42Q Production Scheduling Whitepaper

Production Scheduling

In today’s manufacturing market, production planning and scheduling processes require to be more effective than ever, because they are critical to streamlining production and increasing profits. Success means efficiency, reduced time to complete jobs, and capacity utilization from the initial stage of plan location to plan operation and manpower scheduling.

That is why the importance of Production Scheduling consists of identifying the requirements before taking up a project by planning manufacturing activities like investment, logistics, procuring input goods, labor, etc. for a specific time period in a sequential manner.

In 42Q you will find an effective tool to schedule these activities.

What Is Production Scheduling?

For the manufacturing industry, Production Scheduling is the process where production activities are planned on a timescale. Traditionally, this planning has been done manually or with a separate software from the one where the manufacturing process is configured, however, 42Q Production Scheduling is a portlet where you can easily manage planning in the same cloud-based MES where your company configures, tracks, analyzes and administers work instructions and operations.

In this application, users can manually schedule Shop Orders by line, personalize the configuration, have access to the Targets and Cycle time information, import and export schedules, display the percentage of completion of each sub schedule, and more.

How can Production Scheduling Help Your Business?

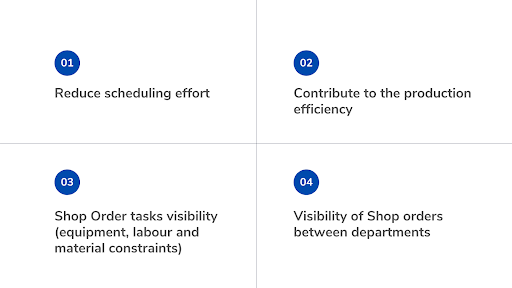

With 42Q Production Scheduling you can have visibility of the whole planning process by displaying the production status of each Shop Order on each MFG line, see in the calendar what has been completed, what is in the current shift and needs to be completed, and even see the changes done to the scheduled Shop Orders. All that involves Shop Order completion percentage, start and end time, and target TPHR and allows planners to adjust the schedules in advance because they have visibility of the completed or delayed Shop Orders, as well as quickly find Shop Orders of the same part family to enhance scheduling and reduce line changeovers.

Different areas of your company will have a complete picture of production scheduling and be able to see what the priorities are and remain focused on the priority tasks. All that contributes to a significant reduction of time usually spent to create a production schedule and perform what-if analysis. The advanced 42Q Production Scheduling application can keep up the high demand from the manufacturing industry.

How does Production Scheduling Work?

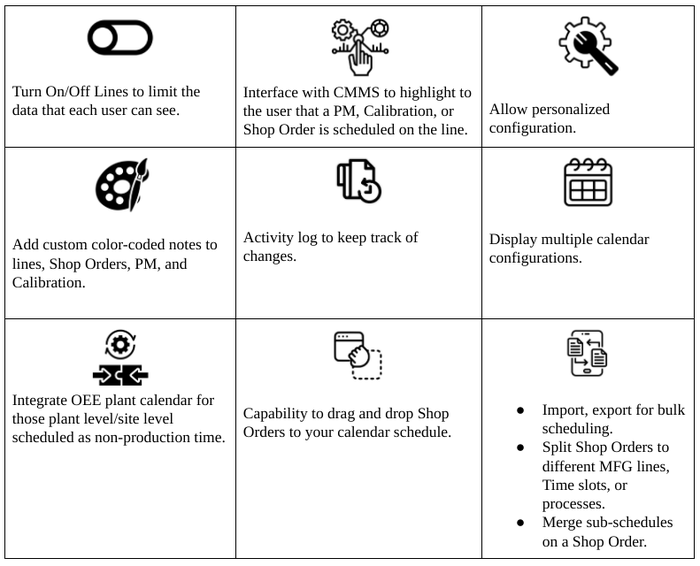

The Production Scheduling tool is displayed as a calendar where users can set up manually the MFG Lines by day, week or month and customize the planning configuration by adding colors or notes to the split Shop Orders or Lines. The following are some of its principal features:

Please refer to the 42Q documentation for information concerning Production Scheduling and how it is used in the 42Q portal.