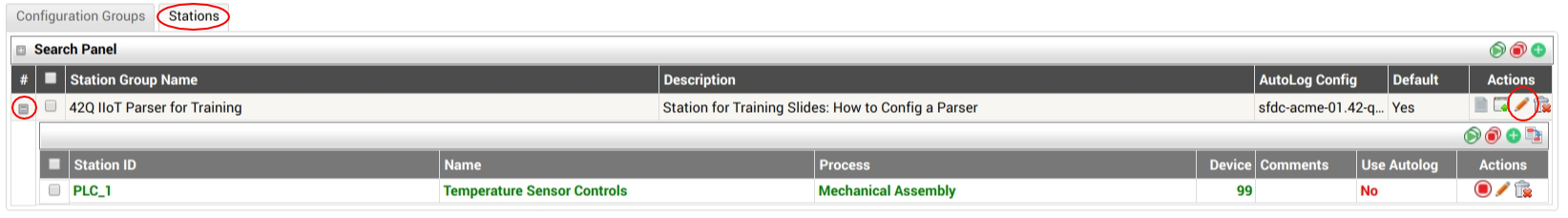

- The new station is now available in the station list (see Figure, below).

Figure 34: Newly Configured Work Station

Document Revision History

| Date | Author | Title | Version | Change Reference |

| 05/11/18 | Luiz Santos/Martha Jordan | Development Supervisor/Technical Writer | v. A | This is the first version of Rapid IIoT. |