SOP-42Q-MES0041 100 Traceability

Hand Placement

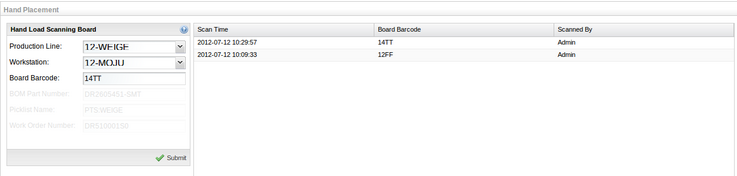

To Use Hand Placement Portlet, click PTS-->100% Traceability-->Hand Placement.

Choose the Production Line and Workstation, then input the Board Barcode and click Submit. If materail is enough, then will

pop up a message:Successful,in the right section of the Portlet will show the "Scan Time", "Board Barcode", "Scanned By" info.

If material is not enough, then will pop up a message:Error-Workstation material has run out when scan! Some things need to

be verified before using 100% traceability hand placement function.

First, The choosed Production Line must on line. Also you can Add a Production Line and Workstation by yourself at other

Portlets in PTS, then Set it on line.

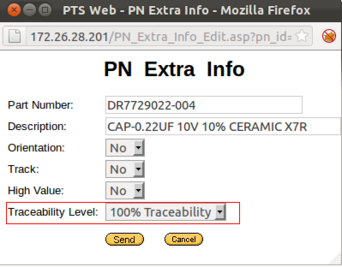

Second, the Part Number must set 100 Traceability at "PN Extra Info" Portlet.

When hint Error, we need to load material of the same Part Number for scanning. you can click "Load Material" Portlet to load

material to workstation. After this you can repeat the actions:Choose Production Line, workstation, and input a Board Barcode

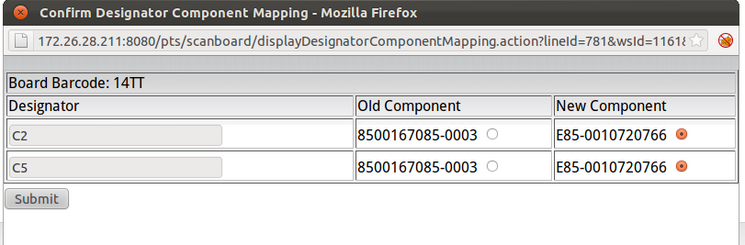

for scannig. Then will pop up a dialog box(as Figure). Operator can choose the Old Component and New Component to the

corresponding Designator.