SOP-42Q-MES0049 SMT Part Traceability

Contents

Convert SMT Program to Picklist

Figure 1: Convert SMT Program to Picklist – Main Menu

- Select “EZPicklist” menu under “SMT Machine” main functional module.

Select SMT Program File

Figure 2: SMT Program File Selection Window

- Click “Select Picklist” button to locate the desired material placement file.

- Select the SMT program file name. Please refer to SMT job profile which prepared by SMT Engineer for the file name for each

SMT machine.

- Click “Open” button. Details of the picklist will be shown.

Figure 3: Full Picklist Details Window

All SSCI part number, station, feeder, count, and designator are encoded in SMT placement program which were prepared by

SMT Engineer.

Material(s) Selection for Traceability in EZ-Picklist

Figure 4: Material(s) Selection Option in EZ-Picklist

- Select the 1st production side and/or 2nd production side (as per picklist setup for production environment):

- In case the selected picklist is intended for a double-sided board which have one or multiple common materials in both sides,

refer to green-framed items in below figure, there are 2 items of the same Part Number in the picklist, which means, this is a

double-sided board, side 1 and side 2 have one common material.

- To make no confusion during the production for such boards, we need to configurate which item needs to be used in which

side. As common material items share the same part number but match with different board numbers, we can simply

match board numbers with sides to realize the configuration of items to sides.

Figure 5: Double sided board with the same material handled in the same station

- Click on 1st Side or 2nd side option in this instance, a dialog box like below will prompt:

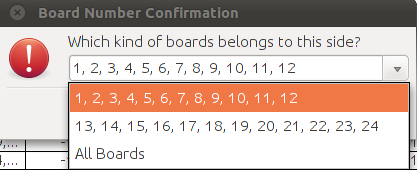

Figure 6: Board number confirmation

- This dialog box allows user to perform board-number-to-side mapping for common material(s). There will be 3 options

available in the drop-down list, refer to below figure:

- Board Number Goup 1: Board numbers of one side, auto detected and grouped by system. For normal panel

production(with all boards up or down), user can select this one.

- Board Number Group 2: Board numbers of the other side, auto detected and grouped by sytem. For normal panel

production(with all boards up or down), user can select this one.

- All Boards: With all board numbers included, that is to say, boar number group 1 plus board number group 2.

This option is designated for mirror-board production, with some boards up and some boards down and all are populated at

the same time.

- Simply select an option as per actual production and click on OK to confirm. Take note that board numbers for the other side

will therefore be confirm and no further confirmation needed once one is done.

- In case the selected picklist is for single-sided board, no confirmation is needed and system will simply check materials for

the selected side as per default configuration.

- Select the High Value option, Lead Free option checkbox associated to each individual material part number if required.

Figure 7: Material(s) Sending Option in EZ-Picklist

- Click “Send” button to send the picklist to PTS server.

Confirm the Picklist Successfully Generated

Figure 8: Successful Prompt upon Completed Picklist Conversion

- After the picklist is submitted to server, message prompt “Complete” will display as shown in Figure 6.

- Click “Confirm” button to confirm it.

Generate Loading List

Figure 9: Loading List Option in EZ-Picklist

- Click “Loading List” button to send the picklist to default path: C:\pts\loadinglist\ (Windows); /temp/loadinglist (Linux) .

Note:

- Default path for Loading List report is customizable. Local plant can simply contact PTS team to do the

customization.

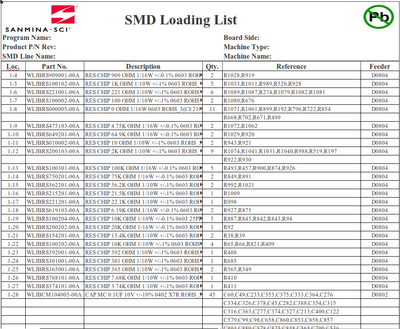

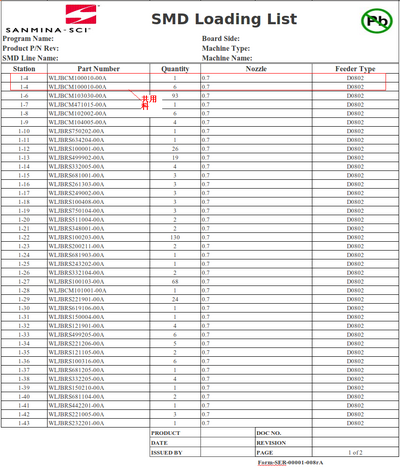

- There are two available templates for Loading List report, refer to below Template 1 and Template 2. Template 1 is the

default one, local plant can also contact PTS team to switch to Template 2.

Figure 10: Available Loading List templates

| Template 1(Default) | Template 2(Adding Nozzle Info) |

Please be noted that this Surface Mount Devices (SMD) Loading List cannot be used as a control document without stamp/sign

by authorized personnel defined by plant such as SMT production line supervisor/team leader. This is designed to be used for

materials loading reference only.

Figure 11: Confirm the Loading List Successfully Generated

- After the Loading list is generated successfully, message prompt “Complete” will display as shown in Figure 8.

- Click “Confirm” button to confirm.