MES Fuji Configuration

Background

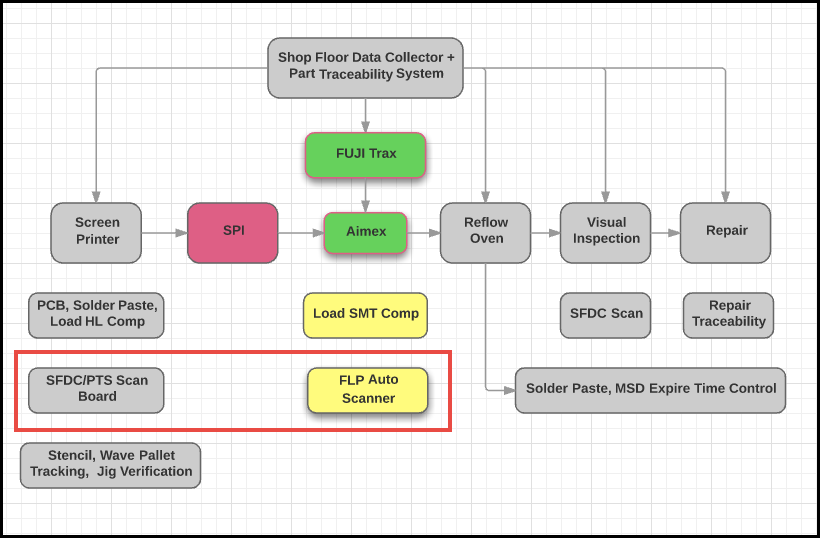

Per manufacturing industry best practice, a typical production line in 42Q’s MES uses one shop floor data locator per process as well as a logical work station configured for Advanced Traceability. Together, the tools allow the operator to enable board scanning after the screen printer but before the SMT (Surface Mount Technology) machine. By combining the robust technology of Fuji’s Pick and Place machine with Fujitrax vendor software, component placement can be accomplished. However, this solution has its own set of flaws. Currently, the Fuji line profiler does not read each board’s serials in Printed Circuit Boards (PCBs) containing multiple panels. The reader can only identify the first serial detected; the remaining serials are then autogenerated by Fujitrax (vendor software). Additionally, the automatically generated serials do not match consistently with the actual board serials. To track each board’s serials using Fujitrax, Fuji must request to link the panel, and each board within the panel, in order to avoid duplicated board scanning and linking efforts. UI is a new application that accomplishes the above tasks efficiently. By associating the panel with each child board, UI is able to submit each board’s serials to SFDC (Shop Floor Data Collector) and PTS (Parts Traceability System) simultaneously.

Figure 1: Fuji Production Line Sample: