SOP-42Q-MES0069 Statistical Process Control

Contents

- 1 Notification

- 2 Introduction

- 3 Server Information Configuration

- 4 Monitor Group Maintenance

- 5 Monitor Maintenance

- 5.1 Brief Introduction

- 5.2 Create New Monitor

- 5.3 Search Monitor

- 5.4 Hide Inactive Monitors

- 5.5 Edit Monitor

- 5.6 Manually Input Data to Monitor

- 5.7 Start, Stop, Disable, Enable, Delete Monitor

- 5.8 View Control Chart, Data & Write OCAP

- 5.9 View & Edit Data

- 5.10 Maintain Lock

- 5.11 View Monitor Details

- 5.12 View Monitor History

- 6 Email Maintenance

- 7 Location Family Maintenance

- 8 System Log Maintenance

- 9 SPC System Parameter Maintenance

- 10 SPC Portal System Parameter Maintenance

- 11 Roles & Permissions

- 12 Glossary

- 13 Change Log

Notification

CDC SPC team dedicates to develop new functions and fix bugs to provide our users a more perfect SPC system. New version will be periodically released. This user manual is based on MES 15 Quality SPC 1.1. Older or newer version of SPC is not suitable for this manual. So please make sure your SPC version MES 15 Quality SPC 1.1.

Introduction

Based on statistical theories, SPC (Statistical Process Control) is applied to Sanmina’s manufacturing / production line for the purpose of quality control. SPC enables users to continuously monitor, analyze and control the production process in real time, to reduce the possible waste and improve the process capability. Key tools used in SPC include control charts, monitor maintenance, email notifications, system configuration, line stoppage, etc. In client side, SPC system includes two components: SPC portlet and SPC TV portlet.

Server Information Configuration

After SPC deployed to your web server, you need to set up a server and configure the server information.

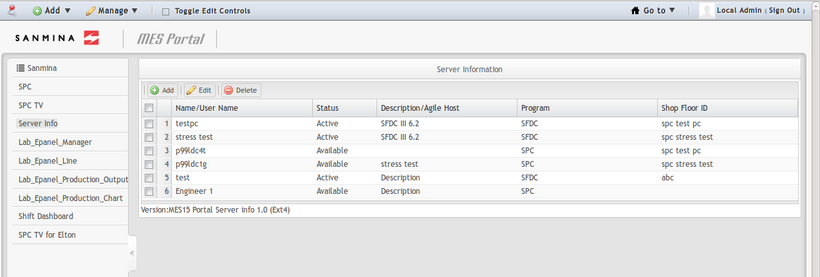

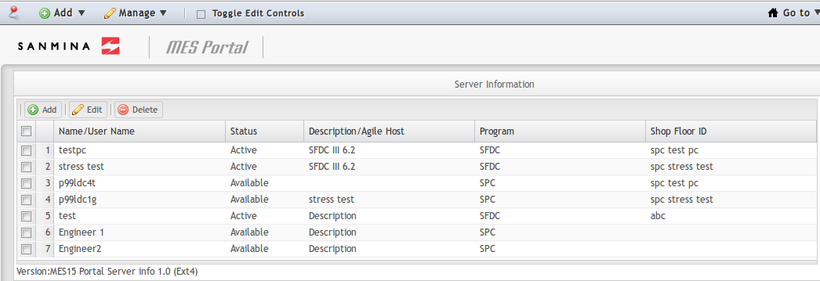

In MES Portal, you can click 'Server Information' in the left navigation bar to enter Server Information portlet

Create SPC Server

To create SPC server, you just need to click the 'Add' button in the toolbar to proceed

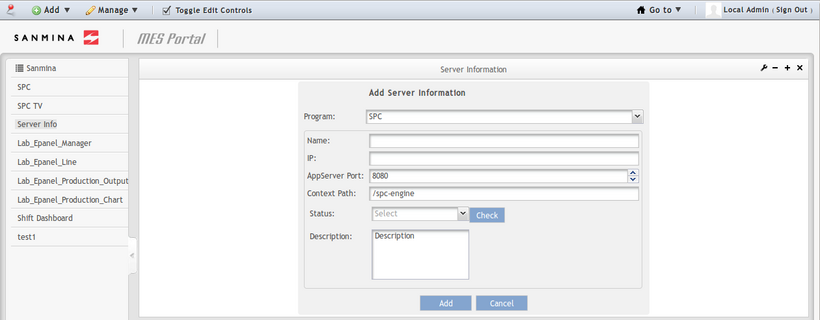

In 'Add Server Information' page, choose 'SPC' from 'Program' drop down list, complete all the fields and click the 'Add' button to save the configuration to database.

Fields as seen in the above screenshot need to be explained here:

Name: the name of the SPC server

IP: specify the SPC server IP address

AppServer Port: the port that SPC server deploys on Tomcat server

Context Path: the patch that SPC server deploys on Tomcat server

Status: After you have input all the field above, you can select a status from this drop down list, and click the Check button to check if the SPC server connection is working or not.

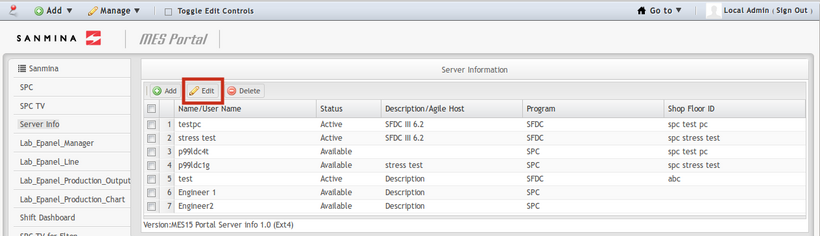

Edit SPC Server

To edit an existing server, just select the server and click the 'Edit' button in the toolbar to proceed

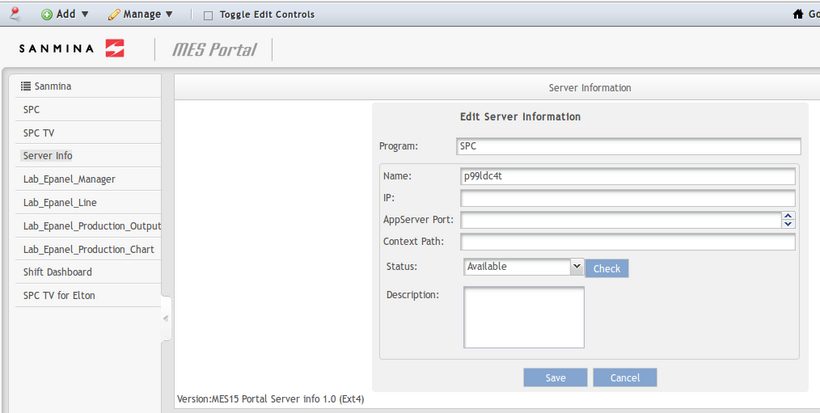

In 'Edit Server Information' page, update the values of any field as you need, click the 'Save' button to save the update to database, otherwise click the 'Cancel' button if you want to quit the action without change to the server.

Delete SPC Server

To delete an existing server, you just need to select the server and click the 'Delete' button in the toolbar

View Existing SPC Server

In SPC portlet 'Server List' page, you can view all existing SPC servers that created in MES Portal 'Server Information' portlet, in addition, you can choose a server and click the 'Go' button to enter the server for further manipulation

Monitor Group Maintenance

MES 15 Quality SPC 1.1 uses Monitor Group to maintain SPC monitors that collect data different sources, such as SFDC Archive, SPI, etc. However, MES 15 Quality SPC 1.0 does not actually collects data from SPI, it still collects data from SFDC archive as associated database schema and support are not fully ready yet.

View Monitor Group

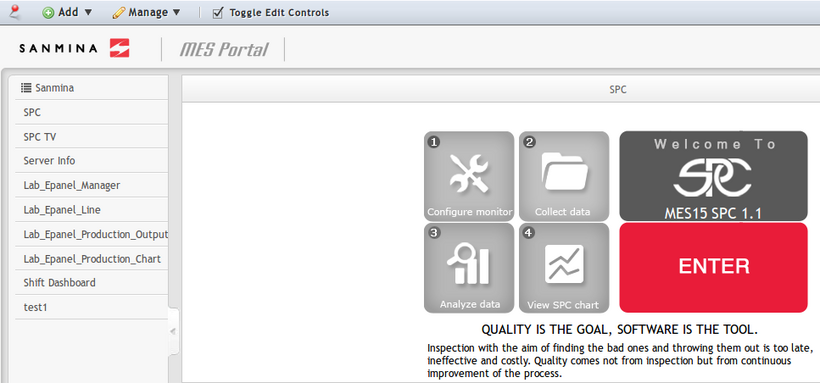

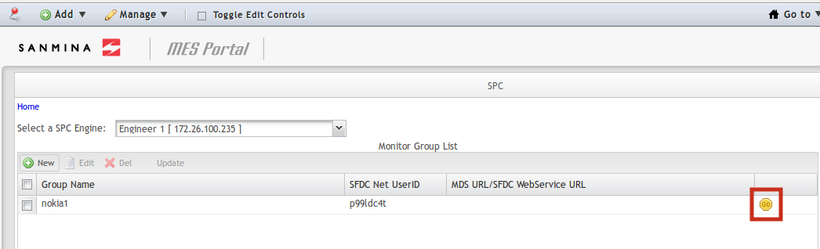

To view existing monitor groups, click SPC portlet on the left navigation bar, SPC opens the Welcome page, then click the red Enter button

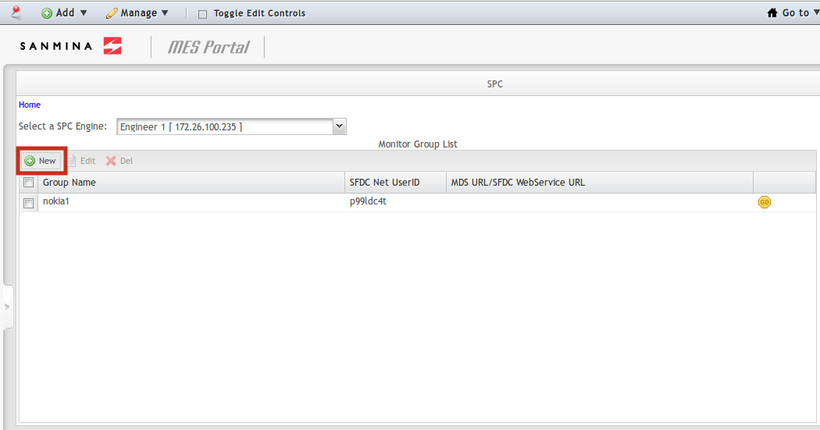

In Monitor Group List page, first select a SPC engine from the drop down list, by default the first SPC engine will be selected, once you select a SPC engine, the existing monitor groups that created under this SPC engine will be listed in the gird

Create Monitor Group

In MES 15 Quality SPC 1.1, every monitor is created under a monitor group. So before creating a monitor, you need to create a monitor group first.

To create a monitor group, first select a SPC engine from drop down list, then click the ![]() button in toolbar

button in toolbar

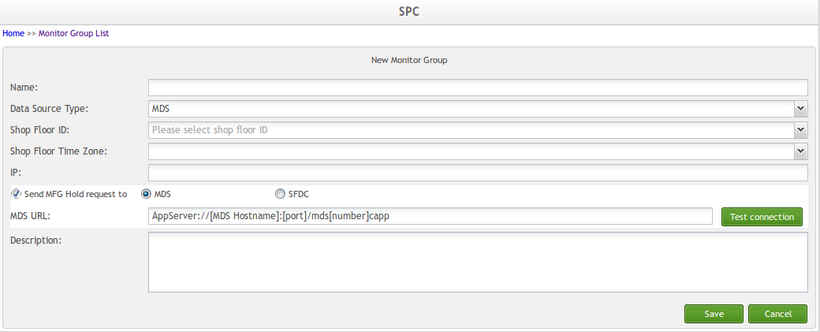

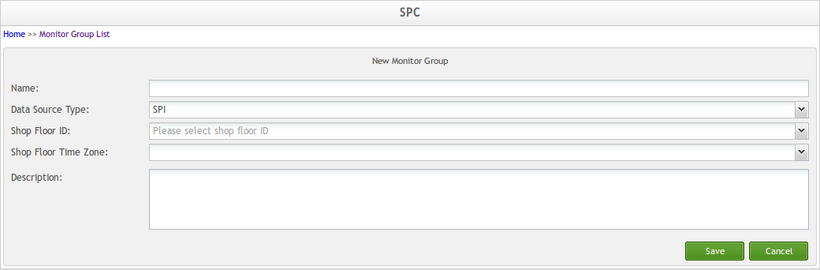

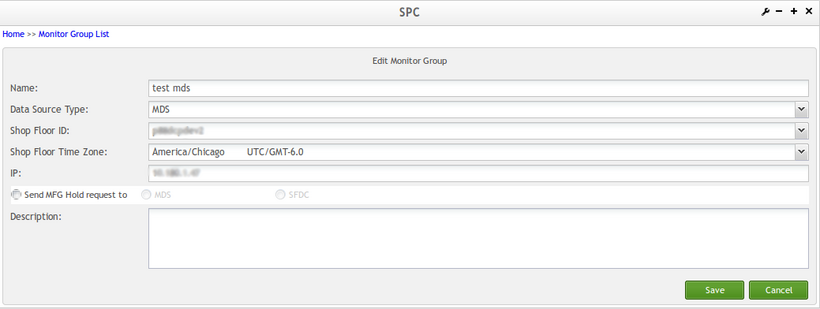

SPC opens New Monitor Group page, here input the monitor group name in the Name field, select MDS or SPI from the Data Source Type drop down list, select a shop floor ID, choose a shop floor time zone, input IP, if you need to send MFG Hold to stop production line, you can enable the 'Send MFG Hold request to' checkbox

Select SPI in the Data Source Type field if you need to create a SPI monitor group.

Some of the fields as seen in the above screenshot need to be explained here:

Shop Floor ID: defines which SFDC that SPC should collect data from.

Shop Floor Time Zone: the time zone of the selected SFDC PC.

IP: This is a text field for user to input the SFDC IP address to which MFG hold sends.

Background knowledge: Starts from version 3.1.3, SPC program is deployed on Amazon cloud server (in USA). Users scan SNs in their local SFDC PC. So there will be a time zone difference between the SPC server and SFDC if they’re not in the same time zone. SPC uses the value of this field to calculate the timezone of local SFDC, compares it with the Amazon cloud server time zone, calculates the time offset, and determines the right time for SPC monitor to retrieve data (create time + time offset), so that the scanned SNs data can display on monitor charts.

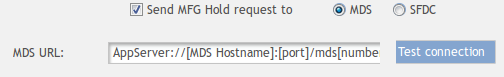

Send MFG Hold request to: This checkBox is not selected by default. It’s optional. If you want SPC to send MFG hold to stop the manufacturing line, you can tick the ‘Send MFG Hold to request to’ checkBox, and choose one of the two radio buttons: MDS, SFDC. If you choose the ‘MDS’ radio button, the MFG hold will be sent to MDS and then MDS sent MFG hold to local SFDCs.

After this, you’ll need to input the MDS URL which enables SPC to send the MFG hold to the right MDS service. Click the ![]() button if you want to test the web service connection.

button if you want to test the web service connection.

Notification: The MDS radio button DOES NOT work properly at the moment as associated MDS service has not been deployed to our plants yet. We have to wait until MDS provide the associated service.

If you choose the SFDC radio button, SPC will directly send MFG hold to local SFDC. Also, you need to input the SFDC web service URL in the text field.

Edit Monitor Group

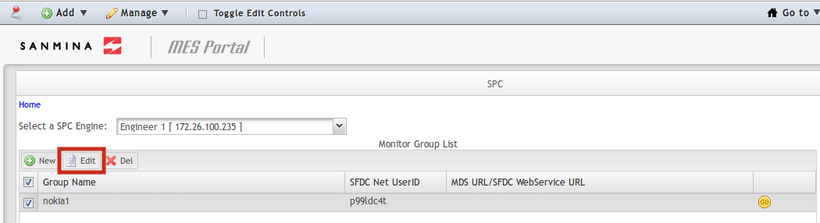

Select the monitor group that you need to edit and click Edit button in toolbar

SPC opens Edit Monitor Group page, here edit any field as you need and click the Save button to save the change

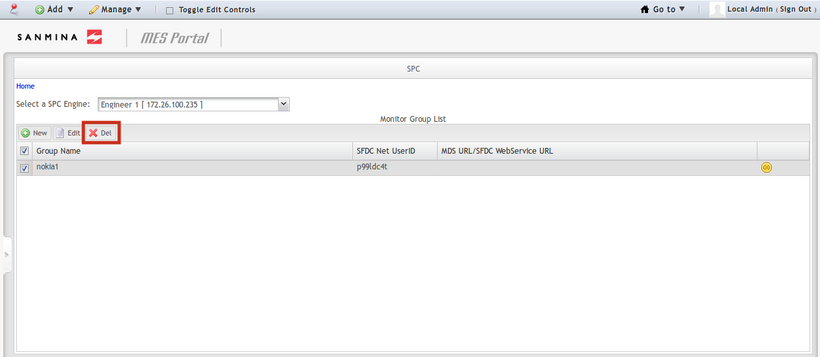

Delete Monitor Group

Select the monitor group that you need to delete and click the Delete button

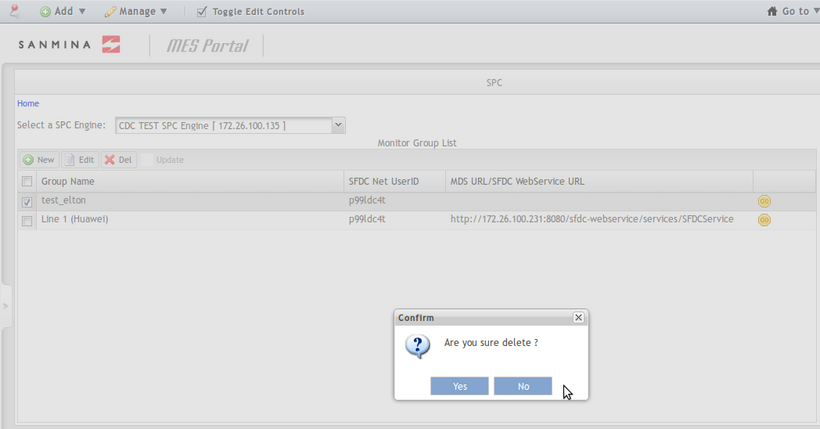

In the pop-up window, click Yes or no as you need

Monitor Maintenance

Brief Introduction

SPC portlet provides users plenty of parameters to maintain SPC monitors. A SPC monitor is a platform to set up things include monitoring objects, data collection strategy, rules, control charts, actions, etc. With monitor maintenance function, you can create new monitor, edit existing monitor, disable or enable monitor, show monitor data or control charts, lock monitor and so on. So monitor maintenance is a key function to SPC.

Create New Monitor

In MES 15 Quality SPC 1.0, SPC monitors should be created under an existing monitor group. To create a monitor, you need to go to Monitor Group List page, select a SPC engine from drop down list, select a monitor group and click its ![]() icon.

icon.

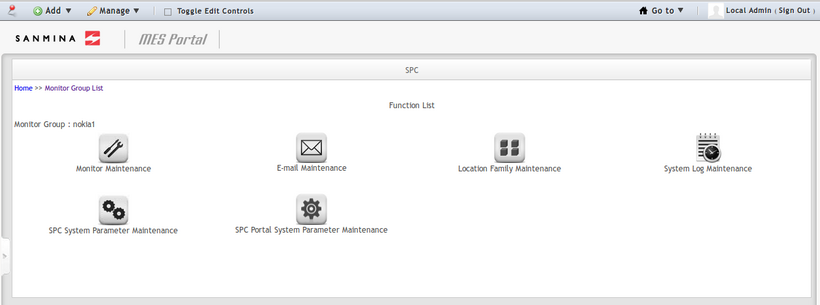

SPC opens ‘Function List’ page, here click ![]() (Monitor Maintenance) icon to the next step

(Monitor Maintenance) icon to the next step

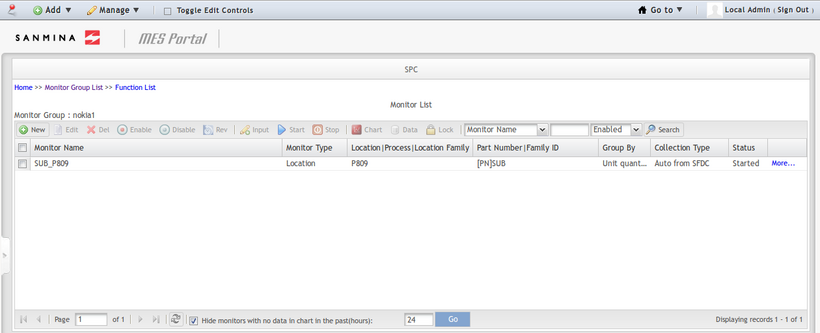

On ‘Monitor List’ page, click the ![]() icon in the toolbar to go to the next step

icon in the toolbar to go to the next step

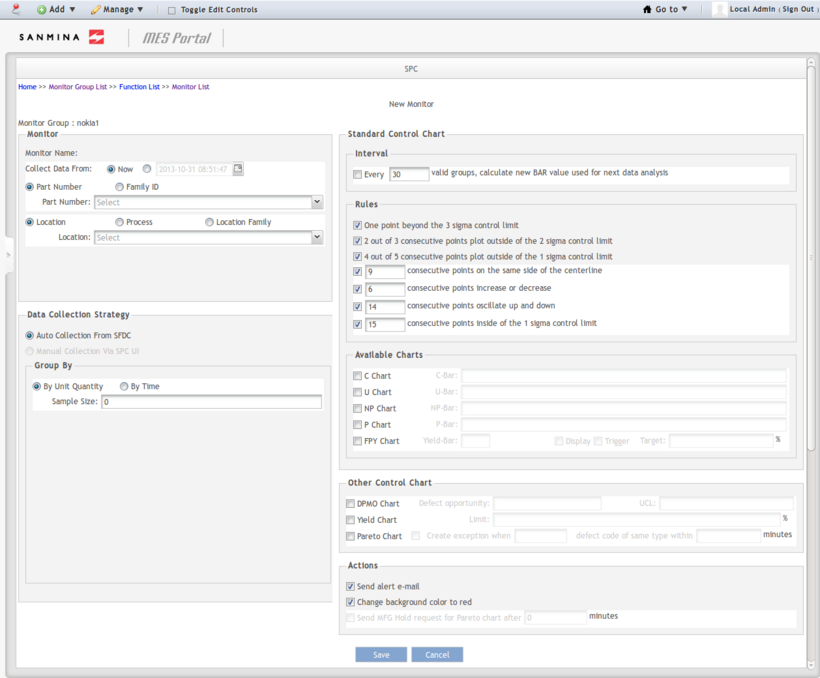

Now you’re in the ‘New Monitor’ page. This page provides all parameters for you to set up a customized monitor in SPC. These parameters are divided into and displays in 5 sections. We should make clear what the parameters mean before we configure them.

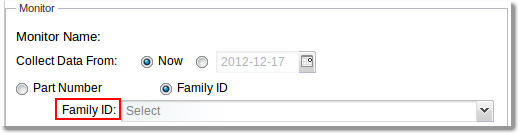

Monitor

The first section is ‘Monitor’.

Monitor name: The name of this monitor. It’s not editable as it will be automatically created after you choose the Part Number / Family ID and Location / Process / Location Family. If monitor data is automatically collected from SFDC, the monitor name will consist of two parts separated by hyphen: The first part is Part Number / Family ID, the second part is Location / Process / Location Family. If monitor data is collected manually via SPC UI, the monitor name will also contain the third part: the attribute name.

Collect Data From: Enable SPC to collect data from now on or from a day in the past.

Notification:

Historical data that contains exception may have the possibility to stop the present production line. If you've selected a previous date here and selected the 'Send MFG Hold request to' checkBox when creating the server, when you save the monitor, you’ll be prompted by a warning message that shows ’Analyzing historical data with the Mfg Hold function turning on, your present workstation might be stopped by SPC if historical exceptions are examined based on the rules you selected above. Are you sure you want to save?’, you can click the ‘Yes’ button to confirm the configuration or ‘No’ button to cancel.

Part Number: The part number you want SPC to monitor. It’s a monitoring object. Part number is created and configured in jMDS before you create the SPC monitor. The ‘Part Number’ radio button is chosen by default, and you need to choose a part number from the associated drop down list below it.

Tip:

SPC has instant search feature when user inputting part number in the ‘Part Number’ drop down list. When the input character count reaches 4, the instant search function automatically turns on, then SPC will automatically search part numbers that match the input in database, and list the matching part number in the drop down list in less than 1 second, what you need to do is just to select one item from the provided list. So far this instant search feature supports inputting in Part Number, Family ID, Location, Process and Location Family drop down list.

Family ID: The family ID you want SPC to monitor. It’s a monitoring object. Family ID is created and configured in jMDS before you create the SPC monitor. If you choose the Family ID’ radio button, below which the label name will changed automatically and you need to choose a family ID from the drop down list.

Location: The location you want SPC to monitor. It’s a monitoring object. Location is created and configured in jMDS before you create the SPC monitor. The ‘Location’ radio button is chosen by default, and you need to choose a location from the associated drop down list below it.

Process: The process you want SPC to monitor. It’s a monitoring object. Process is created and configured in jMDS before you create the SPC monitor. If you choose the ‘Process’ radio button, below which the label name will changed automatically and you need to choose a process from the drop down list.

Location Family: The location family you want SPC to monitor. It’s a monitoring object. Location Family is created and configured in jMDS before you create the SPC monitor. If you choose the ‘Location Family’ radio button, below which the label name will changed automatically and you need to choose a location family from the drop down list.

Data Collection Strategy

The second section is ‘Data collection strategy’.

Auto collection from SFDC: Allows SPC monitor to automatically collect data from SFDC service. This option is chosen by default.

Manual collection via SPC UI: This radio button’s status is determined by the settings in Monitor section. If data of the the ‘Monitor’ section contains attribute data, then this radio button will automatically become available, otherwise, this option is grey (unavailable).

Auto Collection From SP machine: Enable SPC to collect data from solder paste machine, so that you can view SPC chart with data collected from SP machine. SPC retrieves SP machine data from a database table 'spi_data', which has clear definition on data fields, data types, limitations and instruction. You need to follow the table structure while inputting data to this table so that SPC can retrieve data correctly from this table and generate control charts. The table below shows details of the 'spi_data' table structure.

| Field Name | Data Type | Allow Nulls | Field Description |

|---|---|---|---|

| apk_id | integer | No | table ID |

| board_id | character varying(40) | No | SPI board id , this field use to be serial number |

| ref_desc | character varying(40) | No | SPI board location number |

| height | character varying(40) | No | SPI board height , this field use to be attribute value |

| part_number | character varying(40) | No | |

| import_date | timestamp | No | The import date means when parsing the SPI file and import the data into database |

| test_date | timestamp | No | The test date means when QA record SPI data |

| a_DateTime | integer | No | Total seconds with test date field |

| file_type | character varying(40) | No | SPI machine name, this field use to be monitor location |

| attribute_name | character varying(50) | No | SPI board location name |

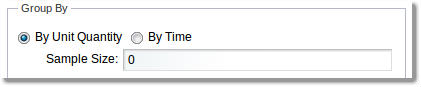

Group by: This field defines the rules how data should be organized to form a series of points plotted on control charts. It consists the following components: By Unit Quantity radio button, By Time radio button, Sample Size textBox which pertains to By Unit Quantity radio button and Time Range drop down list which pertains to By Time radio button.

- By unit quantity: The data will be grouped by quantity. The quantity is defined in the ‘Sample size’ textBox. For example, if a data source contains 100 data items, and the ‘Sample size’ value is 2, then this data source will be divided into 50 groups (100 / 2 = 50). This radio button is chosen by default.

- By time: The data will be grouped by time range. For example, if a sampling period is 60 minutes, and the time range is 10 minutes, then this sample period will contain 6 groups of data (60 / 10 = 6). If you’ve chosen this radio button, below which the label name will automatically change to ‘Time range’ and you need to choose a time range value from the drop download list.

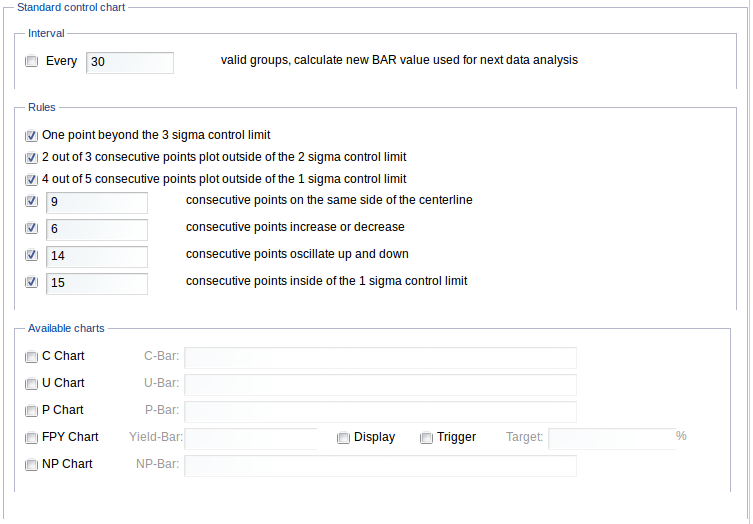

Standard Control Chart

The third section is ‘Standard control chart’, which contains three sub-sections: Interval, Rules and Available charts.

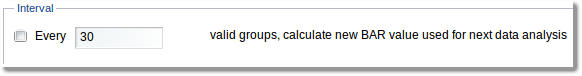

Interval

This sub-section has a checkBox and a textBox that defines the frequency that SPC recalculates the center line value of a control chart. Here we use valid groups as the frequency unit.

Rules

This sub-section lists all 7 rules which are considered to be out-of-control exceptions. You can select one or more rules in this checkBox group.

Available charts

This sub-section displays all available control charts in the current context. We know that SPC control chart is generated based on data source, which is configured in Monitor section, so different configurations in Monitor section may have different available charts. You can choose one or more control charts in this checkBox group

The textBox on the right of chart name is used for defining the center line value of control chart. For example, if you choose the ‘C Chart’ checkBox, the ‘C-Bar’ textBox automatically turns available, then you can manually input a number in the textBox, the number you input becomes the center line value of the chart.

Notification:

Be careful to the values you input in the textBox for control charts if you’ve enabled the line stoppage function. If you’ve enabled the ‘Send MFG Hold request to SFDC / MDS’ checkBox when creating SPC server, SPC may stop the production line if you define unreasonable values for control chart in its textBox based on the rules you selected.

For ‘FPY Chart’, choosing the ‘Display’ checkBox enables SPC to display FPY chart in monitor. The ‘Trigger’ checkBox enables out-of-control warning.

Before SPC 3.2, SPC Cpk / Ppk chart data has only one revision that contains all data. This is inconvenient particularly when user wants to generate Cpk / Ppk chart once a month for their clients. Starts from SPC 3.2, Cpk / Ppk chart adds date range setting function enabling user to set date range for Cpk / Ppk chart data. There are two types of date range: all data, by month.

Suppose you're creating a new monitor, in Available charts section, you will find a new field Calculation by in to Cpk / Ppk chart settings. There are 2 items available in the Calculation by drop down list: All Data and Month. By default, All Data is selected.

All Data: SPC generates only one revision with all attributes' data of Cpk / Ppk chart

Month: The Cpk / Ppk chart data collection duration for this monitor will be based on a natural full month. New revision will be automatically created when it comes to a next month.

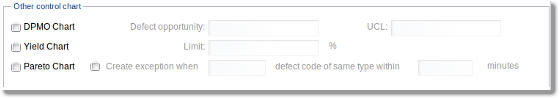

Other Control Chart

The fourth section is ‘Other control chart’

DPMO Chart: Enable SPC to monitor manufacturing line with DPMO chart. ‘Defect opportunity’ and ‘UCL’ text boxes are two parameters used for defining DPMO chart.

Yield Chart: Enable SPC to monitor manufacturing line with Yield chart. ‘Limit’ text box is a parameter used for defining Yield chart.

Pareto Chart: Enable SPC to monitor manufacturing line with Pareto chart. You can define Pareto chart exception rule by selecting the 'Create exception when' checkBox, for example, 3 defect code of same type in 10 minutes. Starts from SPC 3.2, only Pareto chart triggered MFG hold requests can be sent to SFDC / MDS.

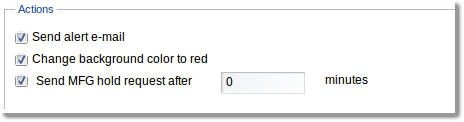

Actions

The fifth section is ‘Actions’. This section defines what actions should be taken after out-of-control exception is triggered.

Send alert e-mail: This action sends alert email to specified person. You can specify who would receive these alert emails in Email Maintenance module.

Change background color to red: If exception was triggered, background of associated data record in this monitor will turn to red.

Send MFG hold request after n minutes: This action is a SPC line stopper function. To enable this action, you need to enable other three checkBoxes first:

- ‘Send MFG Hold request to SFDC / MDS’ checkBox in Add Server Information page

- Pareto Chart checkBox in Other Control Charts section

- Create Exception when n1 defect code of same type within n2 minutes checkBox in Other Control Charts section.

If Send MFG hold request after n minutes checkBox is enabled and if n1 defect code of same type were scanned via NetDC within n2 minutes, SPC will send MFG hold request to SFDC / MDS after n minutes. If the input minutes is 0, SPC will send the MFG hold immediately.

Notification:

- This checkBox is not selected by default.

- Line stopper only supports part number. So if you’ve selected ‘Family ID’ in the Monitor section, this option will not be available.

Lastly, remember to click ![]() button to save all the configurations before you leave the page, or click

button to save all the configurations before you leave the page, or click ![]() button if you want to give up the configuration and return to the ‘Monitor List’ page.

button if you want to give up the configuration and return to the ‘Monitor List’ page.

Search Monitor

The ‘Search Monitor’ function makes it very convenient to find a specific monitor from monitors list. You can find this function in the toolbar in ‘Monitor List’ page.

You can search monitor by keyword and monitor status.

By keyword: You can search existing monitor by keyword. Click the keyword categories drop down list (the green framed area in Figure 5.20) and you will see all those search criterias. You can input keyword in the keyword textBox (the red framed area in Figure 5.20).

By monitor status: In addition to keyword, you can search monitor by monitor status, just select a monitor status from the status categories drop down list (the blue framed area in Figure 5.20).

After the above search criterias configuration is done, hit the ![]() icon to execute the search action.

icon to execute the search action.

Hide Inactive Monitors

It allows you to filter out those monitors that have no new data coming in during the past settable hours. You can define the settable hours in SPC System Parameter Maintenance module, and view active monitors in Monitor List page. Besides, you can turn off the filtering inactive monitors function.

View Active Monitors by Default Hours

In 'Monitor List' page, you can see a checkBox 'Hide monitors with no data in chart in the past(hours)' which is selected by default, and a textBox displaying the hours that defined in SPC System Parameter Maintenance module. SPC system filters out those inactive monitors that meet the condition, so that they won't be displayed on monitor list.

Edit Settable Hours

You can edit the hours textbox value and click the 'Go' button to view corresponding monitors. Value allowed in this textBox is positive integer between 1 to 168. Modification of the value here does not affect the value defined in SPC System Parameter Maintenance module.

Disable Hide Inactive Monitors Function

You can disable the 'Hide monitors with no data in chart in the past(hours)' checkBox to turn off the monitor filtering function, so that SPC system shows all existing monitors.

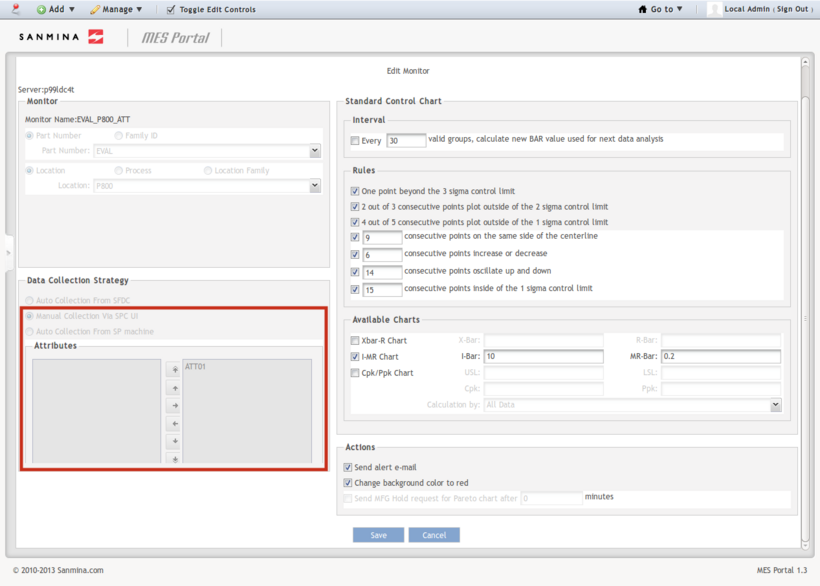

Edit Monitor

SPC allows users to modify parameters of an existing monitor according to their needs. Users can modify sections including Interval, Rules, Available charts, Other control chart, and Actions.

To modify a monitor, you need to select a monitor from the monitor list in ‘Monitor List’ page, then hit the ![]() icon in the toolbar.

icon in the toolbar.

Now you've moved on to the ‘Edit Monitor’ page. All sections except the Monitor section and Data Collection Strategy section are allowed to be modified

Lastly, remember to click the ![]() button to save all modifications before you leave the page.

button to save all modifications before you leave the page.

If the ‘Data Collection Strategy’ is ‘Manual Collection via SPC UI’, you can also modify the ‘Attributes’ values.

Manually Input Data to Monitor

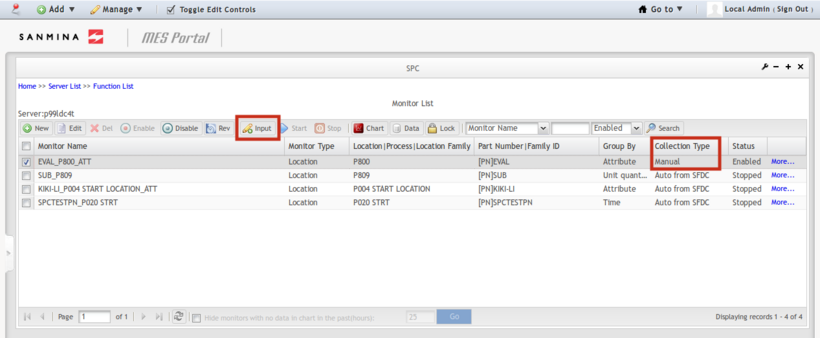

So far SPC monitor supports three data collection strategies: Auto Collection From SFDC, Manual Collection Via SPC UI and Auto Collection from SPC Machine, which can be configured in the Data Collection Strategy section. If you’ve chosen ‘manual collection via SPC UI’ as data collection strategy, you need to manually input data after the monitor is created. Starts from version 3.2, SPC supports inputting data once to both a single monitor and multiple monitors.

Input Data for Only One Monitor

To do this, you can go to ‘Monitor List’ screen, select the monitor that needs to be manually input data (the ‘Collection Type’ value of this monitor is ‘Manual’), and then click the ![]() icon in the toolbar

icon in the toolbar

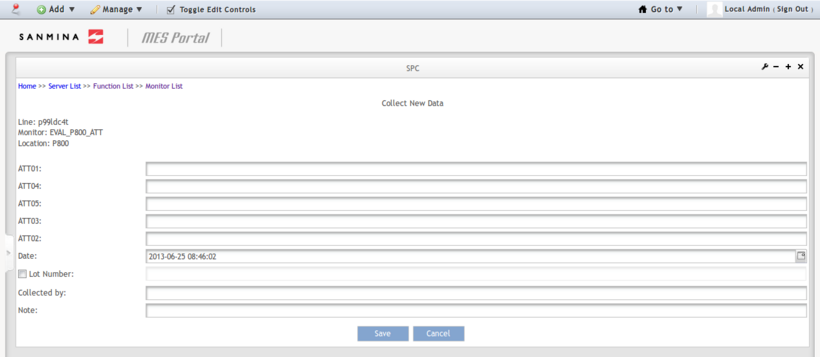

In Collect New Data page, input attributes data to correspondent fields

Input Data for Multiple Monitors At Once

You can select and input data to multiple monitors at once, as long as all of the selected monitors' Collection Type is Manual

If you have selected monitors which contain at least one monitor whose Data Collection Type is not 'Manual', and click 'Input' button, you will be prompted by an alert window saying 'You have selected at least one monitor that is not for manually data collecting. Please check and try again.', you can close the alert window by clicking its OK button

Input Attributes for The Current Monitor

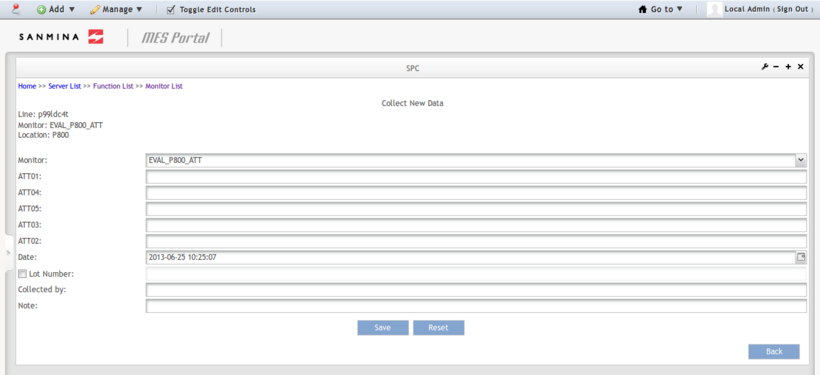

In Collect New Data page, you can input attributes for multiple monitors at once. The Monitor drop down list displays the current selected monitor to be input data. You can view Line, Monitor name and Location of the current monitor on the top left corner. Note that the allowed input of attributes is number only.

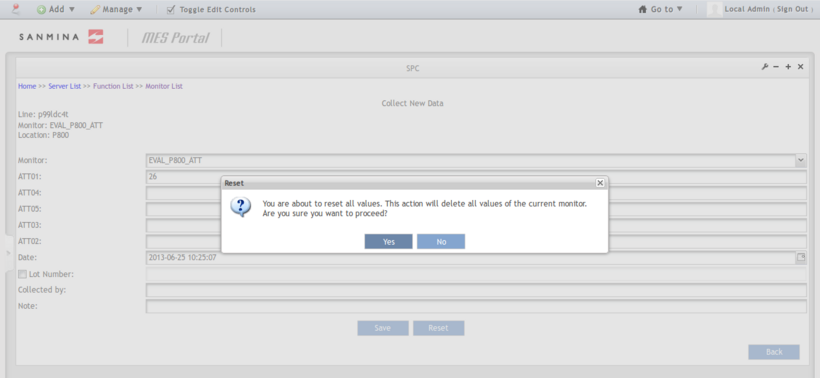

If you have input values to at least one of the fields, and click the Reset button, you'll be prompted by an alert window with warning message 'You are about to reset all values. This action will delete all values of the current monitor. Are you sure you want to proceed?', if you click Yes of the alert window, all input of the current monitor will be reset to default value

If you have input values to at least one of the fields, and choose another monitor from the Monitor drop down list, you will be prompted by an alert window with warning message 'The data for the current monitor have not been saved yet. Are you sure you want to go to another monitor?', if you click Yes of the alert window, you'll move forward to another monitor without current monitor's data stored in SPC system

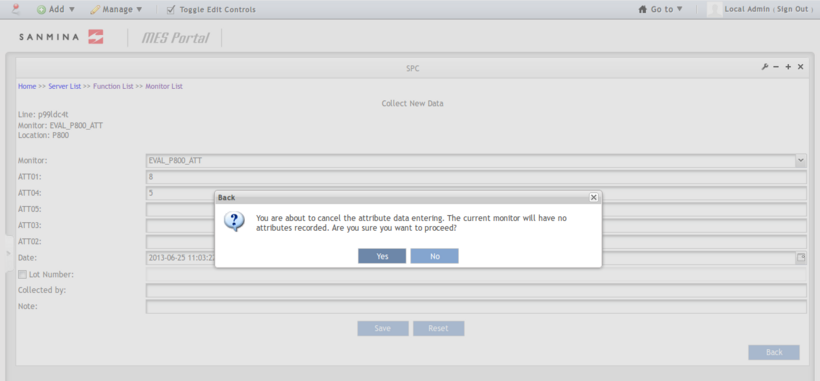

If you have input values to at least one of the fields, and click the Back button, you will be prompted by an alert window with warning message 'You are about to cancel the attribute data entering. The current monitor will have no attributes recorded. Are you sure you want to proceed?', if you choose Yes of the alert window, you will move forward to Monitor List page without current monitor's data stored in SPC system

Save current monitor's attributes data

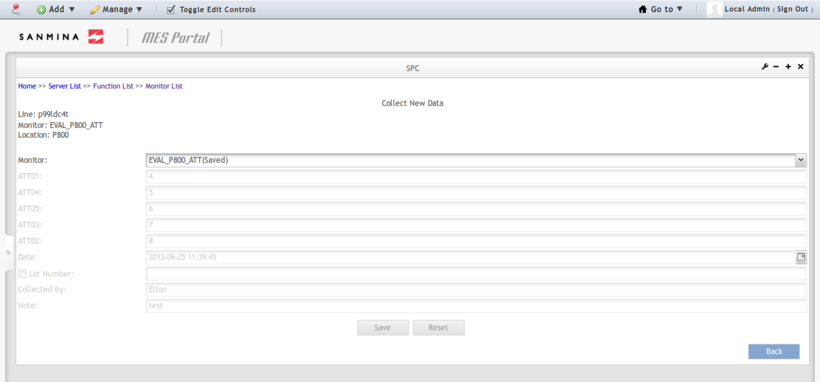

In Collect New Data page, if you have finished inputting data to current monitor, you can click the Save button to save its data to SPC, you will find that all fields of current monitor will turn to grey color except the Monitor drop down list, you can not edit any data of current monitor in this page. The current monitor name in the Monitor drop down list changes to 'monitor_name (Saved)' where monitor_name is the name of current monitor. Now you can switch to another monitor to input attributes data to that monitor if it exists, or just click the Back button to go back to Monitor List page.

Switch to Another Monitor

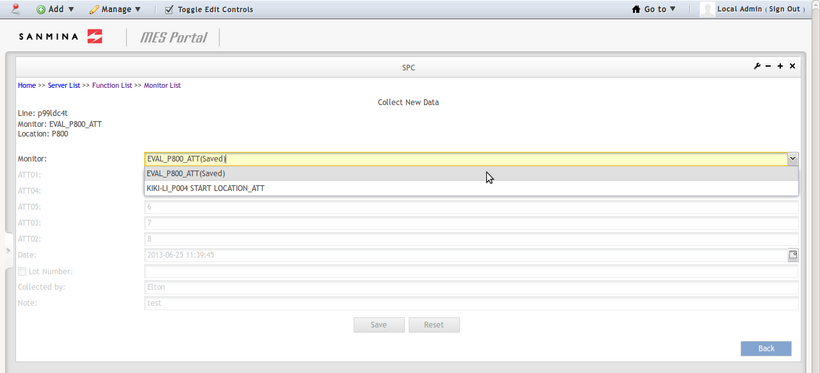

If you want to switch to another monitor to input attributes, you can click the Monitor drop down list and select that monitor from the list

Back to 'Monitor List' page

If you need to go back to Monitor List page, you can click the ![]() button to move on

button to move on

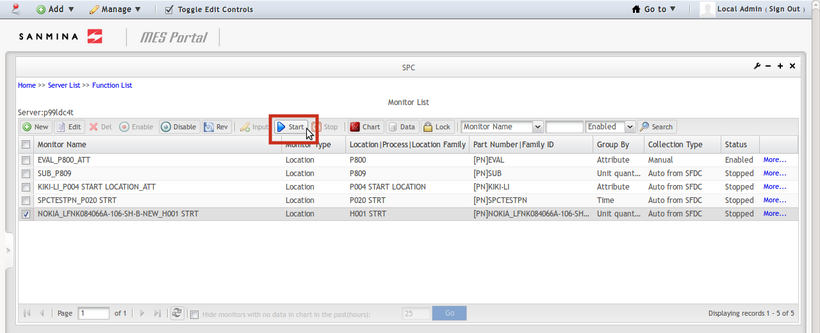

Start, Stop, Disable, Enable, Delete Monitor

Start monitor

After a new monitor is just created, its status is ‘Enabled’ by default. If the monitor's data is automatically collected from SFDC, you need to manually ‘Start’ this monitor to make it collect data from SFDC. To start a monitor, you just need to select the monitor and click the ![]() button in the toolbar.

button in the toolbar.

You can find the started monitors in the started monitor list, which can be found through this way: find search function in the toolbar >> select ‘Started’ from the monitor status drop down list >> click the ![]() button

button

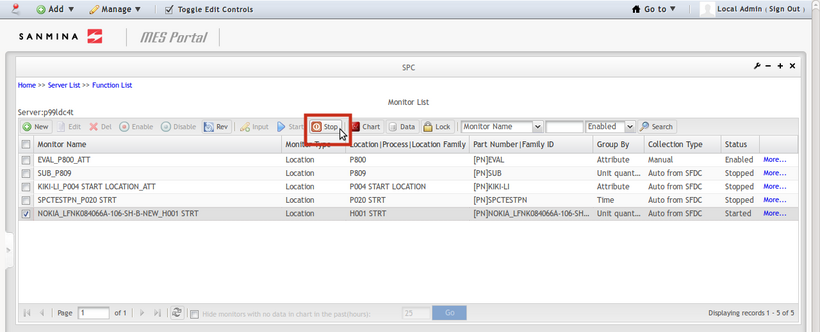

Stop monitor

If you don’t want this monitor to collect data from SFDC, you can ‘Stop’ the monitor. Like starting a monitor, to stop a monitor, just select the monitor and click the ![]() button in the toolbar.

button in the toolbar.

You can find the stopped monitors in the stopped monitor list, which can be found through this way: find search function in the toolbar >> select ‘Stopped’ from the monitor status drop down list >> click the ![]() button

button

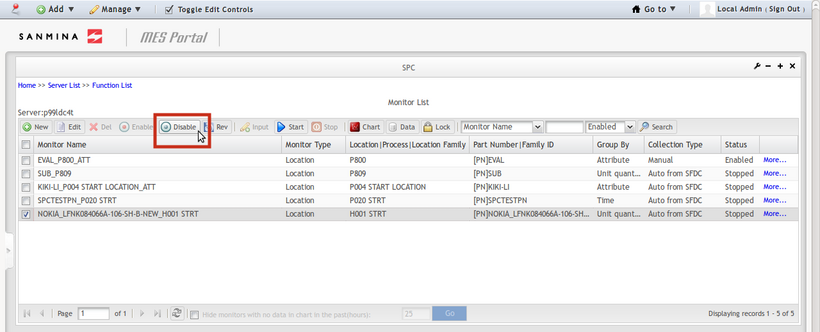

Disable monitor

If you don’t need a monitor temporarily, you can disable it. To disable a monitor, first stop the monitor, then click the ![]() button in the toolbar

button in the toolbar

You can find the disabled monitors in the disabled monitor list, which can be found through this way: find search function in the toolbar >> select ‘Disabled’ from the monitor status drop down list >> click the ![]() button

button

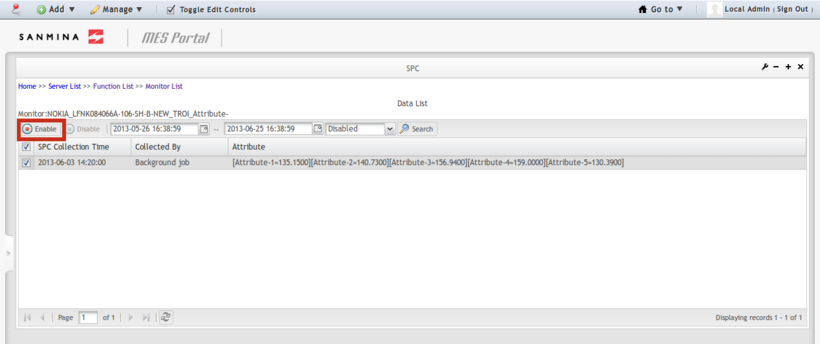

Enable disabled monitor

To enable disabled monitor, first find the monitor in disabled monitor list, then select the monitor and click the ![]() button in the toolbar

button in the toolbar

To find the enabled monitor, you can check the enabled monitor list, which can be found through this way: find search function in the toolbar >> select ‘Enabled’ from the monitor status drop down list >> click the ![]() button

button

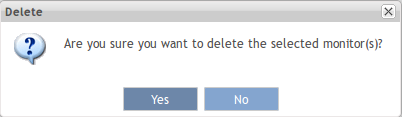

Delete Monitor

If you don’t need a monitor any more, you can delete it. Note that once a monitor is deleted from SPC, it can’t be restored, and this is permanent.

To delete a monitor, you need to disable it first. After you’ve disabled the monitor, you can find it in the disabled monitor list, then select the monitor and click the ![]() button in the toolbar

button in the toolbar

Then choose ‘Yes’ in the pop-up window

View Control Chart, Data & Write OCAP

Control chart is a very important tool for SPC to monitor manufacturing line. Through the analysis of control charts, users can learn if manufacturing line or process is under control, and tell the reasons of an out-of-control exception, so that they can take appropriate measures. So far our SPC system supports 11 control charts: C chart, U chart, P chart, NP chart, DPMO chart, FPY chart, Yield chart, Pareto chart, X Bar-R chart, I-MR chart and Cpk / Ppk chart

Starts SPC 3.2, SPC development team applies Ext JS technology other than the old Jfreechart technology to all of the 11 control charts. The Ext JS technology enables SPC to represent more interaction with user from UI perspective, for instance, if you move cursor over the chart point, you can view more information of the point. Besides, you can view both SPC Chart and data in the same page, other than opening them in different pages.

View Control Chart

Here take C chart as example to demonstrate how to view control chart with the Ext JS technology enhancement. Operation of Other control charts is just similar to C chart.

To SPC view control chart, you can go to Monitor List page, select a monitor and click the ![]() button in the horizontal toolbar

button in the horizontal toolbar

You will go forward to chart displaying page. On the top of the page you will see a few brief information of the control chart, such as monitor name, part number, location. Family ID can also be displayed here if you’ve enabled the ‘Display Family ID in chart’ checkBox in SPC Portal System Parameter module.

To view C chart, you need to choose 'C' chart from the chart drop down list, select a revision from the revisions drop down list, and click the 'Retrieve' button, then SPC generates a C Chart according to the parameters you submitted and displays the C Chart and its data in current page.

Tips:

- On the Chart, blue points are normal points, red points are exception points, green points are exception points that has been written OCAP

- If you move cursor over a point in the chart, a pop-up window will be prompted showing more information of the selected point, including SPC Collection Time, Inspected, Defects and Cause. Note that control charts vary in more information of a selected point.

- If you click a point on the chart, the corresponding data line in the data list will be highlighted; if you select a data line from data list, the corresponding point on the chart will be highlighted as well

- Red background of a data line means that this data item has violated the rules you defined in the Rules section, and the OCAP of this data record has not been processed yet; green background of a data line indicates that OCAP of this data record has been processed.

- This data list table structure consists of 9 columns: SPC Collection Time, Inspected, Defects, UCL, LCL, OCAP, OCAP History, Cause and Affected S/Ns.

Write OCAP

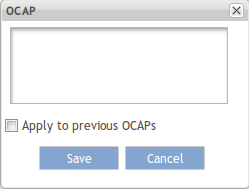

To write OCAP means to write something about the fix to the exception. To do this, you can click the ![]() button, then input description of this OCAP in the pop-up ‘OCAP’ windows, and click the

button, then input description of this OCAP in the pop-up ‘OCAP’ windows, and click the ![]() button to save the change to SPC.

button to save the change to SPC.

If there are more than one unprocessed OCAPs, after you’ve input description of the current OCAP, enabling the ‘Apply to previous OCAPs’ checkBox will apply the change to all the unprocessed OCAPs.

After the OCAP was processed, the background of the associated data record will turn to green.

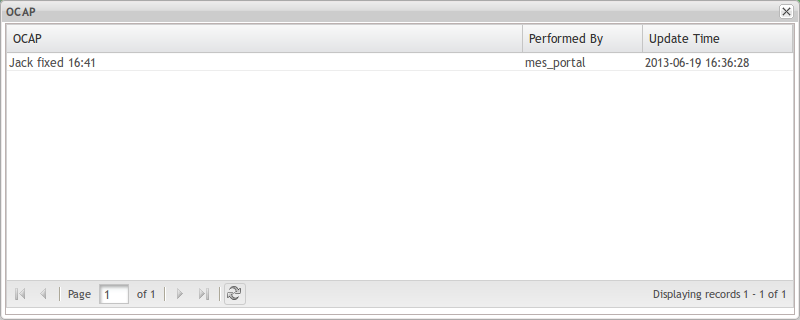

View OCAP History

You can click the ![]() button to view OCAP history of a data record in the pop-up OCAP history window

button to view OCAP history of a data record in the pop-up OCAP history window

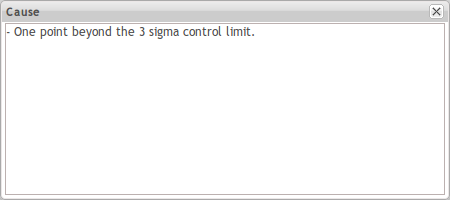

View Cause

You can click the ![]() button to view the rules that the current point has violated

button to view the rules that the current point has violated

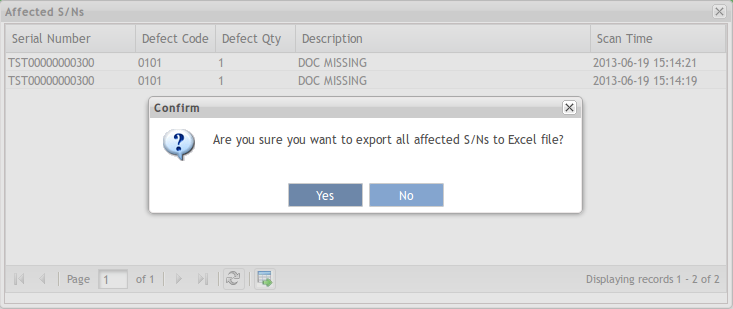

View Affected S/Ns

You can view the affected serial numbers and export them to Excel file.

click the ![]() button and you’ll activate a pop-up window where you can see the affected S/Ns list,

button and you’ll activate a pop-up window where you can see the affected S/Ns list,

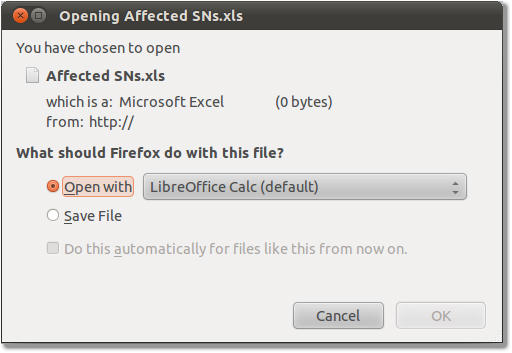

If you want to export the affected S/Ns to Excel file, you can click the ![]() icon at the bottom of the prompted window, then choose ‘Yes’ to confirm the action

icon at the bottom of the prompted window, then choose ‘Yes’ to confirm the action

Choose whether to open the .xls file or just save to hard drive

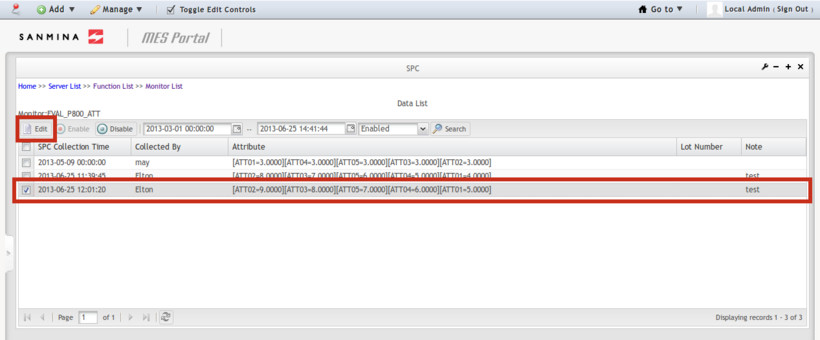

View & Edit Data

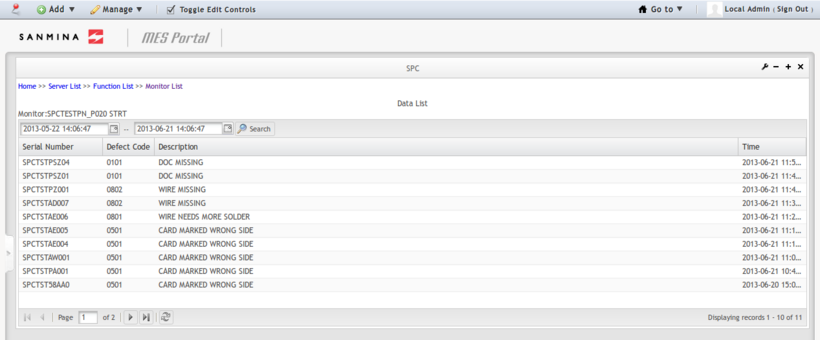

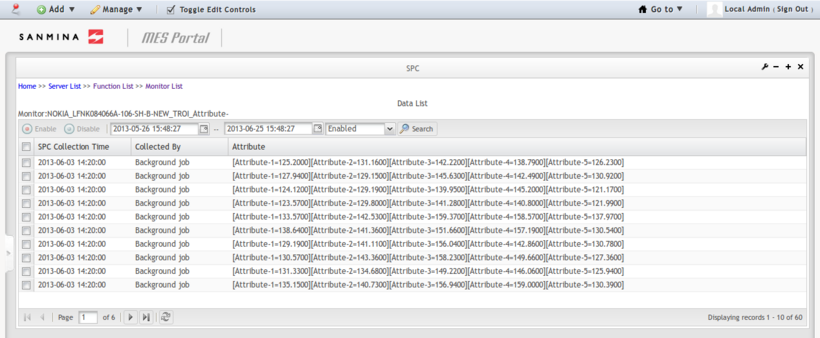

View Data List

You are allowed to view detail data of a monitor. To do this, select a monitor and click the ![]() icon in the toolbar in ‘Monitor List’ page

icon in the toolbar in ‘Monitor List’ page

In ‘Data List’ page, you need to set the time frame for the searching by selecting beginning day and ending day in the toolbar (the green frame area in Figure 5.58), then select a status from the data status drop down list (the red frame area in Figure 5.58) and click the ![]() icon to view the matching data

icon to view the matching data

Figure 5.59 shows data records of a monitor whose data is automatically collected by SFDC

Figure 5.60 shows data records of a monitor whose data is manually collected via SPC UI

Disable data

A data record in the data list stands for a single point in a control chart. Disabling a data record will remove the associated point from control chart. To disable a data item, select a data record, then click the ![]() icon in the toolbar

icon in the toolbar

You can find disabled data records by searching: set the time frame for the data record by selecting beginning day and ending day in the toolbar (the green frame area in2.1.9-6), then select ‘Disabled’ from the data status drop down list (the red frame area in 2.1.9-6) and click the ![]() icon to execute the search action

icon to execute the search action

Enable data

Enabling data is to restore a data record from disabled status. To do this, you need to select the data record from the disabled data list, then click the ![]() icon in the toolbar

icon in the toolbar

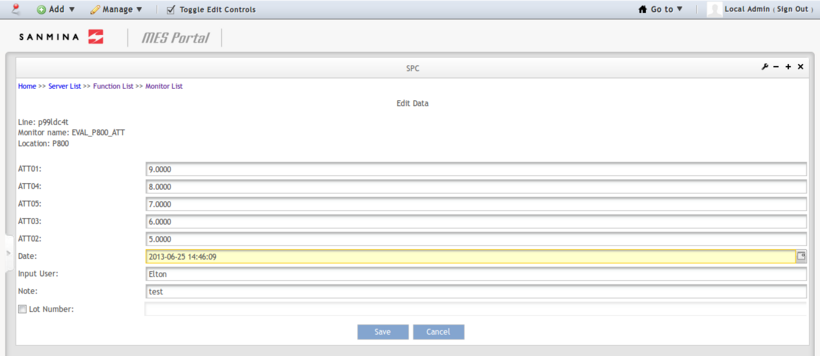

Edit data

This function is limited to the monitor whose data is manually collected by SPC UI. To edit data record, you can go to the ‘Monitor List’ page, select a monitor whose ‘Collection Type’ value is ‘Manual’, and click on the ![]() icon in the toolbar, in ‘Data List’ page which lists the enabled data, go to the last page of the list, select the last line and click the

icon in the toolbar, in ‘Data List’ page which lists the enabled data, go to the last page of the list, select the last line and click the ![]() icon in the toolbar (Only the last data record is allowed to be modified)

icon in the toolbar (Only the last data record is allowed to be modified)

You’ll be redirected to the ‘Edit Data’ page where you can edit any field as you want, finally click the button to save the changes

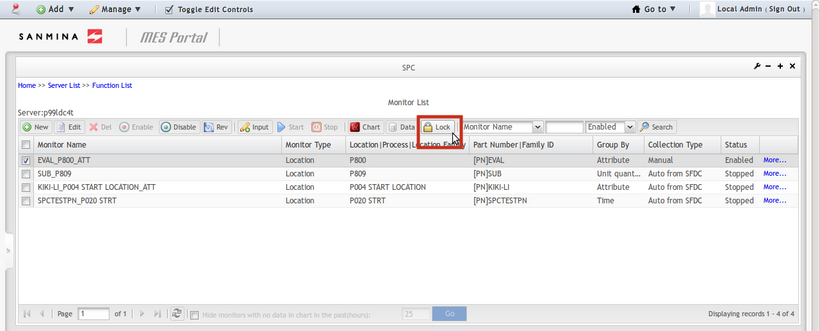

Maintain Lock

SPC offers you a full set of functions to manage MFG hold. When creating a new SPC server, you can decide whether to send MFG hold request to MDS / SFDC. When creating a new monitor, you can define the minutes of delay before MFG hold was sent. You are allowed to view lock records and unlock existing locks as well.

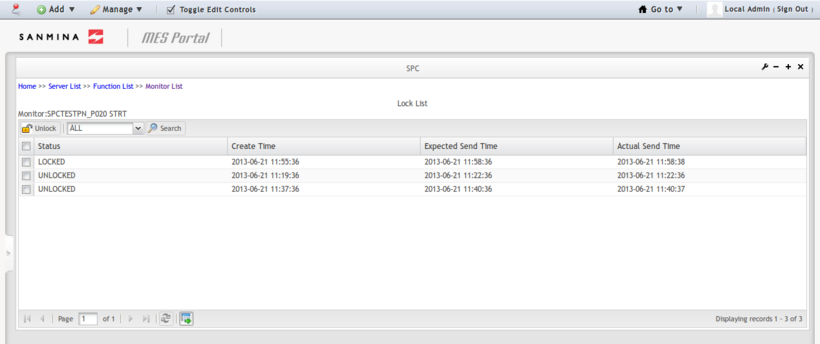

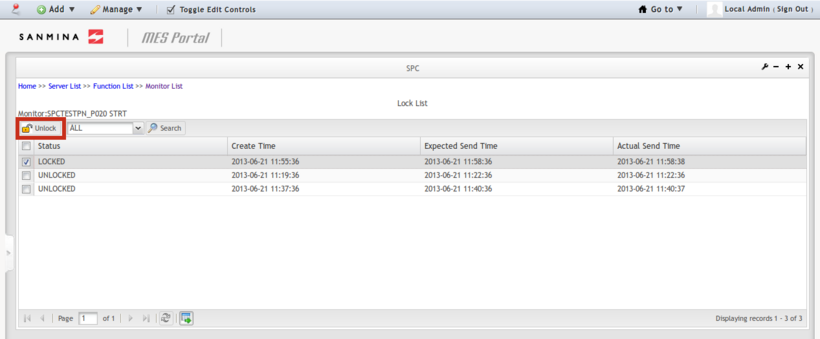

View Lock

Suppose you’re in the ‘Monitor List’ page, to view lock, you just need to select a monitor and click the ![]() button in the toolbar

button in the toolbar

Now you’re in the ‘Lock List’ page

Starts from SPC 3.2, lock mechanism has been modified that only Pareto chart can send MFG hold request to SFDC / MDS. You can view locks in different status as long as you choose different values in the lock status drop down list. For example, if you want to find locked locks, select ‘LOCKED’ from the lock status drop down list, and click the ![]() icon in the toolbar

icon in the toolbar

There are 4 status of locks: WAITING, LOCKED, UNLOCKED and CANCELED. The CANCELED status is a new added status starts from SPC 3.2.

- WAITING: the lock that is waiting to be sent to MDS / SFDC. When out-of-control case is detected, SPC will wait some minutes before sending the MFG hold to MDS / SFDC until it reaches the number of minutes that defined by ‘Send MFG hold request after * minutes’ field in Actions section, during this period, the lock is in ‘WAITING’ status.

- LOCKED: MFG hold has been sent, associated location or process has been locked and OCAP has not been processed

- UNLOCKED: User input OCAPs to unhold associated location or process, then the locked lock becomes UNLOCKED.

- CANCELED: This lock status is a new status starts from SPC 3.2. To get a better understanding of this status, let's consider the following scenario: A SPC monitor was created for Pareto Chart that 3 defect codes of the same type within 10 minutes will trigger the exception, and MFG hold will be sent to SFDC / MDS after 5 minutes later. A few minutes later, a first MFG hold was triggered, if a second MFG hold was triggered during the first hold’s delay sending time, in our new lock mechanism, the second hold won’t be sent to SFDC / MDS, and the status of the second MFG hold is ‘CANCELED’.

Unlock Lock

To unlock a lock, you need to select the lock and click the ![]() icon in the toolbar

icon in the toolbar

In the pop-up window, input OCAP to unlock the associated location or process.

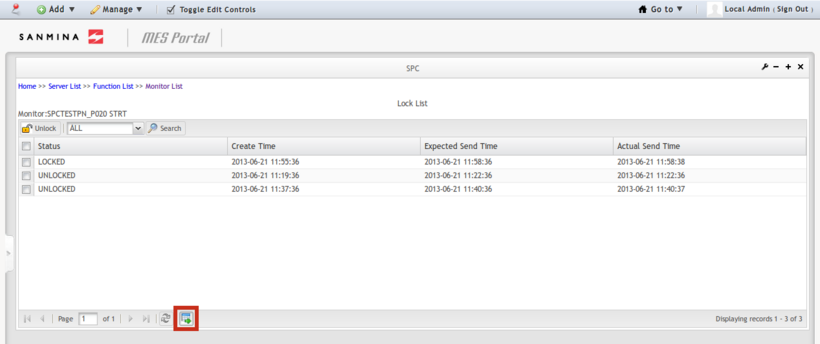

Export Lock List to Excel

User can export the lock list to Excel file: On ‘Lock list’ page, click the ![]() icon at the bottom of the list

icon at the bottom of the list

Click ‘Yes’ in the pop-up window to confirm the action

View Monitor Details

To learn detail information about a monitor, you can first go to ‘Monitor List’ page, select a monitor and click the ![]() text link at the right side of the line

text link at the right side of the line

In the pop-up Monitor details window, you can view detail information of the monitor. Information items you can view include monitor name, data collection strategy, interval, rules, selected charts and actions.

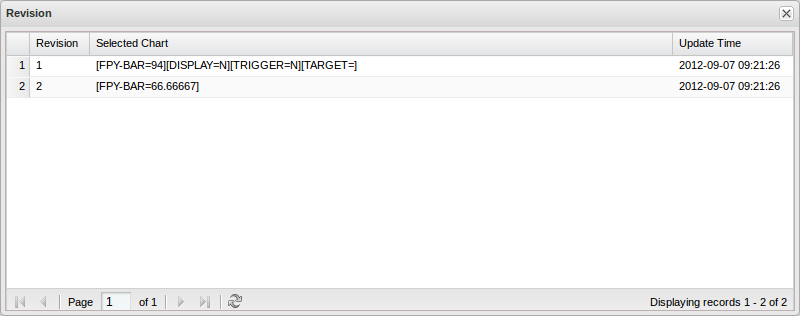

View Monitor History

To view modification history of a monitor, go to ‘Monitor List’ page, select a monitor and click the ![]() button in the toolbar

button in the toolbar

Then you can view the monitor modification history in the pop-up ‘Revision’ window

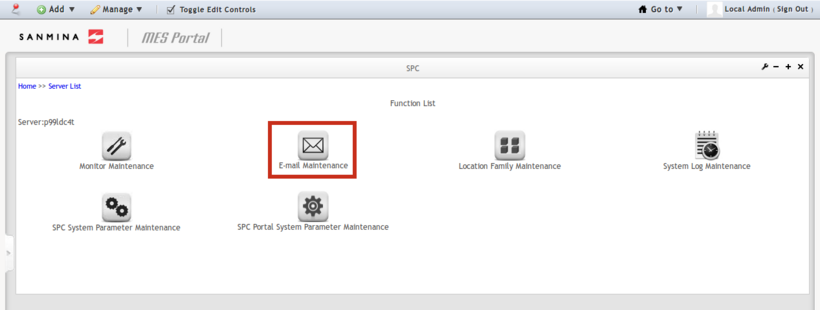

Email Maintenance

Brief Introduction

Email notification is an important way for SPC to monitor manufacturing line in real time. When exceptions were found, SPC will send email alert to associated employee or supervisor, so that they can analyze the exception according to the alert email and other SPC tools and take appropriate measures, such as checking production line, writing OCAPs, stopping line, etc.

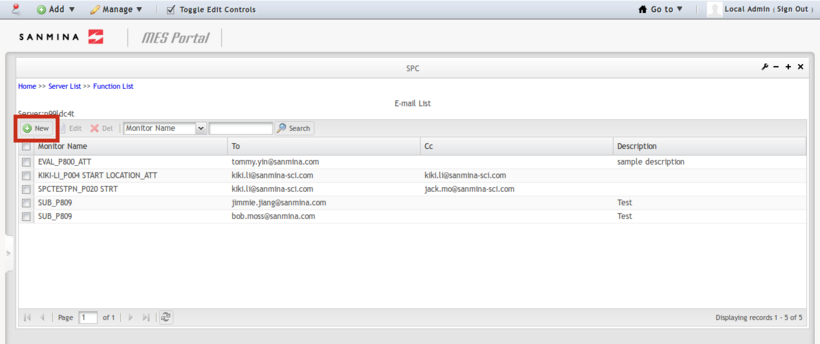

Add New Alert Email

First go to ‘Function list’ page and click the ![]() icon to enter the email maintenance module

icon to enter the email maintenance module

In ‘E-mail List’ page, click the ![]() icon in the toolbar

icon in the toolbar

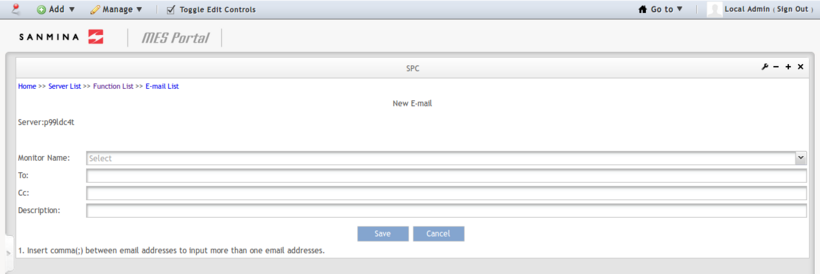

In ‘New E-mail’ page, fill in the blanks and click the ![]() button to save the configuration to SPC.

button to save the configuration to SPC.

Monitor Name: Select a monitor from the available monitors drop down list. All listed available monitors here are created in the current SPC server. The recipients will receive alert emails from the monitor you defined here.

To: Input recipients of the alert email here. This field is mandatory.

Cc: Input some other recipients here. This field is optional.

Description: Write more information about the email if necessary. This field is optional.

Tip: You can input more than one email addresses with a comma(;) between two email addresses.

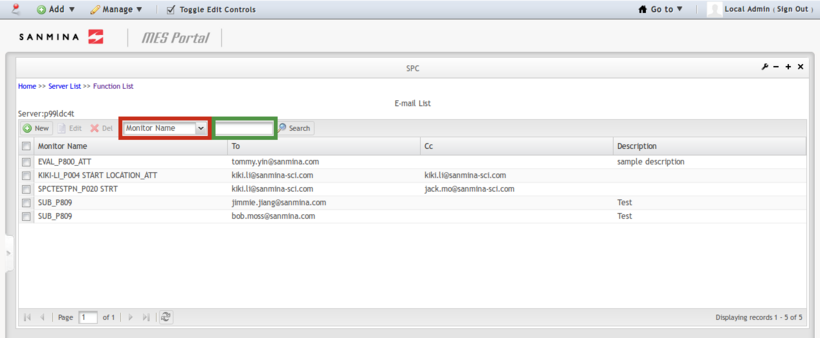

Search Email

In SPC, you can search existing alert email by keyword. First, you can select the kind of keyword in the keyword category dropdown list (the red frame area in Figure 6.4), then input keyword in the keyword textBox (the green frame area in Figure 6.4), and click the ![]() icon to submit your search action.

icon to submit your search action.

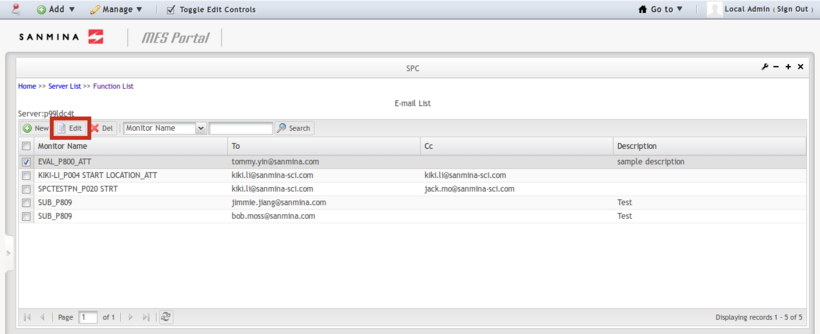

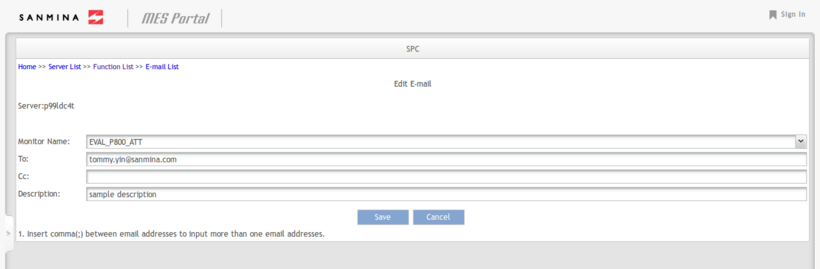

Edit Email

To edit an email, you need to select the email record and then click the ![]() icon in the toolbar to open the ‘Edit E-mail’ page

icon in the toolbar to open the ‘Edit E-mail’ page

In ‘Edit E-mail’ page, correct values in any of the 4 fields and save the changes.

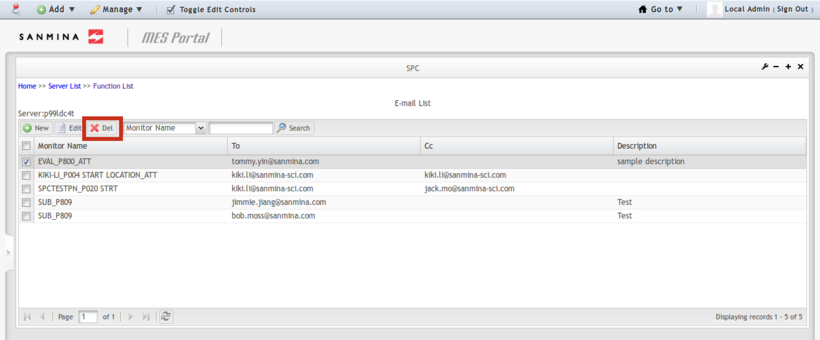

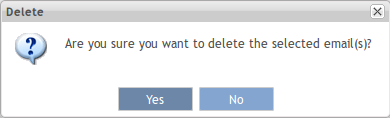

Delete Email

To delete an email from the email list, you just need to select the email record and click the ![]() icon in the toolbar

icon in the toolbar

Choose ‘Yes’ to delete the email

Example of an Alert Email

In email inbox, an alert email from SPC has title like “Alert message from SPC application’. Here is an example of a SPC alert email, which contains 7 information fields (the red background area): Line, Monitor, Part Number, Location, Chart, Date and Description.

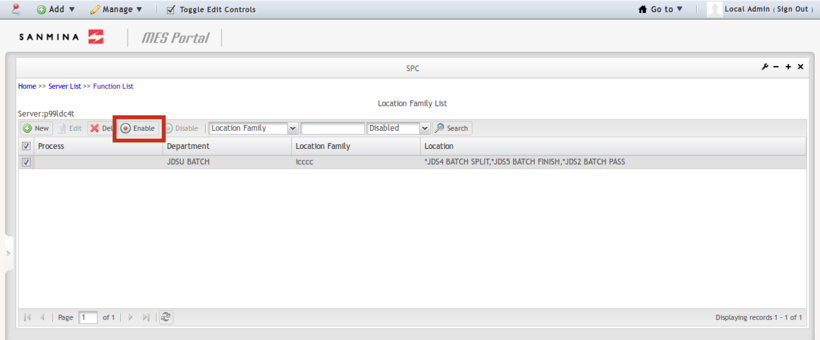

Location Family Maintenance

Brief Introduction

Location family is a collection of locations. Numerically, one location family consists of one or more than one locations, which can be derived from different processes and departments. Authorized user can create, search, edit, disable, delete and enable location family.

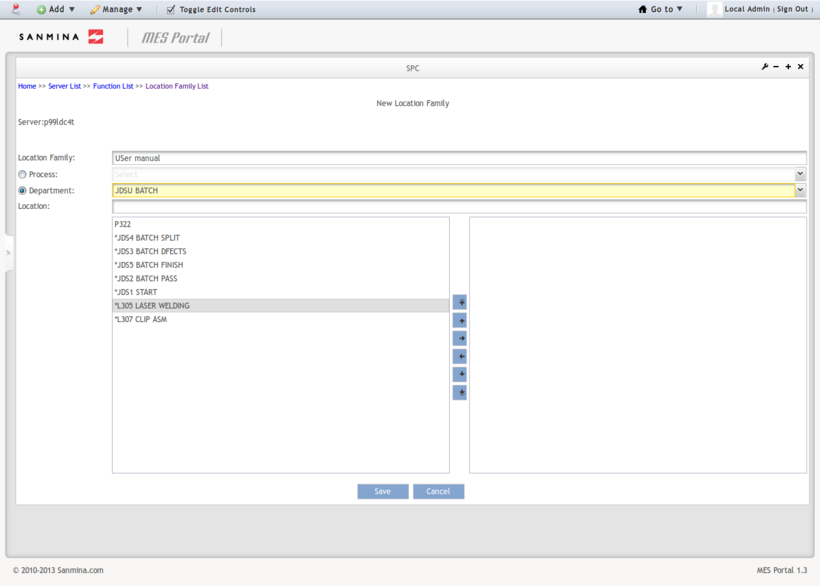

Create Location Family

To create a new location family, you can click the ![]() icon on the ‘Function List’ page

icon on the ‘Function List’ page

In Location Family List page, click ![]() button in toolbar

button in toolbar

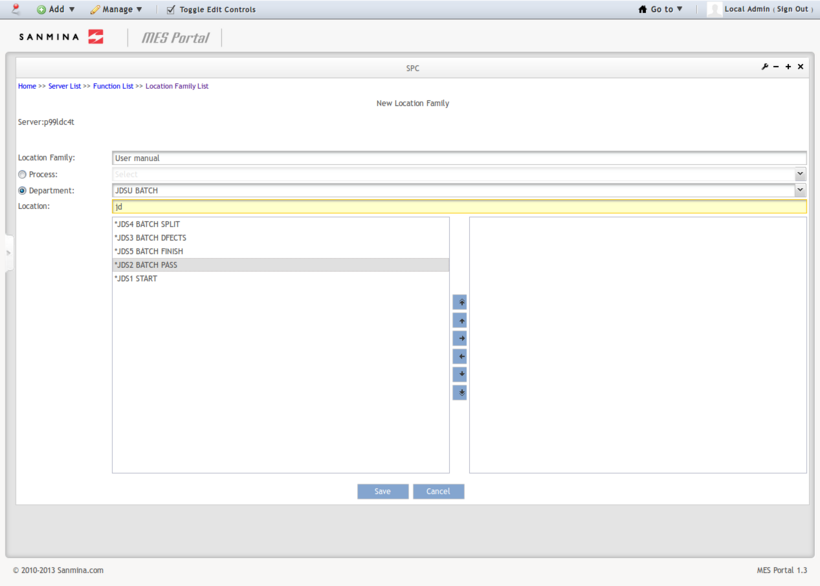

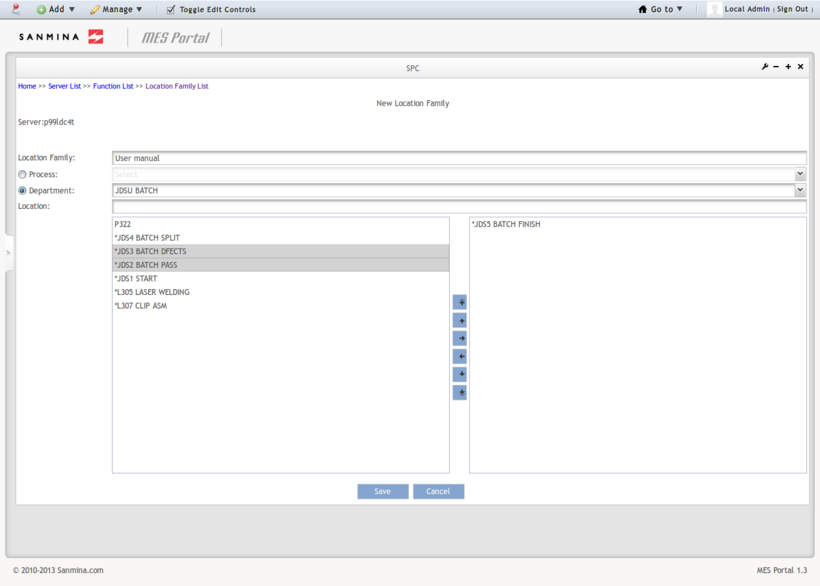

Choose Process radio button or Department radio button, for an instance, here choose the latter, then choose a department from Department drop down list

You can input value to the Location textbox to filter locations. If you change value of the Location textbox, its instant search function automatically turns on, SPC system automatically searches matching locations from the locations that belongs to the selected department, and displays matching locations in the ‘Location’ multiple selection box

Select a location and click the ![]() button to add locations from the left panel to the right panel, you can select more than one locations at a time as well.

button to add locations from the left panel to the right panel, you can select more than one locations at a time as well.

Lastly, click the Save button to save your data to SPC.

Search Location Family

SPC enable users to search for location family by keyword and status. To search for location family, you need to go back to ‘Location Family List’ page, select a keyword category (the green frame area in Figure 7.6), input a keyword in the text input box (the red frame area in Figure 7.6), select a location family status (the blue frame area in Figure 7.6) and click the ![]() icon

icon

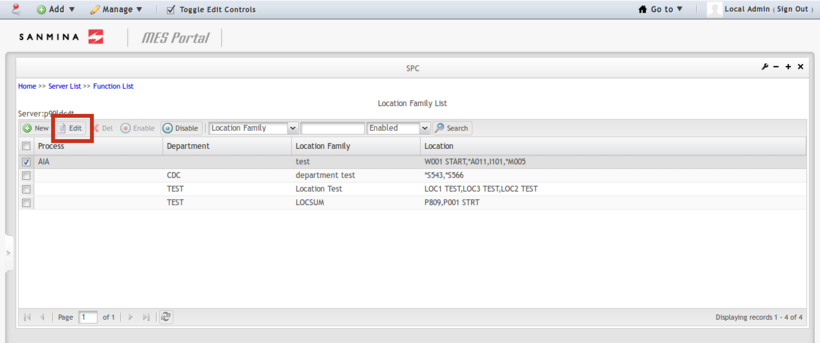

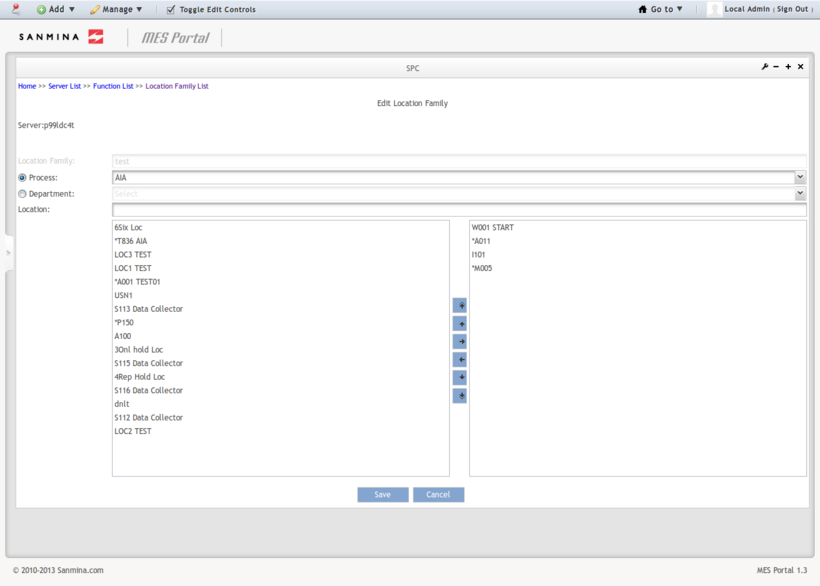

Edit Location Family

To edit a location family, select a location family from the list, then click the ![]() icon in the toolbar, then you’ll be redirected to ‘Edit Location Family’ page

icon in the toolbar, then you’ll be redirected to ‘Edit Location Family’ page

In ‘Edit Location Family’ page, edit any field you want and save the changes.

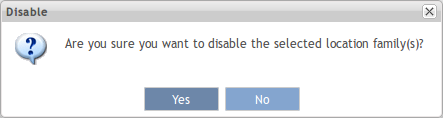

Disable Location Family

Select a location family and click the ![]() icon in the toolbar

icon in the toolbar

Choose yes in the pop-up confirm window

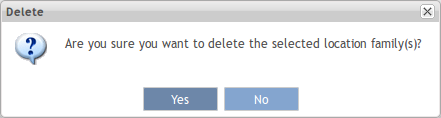

Delete Location Family

To delete a location family, you need to disable it first, then search the disabled location family and delete it

Click Yes to confirm the action

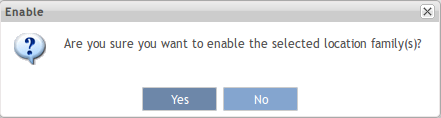

Enable Location Family

Select a location family and click the ![]() icon in the toolbar

icon in the toolbar

Choose yes in the pop-up window

System Log Maintenance

Brief Introduction

Some important system events, such as data modification and stopping monitor, will be automatically added to SPC system log. System log plays an important role in system security. Users can analyze the system log and decide to take appropriate measures, like data recovery and file backup, to defend the system. In our SPC system, authorized user can search, view and delete system log.

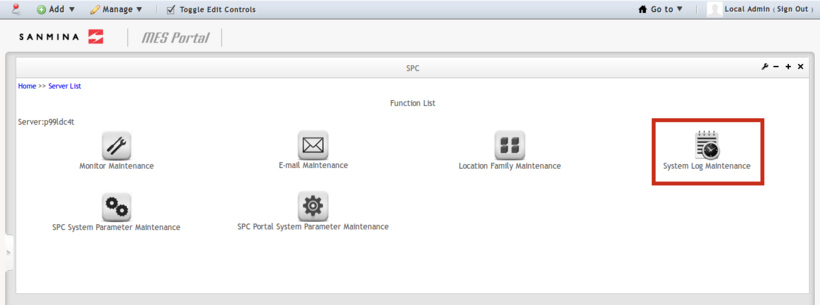

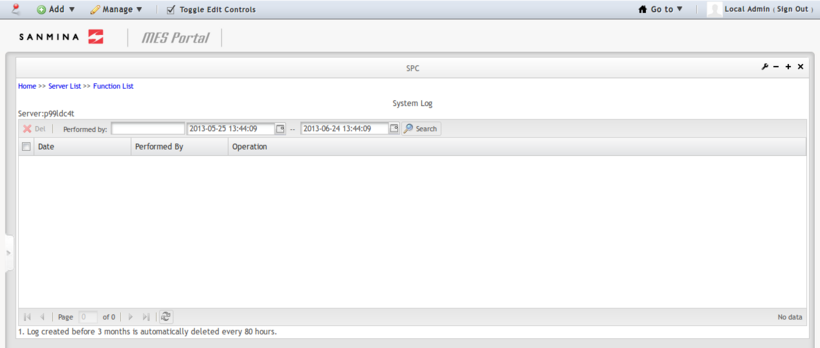

Search & View System Log

On ‘Function List’ page, click the ![]() icon

icon

In ‘System Log’ page, you can search system log by time frame or by event owner.

Input event owner in the ‘Performed by’ textBox or choose a time frame and click the ![]() icon in the toolbar

icon in the toolbar

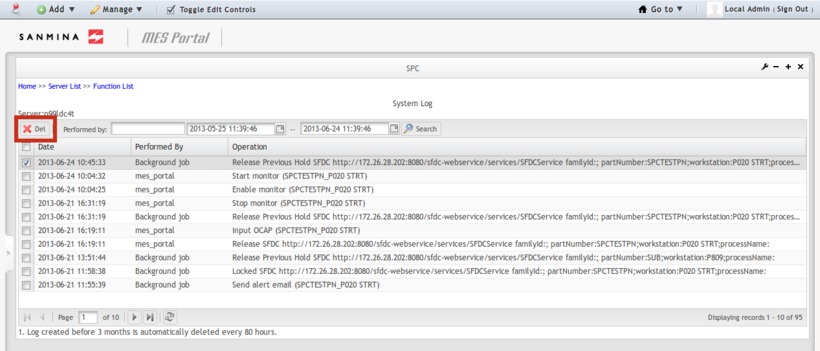

System log list table structure contains 3 columns - Date, Performed By and operation

Date: when did the operation take place

Performed By: who did the operation, user or system

Operation: what is the operation

Delete System Log

SPC automatically deletes system logs created 3 months before every 24 hours. Besides, authorized user can delete log manually via SPC UI. User can delete log one by one or by batch.

Confirm to delete system log

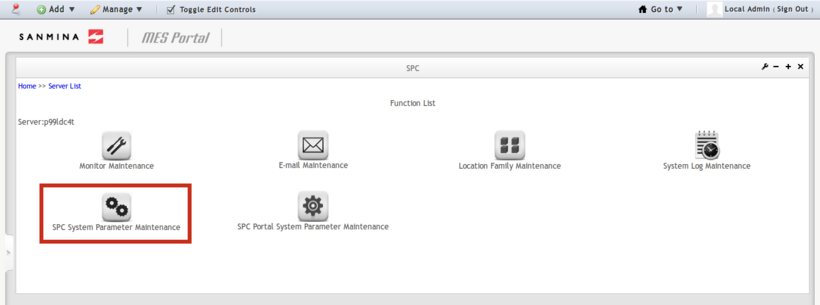

SPC System Parameter Maintenance

Brief Introduction

Authorized users are allowed to set general system parameters according to their local plants, manufacturing lines or other special needs. This part of system parameters configuration affects the performance of the current SPC server, so please be careful when defining the parameters’ values.

Maintain SPC System Parameters

Click the ![]() icon in ‘Function List’ page

icon in ‘Function List’ page

In ‘SPC System Parameter’ page, you can see 5 fields: ‘# of running monitor’, ‘Start time of data collection (month)’, 'Hide monitors with no data in chart in the past(hours)', 'Hide monitors with no data in chart in the past(hours)' and 'Enable Previous SPC Hold function'. If you’re not sure what they mean, you can move mouse over the ![]() icon to learn more information about the labels.

icon to learn more information about the labels.

Explanation to the fields as seen in the above screenshot

# of running monitor: How many monitors can be running at same time. Its default value is 200.

Start time of data collection (month): After one monitor is created, this monitor related data can be retrieved from past time, this setting determines How old data can be retrieved by monitor. Its default value is 3 months.

Hide monitors with no data in chart in the past(hours): It allows you to filter out those monitors that have no new data coming in during the past settable hours. You can input a positive number between 1 to 168 in the textBox, default value to this textBox is 24. To view the effect, you can check the Hide Inactive Monitors feature in Monitor List page.

Disable monitors with no data in chart in the past (hours): If you've enabled this checkBox, SPC will automatically disable those monitors that has no new data during the past settable hours. By default, this checkBox is enabled. The hours quantity textBox next to it has a default value of 24 (hours), value allowed in this textBox is positive integer between 1 to 168.

Enable Previous SPC Hold function: Previous Hold function will be invoked in the following scenario: after a part number was put on SPC Hold by SPC for the settable number of consecutive defect codes within a set time limit, displays ‘PREVIOUS SPC HOLD’ in NetDC rather than issuing an immediate SPC hold.

Note:

- If a monitor is stopped, disabled or deleted, the Previous Hold function of this monitor will be automatically turned off as well.

- You need to enable the Send MFG hold to SFDC / MDS checkBox in Add Server Information page first, then you can enable the Enable Previous SPC Hold function checkBox.

You can also restore the system parameters from previous 3 configurations. To do this, just click the ‘Select one from last 3 changes’ drop down list (the red frame area in Figure 9.2), and select one from the list, the values in the text input boxes will be automatically restored.

After all configurations are done, remember to click the ![]() button. If saving is okay, user can see message 'Configurations are successfully saved and will be immediately effective'. If saving is not okay, user can see error message 'Configurations are not saved, please try again or contact administrator'.

button. If saving is okay, user can see message 'Configurations are successfully saved and will be immediately effective'. If saving is not okay, user can see error message 'Configurations are not saved, please try again or contact administrator'.

SPC Portal System Parameter Maintenance

Brief Introduction

Authorized users are allowed to set general system parameters according to their local plants, manufacturing lines or other special needs. This part of system parameters configuration affects the performance of the whole SPC system and all SPC servers listed in ‘Server List’ page, so please be careful when defining the parameters’ values.

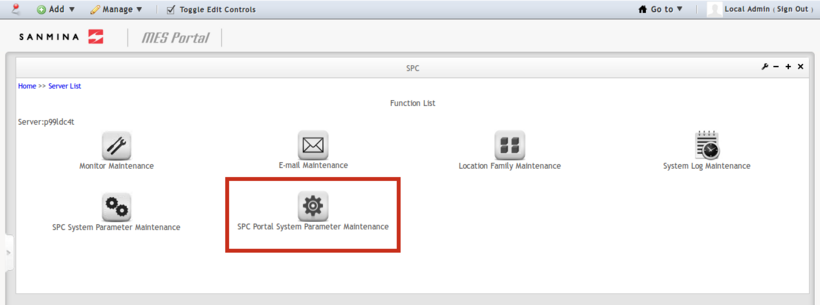

Maintain SPC Portal System Parameters

Click the ![]() icon in ‘Function List’ page

icon in ‘Function List’ page

In ‘SPC Portal System Parameter’ page, you can input new values to the text input boxes to configure the parameters. If you’re not sure what they mean, you can move your mouse over the ![]() icon to learn more information about the labels.

icon to learn more information about the labels.

# of active thread: Java thread is created for one real-time monitoring, Java thread are in one thread pool, some of them are active, some of them are inactive, this setting determines how many Java thread can be active at same time. Its default value is 50.

Interval of collecting data (second): During real-time monitoring, each monitor will periodically collect data from SFDC archive database or other data source, the setting determines how often each monitor collects data. Its default value is 120 seconds.

Interval of deleting log (hour): There is one background job (thread) responsible to periodically delete the system log, this setting determines how often the background job deletes some system logs. Its default value is 24 hours.

Time of log saved (month): System log will not be saved forever, too old log will be deleted by background job, this setting determines how long the system log is saved in database. Its default value is 3 months.

Interval between lock reviews (second): How often the background job reviews lock(or called MFG hold request) to determine if one waiting lock should be sent to SFDC (or MDS). Its default value is 10 seconds.

Display Family ID in chart: Enable SPC to display Family ID on control chart. This checkbox is not selected by default.

You can also restore the system parameters from previous 3 configurations. To do this, just click the ‘Select one from last 3 changes’ drop down list (the red frame area in Figure 10.2), and select one from the list, the values in the text input boxes will be automatically restored.

After all configurations are done, remember to click the ![]() button. If saving is okay, user can see message 'Configurations are successfully saved and will be immediately effective'. If saving is not okay, user can see error message 'Configurations are not saved, please try again or contact administrator'.

button. If saving is okay, user can see message 'Configurations are successfully saved and will be immediately effective'. If saving is not okay, user can see error message 'Configurations are not saved, please try again or contact administrator'.

Roles & Permissions

| Roles→ Permissions↓ |

SPC_Corp_Support |

SPC_Plant_Admin |

SPC_Plant_Manager |

SPC_Plant_User |

*SPC_Plant_Operator |

|---|---|---|---|---|---|

| SPC |

|||||

| Add/Edit/Delete Monitor |

|||||

| Start/Stop Monitor |

|||||

| Disable/Enable Monitor |

|||||

| Add/Edit/Delete Monitor Group |

|||||

| Input/Edit Data |

|||||

| Add/Edit/Delete Email |

|||||

| Delete Log |

|||||

| Edit OCAP |

|||||

| Disable/Enable Data |

|||||

| Add/Edit/Delete Location Family |

|||||

| Disable/Enable Location Family |

|||||

| Edit System Configuration/Global System Configuration |

|||||

| Unlock |

|||||

| View |

|||||

| Add to Page |

|||||

| Configuration |

|||||

| SPC Server Information |

|||||

| Add/Edit/Delete Server |

|||||

| View |

|||||

| Add to Page |

|||||

| Configuration |

Notification:

- ‘SPC_Plant_Operator’ is for plant E68 only.

Glossary

1. MFG hold: MFG hold is short for manufacturing hold. SPC sends MFG hold to MDS or SFDC to stop manufacturing line. It is another action SPC can take when point is out of control limit.

2. MDS: Short for Manufacturing Data System.

3. SFDC: The SFDC (Shop Floor Data Collection) System is the main software/hardware system used by Sanmina-SCI for production control and the collection of manufacturing data.

4. Exception: SPC considers some out-of-control caA valid group here means the group oses as exception based on the rules you selected when configuring monitor parameters.

5. Valid group: It means the data that is in the normal scope. On SPC control charts, a valid group of data points are plotted between the UCL and LCL.

6. DPMO: Short for Defects Per Million of Opportunities.

7. OCAP: Short for Out of Control Action Plan.

8. Ext JS: Ext JS JavaScript Framework. Ext JS is a pure JavaScript application framework for building interactive web applications using techniques such as Ajax, DHTML and DOM scripting.

Change Log

| Date | Author | Title | Version | Change Reference |

|---|---|---|---|---|

| February 1, 2014 | Elton Wang | Tech Writer | 1.0 | initial release |