How to Leak Scan Board

Contents

How to Leak Scan Board

Background

42Q PTS production scanning has a strong process(need scan the board at the previous workstation first, can not skip workstation when scan board ) that can avoid scanning board records missing. Most PTS plants are fine with this function.

But some plants use two PTS production lines to produce the PCB board top & bottom side separately (In different lines).

For Example: Product has B and T two sides. Plants need to create two workstations separately for the B / T side. Sometimes they already processed the B side in another production line(Line1) and then they just need to process the T side in the current line(Line2) and the current workstation with others workstation not scan board .

Detailed production lines setting:

PTS Production Line 1

First Workstation: L1 SP (Scanned By Later Workstation)

Second Workstation: L1 AIMEX_B (Scan For Previous Workstation) First Scanning

Third workstation: L1 AIMEX_T (Scan For Previous Workstation)

PTS Production Line 2

First Workstation: L2 SP (Scanned By Later Workstation)

Second Workstation: L2 AIMEX_B (Scan For Previous Workstation)

Third workstation: L2 AIMEX_T (Scan For Previous Workstation) Second Scanning

Before this enhancement, production will prompts "Previous WS not scanned." error message when scan board in line2.

Solution

- First, supply a new configuration item ‘Allow Leak Scanning Board‘ inPTS System Setting function.

- PTS Workstation Setup function to add a new configuration switch item named 'Allow Leak Scanning Board'.

- Improve the Scan Board function, and only when switch 'Allow Leak Scanning Board' in System Setting function and switch 'Allow Leak Scanning Board ' in Workstation Setup function are all in opened status(Value is Yes) the scanning board allows leak scanning for current workstation.

How to operate in 42Q

System Setting

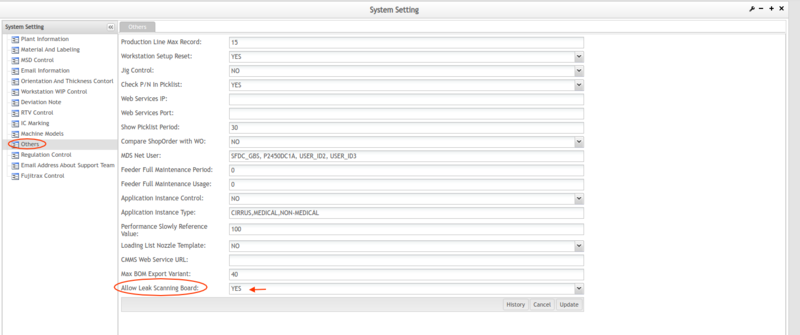

Go to Administration > Traceability Administration > System Setting, at the Others tab, set the Allow Leak Scanning Board =YES

Figure : System Setting - Allow Leak Scanning Board

Workstation Setup

Go to Shop Floor Control > Production Control > Traceability Setup.

At the module, manage the Production lines and workstations.

For a Leak scanning board, this setting is important for all workstations.

Right click on the workstation to open the menu, then select Workstation Setup to set the workstation configuration.

Figure : Workstation Setup

After setting all the workstations, please set the lines on line.

This is an example of the two production lines with three workstations each.

Figure : An Example Leak scanning Production Line

Touch

- Load all the materials to all workstations at the Load material function.

- Scan one Board for the B side at the station L1AIMEX-B (Production Line1 TestLine1,B side) at theScan board function.

- Scan one Board with the same barcode of B side for the T side at the station L2 AIMEX-T (Production Line2 TestLine2, T side) at thescan board function.

- Go to theLoad material report to check the material quantity for Production line2(TestLine2), the quantity of the material for station L2 AIMEX-T is reduced, but the materials quantity for the other two stations (L2 SP, L2 AIMEX-B) are not reduced . This step is optional.

Figure: An example for scan board

Revision History

| Date | Author | Title | Version | Change Reference | Approved By |

| 4/16/2020 | Helena Wang | Technical Writer | A1 | This is the first version |