Local Commands

Contents

- 1 Table of Revisions

- 2 Introduction

- 3 The SFDC PC

- 4 The SFDC PC Index

- 4.1 SFDC Local Web

- 4.2 SFDC Command GUI

- 4.3 AutoSFDC XML

- 4.4 Data Collector GUI

- 4.5 SPC Web

- 4.6 Defect GUI

- 4.7 Batch Process GUI

- 5 Attributes

- 6 Defect / Repair GUI (MES Portal)

- 7 Employee Validation

- 8 HPU/Cycle Time

- 9 Multi-threading

- 10 MFG Hold

- 11 Non-Serialized Batch Processing

- 12 Shop Order

- 13 Containerization and Lot Tracking

- 14 Data Collection

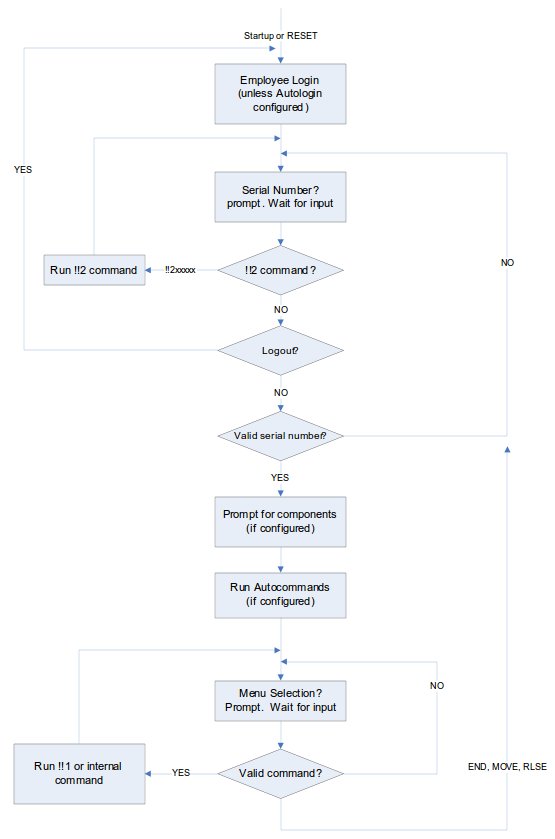

- 15 Employee Login and Logout

- 16 Custom Commands

- 17 Serial Number Prompt

- 18 Menu Selection

- 19 Add Comment (ADCOMMENT)

- 20 Add Components (ADCMP)

- 21 Add Component 2 (ADCMP2)

- 22 Add Tracked Component (ADCMP3)

- 23 Apply MEO (ADMEO)

- 24 Add Attribute (ATTADD)

- 25 Add Attribute by Group (ATTADDGRP)

- 26 Remove Attribute (ATTREMOVE)

- 27 Change Serial Number (CHGID)

- 28 Change Product Number (CHGPN)

- 29 Change Revision (CHGRV)

- 30 Clear Attribute (CLRATT)

- 31 Create Batch Serial Number (CR8BSN)

- 32 End

- 33 Measure Key (MEASKEY)

- 34 Merge Batch Serial Number (MERGBSN)

- 35 Move

- 36 PTS Record Defects (PRCDFC)

- 37 PTS Record Repairs (PRCRPR)

- 38 Record Defects (RCDFC)

- 39 Customized Record Defects

- 40 Record Defects Sub-assembly (RCDRSA)

- 41 Record Repairs (RCRPR)

- 42 Release (RLSE)

- 43 Remove Component (RMCMP)

- 44 Remove Component 2 (RMCMP2)

- 45 Remove All Components (RMCMPALL)

- 46 Remove All Units from Batch (RMVALLUNIT)

- 47 Remove Unit from Batch (RMVUNIT)

- 48 Replace Component (RPCMP)

- 49 Replace Component 2 (RPCMP2)

- 50 Remove/Replace Sub Component (RPSCMP)

- 51 Reset (RESET)

- 52 Reset Error (RESETERROR)

- 53 Sample command (SAMPLE.sample_plan)

- 54 Split Batch Serial Number (SPLTBSN)

- 55 Split Normal (SPLTN)

- 56 Split Partial (SPLTP)

- 57 Add Sub Attribute (SUBATT)

- 58 Verify Attribute (VERATT)

- 59 Verify Component (VERCMP)

- 60 View Components (VWCMP)

- 61 View Defects (VWDFC)

- 62 View History (VWHST)

- 63 Macro Barcodes

- 64 Macro Barcode Error Messages

- 65 Error and Prompt Messages

- 66 Unit Status Definitions

Table of Revisions

| Date: | Author: | Description: |

| 6/23/04 | Karen Ellington | Initial release of document to website. |

| 8/4/04 | Karen Ellington | Added status 36 to Unit Status Definitions section. General edit and format clean up. |

| 1/06/09 | Keith Fuqua | Added SFDC3 specific items, new commands, features, and updates. |

| 01/22/10 | Keith Fuqua | Batch processing, Employee validation, new commands & features. |

| 10/29/10 | Keith Fuqua | Table cleanup, document corrections. |

| 06/17/11 | Keith Fuqua | Updates for SFDC 5.22.02 – SFDC 6.0. |

| 07/02/12 | Eric Moldenauer | Updates for SFDC 6.1. |

Introduction

This document provides instruction and support for operation of the Shop Floor Data Collection (SFDC) PC System.

The data configuration for SFDC PC is handled within the Manufacturing Data System (MDS), which is a complete factory automation system. The SFDC System uses barcode scanning, both manual and automated, to monitor and control a single product line or an entire plant. It can be used with the Customer Order Processing System (COPS), Statistical Process Control / Statistical Quality Control (SPC/SQC), or order entry systems. MDS makes the communication between these systems possible.

SFDC provides a wide range of data storage and analysis tasks, making communication between data collection and corporate management more solid. Reports available include the following:

- Work-In-Process

- Current and Previous Shift Yields

- Delinquent Units

- Unit History

- Current Shift Defects

- Historical Defects

NOTE: For information on off-line reporting through MDS, see the SOP-5-I-MDS0019-C_MDS_Reports_Generator. Available off-line reports include Component Activity, Container/Lot, Old Age and Sick Units, Manual Move, and Shop Order Operation History, as well as the reports shown in the list above. For information on reporting through MESR (MESWeb) please refer to MESWeb documentation.

Some of the standard features are as follows:

- Flow control

- Tracking sub-products (components or subassemblies)

- User-defined prompts

- Manual “move to“ functions

- Block of serial number moves

- Product and sub-product (component or subassembly) verification

- View serial number history

- Unit history comments

- On-screen display of communication status between SFDC and Data Collection Stations and between SFDC and the plant server network

- Attributes

- Shop Order

- Containerization

The SFDC PC

The SFDC PC is a Linux based server, and does not have a GUI (Graphical User Interface) running on the console itself. All operations are through the command line interface. After logging into the console, there base menu will be displayed. Each item in the menu is discussed below.

- sfdc help – Displays the base menu.

- sfdc -v – Displays the current version of SFDC software.

- netdc -v – Displays the Device Manager version.

- Individual SFDC commands - Type sfdc followed with a space and then the command. (STOP, START, RESTART, TEST, DNLD, CONFIG)

- dnld – Displays the SFDC download commands menu.

- sfdcdnld – Downloads SFDC configuration from MDS.

- emvdnld – Downloads Employee Validation configuration from MDS.

- spcdnld – Downloads SPC configuration from MDS.

- downdata all – Downloads all WIP serial information from MDS.

- downdata [startdate] [enddate] – Downloads WIP serial information from MDS for the specified date range.

- sampdown – Downloads Sample Plan configuration from MDS.

- defectguidnld – Downloads Defect/Repair GUI configuration from MDS.

- sfdcdnld empty – Performs an empty download, clearing out current configuration from the SFDC PC. Useful if changing the SFDC PC configuration from one line to another.

- attribdnld – Downloads Attribute Definition configuration from MDS.

NOTE: The listed commands can all be run from the command line in addition to running from the menu.

- YUM commands – YUM is the method for installing, updating, downgrading, software packages in versions 5.12.02 and higher. The SFDC Install command should never be used in these version, as it corrupts the YUM configuration, requiring reinstallation from CD. Please see the YUM CD manual documentation for further information on the capabilities and usage of the YUM commands.

- taskmenu – Displays the command line task scheduler menu. SFDC tasks can be scheduled to run at a set future date and time. In SFDC V6.1 and higher, up to 30 reoccurring tasks may be scheduled.

- Create Task – Creates a scheduled task from the displayed list of available tasks for execution at a future date and time. (NOTE: As futures tasks become available, the list of available tasks will be updated.)

- Edit Task – Displays a list of currently scheduled tasks. Allows editing of a scheduled task's date and time. (NOTE: A scheduled task cannot be changed to a different task. Only the date and time can be modified. To change a task, delete the current scheduled task and create a new task.)

- Delete Task – Displays a list of currently scheduled tasks. Allows deletion of the displayed scheduled tasks.

- View Task – Displays a list of currently scheduled tasks.

- toolmenu - Displays a list of routine maintenance items.

- Reindex tables – Used to re-index all the tables in the local database. This tool should be run once a month. Re-indexing the tables will increase overall performance on the SFDC PC, especially on high volume machines.

- Vacuum database – Cleans up records that are no longer WIP on the SFDC PC. A background vacuum db task runs daily and is configured in sfdc config.

- Backup SFDC – Creates a local backup of locally configured files and some data tables to the /home/mfguser/backups/ directory on the SFDC PC. The backup files can then be backed up to the MDS server using the Backup to MDS tool. This provides a way of backing up configuration performed on the local PC, as well as backing up tables storing data that is only used by SFDC, prior to an upgrade or other scheduled event. The backed up files and tables include Configure Workstation, AutoSFDC device control, Defect & Repair GUI Top 5 calculations and Repair Notes, Tasks, Wip & Yield data.

- Restore SFDC – Restores the files and tables previously backed up to /home/mfguser/backups/ to the appropriate directories.

- Backup SPC data – Creates a local backup of SPC data to the /home/mfguser/backups directory. The backup files can then be backed up to the MDS server using the Backup to MDS tool. This provides a way of backing up production SPC data prior to an upgrade or other scheduled event.

- Restore SPC data – Restores SPC data previously backed up to /home/mfguser/backups/ to the appropriate directories. When used with the Restore from MDS tool, this provides a way of restoring production SPC data after an upgrade or other scheduled event.

- Delete old data – Deletes old data in the local database such as serial numbers that are no longer in WIP.

- Backup to MDS – Bundles all files and tables in /home/mfguser/backups/ together, create a tar (tape archive) file, and then upload it to the MDS server using FTP. When used with the Backup SFDC and Backup SPC data tools, this provides a way of uploading all necessary backup files and tables to the MDS server prior to an upgrade or other scheduled event.

- Restore from MDS – Downloads previously uploaded tar file from the MDS server to the local SFDC PC, then untar (un-archive) it to the /home/mfguser/backups/ directory as well as their appropriate directories. This provides a way of restoring all locally configured files and tables after an upgrade or other scheduled event.

- timeconfig – Used to configure the timezone on the SFDC PC.

- Reboot and Shutdown commands.

The SFDC PC Index

The SFDC PC application is Java based and therefore can be accessed via a web browser. Typically, access to the SFDC PC is performed using a web browser. To access the SFDC PC Index page, enter the IP address of the SFDC PC. The main Index page for the SFDC PC will be displayed. The index will contain different buttons to access different functions on the SFDC PC. Some or all of the listed applications below can be displayed, depending upon the version of SFDC software running on the SFDC PC and the software installed. A means of returning to the SFDC PC Index page is also included in all the different GUI screens. Clicking on the SFDC logo in the upper left corner will return you to the Index page. If you are logged into a device in an application such as the Data Collector GUI, or the Batch Process GUI, if you click on the SFDC logo to return to the Index page, you are logged out of the device and returned to the Index page.

- Local Web

- Command GUI

- AutoSFDC XML

- Data Collector GUI

- SPC Web – removed in SFDC 6.0

- Defect GUI – removed in SFDC 6.0

- TWIST – added in SFDC 6.1

- Batch Process GUI

Each menu item is discussed in detail in the following sections.

SFDC Local Web

The Local Web page is where all the normal SFDC data is accessed. There are 6 Menu tabs that display the bulk of the SFDC information. To the right of the Menu tabs, the SFDC PC NetUserID is displayed. The IP address that is displayed is the IP address of the machine currently connected to the SFDC PC, meaning the user’s IP address. The MDS server name is also displayed. Along the bottom of the main window is the local time at the plant, the date, the current shift, Network and SFDC status indicators. Network Status is critical for troubleshooting the system. It displays the network status between the SFDC PC and the plant server. If the Network Status displays a DOWN condition, certain SFDC operations are not functional. Some SFDC operations rely on immediate response from the server. Communication between SFDC PC and data collectors may be very slow during a DOWN condition.

All this information is displayed in every screen or menu.

Note: Beginning in version 5.12.01, you can sort the displayed data, in ascending or descending format, in the following 4 screens, Work In Progress, Serial Number, Current Yield, and Current Defects by clicking on a heading.

Note: In SFDC 6.0 and higher, a new OPTIONS line allows for password protecting access to the SFDC Local Web page. Please see the SFDC Setup Data Editor Quick Reference for more information.

Work-In-Process

The Work-In-Process screen displays product quantities at the listed stations. On the left side of the screen, a Product: drop down menu is available to select a specific product number to filter by. A Station Summary Display check box is also available which will change the WIP display to only stations and summary quantities.

Serial Number Display

The Serial Number Display screen displays all active serial numbers in alphanumeric order. The display includes the serial number, the product number, serial number quantity (typically 1 unless the serial number is a batch serial number), the present location, and a Last Activity Scan flag. This flag signifies that a unit has not been scanned for the length of time specified in the Miscellaneous Setup table in the database. On the left side of the screen, a Workstation and Product: drop down menu is available to select a specific workstation and or product number to filter by. A Shop Order Mode check box is also available which will change the Serial Number display to be based upon Shop Orders. The Product: drop down menu will change to Shop Order: to allow filtering by specific shop order. A serial number entry field is also available to search for a specific serial number or to display the history of a serial number. Links are also available to Move a range of units, post a comment to a range of units, or to format a report for printing.

Post a Comment to a Range of Units

Select Post a comment to a range of units. The User Password, Employee ID, Enter Lowest serial number, Highest serial number, Comment key-ins display. Key in the information for each field, then click on the Comment button. A verification message displays. Press the OK button to accept.

Move a Range of Units

Select Move a range of units. The User Password, Employee ID, Enter Lowest serial number, Highest serial number, Reason for Move key-ins display. Product, From Workstation, New Workstation drop down menus display. Key in the information for each field, and select the correct information from the drop down menus, then click on the Move button. A verification message displays. Press the OK button to accept the move.

The Serial Number Display updates to show the units at the new location.

Clicking on a serial number in the main display will bring up the unit history of that particular serial number. The left menu changes to the options available for that particular serial number.

Move Unit

Select Move unit. The User Password, Employee ID, Reason for Move key-ins display. The New Workstation drop down menu displays. Key in the information for each field, and select the correct information from the drop down menu, then click on the Move Unit button. A verification message displays. Press the OK button to accept the move.

The Serial Number Unit History Display updates to show the unit at the new location. A Manual Move activity is recorded in the unit history.

Add Comment to a Unit

Select Post a comment to a range of units. The User Password, Employee ID, Comment key-ins display. Key in the information for each field, then click on the Comment button. A verification message displays. Press the OK button to accept.

Change Unit Serial Number

Select Change unit serial number. The User Password, Employee ID, New Serial Number key-ins display. Key in the information for each field, then click on the Change button. A verification message displays. Press OK to accept the serial number change.

NOTE: The change is logged in the history of the old serial number, and the old serial number leaves the Serial Number display. The new serial number takes all historical data from the old unit and the old serial number is recorded as part of the unit history.

Change Unit Product Number

Select Change Unit Product Number. The User Password, Employee ID key-ins display. The New Product Number drop down menu displays. Key in the information for each field, select the new product number from the drop down menu, then click on the Change button. A verification message displays. Press OK to accept the change.

As units are completed or pass to Online Line Hold, the serial numbers are removed from the SFDC local database.

Current Shift Yields

The Current Shift Yields screen displays quantities of each product type scanned at all stations. Also displayed are the quantity of units tested, passed and the yield percentage for each product. On the left side of the screen, a Product: drop down menu is available to select a specific product number to filter by. A Work station/Process Summary check box is available which will change the Yield display to stations and an overall summary yield. A Process View check box is also available which will change the Yield display to display by process, rather than Workstation.

Current Shift Defects

The Current Shift Defects screen displays the number of products that have failed at any listed station. The display includes station, product type, and defect code, description and a total quantity. On the left side of the screen, a Product: drop down menu is available to select a specific product number to filter by.

Historical Yield / Defects Report

The Report Parameters key-in displays. Key in From date, To date, and Shift. Date format should be MM-DD-YYYY, where MM is the month, DD is the day, and YYYY is the year. Click on either the Yield or Defects Button to select the type of report to display.

Administration Menu

In order to access the Admin menu, an Administrator Password must first be entered. Initially, the Input Device Status is displayed. In the left Menu are buttons for Input Device Status (current displayed), NetDC Device Status, System Log Displays, View Defect Code, Set / Change User Password, and Set / Change Admin Password. Selecting an item on the left display will display the default screen information in the main window.

Each menu item is discussed in detail in the following sections.

Input Device Status

In the main window, the PCC boards and subsequent ports are displayed. Clicking on any board/port will bring up the Data Collector Device status for that particular board and port. The Device number, Location Name, Status, and communication counters are displayed. Enable / Disable buttons, along with a checkbox to the right, allow individual devices to be selected and either Enabled or Disabled. The Left Menu changes, displaying the following options in addition to the Admin Section Menu: Refresh Report, Reset Device Statistics, Enable All Devices, Disable All Devices, Enable Selected Devices, and Disable Selected Devices.

Data Collector status settings are as follows:

- OK Communicating properly

- NO RESPONSE Configured but not communicating

- DISABLED Configured but disabled from the SFDC PC

- NOT CONFIGURED Not listed in the Scanner Table

Disable

Select a location, checking the box to the far right, then click on Disable. The screen updates to show the location as DISABLED. Communication testing is verified by communicating with one data collector at a time. Disabling all but the first station allows continuous communication with the one station. Adding one data collector at a time simplifies installation. DISABLE should also be used when a new data collector is installed, but the hardware has not.

NOTE: Disable data collectors that are not active. If they are not disabled, errors occur in processing, which will slow the scanning on that port.

Enable

Select a location, checking the box to the far right, then click on Enable. The screen updates to show the location as ENABLED.

Use the right check boxes to select individual or multiple devices, then use the Enable / Disable Selected Devices links in the left menu to change their status all at once. The Refresh Report link will refresh the main display, after changes have been made. Reset Device Statistics zeros or clears all the communication counts for all devices displayed.

NetDC Device Status

In the main window, by default, only the Online NetDC devices are displayed. At the top are two buttons for selecting either Online or All devices. DEVICE ID, LOCATION, STATUS, VERSION (firmware) MAC ADDRESS, NETDC IP address, and COM PORT INFORMATION are also displayed. Selecting the All button will display all online and offline configured devices. Clicking on the NetDC IP address with connect you to that device.

System Log Displays

In the main window, by default, the SFDC Setup file is displayed. This is the setup.txt file is created by the Setup Editor in MDS. The Left Menu displays a Log File drop down menu, which is used to select the type of log to display. Also available are a Refresh Status link and a Print Report link and the Admin Section Menu items.

In the Log File drop down, the following logs are available: SFDC System, SFDC Setup, NetDC, Database, ScanLog, and SFDCDNLD Log. Select the type of log you wish to view, and the main window will update, displaying the chosen log. Use the Refresh Status link to update the display in the main window.

View Defect Code

In the main window, by default, the entire list of available defect codes is displayed. Above this list, on the right is total count of defect codes. A field to enter a specific defect code, along with the Go button, provides search capabilities. 25 defect codes are displayed in a page. Below the main window is count of the total number of pages, along with links to select a particular page of defect codes. A page entry field is also available.

NOTE: Various SFDC features can change the historical record of a product permanently. Required passwords protect the system and prevent unauthorized changes or shutdowns. If activated, a password is required for the following:

Tasks:

- Manual Move Unit (Serial Number Display)

- Manual Move Range (Serial Number Display)

- Change Serial Number (Serial Number Display)

- Change Product Number (Serial Number Display)

- Post a Comment to a Unit (Serial Number Display)

- Post a Comment to a Range (Serial Number Display)

Set / Change User Password

The User password provides a level of protection against unauthorized changes to serial number or WIP. The tasks this password are used to perform are:

- Manual Move a Unit

- Manual Move a Range of Units

- Change Serial Number

- Change Product Number

- Posting a Comment to a Unit or a Range of Units.

In the main window are three fields, Old Password, New Password, New Password Again. Enter the Old Password, enter the New Password. Re-enter the New Password to confirm it. Click on the Change Password button to change the password. A message will display below to confirm the password change was successful.

Set / Change Admin Password

The Admin password is used to control various operations on the SFDC PC. Mainly it is used to control access to the Admin Menu items and the functions within. It is also the password that allows an SFDC admin to log into the SFDC PC remotely to perform operations such as a download, stopping or starting the SFDC service, etc. In the main window are three fields, Old Password, New Password, New Password Again. Enter the Old Password, enter the New Password. Re-enter the New Password to confirm it. Click on the Change Password button to change the password. A message will display below to confirm the password change was successful.

Configure Workstation

The Configure Workstation menu is used to create customized workstation description labels for use with the Data Collector GUI and Batch Process GUI applications. By default, there is no configuration. To create an entry, click the Add button, enter a Device Number and Description, then click on the Save button. A well thought out naming convention will be helpful in grouping like workstation descriptions. Follow the same process to create additional entries. Create as many entries as needed. There may be multiple entries for the same device number to allow for different descriptions for a multipass device. Edit the configuration by selecting the device, using the check-box, and click the Edit button. Make the desired changes, then click the Save Button. To cancel, click the Cancel button. Delete a configuration by selecting the desired device, using the check-box, and click the Delete button. The Upload button is used to save already created configuration file to the /home/mfguser directory on the SFDC PC. An SFDC Administrator can then use the Local SFDC Configuration Backup function to backup the configuration file to the MDS server. This prevents having to recreate this configuration when installing a new version of SFDC software. It is also possible to use FTP to pull the file from this directory to save it elsewhere. The Download button is used to load a configuration file previously saved in the /home/mfguser directory.

NOTE: When a new version of SFDC software is installed from CD, the entire hard drive is wiped out. If saving a configuration file in the /home/mfguser/ directory, be sure to backup the configuration file using SFDC Configuration Backup, or by FTP and saving in another location off the SFDC PC, else it will be lost.

In SFDC v6.1 or higher, the ability to sort by Device Number or Description has been added. To sort, click on the Device Number or Description header title. This is helpful when many devices have been configured. The most recent sort order will be the order in which devices are displayed in the GUI applications.

SFDC Command GUI

The Command GUI web page is a web-based interface for use by the SFDC Admin or other authorized user. This interface provides menu based administration commands to handle all the day to day operations on the SFDC PC. Access to the administration commands is controlled by only allowing access by logging in using the Universal Login.

Initially, in the main window the Status of SFDC, Tomcat, and Apache are displayed. On the top of the page are drop down menu items for various functions. These are Status, SFDC Application, Tomcat, Apache, and Logout. Passing the pointer over the menu items will display the lower level items.

Each menu item is discussed in detail in the following sections.

Status

The Status menu has one drop down item. This is also called Status and returns the main window back to displaying the status of SFDC, Tomcat, and Apache.

SFDC Application

The SFDC Application menu contains all the commands that are used to manage the SFDC PC. These are Start, Stop, Restart, Nodata, and SFDC Config.

Start

Start is used to start the SFDC service if it is not running. The RESTART command will perform the same function but also includes stopping the service.

Stop

Stop is used to stop the SFDC service. This is typically done to perform subsequent operations such as an upgrade to resolve a problem that might have occurred.

Restart

Restart is used to stop and start the SFDC service. This is typically required when an SFDCDNLD command is run, which can occur without stopping SFDC. In order for the downloaded changes to take effect, the SFDC service must be stopped and restarted. Restart can also be used in place of the Start command to start the SFDC service, once it has been stopped.

Nodata

The Nodata command is used to remove all the local WIP information from the local database on the SFDC PC. Nodata is not recommended unless a specific reason requires it. All Yield and Defect information is also deleted from the SFDC PC. After a Nodata command has been run, each serial number scanned into SFDC requires that the unit information be pulled from the MDS server. This can drastically slow down production, as each serial number must be retrieved from the MDS server when it is scanned the first time.

SFDC Config

The SFDC Config command is used to configure the SFDC PC. When launched, the user will be prompted for the following items:

- MDSUSER

- MDSHOST

- MDSIP

- MEASIP

- MEASDB

- SAVE_DATA_DAYS

- AUTO_DEL_TIME

- DB_VACUUM_TIME

- IP FILTER Y/[N]

- MULTI_THREAD Y/[N]

MDSUSER = SFDC PC name (pXXdcX)

MDSHOST = MDS Server name (pXXlsX or pXXasX)

MDSIP = MDS Server IP address (xxx.xxx.xxx.xxx)

MEASIP = SFDC Measurement Server IP address (xxx.xxx.xxx.xxx) The prompt is displayed as part of sfdc config in version 6.1 and higher.

MEASDB = SFDC Measurement Server database name (CPR) The prompt is displayed as part of sfdc config in version 6.1 and higher.

SAVE_DATA_DAYS = 7 by default. This defines the number of days worth of data to store in the local db for status 20 and 25 units. It also defines the number of days to retain Finished units history in the local db.

Note: In SFDC version 6.1 and higher, a second number defines the number of days worth of data to store in the local db for all other statuses. Add a comma after the first number to define the second value (For example: 21,7).

SAVE_DATA_DAYS=x,y

- Delete any wip units (Status 20, 25) older than "x" days

- Delete any non-wip units (Status 26,27,28,29,30,63) older than "y" days.

- If only one value is defined, system will use the same number of days for all unit statuses.

AUTO_DEL_TIME = Time of day to move units from local db to MDS db. This time should be during a break or downtime when production is not running to minimize impacting performance. Time of day to remove Finished units from the local db (based on SAVE_DATA_DAYS parameter).

DB_VACUUM_TIME = Time of day to rebuild the indexes in the local database and optimize the machine. This is similar to a defragmentation operation in a Windows computer. This time should be during a break or downtime when production is not running to minimize impacting performance. It should also be different from the AUTO_DEL_TIME, so as not to interfere with that operation.

IP FILTER Y/[N] = Enables/Disables (default) access control to the SFDC through AutoSFDC XML. Please refer to the AutoSFDC Client section for further information about controlling access to SFDC through AutoSFDC XML. The prompt is displayed as part of sfdc config in version 5.21 and higher.

MULTI_THREAD Y/[N] = Available in SFDC 6.0 and higher. Default setting is No. Enabling will allow SFDC to create multiple socket connections to MDS when needed. Please see the section on multi-threading for more information.

SFDC Install

The SFDC Install command is only in versions of SFDC from 5.12 and earlier.

NOTE: In versions 5.12.02 and greater, do not use the SFDC Install command. YUM is the preferred method of performing installations, upgrades, etc. Using SFDC Install will corrupt YUM and will require reinstallation from CD to correct.

SFDC Download

The SFDC Download menu contains all the commands that are used to download configuration and other data to the SFDC PC. These are SFDCDNLD, SFDCDNLD Empty, Downdata ALL, Downdata [start date], EMVDNLD, SPCDNLD, SAMPLEDNLD, ATTRIBUTEDNLD and DEFECTGUIDNLD.

SFDCDNLD

The SFDCDNLD command is used to download configuration changes made in MDS to the local database on the SFDC PC. This is done through a proxy. SFDCDNLD can be run without stopping the SFDC service. This allows production to continue to run while the download is performed. Once the SFDCDNLD command has completed, a Restart command is used put the downloaded changes into effect, minimizing the amount of downtime required for changes to be made to the system.

SFDCDNLD Empty

The SFDCDNLD Empty command performs an empty download, clearing out current configuration from the SFDC PC. Useful if changing the SFDC PC configuration from one line to another.

Downdata ALL

The Downdata ALL command is used to retrieve all the WIP serial numbers and information from the MDS server. This is typically required if an upgrade was performed to SFDC, as the local database is typically updated with a new database. Downdata does not run by proxy, therefore it requires that the SFDC service be stopped in order to download the WIP data. Depending upon the amount of WIP, this operation can take a significant amount of time, thereby requiring SFDC to be down for the duration.

Downdata [start date]

The Downdata [start date] command is used to retrieve the WIP serial numbers and information from the MDS server for specified date range. This is typically necessary if an upgrade was performed to SFDC, and only a portion of the MDS data is to be downloaded to the local database. Downdata does not run by proxy, therefore it requires that the SFDC service be stopped in order to download the WIP data. Depending upon the amount of WIP, this operation can take a significant amount of time, thereby requiring SFDC to be down for the duration.

EMVDNLD

The EMVDNLD command is used to download Employee Validation configuration changes made in MDS to the local database on the SFDC PC. This is done through a proxy. EMVDNLD can be run without stopping the SFDC service. This allows production to continue to run while the download is performed. Once the EMVDNLD command has completed, any changes will take effect immediately, alleviating any SFDC downtime. Unlike SFDCDNLD, the SFDC service does not need to be stopped and restarted for the changes to take effect. EMVDNLD does not download any SFDC configuration changes, only those made with the Employee Validation module in MDS. See SOP-5-I-MDS0003-C MDS Employee Validation user guide for more information.

Note: In version 6.1 and higher, the SFDC version is sent to MDS upon emvdnld so that it knows which version is requesting the EV records. If the version sent is not 6.1 or higher, MDS 14-5 does not send part-key values in the empval records. (The version information is not used by MDS versions prior to 14-5.) Also in version 6.1 and higher, a successful download is verified prior to overwriting existing configuration to alleviate problems caused if/when the appserver is stopped, or interrupted, while an emvdnld is running.

SPCDNLD

The SPCDNLD command is used to download SPC configuration from MDS to the local database on the SFDC PC.

SAMPLEDNLD / SAMPDOWN

The SAMPLEDNLD menu runs the SAMPDOWN command, which is used to download Sampling Configuration changes made in MDS to the local database on the SFDC PC. This is done through a proxy. SAMPDOWN can be run without stopping the SFDC service. This allows production to continue to run while the download is performed. Once the SAMPDOWN command has completed, any changes will take effect the next time the SAMPLE command is run. Unlike SFDCDNLD, the SFDC service does not need to be stopped and restarted for the changes to take effect. SAMPDOWN does not download any SFDC configuration changes, only those made within the Sampling Plan Configuration module in MDS. See the Sampling Plan Configuration section of the SOP-5-I-MDS0009-C_RA1_MDS_SFDC_Configuration for more information.

ATTRIBUTEDNLD / ATTRIBDNLD

The ATTRIBUTEDNLD menu runs the ATTRIBDNLD command, which is used to download Attribute Definition configuration from the MDS server to the local database on the SFDC PC. This is done through a proxy. ATTRIBDNLD can be run without stopping the SFDC service. This allows production to continue to run while the download is performed. Once the ATTRIBDNLD command has completed, a Restart command is used put the downloaded changes into effect, minimizing the amount of downtime required for changes to be made to the system. ATTRIBDNLD does not download any SFDC configuration changes, only those made to the Attribute Definition module in MDS. See the Attribute Definition section of the SOP-5-I-MDS0009-C_RA1_MDS_SFDC_Configuration for more information.

DEFECTGUIDNLD

The DEFECTGUIDNLD command is used to download Defect/Repair GUI configuration from MDS to the local database on the SFDC PC. Downloaded configuration for the Defect/Repair GUI is available immediately without restarting the SFDC service.

Tomcat

The Tomcat menu has three commands, Start, Stop, and Restart. These commands function in the same manner as the comparable SFDC Application commands. These commands are used for controlling the Tomcat application, which handles all the web based applications such as AutoSFDC XML, the Data Collector GUI, the Command GUI, and SPC Web. In order for these applications to function, Tomcat must be up and running.

Apache

The Apache menu has three commands, Start, Stop, and Restart. These commands function in the same manner as the comparable Tomcat commands. The Apache application is the code that handles all the web server functionality. This software allows for Web access and in conjunction with Tomcat, allows for all the different SFDC applications to run.

Task Scheduler

The Task Scheduler is designed to allow SFDC tasks such as downloads, restarts, etc. to be scheduled in advance and run, without user intervention. This allows tasks to be run when production is down, and the SFDC admin is not present. The Task Scheduler menu has four commands, Create Task, Edit Task, Delete Task, and View Task. A list of the available tasks that can be scheduled is provided. This list will be updates as tasks become available for use. A command line task scheduler is also available and can be run from the command prompt.

NOTE: If a scheduled task is running when another scheduled task is to start, the task will be delayed and run once the first task has been completed.

Create Task

The Create Task button is used to define the task to be scheduled and the date and time to run it. To schedule a task, click on the task scheduler menu button, then select Create Task. The Create Scheduled Task window will be displayed. A table of tasks available to be scheduled is displayed. At the bottom of the screen are three fields, Task to Schedule, Task Date, and Task Time. Enter the task number to schedule in the Task to Schedule field. Clicking in the Task Date field will bring up a calendar. Select the date for the task to run. You can also manually enter the date in the Task Date field. Clicking in the Task Time field will bring up a clock. Select the hour to run the task by moving the hour hand to the appropriate hour. Select the minute by holding the CTRL key and moving the minute hand to the appropriate position on the clock. Clicking on the AM/PM will toggle the setting. The time can also be entered manually in 24 hour time.

Note: In SFDC V6.1 and higher, up to 30 reoccurring tasks may be scheduled. Select Daily, Weekly or Monthly from the "Repeats" field. Select After __ occurrences (define the number of occurrences) or On [enter yyyy-mm-dd] from the "Ends" field.

To schedule the task, click on the Submit button. To cancel task scheduling, click on Cancel.

Edit Task

The Edit Task button is used to edit the time or date for a task that is already scheduled. To edit a scheduled task, click on the Task Scheduler button then select Edit Task. The Edit Scheduled Task window will be displayed. A list of scheduled tasks is displayed.

NOTE: A scheduled task cannot be changed to another task. Only the date and time can be modified. Delete the task and create a new scheduled task.

At the bottom of the screen is a Task # field. Enter the task number from the list to modify. Click in the Task Date field to change the scheduled date. Click in the Task Time field to change the scheduled time. After making the necessary changes, click on the Submit button for the changes to take effect. To cancel the changes, click on the Cancel button.

Delete Task

The Delete Task button is used to delete a scheduled task. To delete a scheduled task, click on the Task Scheduler button then select Delete Task. The Delete Scheduled Task window will be displayed. A list of scheduled tasks is displayed. Below the list is a Task # field. Enter the task number from the list, for the scheduled task to delete. To delete the task, click on the Submit button. To cancel the deletion, click on Cancel.

View Task

The View Task button is used to view all scheduled tasks. To view a scheduled task, click on the Task Scheduler button then select View Task. The View Scheduled Task window is displayed. A list of scheduled tasks is displayed. If there are more tasks scheduled than fits in the window, there will be a scroll bar on the right side move up or down in the list.

Logout

To exit the Command GUI, click on the Logout button on the menu bar and select Exit. The screen will return to the main login window.

AutoSFDC XML

The AutoSFDC XML application is a Java application that runs on the SFDC PC. This application allows for direct data entry to SFDC without having to use a physical data collector. AutoSFDC XML is typically used by testers or test equipment to provide data collection information directly to SFDC, eliminating the need for a user to enter test data into SFDC. AutoSFDC XML also allows software emulators to interface with SFDC as another data collection interface. A software emulator is a program that replicates a physical data collector, but runs on a computer. Please refer to the Data Collection section for more information regarding emulators.

NOTE: Access to the AutoSFDC XML GUI module is password controlled. The administrator password is required.

After clicking on the AutoSFDC XML button on the Index page, the AutoSFDC XML page is displayed. The version of software running is displayed in the header. There are four menu items available. See below for detailed descriptions of each menu button.

Service

Click on the Service menu to display the service information log. There is no configurable setting under this menu, only information.

Scan Log

The Scan Log menu item displays a Scan Log of current scanning activity recorded since the last restart of the AutoSFDC service or since the last SFDC service restart. This information is the listed requests and responses received for all device numbers accessing SFDC through AutoSFDC XML.

AutoSFDC Client

The AutoSFDC Client button is used to launch an application that allows for access control to the SFDC PC through the AutoSFDC XML application. Access can be controlled by IP Address, MAC ID, and Unit number, or a combination of these. Please refer to the AutoSFDC XML Access Control Instructions for further information on configuring AutoSFDC XML to limit access.

NOTE: In order to gain access to the access control application, a profile must exist in MDS and the user must have the profile assigned in order to configure the application.

Upon clicking on the AutoSFDC Client button, Java Web Start will launch and download the application. A Login page will be displayed. Upon successfully logging in, a window similar to jMDS will be presented and the Access Control module will be listed. Despite the appearance, this application is running on the SFDC PC, not the MDS server.

A configuration file is created when using the access control application. Running the SFDC Backup maintenance tool will create a copy of the file, autosfdc_device_control, in the /home/mfguser/backups/ directory. This can then be stored off the SFDC PC so as not to have to re-enter the information after an upgrade.

Access Control Off/On

The Access Control button is used to turn access control through AutoSFDC XML on and off. There is also a command line prompt for access control, to enable or disable, as part of the sfdc config command. Clicking the button will enable or disable the access control, depending upon the current state.

- Access Control Off = Disabled

- Access Control On = Enabled

The button states the current status of the access control program.

NOTE: Enabling or turning the access control program on will effectively limit all access to the SFDC PC through AutoSFDC. Only IP addresses or MAC Addresses that have been configured will be able to access SFDC through AutoSFDC. Do not enable until configuration is setup to allow access.

To return to the Index page, click on the red SFDC text in the top left of the header.

Data Collector GUI

The Data Collector GUI web page is a web-based emulator interface for use by any SFDC user. This interface provides a simple means of entering data directly into SFDC without a physical data collector, or having to install and configure a standalone software emulator program. Upon clicking on the Data Collector GUI, a login screen is displayed. A workstation field is displayed allowing for the selection of the workstation to use. By default, only device numbers that are available are displayed. The SFDC Admin can create custom labels for the workstations, allowing more useful description information to be displayed. The drop down list displays all available or configured workstations. A language field is also available to select a language from the drop down menu.

Upon launching the Data Collector GUI, three menu buttons, OPERATOR, HELP, and EXIT, are displayed. By default, the Operator window is displayed. The Device ID: is displayed in the top field. The history field is used to display the current SFDC prompt and responses to the commands. At the bottom is a Data Entry field for entering data into the interface. Log into the workstation by entering or scanning an employee number into the Data Entry field. When done working in the workstation, the user should log out of the workstation using the LOGOUT command. To switch to a different workstation, click on the EXIT menu, and the application will return to the login screen.

NOTE: Configuration of the custom workstation descriptions is performed through the ADMIN menu on the SFDC Web page.

SPC Web

The SPC Web application provides statistical process control capabilities within SFDC. This is an application that requires installation, in versions of SFDC prior to 5.21. Configuration of SPC is performed through the SPC configuration module in MDS. In order for the SPC Web application to work, all the SPC configuration and code must be installed and present. Refer to the SPC Users guide for additional detail regarding SPC functionality and operation.

NOTE: Access to the SPC Web application is password controlled. The administrator password is required.

After clicking on the SPC Web button on the Index page, the SPC page is displayed. The version of software running is displayed in the header. There are two menu items available. See below for detailed descriptions of each menu button.

Service

Click on the Service menu to display the service information log. There is no configurable setting under this menu, only information.

SPC Client

The SPC Client button is used to launch the SPC application on the SFDC PC. NOTE: In order to launch the SPC application, a profile must exist in MDS and the user must have the profile assigned in order to use the application.

Upon clicking on the SPC Client button, Java Web Start will launch and download the application. A Login page will be displayed. Upon successfully logging in, a window like jMDS will be presented and the SPC module will be listed. Despite the appearance, this application is running on the SFDC PC, not the MDS server. Refer to the SPC Users guide for additional details on using the application. To return to the Index page, click on the red SFDC text in the top left of the header.

NOTE: The SPC Client button has been removed from the SFDC Index page in version 6.0. All maintenance for SPC is performed in the MES Portal.

Defect GUI

NOTE: The Defect GUI has been removed from the SFDC PC in versions 6.0 and higher, as all development of this application has been moved to the MES Portal. Please refer to the documentation on the MES Portal for more information regarding advanced defect and repair capabilities.

The Defect GUI is an application that is being developed for defect and repair logging. Debug functionalities are also being developed which include a Knowledge base and the ability to display a CAD drawing, when available, for easier part identification and as a troubleshooting aide.

Upon clicking on the Defect GUI, a login screen is displayed. A workstation field is displayed allowing for the device number or unit number to be entered. Only device numbers with configuration are displayed. Configuration is managed in MDS within the SFDC GUI Administrator module. Upon entering a character, a drop down menu will be display to allow scrolling and selecting a particular device number. You can also continue to enter characters directly into the Workstation field. A Badge field is also displayed. Enter/Scan your employee number into the field. A language field is also available to select a language from the drop down menu, to display the interface in.

Beginning with SFDC version 5.21, there are only two modules available in the Defect GUI. The first is the Record & Repair Defect screen. The second is the Knowledge Database. What modules are available at a particular device number are controlled by configuration in the SFDC GUI Administrator module.

Record & Repair Defect

Clicking on this button in the menu bar, a screen is displayed that looks somewhat like an emulator window. To begin, enter a serial number in the Serial Number field and click on the Retrieve button. The DC Status box displays information just like a data collector. If the serial number entered is at the correct location, the Menu Selection prompt will be displayed, and the part number field will display the part number of the entered serial number. Revision will also be displayed, if available. If the entered serial number is not at the correct location, a flow error will be displayed in the DC status box, followed by the Serial Number? prompt.

Once the Menu Selection? prompt is displayed, new defect and repair information can be recorded against the serial number. Two fields are always mandatory, the defect and reference designator. Other fields can be configured in the SFDC GUI Administrator module to be mandatory. Mandatory fields are indicated with a red “*” to the right of the field. To record a defect, click in the Defect box and enter the first character of a valid defect code. A fuzzy search capability exists and all matching defect codes will be listed. As you continue to enter characters, the list becomes shorter. Select the defect code to record against the serial number.

NOTE: Defect and Repair codes are managed in the SFDC GUI Administrator module. The defect and repair codes can be controlled using this configuration tool. Only those codes defined in the configuration will be displayed in the GUI.

A repair can be recorded at the same time a defect is recorded, by clicking on the Repaired: YES radio button. If NO is selected, then the Repair Code, Repair Note, and Last Repair Note fields are inactive. Clicking in the Repair Code field, again, a fuzzy search capability exists and as characters are entered, matching codes will be displayed in the drop down menu. After selecting a Repair Code, the Repair Note field can be used to enter notes about the repair. This information is what is used to make up the “Knowledge Base”. Also, if there was a previously recorded Repair Note, this will be displayed in the Last Repair Note field.

After all the information has been entered, click on the Record button to record the defect and repair information. The defect and repair information will be recorded against the serial number. The screen will also reset, allowing for additional defects and repairs to be entered. Clicking the Reset button will perform a “RESET” the same as at a data collector location. All entered information will be cleared from the fields. Clicking the End button will send an END command to SFDC. If a recorded defect was not repaired, the unit will fail to the appropriate location, as determined by the SFDC route. If all defects recorded were repaired, the unit will pass to the next location in the SFDC route. The serial number field will be blank and the DC Status field will be at the Serial Number? prompt. Clicking on the Release button will send a RLSE command to SFDC. The serial number will be released at the current scanning location. The serial number field will be blank and the DC Status field will be at the Serial Number? prompt. The Unit History button will open another window or tab and display the SFDC Unit History report.

Knowledge Database

Clicking on the Knowledge Database button in the menu bar will bring up the Knowledge Database screen. The only mandatory field is the Part Number field. Other fields that can be used for search criteria are Reference Designator, Defect Code, Repair Code, and Note. A starting and ending date can be selected. There is also a checkbox to Show Deleted Defect Notes. Enter the appropriate data and click on the Search button. Any matching records will be displayed. Clicking on the headers will change how the data records are organized.

Exit

Clicking on the Exit menu button will log out of the current location and return to the login screen for the Defect GUI, where another device number / operator number can then be entered.

Batch Process GUI

The Batch Process GUI is an application that provides a web page interface to perform Batch Processing operations. The functions that are available in the GUI are Create Batch, Split Batch, Merge Batch, Remove Unit/All Units, Add Component, and Add Sub Attribute. The GUI screens make it easier to identify the individual unit serial numbers that are in batches, and eliminates the need for running the batch commands at a data collector or through an emulator.

- Batch process allows for a batch serial number (module select type 7) to be created and unit serial numbers added to the batch.

- Unit serial numbers are tracked components of the batch serial number.

- The only tracked components of a batch serial number are the unit serial numbers. SFDC processing is performed using the batch serial number, and all activities are done against the batch serial number.

- Unit serial number processing cannot be “mixed” with batch processing. In order to perform a unique operation to an individual unit, the batch must be split into a batch of one and the individual unit added to the batch. Processing then occurs on the batch serial number.

- Batch serial numbers can be split into smaller batches, or merged to combine small batches of units into a larger batch.

- Upon completion of a batch, all the individual units are removed from the batch and moved to completed status. The batch serial number is marked as “Batch_OLDID”, status 63, and is no longer used again.

- Reporting capabilities have been created for MESWeb to allow all activities performed at the batch level to be reflected in the unit history.

- By default, the maximum batch size is 150 units.

- The batch serial number and unit serial numbers are the same part number.

- Shop orders are created for the unit serial numbers, not batch serial numbers.

- Unit serial numbers are created at the time the shop order is released.

- Multiple batch serial numbers can be created for a single shop order, but only unit serial numbers from a single shop order can be associated to a batch serial number. Mixing between shop orders, even for the same part number, is not allowed.

- Batch serial numbers can be manually created of generated from an algorithm. If using an algorithm to create a batch serial number, the algorithm type must be “general”.

- Split Batch serial numbers are expected to be in the format (parent_sn-nn) where parent_sn is the Source (parent) batch serial number and nn represents an incrementing number (01, 02, 03…).

- Batch serial number label printing is available in the GUI. A “BATCHLABEL” macro must be configured in the Setup Data Editor for print capabilities.

Upon clicking the Batch Process GUI icon in the Index page, a login screen is displayed. A workstation field is displayed allowing for the device number or unit number to be entered. Upon entering a number, a drop down menu will be display to allow scrolling and selecting a particular device number. You can also continue to enter characters directly into the Workstation field. A Badge field is also displayed. Enter/Scan your employee number into the field. A language field is also available to select a language from the drop down menu, to display the interface in.

After logging in, the main Batch Process GUI screen is displayed. Operations are selected from the main menu bar. The active workstation is displayed in red, on the right side of the menu bar.

Create Batch

To create a new batch serial number and associate unit serial numbers to the batch serial number, click on the Create Batch button on the menu bar. The Create Batch screen is displayed. Click in the Shop Order field and enter the first character(s) of a shop order to create a batch serial number for. A “fuzzy search” displays all matching shop orders for the entered characters. Select the shop order to create a batch serial number for.

NOTE: Only released shop order with unit serial numbers not associated to a batch will be available for use. Shop orders that do not have available units are not displayed.

Once a shop order has been selected, the available unit serial numbers are displayed in the box under the shop order. A label under the left box displays the number of unit serial number available in the Shop Order. This value only updates after a batch serial number has been created and units are associated to the batch serial number. On the top right side of the screen are the Batch Serial Number fields. A batch serial number can be created manually, or though the use of an algorithm. There is a check box to use an algorithm and a box to supply the algorithm number. If the algorithm check box is checked, the batch serial number field becomes inactive, not allowing for manual serial number entry. Manually enter a batch serial number, or check the algorithm check box and enter a valid algorithm number. The large box on the right displays the unit serial numbers to be added to the batch serial number. A label under the box displays the current count of unit serial numbers in the box.

NOTE: If manually creating batch serial numbers, SERIAL INPUT line(s) must exist in the SFDC Setup Data Editor to define serial masking and part number assignment.

There is also a print button to print out the Batch Serial Number on a label.

NOTE: In order to print a batch serial number label, a “BATCHLABEL” macro must be defined in the SFDC Setup Data Editor. The Macro command specifies the label type and print queue to use for printing a label. Refer to the Label Printing section of the SOP-5-I-MDS0009-C_RA1_MDS_SFDC_Configuration for Label printing configuration.

In the middle of the screen are left and right arrow buttons. The double arrow buttons move all unit serial numbers from left to right, or right to left, depending upon the button. Individual or multiple unit serial numbers can be selected and moved using the single arrow buttons. Below the arrow buttons is a box to enter a batch quantity. Entering a number in this field, then selecting either Ascending or Descending and clicking on the single right arrow button, will associate the specified number of units from the shop order to the batch serial number.

NOTE: The batch quantity value cannot exceed the maximum batch size, or the number of units available in the shop order.

Once a batch has been defined in the GUI, clicking on the Commit button will create the batch serial number and add the defined unit serial numbers to the batch serial number in SFDC. As long as the Commit button has not been clicked, the batch has not been created and any changes can be made. There is also a Commit & End button. Clicking this creates the batch serial number, associates the unit serial numbers to the batch serial number and passes the batch serial to the next location, as defined by the SFDC route. To cancel creating a batch, click on the Cancel button. The View History button will display the SFDC Batch Serial Number unit history.

Split Batch

To split a batch serial number and associate unit serial numbers from the parent batch serial number to a new split batch serial number, click on the Split Batch button on the menu bar. The Split Batch screen is displayed.

NOTE: A batch serial number can be split into smaller batches, but at least 1 unit serial number must remain in the original batch. A split batch serial number cannot be created for a quantity equal to or greater than the parent batch serial number quantity.

In the top left of the screen is a field to select the Source (parent) Batch Serial Number. Click in the Source Batch Serial Number field and enter the first character(s) of a batch serial number. A “fuzzy search” displays all matching batch serial numbers for the entered characters. Select a parent batch serial number to split into a smaller batch quantity.

NOTE: Only batch serial numbers at the location(s) associated to the workstation currently logged into are displayed.

After selecting a batch serial number, the unit serial numbers attached to the batch serial number are displayed in the box on the left. A label is displayed under the box, defining the quantity of units in the batch serial number. On the top right side of the screen are the Target Batch Serial Number fields. A batch serial number can be created manually, or though the use of an algorithm. There is a check box to use an algorithm and a box to supply the algorithm number. If the algorithm check box is checked, the batch serial number field becomes inactive, not allowing for manual serial number entry. Manually enter a batch serial number, or check the algorithm check box and enter a valid algorithm number.

NOTE: The expectation for split batch serial numbers is to have the format (parent_sn-nn). The parent batch serial number makes up the first part of the split batch serial number, followed by a “-“ (hyphen) and then ascending number (01, 02, 03, …) for each split. If using an algorithm to create split batch serial numbers, the algorithm must be of type general and must be configured correctly to use the parent batch as a value, along with a constant (-) and incrementing number.

The large box on the right displays the unit serial numbers to be added to the split batch serial number(s). A label under the box displays the current count of unit serial numbers in the box.

NOTE: If manually creating split batch serial numbers, SERIAL INPUT line(s) must exist in the SFDC Setup Data Editor to define serial masking and part number assignment.

In the middle of the screen are left and right arrow buttons. Individual or multiple unit serial numbers can be selected and moved using the single arrow buttons. Below the arrow buttons is a box to enter a batch quantity. Entering a number in this field, then selecting either Ascending or Descending and clicking on the right arrow button, will associate the specified number of units from the Source Batch Serial Number to the Split Batch Serial Number(s).

Also on the top right is a check box to create multiple split batch serial numbers and a field to enter the quantity of split batches. Checking the multiple box and entering a value in the quantity field, will trigger the specified number of split batch serial numbers to be created, associating the unit serial numbers in the right box to the split batch serial numbers. For example: If 10 unit serial numbers are in the right split batch serial number box, and the quantity entered for the multiple quantity is 5, each split batch serial number will have two unit serial numbers associated to it. Creation of the Split Batch Serial Number(s) only takes place when the Commit button is clicked. There is also a print button to print out the Batch Serial Number on a label. To cancel the creation of a Split Batch Serial Number(s), click the Cancel button. The View History button will display the SFDC Batch Serial Number unit history.

NOTE: In order to print a batch serial number label, a “BATCHLABEL” macro must be defined in the SFDC Setup Data Editor. The Macro command specifies the label type and print queue to use for printing a label. Refer to the Label Printing section of the SOP-5-I-MDS0009-C_RA1_MDS_SFDC_Configuration for Label printing configuration.

Merge Batch

To merge a batch serial number and associate unit serial numbers to a parent batch serial number, click on the Merge Batch button on the menu bar. The Merge Batch screen is displayed.

NOTE: The merge batch serial number command will only allow batch serial numbers from the same shop order to be merged. The location of the parent batch and the batch to be merged into the parent must be the same. There is no limit on the number of units that can be merged into a parent batch.

In the top left of the screen is a field to select the Source Batch Serial Number. Click in the Source Batch Serial Number field and enter the first character(s) of a batch serial number. A “fuzzy search” displays all matching batch serial numbers for the entered characters. Select a source batch serial number to merge into a larger batch quantity.

NOTE: Only batch serial numbers at the location(s) associated to the workstation currently logged into are displayed.

After selecting a batch serial number, the unit serial numbers attached to the batch serial number are displayed in the box on the left. A label is displayed under the box, defining the quantity of units in the batch serial number. On the top right side of the screen is the Target Batch Serial Number field. Click in the Target Batch Serial Number field and enter the first character(s) of a batch serial number. A “fuzzy search” displays all matching batch serial numbers for the entered characters. In the middle of the screen is a double right arrow button. Clicking on the right arrow button, will associate all the unit serial numbers from the Source Batch Serial Number to the Target Batch Serial Number. To complete the merge of the source batch serial number to the target batch serial number, click the Commit button. To cancel the merge of the source batch serial number to the target batch serial number, click the Cancel button.

Remove Unit / All Units

To remove a unit serial number or all unit serial numbers from a batch serial number, click on the Remove Unit button on the menu bar. The Remove Unit / All Units screen is displayed.

NOTE: Do not remove a unit to process individually. Split a batch and move the individual unit to a new batch serial number.

In the top left of the screen is a field to select the Batch Serial Number. Click in the Batch Serial Number field and enter the first character(s) of a batch serial number. A “fuzzy search” displays all matching batch serial numbers for the entered characters. Select a batch serial number to remove a unit or all units from.

NOTE: Only batch serial numbers at the location(s) associated to the workstation currently logged into are displayed.

After selecting a batch serial number, the unit serial numbers attached to the batch serial number are displayed in the box on the left. A label is displayed under the box, defining the quantity of units in the batch serial number. On the top right side of the screen is the Target Location field. Click in the Target Location field and enter the first character(s) of a location. In the middle of the screen are left and right arrow buttons. The double arrow buttons move all unit serial numbers from left to right, or right to left, depending upon the button. Individual or multiple unit serial numbers can be selected and moved using the single arrow buttons.

NOTE: Removing all units from a batch serial number will cause the batch serial number to be marked at status 63 (Old BatchID) and it will not longer be able to be used.

At the bottom of the screen are fields to enter a Defect Code and/or a Comment. Neither is required, but it is useful for providing information as to why a unit or units were removed from a batch. To complete the removal of a unit or units from a batch serial number, click the Commit button. To cancel the removal of a unit or units from the batch serial number, click the Cancel button.

Add Component (Add Unit)

To add a component (unit serial number) to a batch serial number, click on the Add Component button on the menu bar. The Add Component screen is displayed.

NOTE: Adding a component to a batch serial number is adding a unit serial number from a specified location to the batch serial number. The GUI screen utilizes the ADCMP3 command to perform this operation, allowing a unit serial number, at a location to be added into a batch. The unit serial number must be the correct part number.

In the top field, click in the Batch Serial Number field and enter the first character(s) of a batch serial number. A “fuzzy search” displays all matching batch serial numbers for the entered characters.

NOTE: Only batch serial numbers at the location(s) associated to the workstation currently logged into are displayed.

Select a batch serial number to add a unit serial number to. Unit serial numbers already added to the batch serial number will be listed in the table. In the next field select the Source Location where the unit serial number to be added is located. Click on the Add button and a new line in the table will be created. Enter the Serial Number of the unit serial number to add, enter the Reference Designator (UNITSN), and the Component Part Number. Click on the Save button to add the unit serial number to the batch.

NOTE: The Reference Designator for all unit serial numbers in a batch is UNITSN. The part number of the added Unit serial number must be the same as the part number of the batch serial number.

To cancel the addition of the unit serial number to the batch serial number, click on the Cancel button.

Add Sub Attribute

To add or replace an attribute for a unit serial number attached to a batch serial number, click on the Add Sub Attribute button on the menu bar. The Add / Replace Sub Attribute screen is displayed.

NOTE: An attribute table must exist to define the attribute names, masks, and group name (optional). The attribute table must be configured for a specific part number and it must be created for a location. The location does not have to be used in a route.

In the top left of the screen is a field to select the Batch Serial Number. Click in the Batch Serial Number field to select a batch serial number.

NOTE: Only batch serial numbers at the location(s) associated to the workstation currently logged into are displayed.

In the top right of the screen is a Command field. This is used to select the subatt command. There are four options:

SUBATT – Adds all attributes for the current part number.

SUBATT.LOC – Adds defined attributes for the current part number at a specified location.

SUBATT.GROUP – Adds attributes for the current part number matching the specified group name.

SUBATT.LOC.GROUP- Adds attributes for the current part number, at a specified location, matching the specified group name.

Depending upon the command selection, the Location and Group fields may be selectable. If using a command with the LOC parameter, select the location of the attribute table to use in the drop down menu. If using a command with the GROUP parameter, select an attribute group name, from the drop down menu.

After selecting the required items, select a unit serial number from the drop down list of Unit Serial Numbers. To add attribute values, click on the Add button. The Attribute Prompt and Attribute Name fields will be populated for the required attributes and the Attribute Data fields will be available to add attribute data for each available attribute definition.

NOTE: The attribute data must match the attribute data mask defined in the configuration.

To save the attribute data entered into the data field(s), click on the Save button. A message “Add Attribute successfully” will be displayed. In order to Replace and attribute, attribute data must exist already for the unit serial number. Click the Replace button. The Attribute Data fields will then be available to enter new attribute data. Click on the Save button to update the changes. Clicking on Cancel button will revert back to the original values.

Exit

To logout out or leave the current workstation, click on the Exit button in the menu bar. The Login screen will then be displayed, allowing the user to switch to a different workstation, if required.

Attributes

Attribute definitions are maintained in SFDC Configuration through MDS. See the Attribute Definition Maintenance section of the SFDC Configuration Manual for more information.

Attributes can be added to a serial number with the Add Attribute command (ATTADD) or Add Attribute by Group Name (ATTADDGRP). Attributes can be removed and replaced using the Remove Attribute command (ATTREMOVE) or Clear Attribute (CLEARATTRIBUTE). For definitions and descriptions for these commands, see the SFDC Generic Custom Command Appendix. These commands are executed as !!1 commands (per the command appendix), but are local SFDC commands in version 5.22 and higher.

For SFDC Version 5.22 and higher: The following local SFDC commands are available: ATTADD, ATTADDGRP, ATTREMOVE, CLRATT, and VERATT. These commands eliminate the need to execute the !!1 commands in MDS. Refer to the individual command descriptions in this document for more information.

Defect / Repair GUI (MES Portal)

Additional development of the Defect and Repair GUI has been moved to the MES Portal, in order to be able to add additional functionality. In order to utilize the Defect and Repair GUI functionality, an SFDC PC must be configured in the MES Portal and must be running SFDC 6.0 or higher.

The Defect and Repair GUI portlet provides for the following functionalities.

- Advanced defect recording with PTS integration for component validation. An entered reference designator is validated against the BOM in PTS, in order to insure that the component exists.

- Advanced repair recording with PTS integration for validation of replacement component validation. Based upon the reference designator, the component is validated against the BOM in PTS. A Material Barcode field is included in order to validate the replacement component, insuring the correct part number, manufacturer, valid data code, etc. are used.

- CAD file display, based upon scanned serial part number. GenCAD file is currently the only supported format. Portlet for uploading and managing uploaded CAD files is provided. Multiple layers of the CAD drawing can be displayed using a list of selectable check boxes.

- Component look up in CAD drawing by reference designator. Reference designator specified as part of a recorded defect or repair is automatically displayed, but using Recorded or Repaired switches. Reference designator can also be looked up prior to defect/repair recording.

- Web service link to SFDC Measurement for displaying parametric records for an entered serial number. The Measurement server must be configured in MES Portal in order for records to be accessed. All available records found for the scanned serial number, are displayed.

- Top 5 defects and repairs based upon part number of scanned serial number. Display is based upon defects/repairs entered by the GUI in the Portal. Historical data from SFDC is not used. Chart display or list of defect/repair codes with description.

- Tech Notes field for recording of troubleshooting information. Search capability also exist for Tech Notes.

Employee Validation

The Employee Validation capabilities of SFDC are designed to handle process control through the validation of employee numbers and passwords that have specified certification for a specified process or processes. Employees are configured in the system, processes to be controlled by Employee Validation are defined and then certificates are created with associated class or classes and the training duration is specified. All configuration is performed in MDS and then downloaded to the SFDC PC, using the emvdnld (Employee Validation download) command. When enabled, EV checks an employee number when logging into any device with a controlled process, validates the employee password, and certifications that are not expired, that the employee is assigned to. If a serial number is scanned at a controlled process, and the employee has the required certification, the serial number is allowed to be acted upon. If the employee does not have the required certification, an error is displayed. Locations without EV control allow for normal SFDC scanning. Multipass devices which have both EV controlled processes and non-controlled processes, require an employee to be in the EV system in order to log into the multipass device, and perform non-controlled processes.

Options Lines

There are 4 option lines that can be configured as part of the setup data editor for the SFDC PC. All other Employee Validation configuration is done through the Employee Validation module in MDS.