SOP-5-I-42Q-MES0106-C 42Q APK

This edition applies to MES 15 Portal 1.0 and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

Introduction

The 42Q PSI (Production Scanning Interface) is an accessible platform that makes mobile data collection simple, while also providing administrative access control. 42Q’s MES development team has provided a mobile data collection solution that allows for manufacturing execution at the shop floor level through the use of convenient tablets. These inexpensive tablets provide mobility, flexibility, and scalability to increase productivity while decreasing overhead costs. The PSI offers the ability to not only collect scanned data, but also track the history and scan activity of each individual user using the tablet and display work instructions.

Access control is vital when providing mobile data collection to multiple end users. AppGarden, Android Package Maintenance, and Android Device Maintenance limit the applications that end users can access via mobile devices. Every tablet should have AppGarden installed. App Garden is an Android management tool that allows installation and updates on android mobile devices. Available through 42Q.com, Android Package Maintenance serves as a repository for Android tablet applications. Android Device Maintenance, available in the portal, is the primary module for managing the tablets to which the package maintenance applications are pushed.

Prior to release, the tablets will be configured by an administrator. For more information on how to configure the tablet’s Host, Station ID, or Unit ID, please refer to the Administrator Pre-Configuration section of this document.

Hardware and Software Requirements

Minimum Hardware Requirements:

WiFi:

Built-in wi-fi module which supports IEEE 802.11b/g wireless network

AC Power Adapter: 100~240V input, 9V/1500mA output

Audio: built-in stereo speakers(2pcs x 1W), built-in microphone

Minimum Software Requirements:

Operating System:

Android 4.2.2

Bundled package:

AppGarden

Cirrus APK

CPU:

A20 ARM Cortex-A7 Dual-Core

RAM:

DDR2 512MB

Storage:

Built-in flash internal 2GB; support external TF card (maximum 32GB)

Accessories:

Power Adaptor

USB 2.0 3-Port Hub with Ethernet Adapter (Optional)

USB Cable Connector (Optional)

Mounting Bracket (Optional)

Symbol USB Barcode Scanner (LS2208) (Optional)

Administrator Pre-Configuration

Before a user may begin using the application, the Administrator must set up the device by entering the administrator password and setting the Host and Station ID. Once completed, the device is ready for data collection.

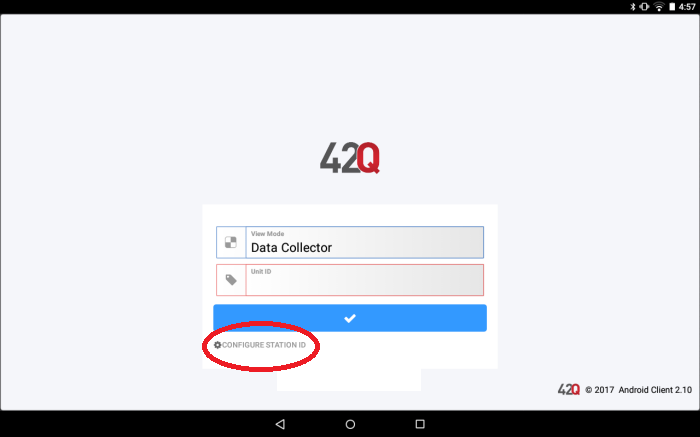

1. On the initial landing page, select the Configure Station ID button to display the Administrator password prompt.

Figure 1: Initial Landing Screen

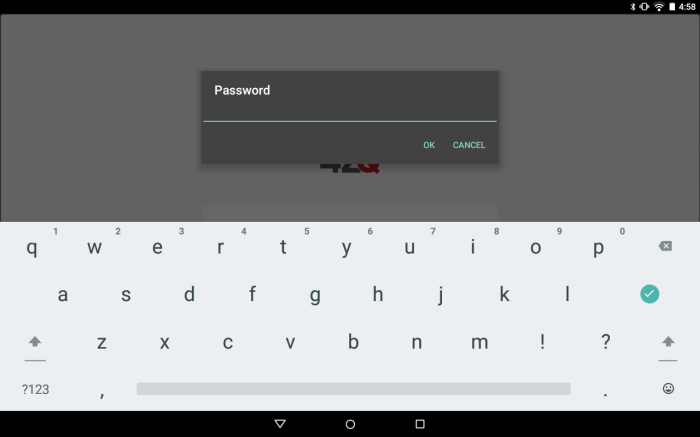

Figure 2: Administrator Password Prompt

2. Enter the Administrator password and select OK.

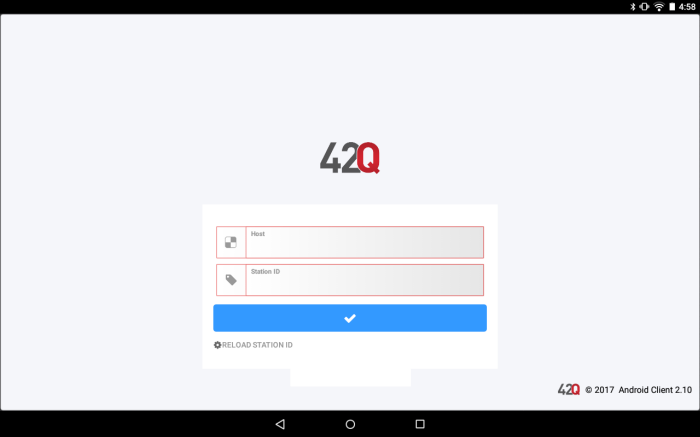

3. To proceed with setup, enter a Host in the entry field and select the Reload Station ID button.

Figure 3: Host and Station ID Selection

Once a successful connection has been made, the Station ID may be selected and the appropriate Unit IDs will be populated.

4. Continue to the View Mode selection by selecting the Checkmark button.

NOTE: The 42Q APK uses a built-in keyboard for ease of use, however for some Android versions, it may be helpful to disable the default keyboard to avoid conflict.

Access

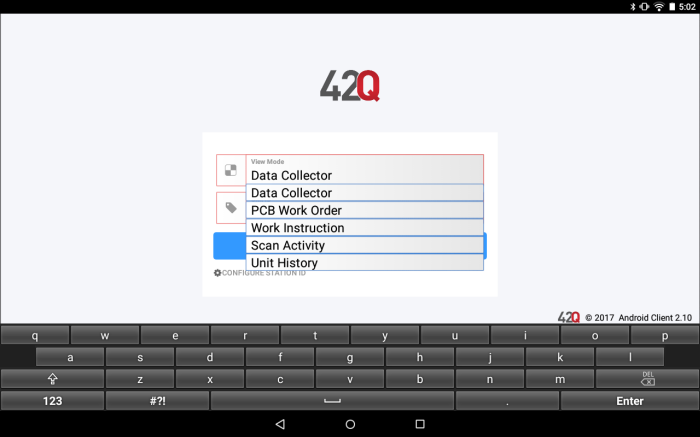

Once the Administrator has launched the 42Q PSI application and entered the Host and Station ID, the user can select a default view mode and Unit ID.

The following View Modes are available to the user:

- Data Collector

- PCB Work Order

- Work Instruction

- Scan Activity

- Unit History

NOTE: The View Mode selection dictates the default view upon logging in. All other view modes are available (unless PCB Work Order is selected) in tabs from the Data Collector screen.

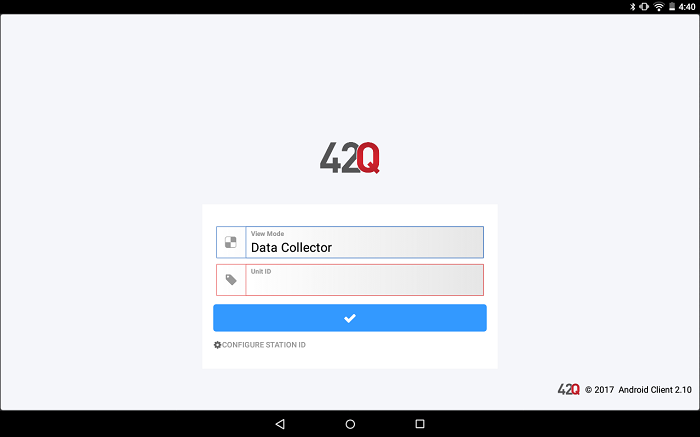

1. To log into the mobile Data Collector, select a View Mode from the drop down list provided.

Figure 4: View Mode Selection

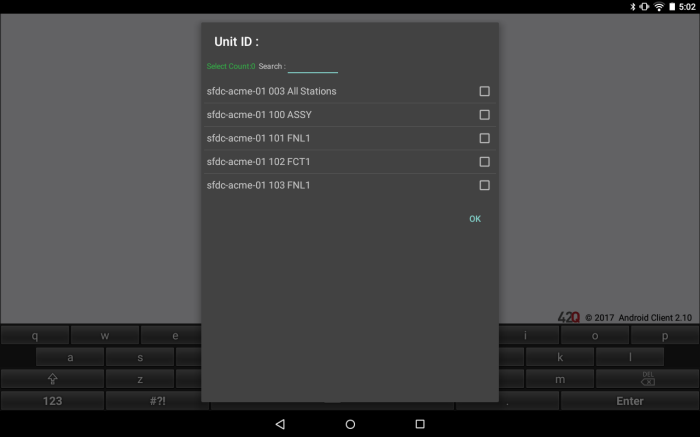

2. Select a Unit ID from the list provided.(The Unit ID list is created from the Device Maintenance portlet in 42Q.)

Figure 5: Unit ID Selection

3. Select the checkmark to log in to the mobile Data Collector.

Figure 6: Log In

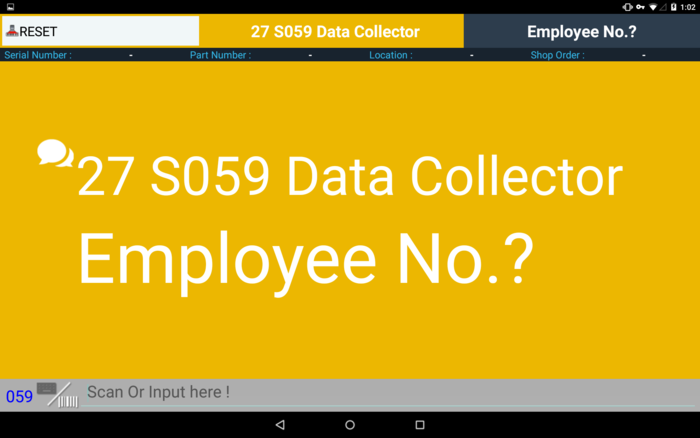

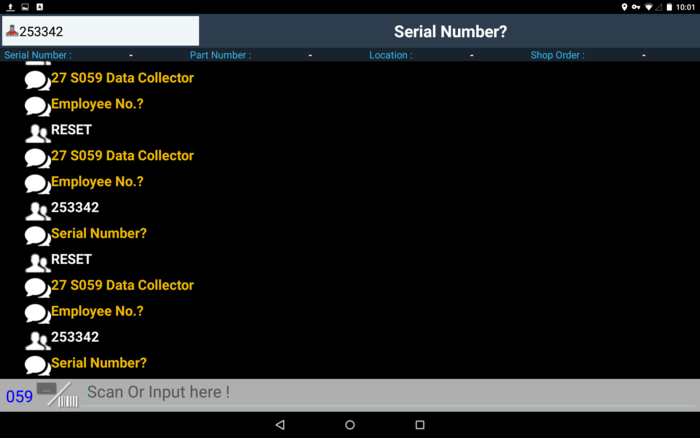

4. The initial log in screen prompts the user for an Employee Number.

Figure 7: Initial Log In Screen

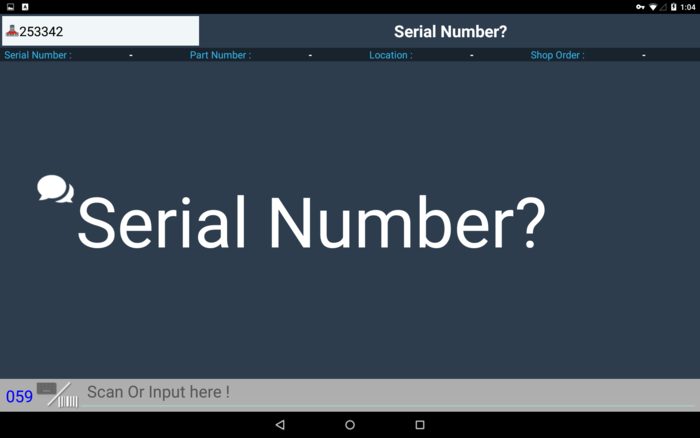

5. Once an Employee Number is entered/scanned, the default view mode will display.

Data Collector Mode

After selecting the Data Collector view mode and entering an Employee Number, the device is ready to begin data collection.

Figure 8: Data Collector Default View Mode

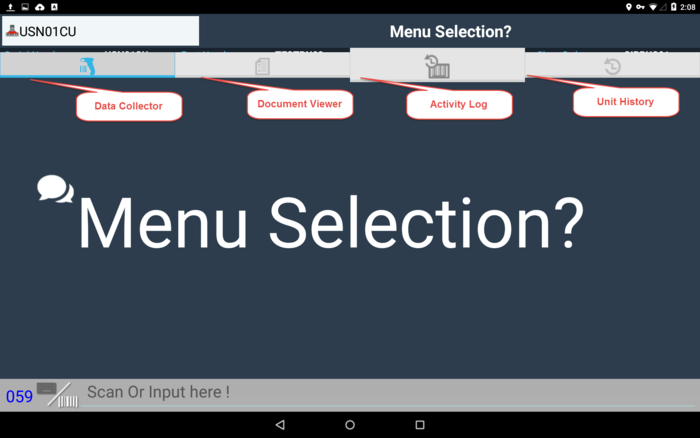

If it is necessary to change view modes, they can be accessed by tapping the top of the screen, as shown in Figure 9.

Figure 9: Additional Tabs

Work Instruction Mode

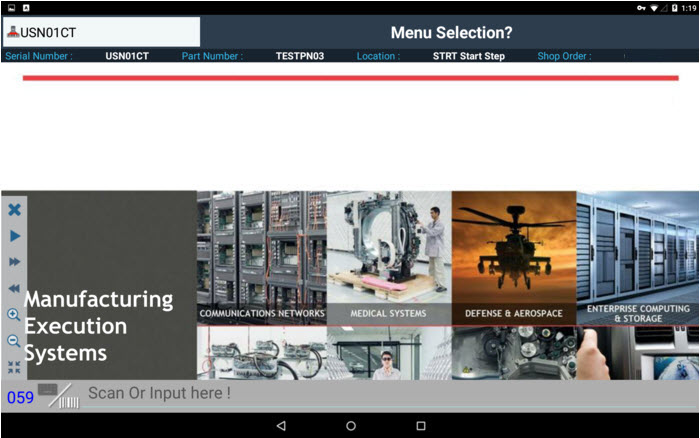

If Work Instruction was selected as the default view mode, the screen will either display the default deviation, or the last uploaded document for the Part Number at that Process.

Figure 10: Work Instruction

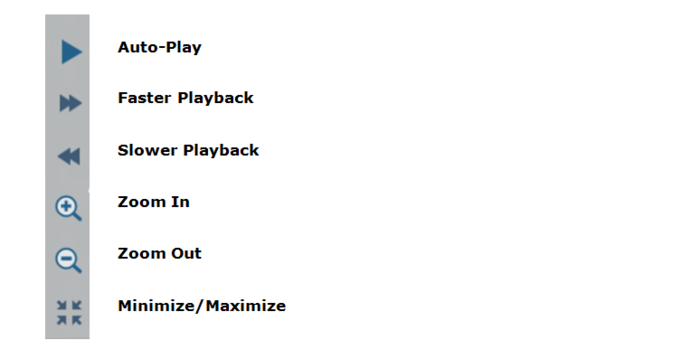

The following navigational controls are provided on the left of the screen:

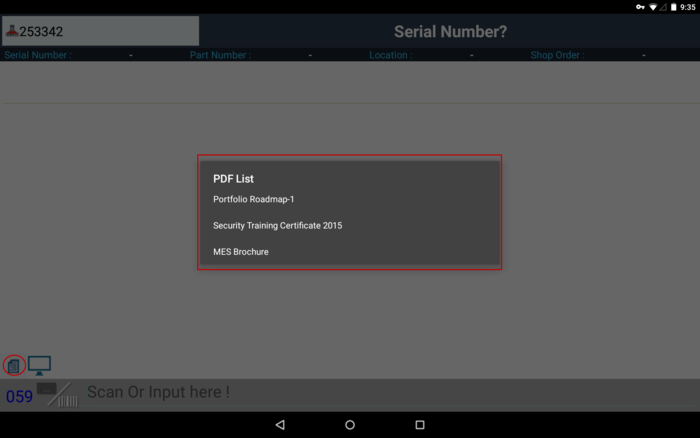

If multiple documents are uploaded for the serial’s Part Number and Process, they can be accessed by closing the current document, then selecting the document icon in the input field at the bottom of the screen. All documents mapped to the scanned part number and process will display in a list for selection.

Figure 11: Multiple Document View

Activity Log

If Scan Activity was selected as the default view mode, the following screen will display after entering an Employee Number:

Figure 12: Scan Activity View

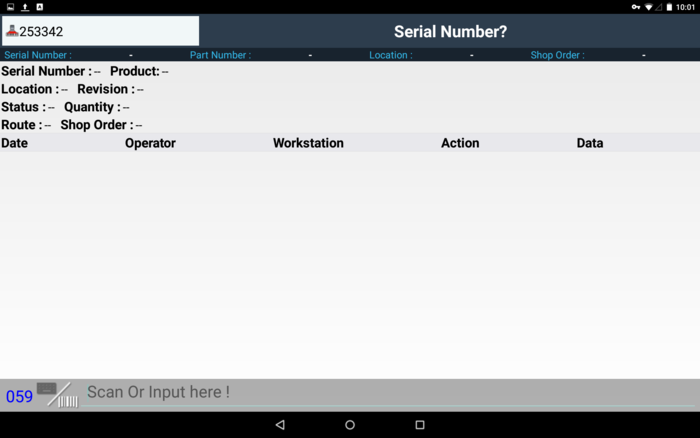

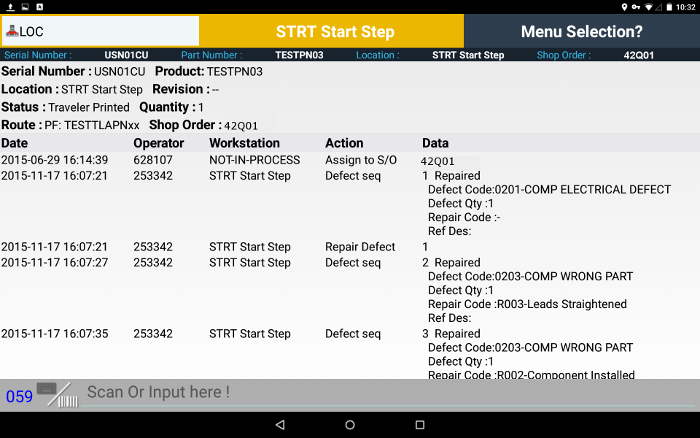

Unit History

If Unit History was selected as the default view mode, the following screen will display after entering an Employee Number:

Figure 13: Default Unit History View

NOTE: Currently, local and custom commands can be executed in the mobile data collector. Any action executed will display in the Unit History report tab.

Figure 14: Command Execution in the Unit History Tab

PCB Mode

The PCB Work Order mode is a customer specific tool that allows for non-serialized batch processing by interfacing with INPLAN-ERP. For more information, please refer to the MES for PCB documentation.

Document Revision History

| Date | Author | Title | Version | Change Reference |

| 07/17/17 | Lucas Hopkins | Technical Writer | v 2.0 | This is the first version of Revision A2 |