SOP-MES0073 CMMS Admin

Cirrus > Production > CMMS Administration

This edition applies to Cirrus and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

Administration

This edition applies to CMMS for Cirrus and all subsequent releases and modifications until otherwise indicated in new revisions.

The administration module is designed for administrators (Manufacturing Engineer profile) to perform all administration-related actions. There are six sub-modules available to local system administrators. Refer to the table below for sub-module names and corresponding functions:

| Sub-module Name | Function |

| User |

|

| Group’s Category |

|

| Group |

|

| Department |

|

| Escalation |

|

| Project |

|

NOTE: See below the available profiles and their respective modules access.

Equipment Operator |

Engineer (Quality, Process, Facility) |

Manufacturing Engineer |

Spare Part/Asset Management |

CMMS Work Order

|

CMMS Work Order

|

CMMS Admin

|

CMMS Asset

|

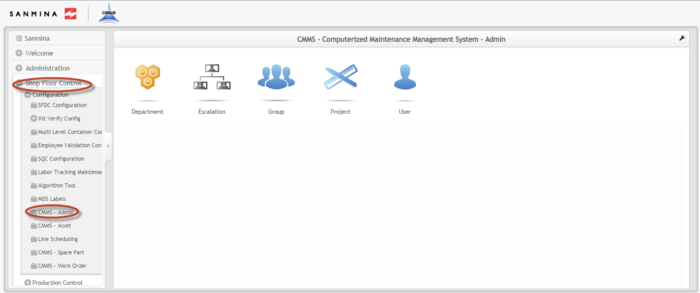

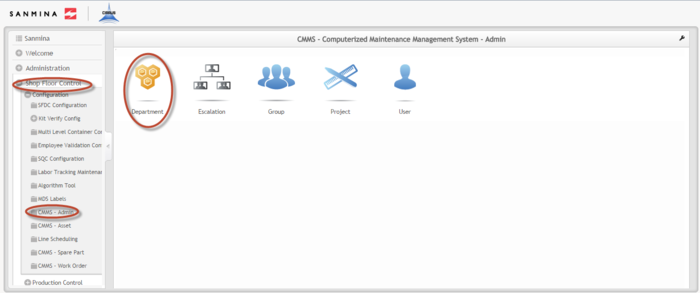

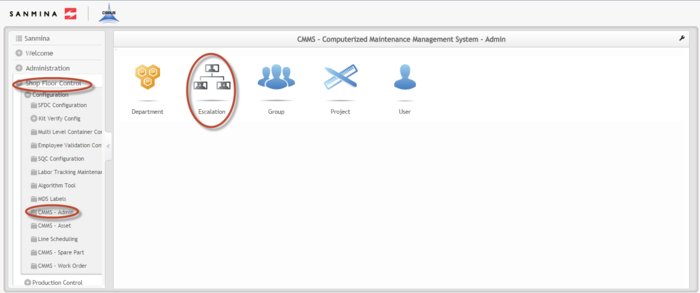

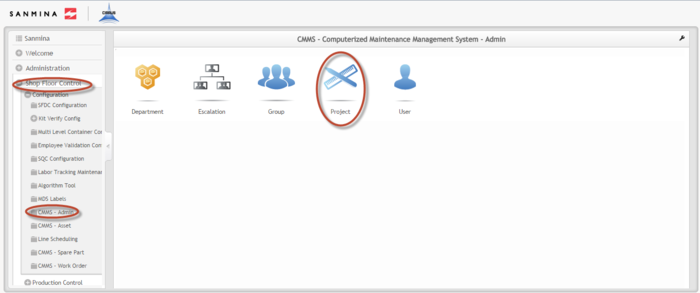

The CMMS Administration Module is accessed by select Shop Floor Control > Configuration > CMMS-Admin

Figure 1: CMMS Administration Module

Now the user is able to access all available CMMS Administration sub-modules.

User

The main purpose of this sub-module is import information from Liferay and allows users to view that information in order to assign for groups, escalation and WO. Only administrator users can access this feature.

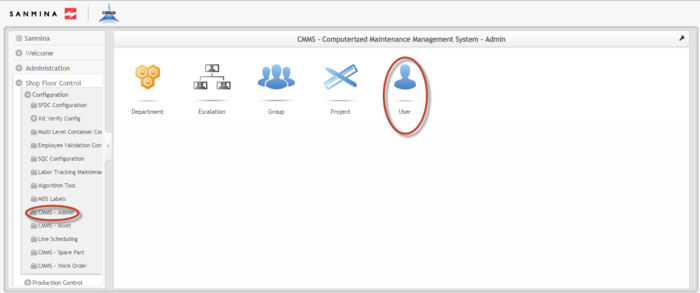

1. To access User sub-module, navigate to CMMS-Admin > User.

Figure 2: User Administration

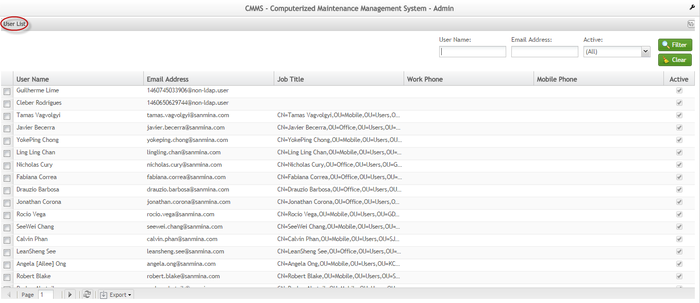

2. The User List displays all existing users.

Figure 3: User List

The user can search by: Active/Inactive, Email Address and User Name fields. It is not allowed to ADD, EDIT or DELETE an user from the list.

User data should be listed by:

- Email address: email address from the user register in the System (MES PORTAL);

- User name: First and last name from the user register in the System (MES PORTAL);

- Job Title: title from the user register in the System (MES PORTAL);

- Work Phone: phone from the user register in the System (MES PORTAL);

- Mobile Phone: Mobile from the user register in the System (MES PORTAL);

- Active: if user is disabled in the System, this information should be presented as unchecked. Otherwised

should be presented checked.

Group

This section covers how to perform group maintenance in the CMMS system. Group in CMMS means a group of users who handle the same group’s category or categories of problems, requests or tasks. Therefore when creating a group, the user must have a clear concept of what group’s categories will handle. The user must also be able to associate target categories to the group and must be able to add users into the group to follow. In Group Maintenance, administrators can add, edit or delete groups as well as assign categories and users to a specific group.

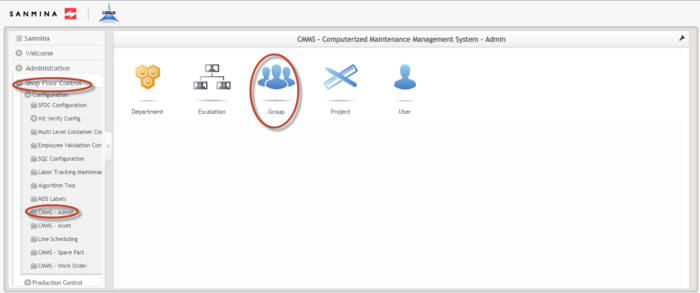

1. To access Group Maintenance, navigate to CMMS-Admin > Group.

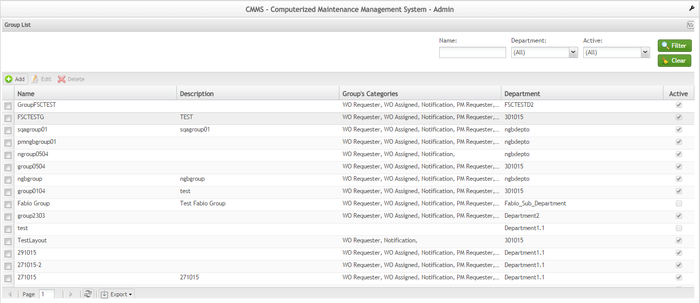

Figure 4: Group Maintenance

2. The Group List displays all existing groups.

Figure 5: Group List

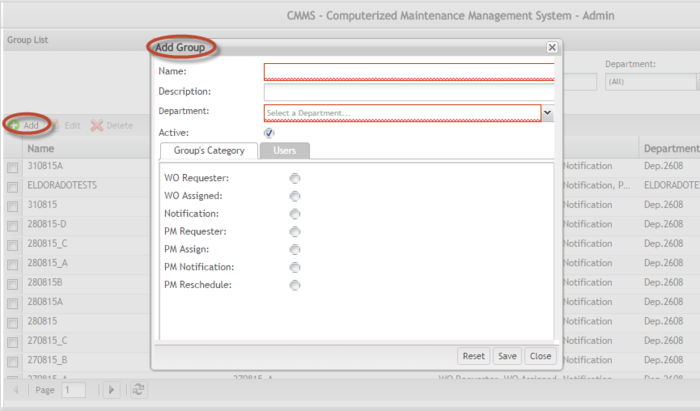

Add Group

1. To add a Group, select Add located above the Group List.

Figure 6: Add Group

2. The Add Group form will display:

3. Enter the following information:

- Name (Mandatory): The group name to be added to system.

- Department (Mandatory): Select a department from the drop down box provided.

- Active: Allows the user to enable or disable a group. Default value is enabled. To disable a group, uncheck the checkbox.

- Description (Optional): Additional details of the group.

NOTE: It is not allowed groups with the same name in the system.

4. If the user doesn’t want assign a category to group or users, select Save to confirm or Close to exit, otherwise, fill out the information in the available tabs (Group’s Category and Users).

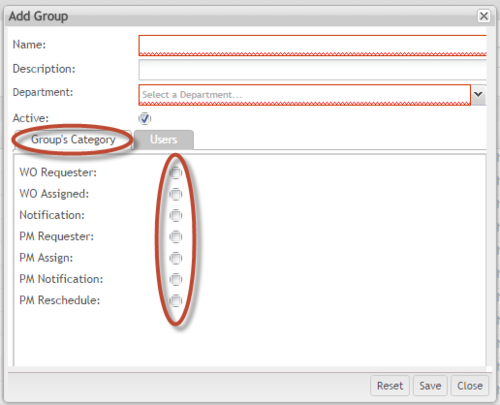

Assign Category to a Group

All existing categories will appear in the list under the Group’s Category tab. The administrator can assign a category to a group from this tab.

1. To assign a category to a group, place a check in the box to the left of the category name.

2. Select Save to confirm or Close to exit.

Figure 7: Assign Category to Group

NOTE: If there is not a proper category in the list, the user will need to create a category before.

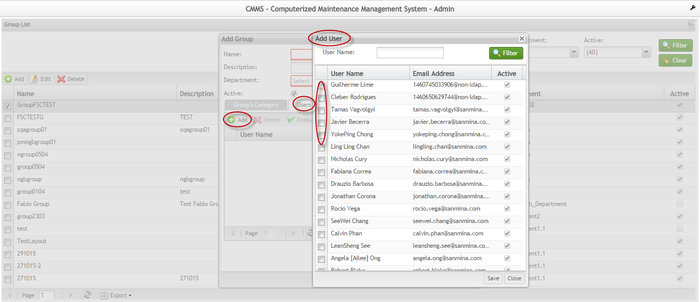

Assign Users to a Group

The administrator can assign users to a group form the Users tab.

1. To assign a user to a group, select Add located above the User Name list.

2. The Add User pop-up displays:

Figure 8: Assign Users to Group

3. Place a check in the box to the left of the User Name to be assigned to the group.

4. Select Save to confirm or Close to exit.

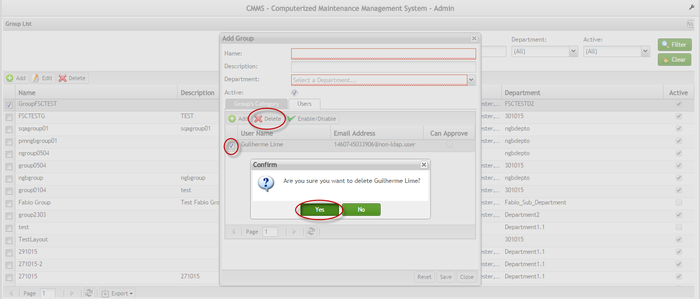

¬Delete Users from a Group

1. To delete a user from a group, select the user from the User Name list and then select Delete.

Figure 9: Delete User from Group

2. Select Yes to confirm or No to exit.

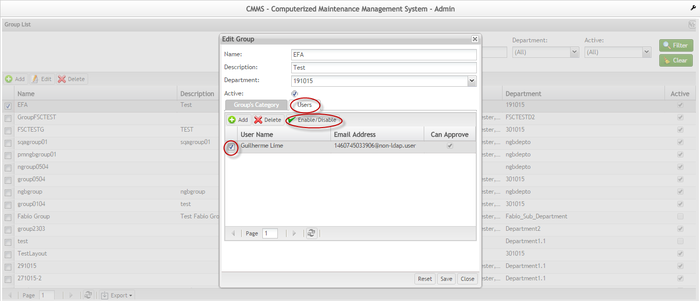

Approving Users from a Group

If the checkbox is marked, it indicates that the user is allowed to re-schedule in the Preventive Maintenance Module.

Figure 10: Approving User

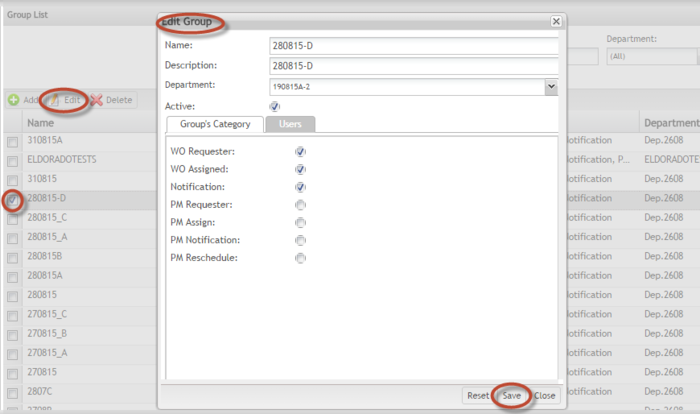

Edit Group

1. To edit an existing Group, select the group from the Group List and then select Edit.

2. The Edit Group pop-up displays:

Figure 11: Edit Group

3. The following items are available to update and the rules are the same as for Add Group:

- Name, Description, Active Status and Department.

- Check or uncheck the Active checkbox to enable or disable the group.

- Assign or remove categories from the group in the Group’s Category tab.

- Add users to or delete users from the group in the Users tab.

4. After updating, select Save to confirm. Select Close to exit without updating.

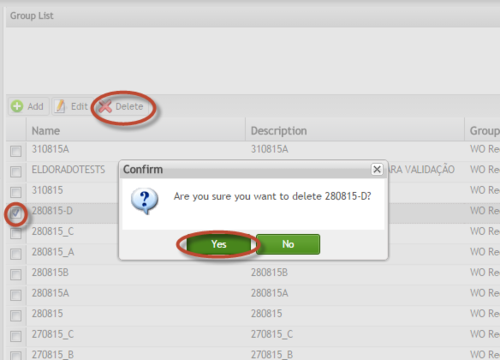

Delete Group

1. To delete an existing Group, select the group from the Group Name list and then select Delete.

Figure 12: Delete Group

2. The confirmation message displays:

3. Select Yes from the confirmation prompt to confirm, or No to exit.

NOTE: If the group is be used, it is not be allowed to delete the group.

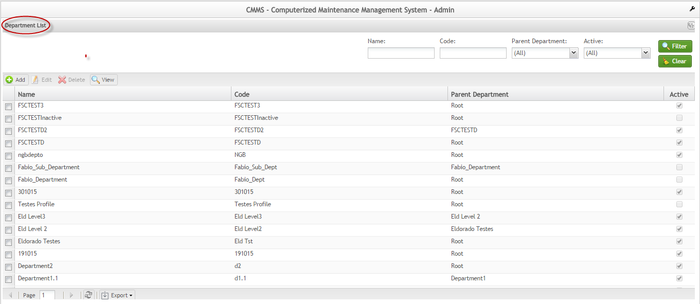

Department Maintenance

This section covers how to perform department maintenance in the CMMS system. In Department Maintenance, administrators can add, edit, delete and view departments hierarchies.

1. To access Department Maintenance, navigate to CMMS-Admin > Department.

Figure 13: Department Maintenance

2. A Department list displays with all added departments.

Figure 14: Department Name List

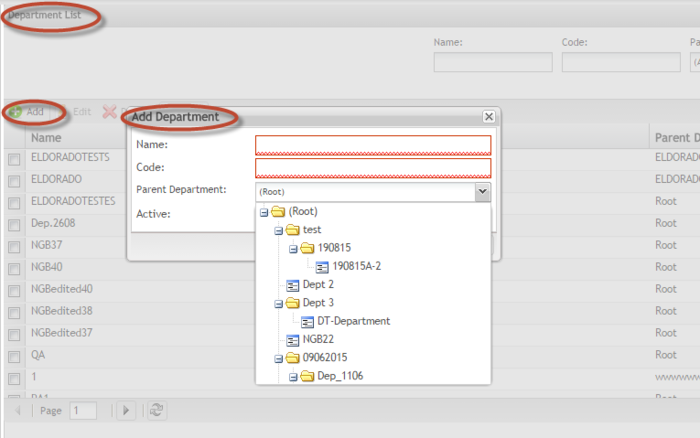

Add Department

1. To add a department, select Add located above the Department list. A pop-up displays with the Add functions.

2. The Add Department pop up displays:

Figure 15: Add Department

3. Enter the Department Name and the Department Code (mandatory). The department will be added as a child if the user doesen’t choose the parent department in the Parent Department node.

4. Select Save to confirm.

NOTE:The maximum level of the tree is six. A warning message is displayed.

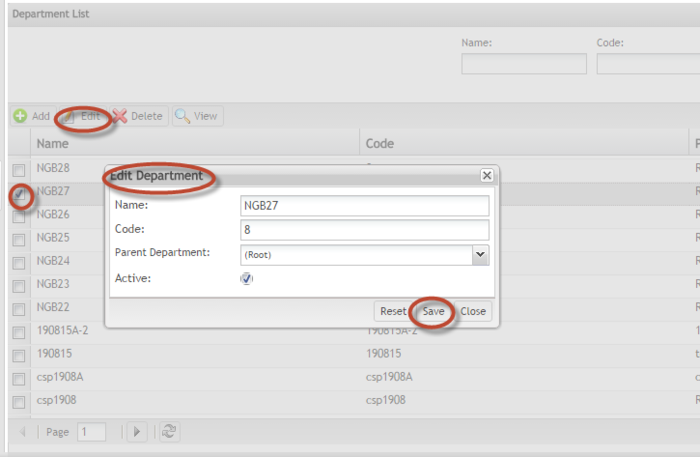

Edit Department

1. To edit a department, choose the department and select Edit. A pop-up displays with the Edit function.

2. The Edit Department form displays:

The ROOT node could be changed.

NOTE: If the user disables a department, all of the children departments associated with it eill be automatically disable.

Figure 16: Edit Department

3. The following items are available to update:

- Name (Mandatory): Enter the department name to update.

- Code (Mandatory): Enter the department code to update.

- Enable (Mandatory): Toggle the check box to change the active status. If the user disables one department, all of the children departments associated with it will automatically disable.

- Parent Department: Displays all available departments in the local system. Select the parent department name that will be the new parent department of the item to be updated.

4. After updating, select Save to confirm.

5. Select Close to exit.

Escalation Maintenance

This section covers how perform escalation setting maintenance. Whenever an asset fails or a work order has been in a certain status for too long, higher levels of authority need to be notified to expedite maintenance. If maintenance fails to respond, higher levels of authority need to be notified. Escalation setting allows the administrator to create, edit or delete escalation settings.

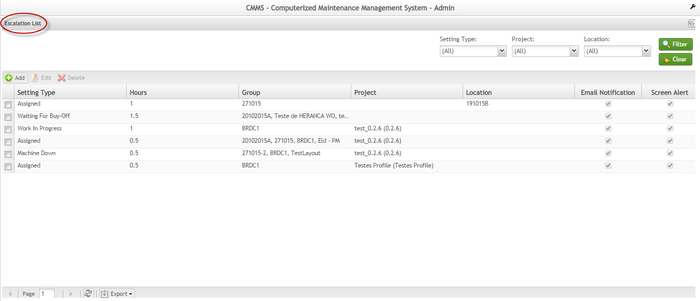

1. To access Escalation Setting, navigate to Administration > Escalation Setting.

Figure 17: Escalation Setting

2. The Escalation List displays all existing setting types.

Figure 18: Escalation List

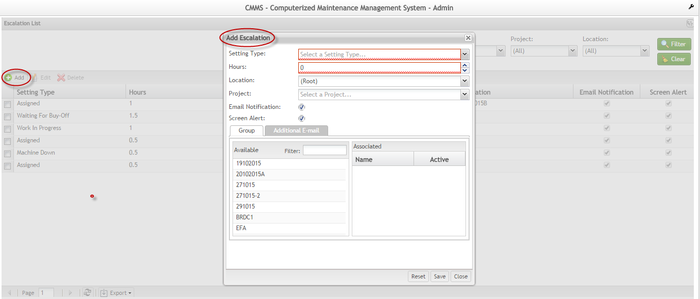

Add Escalation

1. To add an escalation, select Add located above the Setting Type list.

2. The Add pop up displays:

Figure 19: Add Escalation

3. To add an escalation, enter the following information:

- Setting Type- Select a setting type from the following:

- Machine Down: if the corresponding asset has broken down for more than the specified time (defined in the "Hours" field below), send an email or alert the specific group (defined in "Group" tab below).

- Assigned: if the specific work order has been in "Assigned" status for more than the specified time, send an email or alert the specific group.

- Work in Progress: if the specific work order has been in status "Work in Progress" for more than the specified time, send an email or alert the specific group.

- Waiting for Parts: if the specific work order has been in status "Waiting For Parts" for more than the specified time, send an email or alert the specific group.

- Waiting for Buy-off: if the specific work order has been in status "Waiting For Buy-off" for more than the specified time, send an email or alert the specific group.

- Hours- Enter the amount of time maintenance has to change the status of the work order (time in hours).

- Project- Select the Project Code associated with the escalation setting from the drop down list provided. This field is optional. However, if null, the escalation setting will be a default escalation setting. This means every work order, with or without a project code, has to send emails and/or alerts according to this setting. If given a code, this escalation setting is operated only by work orders with the same project code.

- Email Notification- The default is selected. If the user does not want an email notification, remove the checkmark from the box provided.

- Screen Alert- The default is selected. If the user does not want a screen alert, remove the checkmark from the box provided. The alert information appears on the dashboard. If selected, this escalation setting will send alerts on the dashboard once the setting condition is satisfied. If not, no alert will be sent.

- Group Tab- Select the group associated with the escalation setting. It is possible choose more than one group. This will be the receiver of the e-mails or alerts.

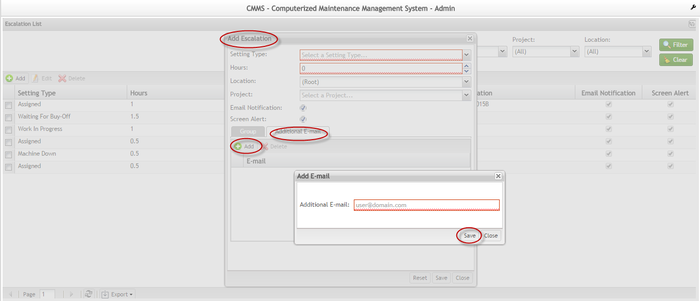

- E-mail tab- Add or delete e-mails different from those inside the company. It is possible to add more than one e-mail and the email can be the same e-mails inserted for the escalation.

Figure 20: Additional E-mail

4. Select Save to add the escalation setting. Select Close to exit without saving.

NOTE: it is not allowed other escalation with the same setting type and a project in the system.

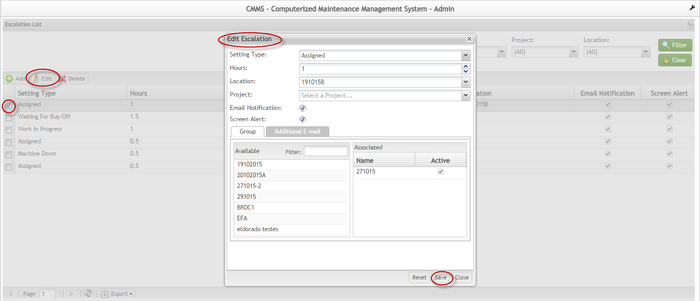

Edit Escalation

1. To edit an escalation, select the setting type from the list and then select Edit.

2. The Edit pop up displays:

Figure 21: Edit Escalation

3. All fields are available to update. After updating, select Save to confirm or Close to exit without saving.

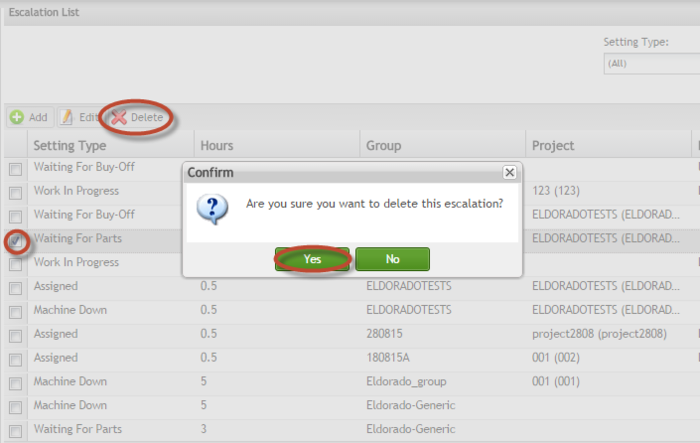

Delete Escalation

1. To delete and escalation setting, select the setting type from the list and then select Delete.

2. A confirmation pop-up will display:

Figure 22: Delete Escalation Setting

3. Select Yes to confirm or No to cancel.

Project

This section covers Project Maintenance. This section provides add, edit and delete functions for project codes used in the Escalation section.

1. To access Project Maintenance, navigate to CMMS- admin > Project.

Figure 23: Project Maintenance

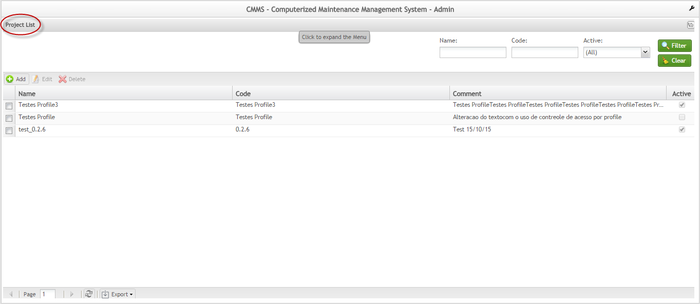

2. The Project list displays all existing projects.

Figure 24: Project List

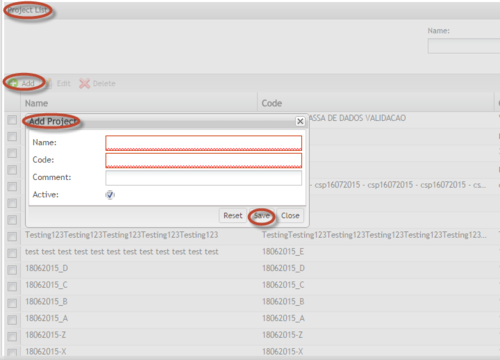

Add Project

1. To add a project, select Add located above the Name list.

2. The Add pop up displays:

Figure 25: Add Project

3. To add a Project, enter the following information:

- Code- an acronym that facilitates the identification of the plant.

- Name- the name of the project.

- Active- The default is selected. If the user wants to deactivate the project, remove the check mark from the box provided.

- Comment- any additional information needed for the project.

4. After entering all necessary information, select Save to confirm addition. The new project will appear in the Project list on the main Project screen.

5. Select Close to exit without saving.

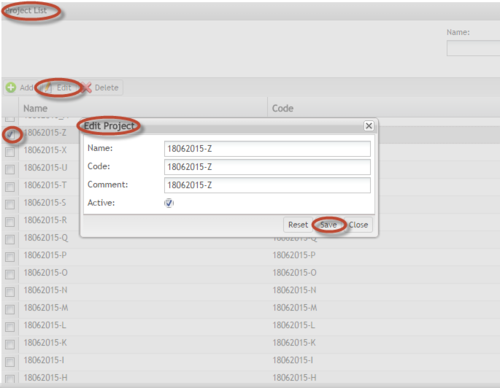

Edit Project

1. To edit a project, select the project from the list and then select Edit.

2. The Edit pop up displays:

Figure 26: Edit Project

3. All fields are available to update. After updating, select Save to confirm or Close to exit without saving.

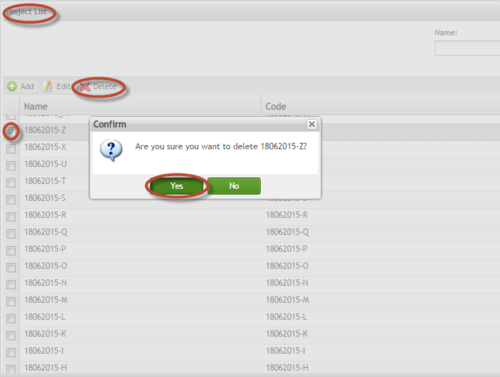

Delete Project

1. To delete a project, select the project from the list and then select Delete.

2. A confirmation message is displayed:

Figure 27: Delete Project

3. Select Yes to confirm or No to cancel.

NOTE: The system verifies if project is being used in another table. If so, it is not possible to delete and a warning message is displayed.

Document Revision History

| Date | Author | Title | Version | Change Reference |

| 09/01/15 | Elaine Fonaro | Technical Writer | v 1.0 | This is the first revision of CMMS Administration for Cirrus |