SOP-42Q-MES0037 Traceability Administrator

42Q Home > Administration > PTS Administrator

This edition applies to MES 15 Portal 1.0 Application and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

- 1 Administration

- 2 PTS Administration

- 2.1 System Settings

- 2.1.1 Plant Information

- 2.1.2 Material and Labeling

- 2.1.3 MSD Control

- 2.1.4 Email information

- 2.1.5 Orientation and Thickness Control

- 2.1.6 Workstation WIP Control

- 2.1.7 Deviation Note

- 2.1.8 RTV Control

- 2.1.9 IC Marking

- 2.1.10 Machine Models

- 2.1.11 Others

- 2.1.12 Regulation Control

- 2.1.13 Email Address about Support Team

- 2.1.14 Fujitral Control

- 2.2 Add Deviation Note

- 2.3 Error message Maintenance

- 2.4 Upload Picture

- 2.5 Upload BOM

- 2.1 System Settings

- 3 Upload AML

- 4 Indirect Material Control

- 5 IC Part Number Mapping

- 6 Printer Setup

- 7 Document Revision History

Administration

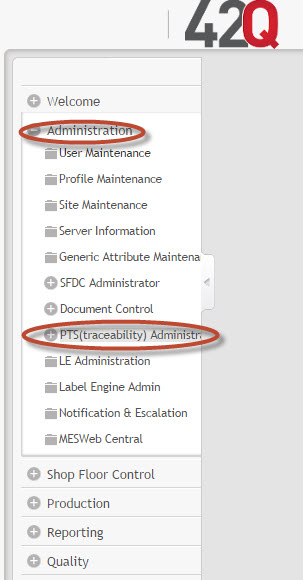

Administrative privileges for the 42Q portal are located in the Administration menu heading. With the portal, Administrators are able to access privileges from one convenient location. Privileges include User Maintenance, Plant Maintenance, Site Maintenance, Profile Maintenance, and Generic Attribute Maintenance. Also located in the Administration menu heading are SFDC Administrator, Document Control, PTS Administrator, and LE Administration.

This work instruction is intended to guide administrators on how to manage and maintain the 42Q Portal, as well as to provide specific user groups a common sense of portal operation.

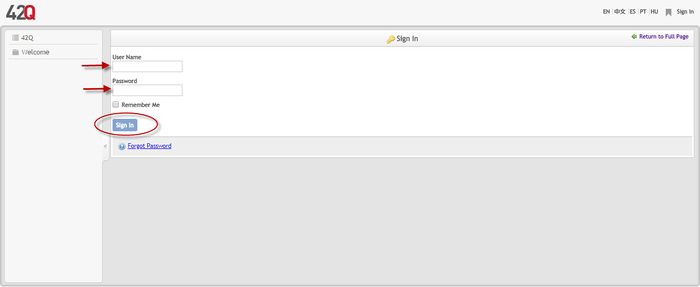

To access any of the Administration functionalities, the user must sign into the 42Q Portal and then select the Administration expandable heading located in the menu on the left of the screen.

Figure 1: User Sign-In

Figure 2: 42Q Welcome

PTS Administration

This Work Instruction is a basic navigation-training guide and is not meant to teach the process flow for individual department functionality. Individual 42Q sites may have minor or specific process changes that will be documented at the site level. Work Instruction alteration suggestions must be reviewed and approved by the site Documentation Manager prior to sending an alteration request to 42Q Corporate. This Work Instruction is a basic administration guide to support local PTSWEB plant only. Please contact a PTS Regional Technologist for PTS database and server administration as

Pre-requisites:

- Preliminary reading up SOP-5-I-PTS0000-C_R2_Glossary

- Preliminary reading up SOP-5-PTS0001-C_R2_Basic Navigation

- Administrator access level in PTSWEB.

Due to the security reasons and controlling purposes, various modules in PTS are strictly restricted to Administrator access only.

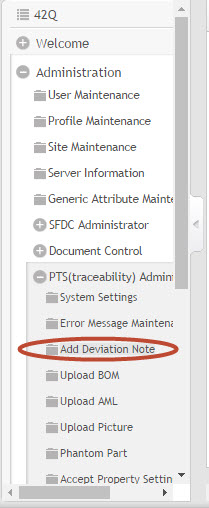

1. To access the PTS (traceability) Administrator page, navigate to Administration>PTS (traceability) Administrator.

Figure 3: PTS (traceability) Administrator

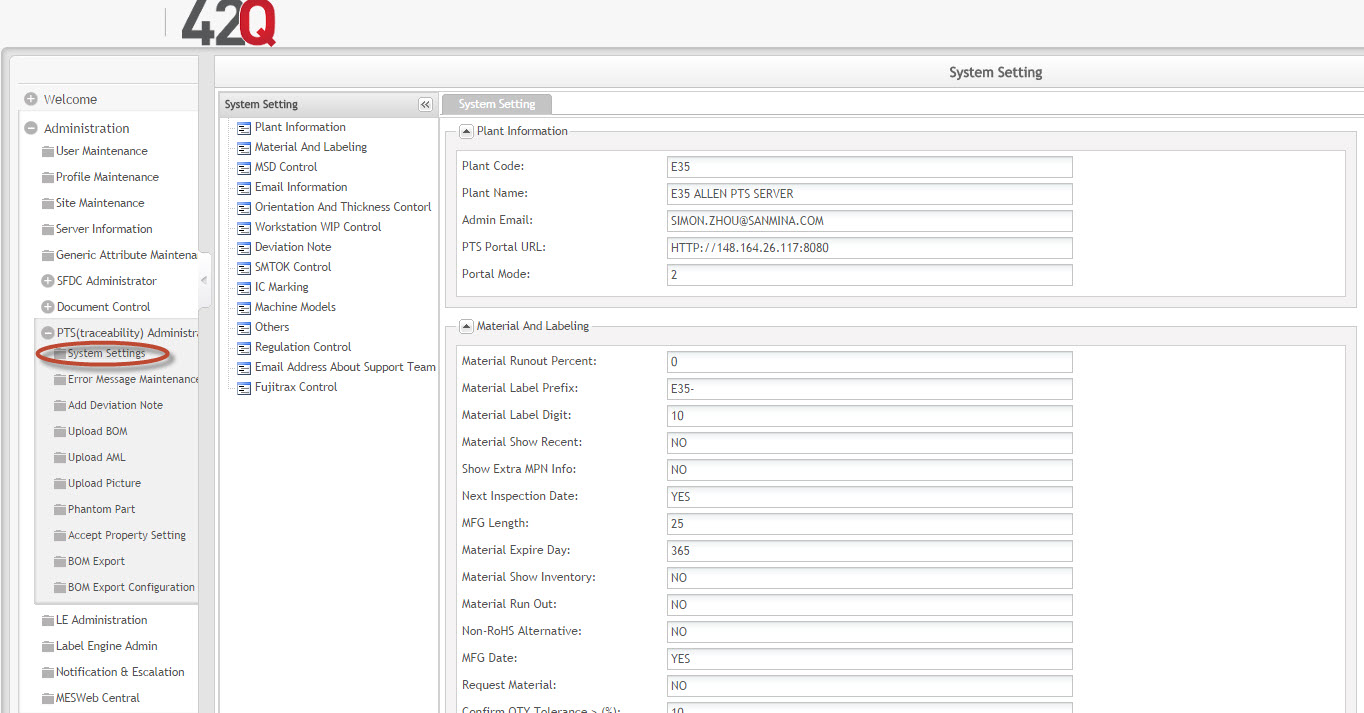

System Settings

This function is used to configure system parameters. Based on plant requirements, systems can be customized by changing system parameters. When PTS needs to set-up or upgrade, the administrator should make sure the parameters are configured correctly. Once changes are submitted, they are effective immediately, so the administrator should take caution when changing system settings.

1. To access the System Settings page, navigate to Administration>PTS (traceability) Administrator>System Settings.

Figure 4: System Settings

Plant Information

- Plant Code: such as E81

- Plant Name: name of plant

- Admin Email: defines administrator e-mail.

- PTS Portal URL: sets PTS login address. This field is optional.

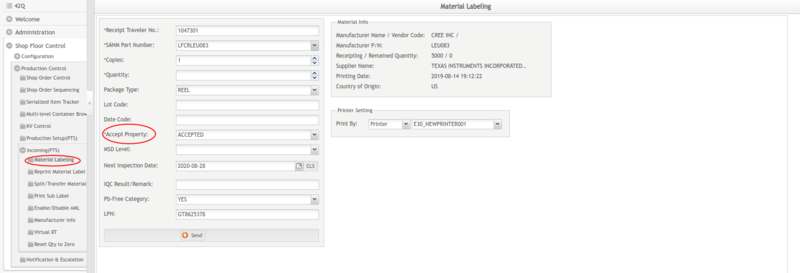

Material and Labeling

- Material Runout Percent: shows material in warning color according to remaining board quantity.

- Material Label Prefix: prefix for material barcode generated by the system. (such as E81-)

- Material Label Digit: the digit after the label prefix.

- Material Show Recent: at Material Labeling’page, select to show material report that was printed recently.

[Yes]:shows recent printing report at PTS Web – Material Labeling page.

[No]:does not show the recent printing report at PTS Web – Material Labeling page.

- Show Extra MPN Info: at 'Material Labeling' page, select to show the information which already defined at 'Manufacture Information' module. (Such as package/orientation).

[Yes]:needs show the information at Material Labeling page.

[No]:does not need to show the information at Material Labeling page.

- Next Inspection Date : Allow user to define whether or not to display the Next Inspection Date option at Material Labeling page.

[Yes]:displays the option at Material Labeling page.

[No]:does not need to display at Material Labeling page.

NOTE:If "Next Inspection Date =Yes", the date which user set at Material Labeling page must be greater than "Receiving day + Material Expire Day". Otherwise, the date which user set will be useless.

- MFG Length: used to define how many letters of manufacture P/N can be displayed on material label (e.g., for manufacture P/N "SIM-012STT87F": if setting is '3', it will only show 'SIM' SIMthe first three letters of manufacture P/N on material label).

- Material Expire Day: defines when material will expire.

NOTE:This parameter only works on 'Material Due Date' must be set to Yes.

- Material Show Inventory: select to show inventory and locator information at 'Material Labeling' page.

[Yes]:shows inventory and locator information at 'Material Labeling' page.

[No]:does not show inventory and locator at 'Material Labeling' page.

- Material Run Out: to control whether allow loading material, preparing material or scanning board while material quantity is zero. (It's a master switch.)

[Yes]:all workstations are not allowed to load material, prepare material or scan board while material quantity is zero.

[No]:do not control when material quantity is zero.

- Non-RoHS Alternative: if part number is same whether to use 'WL' material to replace normal material when normal material is short of.

[Yes]:allows using 'WL' to replace normal material.

[No]:does not allow using 'WL' to replace normal material.

CAUTION:

1) This function is only available for normal material.

2) This function is only available for those plants already implementing RoHS prefix standard.

3) Before activating this function, a plant must make sure all material PN didn't start with WL or LF for normal material.

4) RoHS material could not be replaced with other material.

- MFG Date: used to control whether to show MFG date on label.

[Yes]:shows MFG date on label.

[No]:does not show MFG date on label.

- Request Material: send the request material information to IRMS.

[Yes]:shows Request Material option at Load Material page.

[No]:(default value) does not show Request Material option.

- The following two values are used by plant administrator to pre-define tolerance range for confirmation material qty in order to prevent inputting the wrong qty. They will influence on Pocket PC and PTSWeb – Confirm High-Value Qty module and Load Material module.

» High-Value Tolerance >(%): remaining qty minus input qty < remaining qty multiplied by (%). The lower limitation for high value remaining qty.

» High-Value Tolerance>(%): input qty minus remaining qty < remaining qty multiplied by (%). The upper limitation for high value remaining qty.

- Track all Components: whether to track all components.

[Yes]:(default value) tracks all components.

[No]:tracks selected components as user set in PN Extra Info module.

- Material Label Quantity Control: controls quantity of printed label.

This parameter will affect Material Labeling, Print Sub-Label and Reprint Material Label module.

[Yes]:(default value) the label is not printed over the defined quantity.

[No]:system does not limit printed quantity.

- Lead Free Transfer Control: used to define whether can transfer lead free material to leaded material at Split /Transfer Material module.

[Yes]:(default value) system does not allow transferring.

[No]:lead-free material can transfer to leaded material.

- Show Vendor Code: used to control the display of "Vendor Code" in PTS material label printing modules:

[Yes]:displays Vendor Code in material label printing module. [No]:(default value) system does not display Vendor Code in material label printing module.

- Material Extra Option: used to set the values (drop-down list ) for the field ACCEPT PROPERTY at the page Material labeling. The default value is ""ACCEPT PROPERTY:", "ACCEPTED", "REJECTED", "UAI", "STS"".

- Allow Material Queue: allows material queue when material is running out or was empty. This parameter will affect SMT and AI workstation when loading material. (For additional information, please review Load Material page.)

[Yes]:(default value) allows material queue for SMT and AI workstation. The two option Material Queue Max Reels and Material Queue Max will works only when Allow Material Queue is Yes.

[No]:does not allow to Material queue function

- Material Queue Max Reels: sets the max reels (material lists) that can be jointed for the material queue function.

- Material Queue Max Boards: sets the max boards that can be scanned using the jointed material (material lists) for the material queue function.

MSD Control

- Plant Humidity: calculates the MSD material floor life. Can define humidity default value for Customize Bake Time module.

- Plant Temperature: calculates the MSD material floor life. Can define temperature default value for Customize Bake Time module.

- MSD Expire Stop: select to prepare/load material or scan board for expired MSD material.

[Yes]:will not prepare/load material or scan board when MSD material has expired.

[No] :prepare/loads material or scan board normally.

- Bake Time Control: selects to load material when the material is in baking.

[Yes]:loads material after baking time ends.

[No]:loads material within baking time.

- Thaw Time: defines solder paste thaw time.

- Max Open Times: defines solder paste max open times.

- Solder On Board Time: define solder paste on board time. (Unit is second.)

- Solder On Board: selects to control solder paste on board time.

[Yes]:controls solder paste on board time. [No]:does not control solder paste on board time.

- High Value Level: used to customize whether MSD is high value material (e.g., if inputting "4" in this field, MSD material will be regarded as high value material when MSD material level is or greater than 4).

NOTE:

- 1) High value material can define at System Setting page or manually set at ezPicklist.

- 2) System - Defines MSD level at system setting page, system will automatically recognize that MSD level or higher as high value material.

- 3) Manual - manually defines high value material in the Picklist whether material is MSD or not.

Email information

- Send Email From: sender's email address.

- Email SMTP: email server, every plant has its own email server

- Send Email To: send e-mail to a primary recipient.

- Send Email CC: send e-mail to a secondary recipient.

NOTE:

These email settings only have an effect on load material error. Max 200 characters per field.

Orientation and Thickness Control

- Loading not permitted when fail: select to control material loading when orientation and thickness are unmatched.

[Yes]:does not allow loading material.

[No]:allows loading material.

- Thickness Upper Error: maximum acceptable limit if thickness value of target material is larger than the one in ezPicklist.

- Thickness Lower Error: maximum acceptable limit if thickness value of target material is smaller than the one in ezPicklist.

- Ori Pic & Check (Pre/Cur Comp): select to show the orientation picture for required material when loading material.

[No]:(default value) does not show the orientation picture.

[Yes]:shows the orientation picture if the picture already saved into a specified folder.

- Orientation Check: selects to check the component’s orientation with that in ezPicklist.

[Yes]:needs to verify orientation .

[No]:does not need to verify orientation.

- Thickness Check: whether to check the component's thickness with that in ezPicklist.

[Yes]:needs to verify thickness.

[No]:does not need to verify thickness.

- Auto Rotate Picture: selects to allow to rotate picture with component's Orientation in Manufacture information.

[Yes]:allows auto-rotatation of picture to the orientation defined in Manufacture information.

[No]:does not allow auto-rotation of picture.

NOTE: the default orientation of the uploaded picture is 0.

Workstation WIP Control

- Workstation WIP: select to calculate all loading materials' quantity by scanning board.

[True]:calculates remaining quantity of loading material.

[False]:does not calculate remaining quantity of loading material.

Deviation Note

- Deviation Note Control: select to allow modifying DN in online status.

[True]:does not allow DN modification while production line has online status.

[False]:allows modifying DN while production line has online status.

RTV Control

- RTV Control: select to start RTV control.

[True]:RTV.connects

[False]:no need to control.

- RTV Connect Timeout: timeout for RTV connecting RTV service.

- RTV Connect Port: RTV service port.

IC Marking

- IC Marking Setup: select to load material when IC Marking is unmatched. This parameter will influence on Pocket PC and PTSWeb – Prepare or Load Material module

[Yes]:IC Marking must be right when loading material.

[No]:IC Marking will not be verified when loading material.

Machine Models

- Machine Models: defines machine types in SMT Machine module supported by ezPicklist.

- Combine XML and PGO: select to get data from XML and PGO file.

[Yes]:acquires data from XML and PGO file to compose ezPicklist

[No]:does not use this function.

NOTE:

- The plant should have XML and PGO file format.

Others

- Workstation Setup Reset: select to reset "Check P/N in Picklist" value to Yes for all workstations when production line turning off.

[Yes]:resets value to yes when production line turning off.

[No]:does not make any change.

- Jig Control: select system verification of Jig Barcode for required workstation/product.

[No]:(default option) Jig Barcode will not be verified when system scans board.

[Yes]:required workstations will be verified Jig Barcode when system scans board. This parameter will affect Scan Board Barcode module.

- Check P/N In Picklist: used to check P/N consistency between Picklist and BOM for all workstations when system compares Picklist with BOM.

[Yes]:(default value) checks consistency between Picklist P/N and BOM P/N.

[No]:no need to check Picklist P/N and BOM P/N consistency.

- Show Picklist Period: used to define how many picklists are displayed under Production Setup ---

Defines Picklist page as per time duration (in days). The default value is 30 days, which means the system will only display picklists of last 30 days. This ensures that the end-users are always presented the latest picklists and reduce the potential of using outdated picklists.

- Compare Shop Order with WO: Compares the SFDC Shop Order with the PTS Work Order for the SFDC-PTS integration scanning.

[Yes]:compares the Shop Order with the WO.

[No]:does not compare the Shop Order with the WO.

- MES Shop Floor: sets the MES Shop Floor that will use the function location mapping for workstation setup.

- FUJI VERIFY CONNECTION STRING: defines the connection string for FUJI Verify application.

- FUJI TRAX CONNECTION STRING: defines the connection string for FUJI TRAX application.

- FUJI PROFILER CONNECTION STRING: defines the connection string for FUJI Profiler application.

- Feeder Full Maintenance Period: defines the period that to rework/maintenance all feeders.

- Allow Leak Scanning Board: This option to define allow to leak scan board or not at the production scanning process.

[Yes]: Allow leak scan board.

[No]: Do not allow a leak scan board.

Please see how to Leak scan for detailed information.

- Loading List Nozzle Template: define the EZpicklist Loading list template file with Nozzle or not.

[Yes]: EZpicklist Loading list template file with Nozzle

[No]: EZpicklist Loading list template file don’t with Nozzle

- Max BOM Export Variant: this option fo define the max BOM variant for BOM Export function. It allows numbers.

Regulation Control

- Material Barcode Regulation: defines a regular expression for load material.

NOTE: regulation must be right when user loads material if user defines the material regulation.

Email Address about Support Team

This is to configure the email addresses of the support team so they are well informed of PTS exceptions to perform immediate recovery.

- Field IT Email: input email address of the person in field IT team who is responsible for PTS.

- Regional IT Email: input email address of the person in regional IT team who is responsible for PTS.

- Corporate IT Email: input email address of the person in corporate IT team who is responsible for PTS.

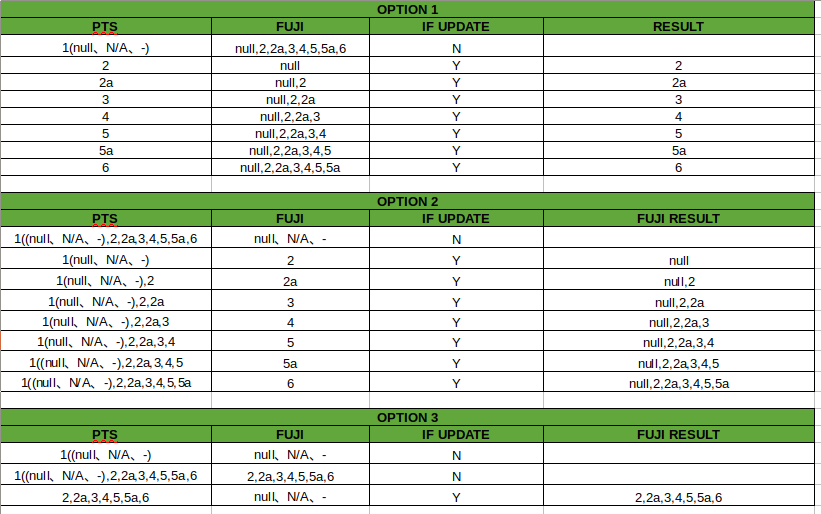

Fujitral Control

- MSD Level Update Rule: This option defines the rule how to set the MSD level of the materials when syn PTS material information into Fuji Database.Users can input 1,2 or 3 for this field, default by 1.

“MSD Level Update Rule”, with option 1,2,3

1: High overwrite Low

2: Low overwrite High

3: Only Update NA MSD Level

Option 1:

If the PTS real MSD level is higher than the Fuji PN MSD level, then overwrite the Fuji PN MSL value.

If the PTS real MSD level is lower than the Fuji PN MSD level, then do not overwrite the Fuji PN MSL value.

Option 2:

If the PTS reel MSD level is higher than the Fuji PN MSD Level, then do not overwrite the Fuji PN MSL value.

If the PTS reel MSD Level is lower than the Fuji PN MSD Level, then overwrite the Fuji PN MSL value.

Option 3:

If the Fuji PN MSL value is none, then insert the PTS reel MSL value into the Fuji PN MSL field.

If the Fuji PN MSL value is not none, then do not overwrite the Fuji PN MSL value.

Note:When option changed, only affect the sync data of next time. The data in processing will use the previous option.If the option is wrong, but some data already been updated, we can't revert database.If the plant don't want to use option 1 as default, need add record at pts database first and change option before deploying new version.

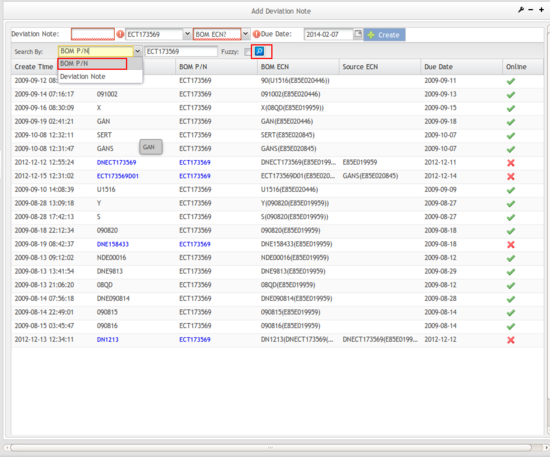

Add Deviation Note

This module is designed to change/update BOM material in case an alternative part is needed. To distinguish the original BOM from the updated one, thus a deviation note is added.

1. To access the Add Deviation Note page, navigate to Administration>PTS (traceability) Administrator>Add Deviation Note.

Figure 5: Add Deviation Note

1. Under Add Deviation Note: Enter a reference number to identify such deviation. Example: (Modify/Temporally) Customer Change Notification (CCN) number or Engineering Change Notification (ECN). Please discuss with your Plant Quality Manager to confirm what deviation note format to be used if required.

2. Under BOM P/N: Enter the BOM Part Number, which requires updating the material part number and/or reference designator.

3. Under BOM ECN: Enter the existing BOM ECN in PTS for this deviation change. When entering BOM P/N, the BOM ECN will show automatically. If there is no BOM ECN, an alert message is displayed.

4. Under Due Date: Select the expiry date of this deviation BOM ECN.

5. Select Create after finished all above steps.

Search Deviation Note

Figure 6: Search Deviation Note

1. Select Search By: BOM P/N or Deviation Note, input the P/N, then click Search. The result is displayed.

2. At the report list, if the BOM ECN is online, only it displays. Otherwise, the font will be blue and it cannot be edited.

3. Click on the Bom Part Number (not online, in blue font) which is required to change the alternative 42Q Part Number material part number and/or associated reference designator. Open the sub-page.

Figure 7: Show BOM Item

Add P/N

Figure 8: Add BOM Item

1. Select Add P/N button to open the Add BOM Item page.

2. Input the Usage, Level,Sequence,Part Number, and Designator; then select Add.

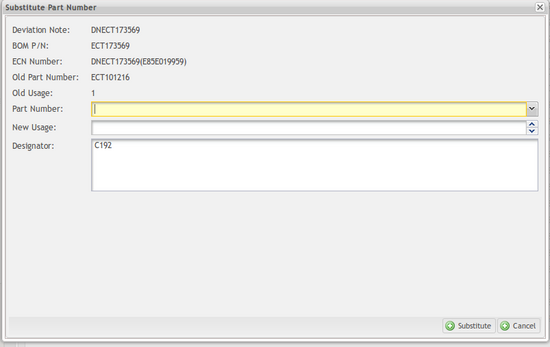

Substitute P/N

1. Select the left checkbox at the show BOM item page, and then select Substitute P/N.

2. Select Substitute P/N to open the Substitute Part Number page.

3. Input the Part Number, New Usage, and select Substitute.

Figure 9: Substitute P/N

Delete Designator

1. Select the left checkbox at the show BOM item page, and then select Del Designator.

2. Select Del Designator to open the Delete BOM Item page.

3. Select the checkbox, then click button Del Designator to delete a designator.

Figure 10: Delete Designator

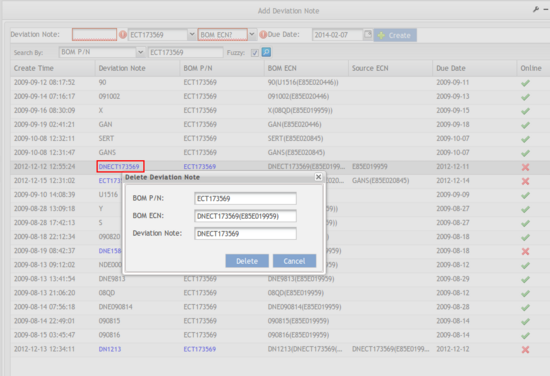

Remove Deviation Note

Figure 11: Remove Deviation Note

1. Select the desired Deviation Note (Not online, in blue font) to be deleted. Open the sub-page.

2. Confirm the deletion by selecting Delete.

Error message Maintenance

Error Message Maintenance is a module under PTS web where users can customize the error content for different platforms, display color, and define whether or not an alert email should be triggered when such an error occurs.

1. To access the Error Message Maintenance page, navigate to Administration>PTS (traceability) Administrator>Error Message Maintenance.

Figure 12: Error Message Maintenance

A list of all PTS error messages will display. The user can scroll down to view or input key words in Error Content textbox to search error messages. Select one error message and click on the Error Description column.

The following screen will display:

Figure 13: Update Error Message Detail

- Error Code: The code of selected error. Display only.

- Error Description: The default error Description of selected error. Display only.

- Web Message: The error description to be displayed on PTS Web when the selected error occurs as per whatever user input in this textbox.

- PPC Message: The error description to be displayed in PPC when the selected error occurs as per whatever user input in this textbox.

- NetDC Message: The error description to be displayed on NetDC when the selected error occurs as per whatever user input in this textbox.

- Display Color: Allow user to define the font color of the error message displayed when the error occurs. Select from the drop-down list. Default in red.

- Send Alert Mail: Defines whether or not for the system to send alert emails when the selected error occurs. Select Yes or No.

- Stop Machine: Defines whether or not for the machine to stop when the selected error occurs. Select Yes or No.

- Send: Saves the configuration.

- Cancel: Goes back to previous window without saving the configuration.

NOTE: The error message can be customized to both English and Chinese.

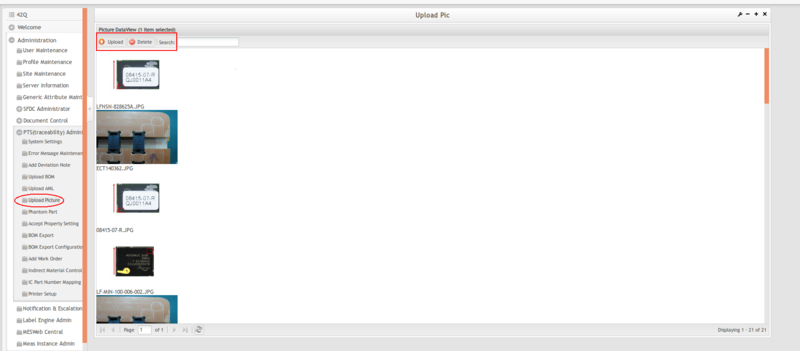

Upload Picture

Upload Picture is a module that allows the user to upload pictures about the orientation named by the Part Number. The images must be in JPG format.

Following is the sample to show/control the Orientation picture in production:

- User needs to configure the Orientation setting (Orientation And Thickness Control) at the PTS System Setting.

- Upload the component image via the Upload Picture GUI.

- The system will display the pre-defined component picture at the load material or PPC GUI during the load material process, so that the operator will refer to the pre-defined component picture to place the component at the SMT with the proper direction.

Importmant Note: The picture must be named in this format: XXX.jpg (XXX=Part Number, which matched with the Part Number in production picklist).

1. To access the Upload Picture page, navigate to Administration>PTS Administration>Upload Picture.

Figure 14: Upload Image

- Select Upload to open the upload sub-page.

- Click the Select button to open the resource folder to select the picture file, and then click the Upload button.

- Select Delete to delete the picture.

NOTE:

- The uploaded picture file name cannot contain Chinese.

- The picture file size cannot be over 3M.

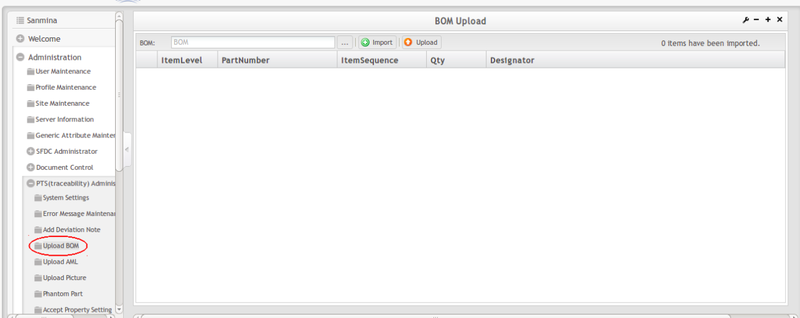

Upload BOM

This function is used to upload BOM into the system. Before upload the BOM, the system read the BOM information from the BOM file(.csv) and show the detailed BOM items at the list. After check the items ,upload the BOM into the system.

1. To access the Upload Bom, navigate to Administration > PTS (traceability) Administrator > Upload BOM.

Figure : Upload BOM main page

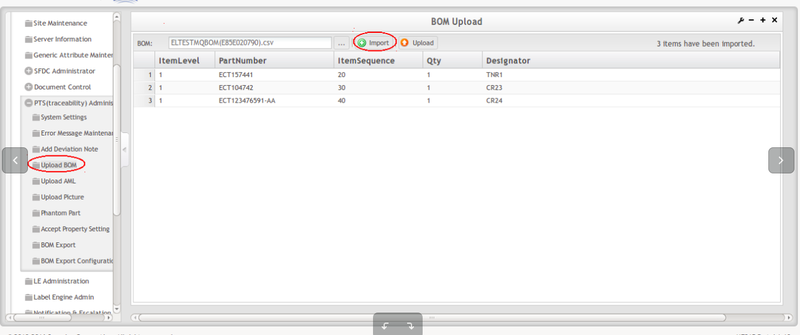

- Click the … ICON to select and open the Bom file, the file name will show at the text field.

Figure: Select the Bom csv file

- Click the Import button to show the detailed bom items at the list.

Figure: Import Bom file

The error message will show at the page If the Bom file is not valid.

Figure : Invalid Bom file format

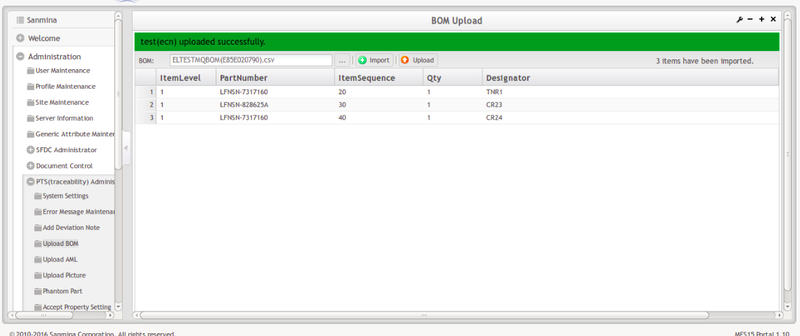

- Click the Upload button to upload the bom into the system.

Figure : Upload Bom

The error message will show if the PN not existed in PTS Database.

Figure: Bom items not exist in PTS

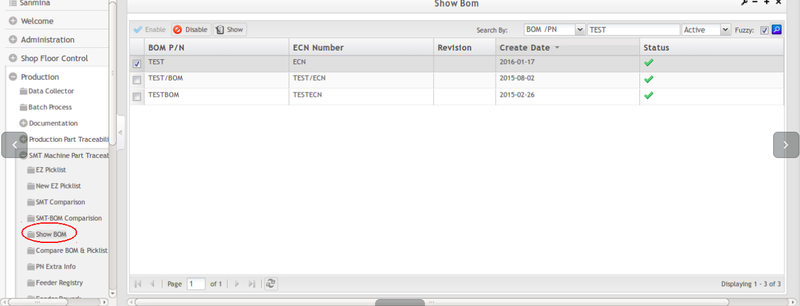

User can check the uploaded bom from the Show Bom module.

Figure : Show Bom

Note:

Only the .csv file format is supported. Cannot upload the BOM when it is in used.

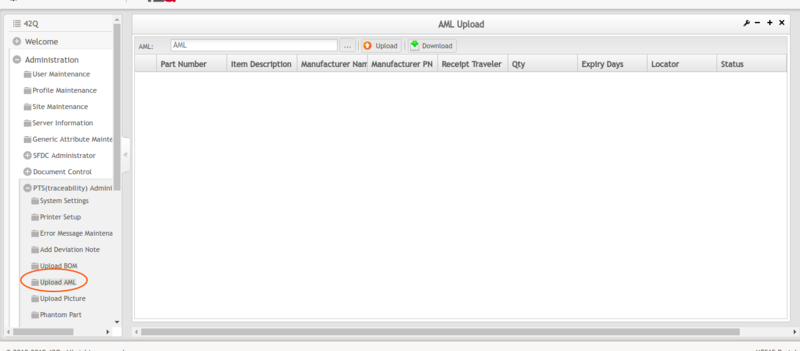

Upload AML

Upload AML module allow users to upload the AML information from csv file, also provides the template download function to let users to download the csv file template.

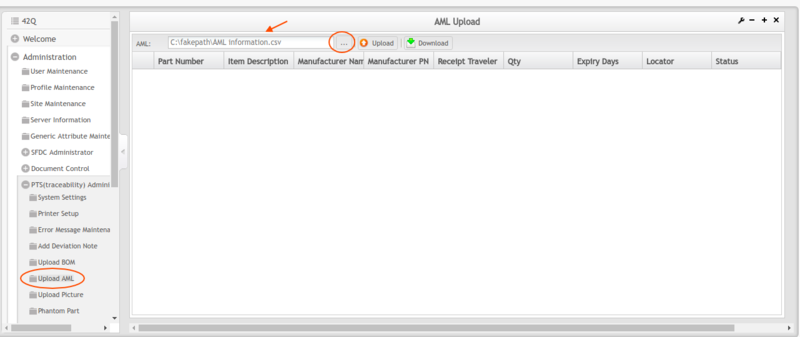

Navigator to Administrator > PTS Administrator > Upload AML.

Figure : Upload AML main page

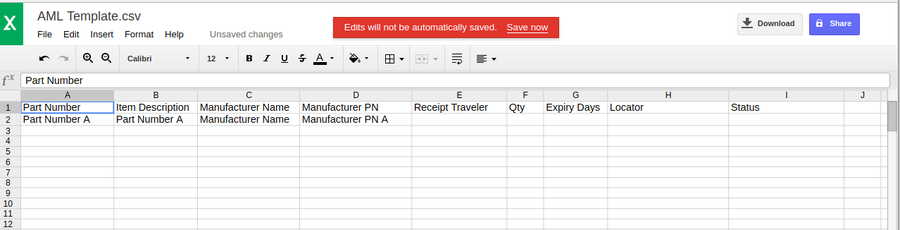

Download the AML template file

- Select the Download at the top menu, to open the AML Template.csv file.

Figure: Download AML template csv file.

The detailed description of the columns for the AML template file as following:

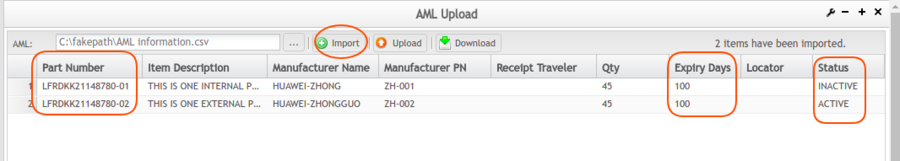

- Part Number: This is the Part Number of material to identify material. This column is mandatory.

- Item Description: The description of the Part Number to make clear to the user. This column is mandatory.

- Manufacture Name: This is the Name for of Manufacturer .This column is mandatory.

- Manufacturer PN: The Part Number of the manufacturer .This column is mandatory.

- Receipt Traveler: The receipt traveler number for the received materials provided by the warehouse staff.This column is mandatory.

- Qty: The quantity of received material.

- Expiry Days: The days that how soon the manufacture will be expired. If the user leave this column as empty, it treas as this manufacture will not expired for ever.

- Locator: The address of the material's manufacturer.

- Status: This column is used to verify the status of the status of the manufacturer, the value is Active/Inactive. if the user leave the status column as empty, it will be treat as the Active by default.

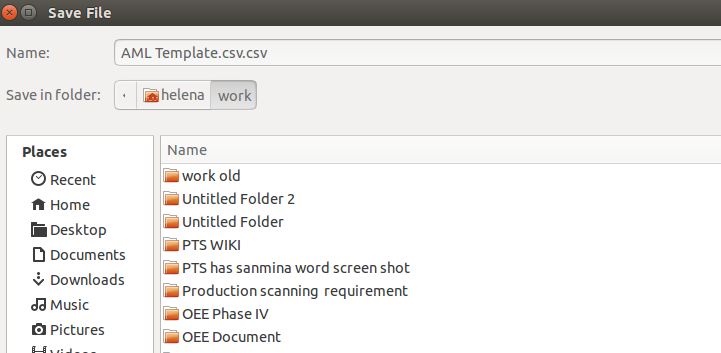

- Click Download to download the AML template csv file to local disk, or click Share to save as google sheet .

Figure : Save AML template file to local

Figure : Save AML template file to Google Driver

Upload AML

- Select the …Icon at the man page to open the prepared AML information csv file.

Figure: Select AML file

- Click the Import button, then the detailed AML information display in the list.

Figure: Import AML file

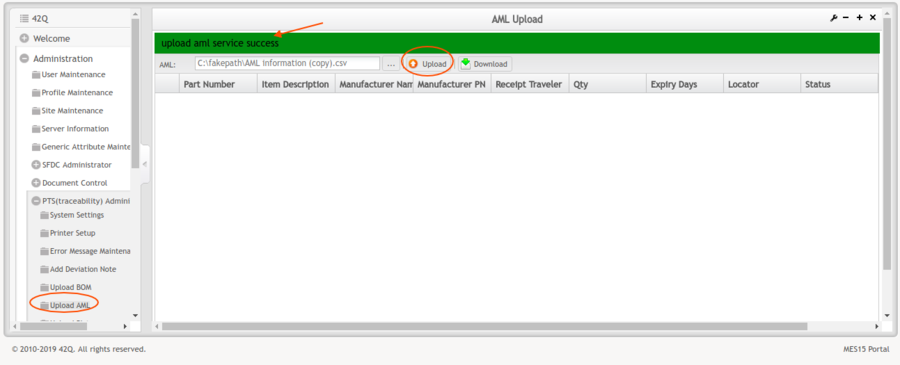

- Click the Upload button, all the AML information will upload into PTS portal DB successfully.

Note: If the AML has existed, system will overwrite the old data with the new AML information in csv file.

Figure : Upload AML Succeed

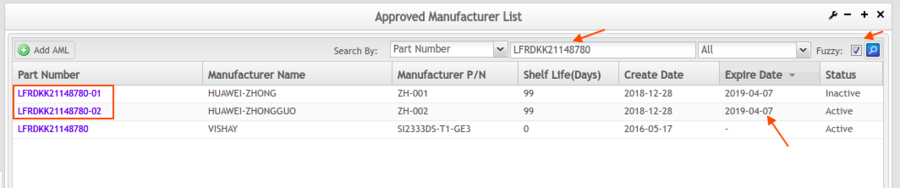

- User can check the upload results at the Approved Manufacturer list module(This step is optional).

Figure: Upload AML results

Phantom Part

Accept Prompt Settings

Users can set the Accept Prompt Settings(for example :Reject,Accepted) for the material.

This Setting is used at theIncoming > material labeling module for Accept Property drop-down list (see figure below).

Figure: Accept Property Drop-down list

- Navigator to Administrator > PTS Administrator > Accept Prompt Settings.

Figure: Accept Prompt Setting Main page

- Select Add

Figure: Add a new Accept Property Setting

- Enter the Accept Property Name, Allow Load Component, Status

- Accept Property Name: The name of accept property, this name will show at the Accept Property drop-down list for material labeling page.

- Allow Load Component: To define the system allow to load the material or not at the load material module if the material is set this Accept property.

Yes: Allow to load this material.

No: Not allow to load this material.

For example: some plants set the Accept property name to Rejected, set the Allow Load Component to Yes, print one label: E76-M001 selecting the Accept Property drop-down list to Rejected, material barcode:E76-M001 can be loaded at the load material module.

For some reason, One plant set the Accept property Rejected(Name),Allow Load Component to No, then print another label: E76-M002. material barcode:E76-M002 can not be loaded at the load material module.

- Status: To set the status(Enabled/disabled) of the Accept property setting. If this setting is Enabled, it will show at the Accept Property drop-down list, if is disabled, will not show at the Accept Property drop-down list.

- Select Save to create a new Accept Property for the material.

- Or double click on the selected Accept Property name, change the fields, select Save to edit the Accept Property setting.

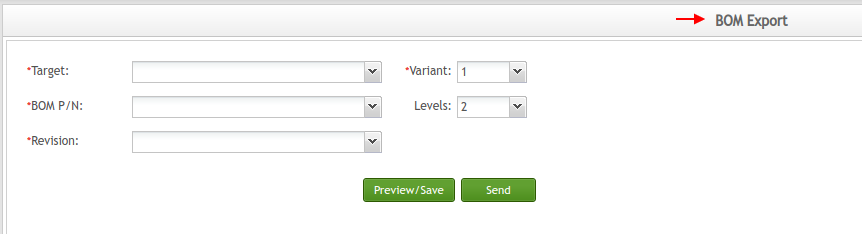

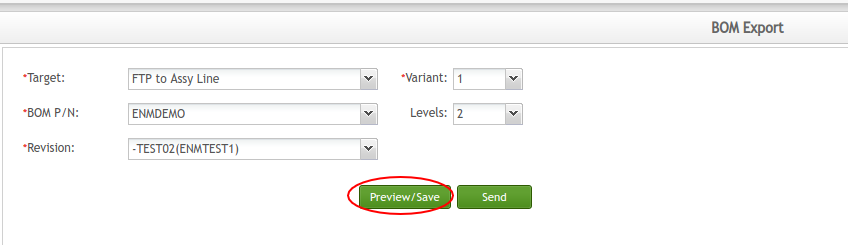

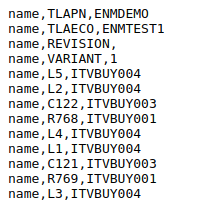

BOM Export

Users can export a special BOM to target PC and folder with this function BOM Export.

At the main page, users select the Target ,BOM P/N,Revision, Variant, and levels, click Sent to export the BOM to the target.

Figure: Bom Export Main Page

Target: Select the target where to export the BOM. Target is defined at the BOM Export Configuration function.

BOM P/N: Input the BOM P/N. The P/N at the BOM.

Revision: Select the revision of the BOM, when users input the BOM P/N, the revision will display automatically.

Variant: The range of the variant is defined at the system setting.

Levels: Input the levels of the BOM P/N.

Figure: Preview BOM Export

ClickPreview/Save, users can preview the exported bom, see Figure below.

Figure: Bom Export Preview File

Click Send to export the BOM file to the target( IP:port/folder).

BOM Export Configuration

Users can set the configurations for BOM exporting at theBOM Export Configuration function.

Figure : BOM Export Configuration Main page

Create Target

Click Create , input the datas at the text fields accordingly , then click Save to create a new target list.

Default Filter P/N:

Default Level:

Target Name: The only

IP:

Port:

Folder:

Login Name:

Password:

Copy Target

Users can create a new target fast with the copy target function.

Select one existing target, then click Copy, one copied target will appear at the list. Change some fields accordingly, click Save. One new target created successfully.

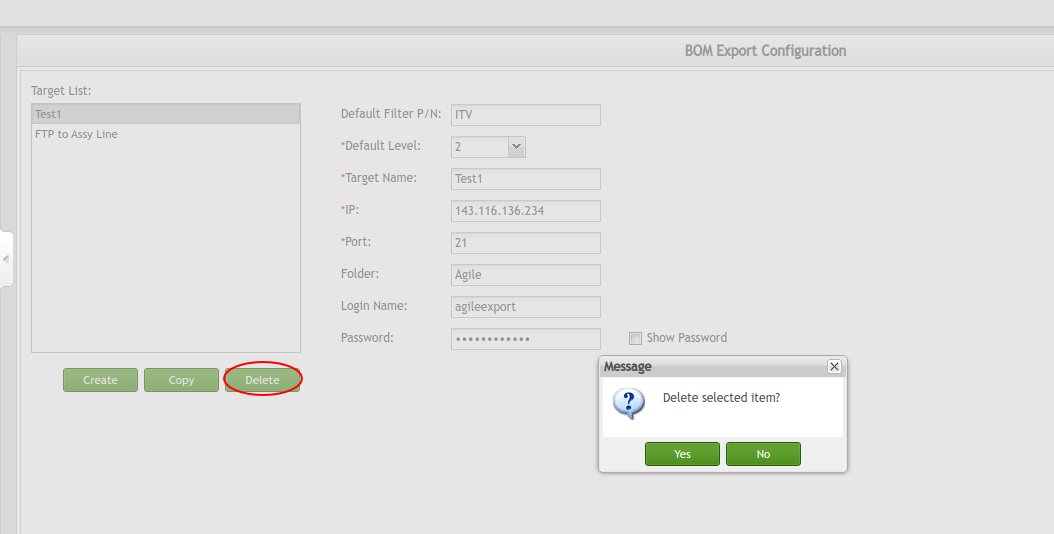

Delete Target

Users can delete a target list.

Select one target from the list, click Delete, select Yes at the pop-up message box to delete the target.

Figure: Delete Target List

Add Work Order

Indirect Material Control

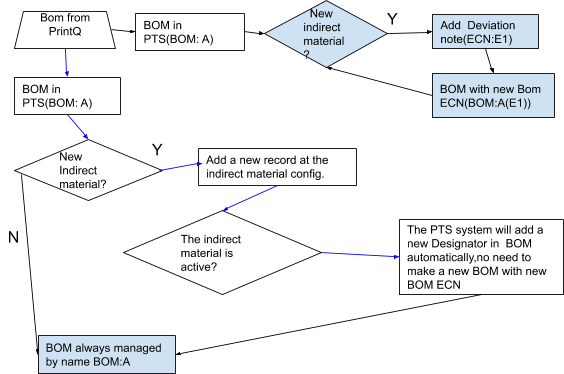

Background

In certain plants, indirect material is not managed in Oracle BOM. In order to track indirect material, engineers must add those indirect material into the BOM through Deviation Note in PTS. This procedure is repeated after publishing each new version BOM ECN. The plants believe this process is not convenient and too time consuming.

Design Proposal

Indirect material config modules allow users to add/delete the indirect material information with effective date and expiration date. The system will check if the indirect material is active or not ,then add or remove the indirect material information into/from the BOM automatically, eliminating the need to create one BOM ECN. After the indirect materials added into PTS BOM, them can be tracked by PTS system as direct materials.

Figure : Solution for Indirect material

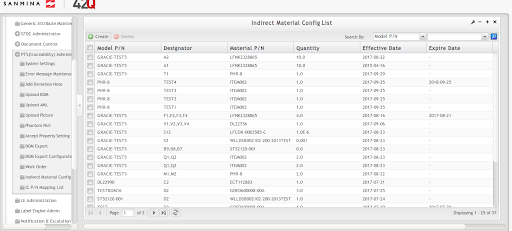

Indirect Material Control

- Go to: PTS Administration > Indirect Material Configuration.

Figure: Indirect Material Config list main page.

In Indirect Material Config portlet , users may create a new indirect material config and delete an existing indirect material config.

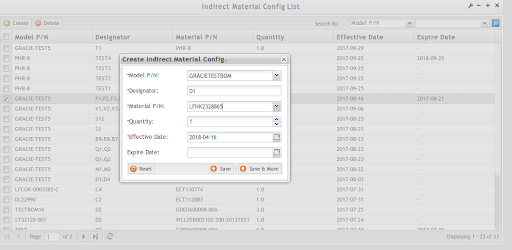

- Select Create to open the Create Indirect Material Config page.

Figure: Create Indirect Material Config.

- Model P/N: Production Part Number.The Model P/N cannot be blank, and must be preconfigured in PTS System.

- Designator: Define the Designator/station where the indirect material will be loaded.

- Material P/N: The material Part Number for the indirect material.

- Quantity: The quantity of the received indirect material, the default value is 1.

- Effective Date: The effective date that to Syn this indirect material to PTS bom,Default is current date.

- Expire Date: The expiration date of the indirect material. If the expiration date earlier than the Date that PrintQ to Syn Bom into PTS process, the indirect material cannot be added to the BOM.

- Reset: To clear the fields to blank.

- Save: Fill in all the requested values, Click Save button to submit the indirect material information to the PTS system. The Create Indirect Material Config page will close.

- Save & More: Fill in all the requested values, Click Save button to submit the first set of indirect material information to the PTS system. The page remains open and all fields in the page will be cleared to blank. Users may now add another indirect material config.

Note: The related field verification when submitting is similar to the previous functional interface. The default for Quantity is 1, for Effective Date the current system date, while the Expire Date may be left empty, i.e. processing is not controlled by Expire Date.

The Indirect material config can’t be duplicated.

Following is the rules to verify if indirect material is active or inactive.

- BOM without related Indirect Material Config, it shouldn't add any Indirect Material P/N to it;

- BOM time < Indirect Material Config Effective time, it shouldn't add the Indirect Material P/N;

- BOM time > Indirect Material Config Expire time, it shouldn't add the Indirect Material P/N;

- BOM time >= Indirect Material Config Effective time & Expire Date is null, it should add the Indirect Material P/N to the PTS BOM;

- Indirect Material Config Effective time <= BOM time < Expire Date, it should add the Indirect Material P/N to PTS BOM;

Note: BOM time= The time that PrintQ interface to Syn Bom information from ERP to PTS database.

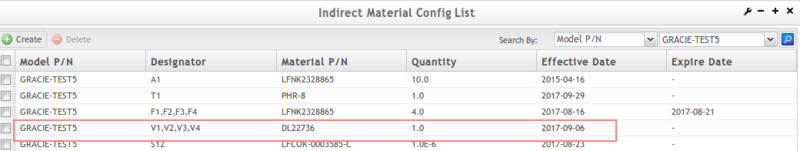

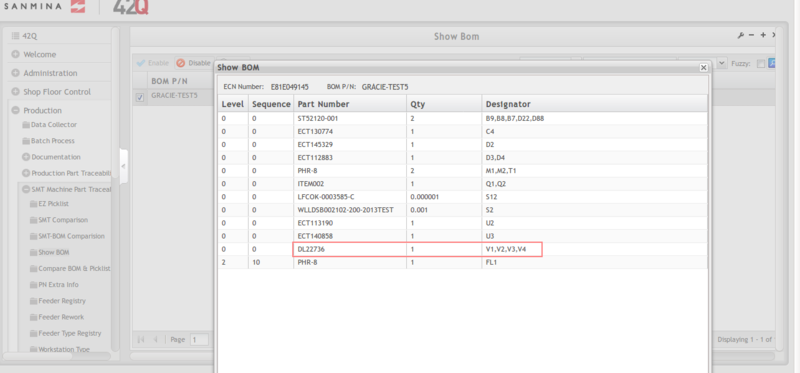

For example: The following indirect material information is already configured and active. Once approved, the information will be automatically added into BOM by PTS system .

Users can then track the indirect material normally at the load material process.

The Model P/N: GRACIE-TEST5

Designator: V1,V2,V3,V4

Material P/N: DL22736

Quantity :1

Figure: Indirect Material Example

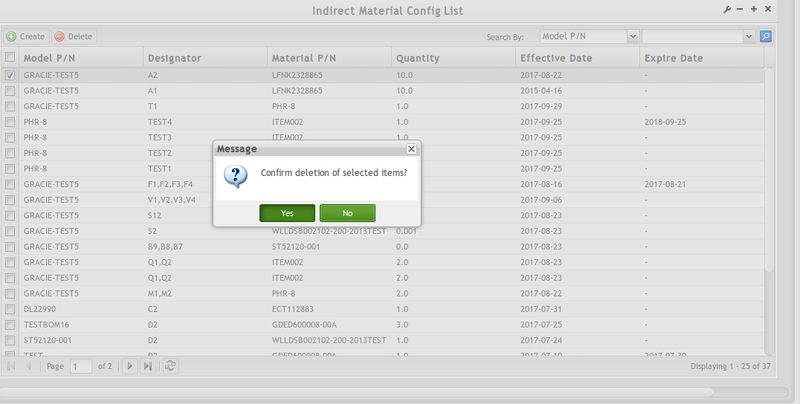

Delete Indirect Material Config

- Tick the indirect material config you wish to delete from the list, then select Delete.

- System displays a confirmation message to confirm the deletion. Click Yes to delete the indirect material config or No to cancel the operation.

Figure: Delete Material Config

IC Part Number Mapping

At some plants, a certain number of ICs require programming prior to surface mounting. For the same IC, some product models require the programming to be burned before mounting, while others require programming after mounting. The ICs have different Sanmina P/Ns before and after programming (Before programming - P/N:A, with IQC PASSED label; after programming - new P/N:B, without IQC PASSED label as plant don't print new label after programmed the IC,operator manually writes the new part number on the existing IQC label). This means that the same IC would exhibit two different statuses during WIP, while the IQC PASSED labels would remain the same. During SMT loading, PTS cannot recognize whether or not the material has been programmed. In the case that the incorrect material is loaded (e.g. if unprogrammed material is loaded instead of the expected programmed material), it would cause a bulk rework. Therefore, PTS must be equipped with setup recognition and binding functions (differing P/N pre- and post-programming), enabling PTS to automatically report an error when a loading error occurs.

IC Part Number Mapping is used to make a connection for the Part Number between the Raw IC Part number(before programming) and the Programmed IC part number.

- Navigator to Administration > PTS(traceability) Administration > IC Part Number Mapping.

Figure : IC Part Number Mapping Main Page

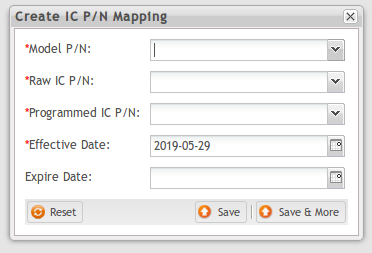

- Select Create to add a new mapping.

Figure : Create a New IC P/N mapping

- Model P/N: The Production Part Number.

- Raw IC P/N: The Raw Part number for the IC, it’s always printer by the warehouse which save into the Oracle ERP system.

- Programmed IC P/N: The Part Number after programming process for the IC.

- Effective Date: The effective date for the PrintQ to sync this Programmed IC P/N into PTS Database. Set current date by default.

- Expire Date: The expire date for the PrintQ to sync this Programmed IC P/N into PTS Database.

- Input the fields , select Save to add a new mapping.

- Or select Save & More to save the mapping and clear all fields to add more mappings.

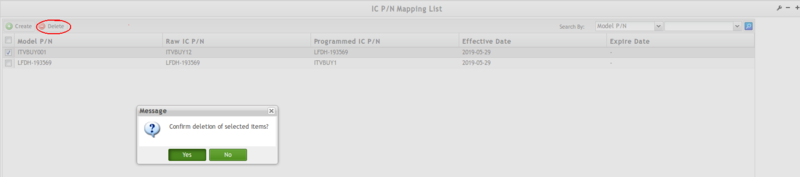

- Select one existing mapping and click Delete to remove the mapping.

Figure: Delete IC P/N Mapping

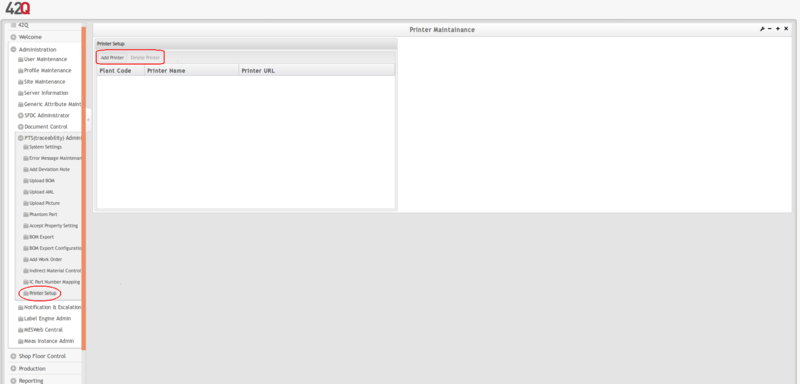

Printer Setup

This Module is to manage the Printer, user can add or delete Printer.

- Navigator to Administration > PTS(traceability) Administration > Printer Setup.

Finger : Printer Setup Main page

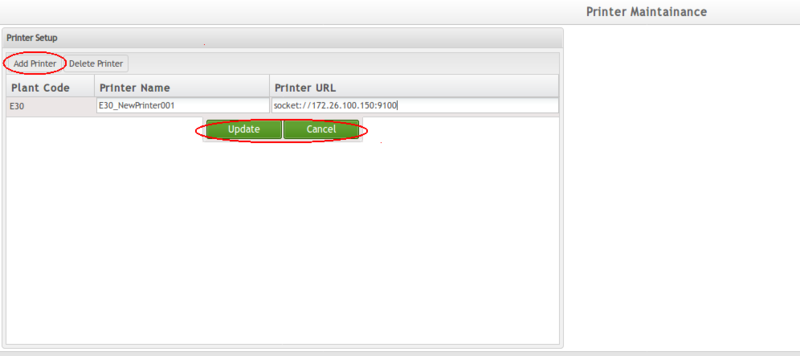

- Select Add Printer to add a new printer.

Figure: Add Printer

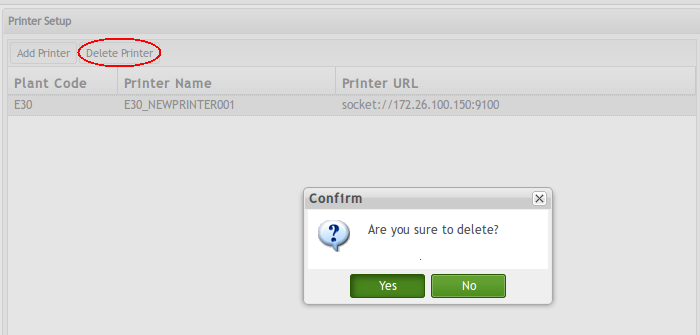

- Select Delete Printer to delete an existing printer.

Figure: Delete Printer

Document Revision History

| Date | Author | Title | Version | Change Reference | Approved by |

|---|---|---|---|---|---|

| 07/02/14 | Helena Wang | Information Systems Engineer | 1.0 | First Version | |

| 25/02/14 | Ashley Martin | Technical Writer | 1.0 | Review/format | |

| 27/02/14 | Elaine Fonaro | Technical Writer | 1.0 | Format for WIKI | |

| 04/28/16 | Elaine Fonaro | Technical Writer | 1.0 | Converted to 42Q | |

| 08/04/16 | Molly Kitts | Technical Writer | 1.0 | Converted to Google Doc | |

| 10/11/16 | Benjamin Ca | Technical Writer | 1.0 | Minor Revision | |

| 05/29/19 | Helena Wang | Technical Writer | 1.0 | Add Section Indirect Material Control, IC Part Number Mapping and Printer Setup | |

| 01/23/2020 | Marisol Vargas | Technical Writer | 1.0 | Typo correction on System Settings Fuji | Juan Lopez |

| 03/13/2020 | Helena Wang | Technical Writer | 1.0 | Add MSD Level Update Rule at system setting section | |

| 4/1/2020 | Helena Wang | Technical Writer | 1.0 | Add Max BOM Export Variant, Allow Leak Scanning Board at the System setting. |