SOP-42Q-MES0078 Kit Verify Layout

Cirrus > Shop Floor Control > Production Control > Kit Verify

This edition applies to MES15 Portal 1.0 and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

Introduction

Kit Verify is a tool that consolidates and validates all of the components in a Kit. A kit is provided to the Shop Floor by a warehouse in place of a shop order. Kit Verify allows users to verify that there are no missing components in a kit.

Kit Verify assists users in choosing the correct Shop Order that belongs to a certain Serial Number (product), separates Part Numbers that are serialized and that are not serialized (parts or components acquired of vendors), shows the components quantity that should be used, adds new Serial Numbers in the MES database, and prints Traveler Reports with the shop orders’ information. It also allows the user to add components to serial numbers attached to Shop Orders, replace components with defects, and modify changes in the database (Repair).

Kit Verify provides controlled communication integrated to SFDC (traceability software of product in the shop floor). This allows operational functionality rather than simply providing information configuration and registration. By Integrating to SFDC, Kit Verify allows the moving of units (orders) of a station for other through commands made available by the SFDC application interface.

Kit Verify consists of the following modules in the MES portal:

- KV Layout Configuration - responsible for the mapping of components by reference designators to layouts.

- KV Control- responsible for consolidation, integration, inspection, and repair of the kit.

KV Layout Configuration

KV Layout Configuration allows users to map Shop Order components by reference designators to assembly layouts. In the KV Layout Config portlet, users can add, edit, or copy an assembly layout.

To access KV Layout Config, navigate to Shop Floor Control > Configuration > KV Laytout Config.

All available Layout Configurations are listed by Part Number, Project, and Model.

Figure 1: KV Layout Config

File:SOP-5-I-MES0078-C KV-Layout-Config.jpg

Filter

The user can filter the available layouts by Part Number, Project, Model, and/or Status.

1. To filter the layout list, enter the Part Number, Project, and/or Model and/or choose the Status and then select Filter.

2. The layout list will display the layouts according to the user’s entries:

Figure 2: Filter

File:SOP-5-I-MES0078-C Filter.jpg

NOTE: To begin a new search, select Clear to empty the fields and re-enter information into the available fields.

Add

Users can add a layout configuration to map reference designators to components on an assembly item. This simplifies the assembly process by providing visual elements for operators to follow.

1. To add a layout configuration, select the Add icon located above the Part Number list.

Figure 3: Add Layout Configuration

File:SOP-5-I-MES0078-C Add-Layout-Configuration.jpg

2. The Layout Configuration portlet displays:

Figure 4: Layout Configuration

File:SOP-5-I-MES0078-C Layout-Configuration.jpg

3. Select the part number for a Shop Order that contains components with reference designators configured from the Part fuzzy search field.

NOTE: The Project and Model fields are optional, but assist in the description of the layout configuration.

4. After selecting the part number, select the add icon from the tab below the Part field to upload an assembly layout.

5. A Confirm pop-up displays. Select Yes to open the File Upload screen.

Figure 5: Upload Assembly Layout

File:SOP-5-I-MES0078-C Upload-Assembly-Layout.jpg

6. Select the assembly layout image file from the File Upload screen, and then select Open.

7. The image file displays in the first tab, and a subsequent tab is created to add multiple images if needed.

Figure 6: Assembly Layout

File:SOP-5-I-MES0078-C Assembly-Layout.jpg

8. Select a reference designator from the drop down box provided.

9. Select a mapping type from the options provided: Square,Circle,Freeform.

10. Map the reference designator to the appropriate component on the Assembly Layout.

11. Select the green check mark at the top right of the image to save the mapping.

Figure 7: Assembly Layout Mapping

File:SOP-5-I-MES0078-C Assembly-Layout-Mapping.jpg

12. Users can add multiple mappings by selecting additional reference designators from the Reference Designator drop down box.

Figure 8: Multiple Mappings Example

File:SOP-5-I-MES0078-C Multiple-Mapping-Example.jpg

13. Once all mappings are created, select Save.

14. To return to the KV Layout Config main page, select Close. The new Layout Configuration will be added to the list.

Edit

Users can edit any available layout configuration. While editing, users can add or remove Layout Assemblies and their mappings.

1. To edit a Layout Configuration, select the layout configuration and then select Edit from the KV Configuration main page.

Figure 9: Edit Layout Configuration

File:SOP-5-I-MES0078-C Edit-Layout-Configuration.jpg

2. The Layout Configuration portlet displays. The user can add or remove assembly layouts and mappings from this portlet.

3. To remove an assembly layout, select the "x" in the top right of the image tab.

4. To remove a mapping, select the mapping from the list and then select Remove.

5. Select Save to confirm the changes.

6. Select Close to return to the KV Configuration main screen.

Figure 10: Remove Layout or Mapping

File:SOP-5-I-MES0078-C Remove-Layout-or-Mapping.jpg

Copy

Users can copy Layout Configurations by adding a new Part Number, Project, and/or Model to an existing configuration.

1. To copy a Layout Configuration, select the configuration from the list and then select Copy.

2. The Copy Layout Mapping form displays:

Figure 11: Copy Layout Configuration

File:SOP-5-I-MES0078-C Copy-Layout-Configuration.jpg

3. Either change the Part Number or change/add the Project and Model, and then select Save.

4. The Layout Configuration will display and the user can make any necessary changes.

Obsolete

Multiple layouts can exist for a single part number with a unique project and model. When the Kit enters the Integration step in KV Control, all layouts for the part number will be listed. The user can only choose one layout per kit. To limit the number of layouts that are available for a given part number, the obsolete function can be used.

1. To obsolete a layout, select the Obsolete radio button at the top left of the Layout Configuration screen.

Figure 12: Obsolete

File:SOP-5-I-MES0078-C Obsolete.jpg

2. Select Save to obsolete the layout.

NOTE: If the layout is already attached to a kit in KV Control, it will still be available for use. The obsolete function only removes the layout from the list of available layouts for new kits entering the Integration step.

KV Control

KV Control allows users to consolidate, integrate, inspect, and repair kits. The KV Production module contains two separate portlets, Kit Browser and Kit Processing. Kit Browser allows the user to search for the correct Shop Order by Shop Order Number, Part Number, or Revision before performing any task in the Kit Processing portlet. Kit Processing allows the user to perform all kitting activities for a Shop Order.

Kit Browser

Kit Browser allows the user to view and search all available Shop Orders in KV Control. This is a convenient way to access Shop Orders without having all of the information that is needed to utilize Kit Processing.

To access Kit Browser, navigate to Shop Floor Control > Production Control > KV Control, and then select the Kit Browser icon.

Figure 13: Kit Browser

File:SOP-5-I-MES0078-C Kit-Browser.jpg

Filter

Users can filter the Shop Order list by Shop Order Number, Part Number, and/or Revision. Filtering for specific Shop Orders simplifies the process of identifying the correct Shop Order for kitting.

1. To filter the Shop Order list, enter a Shop Order Number, Part Number, and/or a Revision into the filter fields provided and then select Filter.

Figure 14: Filter Shop Order List

File:SOP-5-I-MES0078-C Filter-Shop-Order-List.jpg

NOTE: To begin a new search, select Clear to empty the fields and re-enter information into the available fields.

Consolidation

The first step in the kitting process is Consolidation. This process consolidates all of the components in a kit. Once a kit is provided to the floor by a warehouse, all of its components must be consolidated to ensure there are no missing units.

1. To consolidate a kit from Kit Browser, select the Shop Order from the list and then select Kit Consolidation.

Figure 15: Kit Consolidation

File:SOP-5-I-MES0078-C Kit-Consolidation.jpg

2. The Select the Top level Assembly(ies) form displays. All available serials are listed in the right column. The user can enter the serial into the field provided, or select the serial from the available column by double clicking on it.

3. Once the serial is in the left column, select the Serial Number and then select OK to open the Kit Processing portlet.

Figure 16: Top Level Assemblies

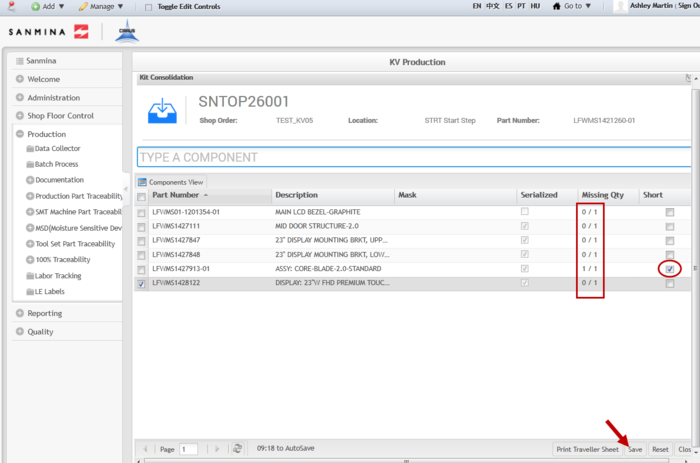

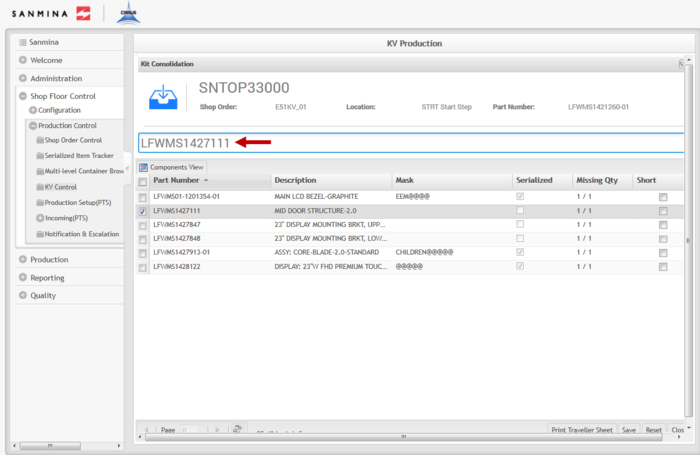

4. The Kit Processing portlet displays in the Kit Consolidation step.

5. All associated Part Numbers are listed for consolidation.

Figure 17: Kit Processing- Consolidation

File:SOP-5-I-MES0078-C Kit-Processing-Consolidation.jpg

6. To consolidate the components, select each part number and then enter or scan the Part Number (for Non-Serialized components) or the serial that fits the mask (for Serialized components).

Figure 18: Consolidation

File:SOP-5-I-MES0078-C Consolidation.jpg

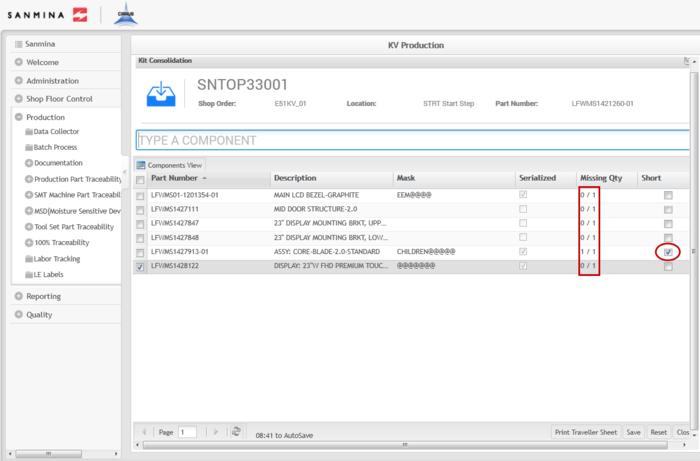

7. This process zeros out the Missing Quantity, thus consolidating all the components in the kit.

8. If there are missing components, mark the item as short by selecting the Short check box in the far right column.

Figure 19: Consolidated with Short Items

9. After consolidating all of the components, select Save to confirm.

10. Select Close to return to the Kit Browser main page.

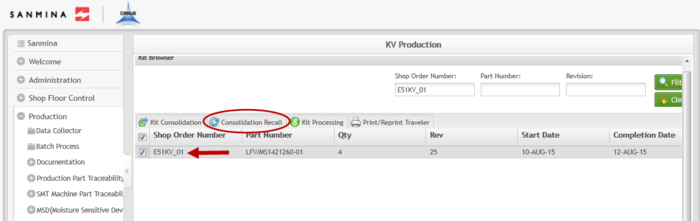

Consolidation Recall

Consolidation Recall removes the consolidation link between a kit’s components and its Top Level serial number. A consolidation recall would be necessary for a Work Order cancellation or a decrease in quantity.

1. To perform a consolidation recall in the Kit Browser portlet, select a Shop Order from the list that has been consolidated and then select Consolidation Recall.

Figure 20: Consolidation Recall

2. The Consolidation Recall form displays. Select a Top Level serial and then select OK.

Figure 21: Top Level Serial

3. A confirmation pop-up displays. Select Yes to continue.

4. The Consolidation Recall Result pop-up displays with the Serial Number, Part Number, and Component information that has been recalled.

Figure 22: Consolidation Recall Result

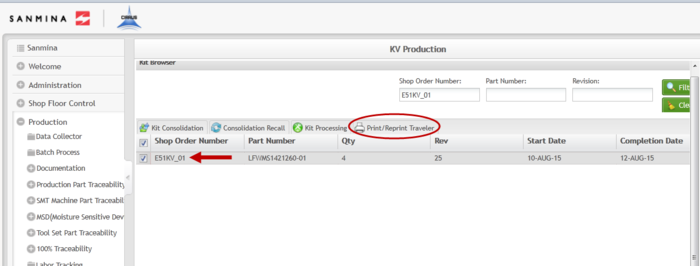

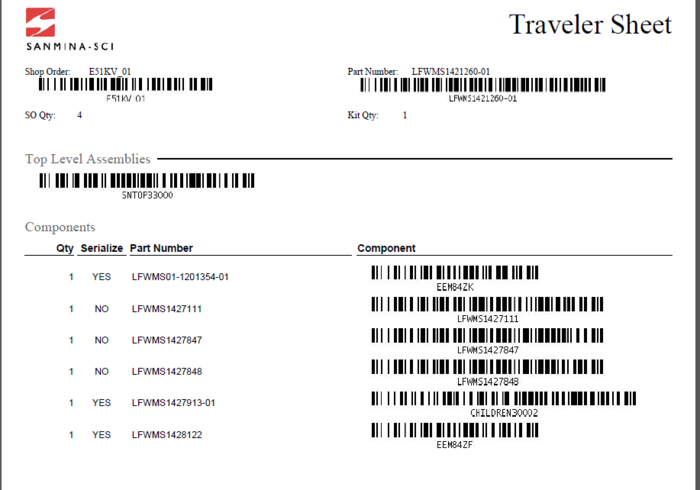

Print/Reprint Traveler

A traveler sheet provides a historical record of the items in a kit. The Shop Order, Part Number, quantity, Top Level Assembly, and all components are provided by the traveler.

1. To print a traveler, select the Shop Order from the Shop Order Number list and then select Print/Reprint Traveler.

Figure 23: Print/Reprint Traveler

2. The One Traveler Per Unit:: form displays. Select the Top Level Assembly serial number and then select Print.

Figure 24: Top Level Assembly

3. The traveler will prompt to be opened with an external program. Select the program with which to open the file and then select OK.

4. The traveler will open in the external program for the user to print.

Figure 25: Traveler Sheet

Kit Processing

Kit Processing allows the user to perform Consolidation, Integration, Inspection, and Repair without having to navigate to the Kit Browser portlet to search for the correct Shop Order. If the Top Level Assembly is available for the Shop Order, it can be entered into the Serial Number field. The kit will display in the proper step in the kitting process and the user can complete the kit from the Kit Processing portlet.

Consolidation

The first step in the kitting process is Consolidation. This process consolidates all of the components in a kit. Once a kit is provided to the floor by a warehouse, all of its components must be consolidated to ensure there are no missing units.

NOTE: Best Practice- Prior to Consolidation, the Assembly Tables for all Serialized Components must be configured with Part Number masks.

1. To consolidate a kit, enter the Top Level Assembly into the field provided.

2. The Kit Processing portlet displays in the Kit Consolidation step.

3. All associated Part Numbers are listed for consolidation.

Figure 26: Kit Processing- Consolidation

4. To consolidate the components, select each part number and then enter or scan the Part Number (for Non-Serialized components) or the serial that fits the mask (for Serialized components).

Figure 27: Consolidation

5. This process zeros out the Missing Quantity, thus consolidating all the components in the kit.

6. If there are missing components, mark the item as short by selecting the Short check box in the far right column.

Figure 28: Consolidated with Short Items

7. After consolidating all of the components, select Save to confirm.

8. "The record has been successfully saved" displays.

Integration

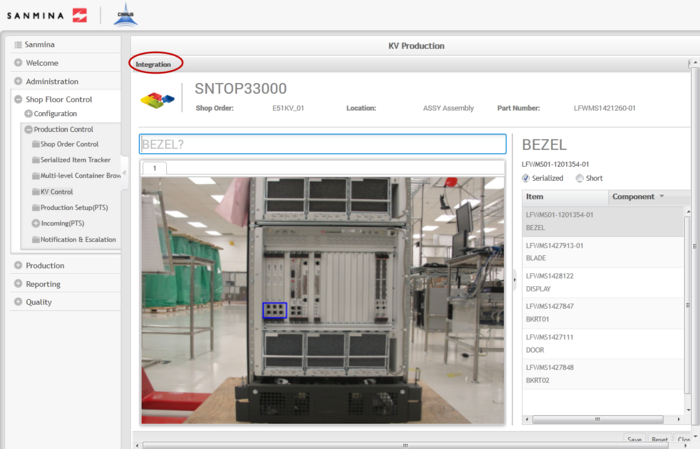

The second step in the kitting process is Integration. Integration is responsible for the assembly of the previously consolidated components.

1. To integrate a kit, enter the Top Level Assembly into the field provided

2. The Kit Processing portlet displays in the Integration step.

Figure 29: Integration

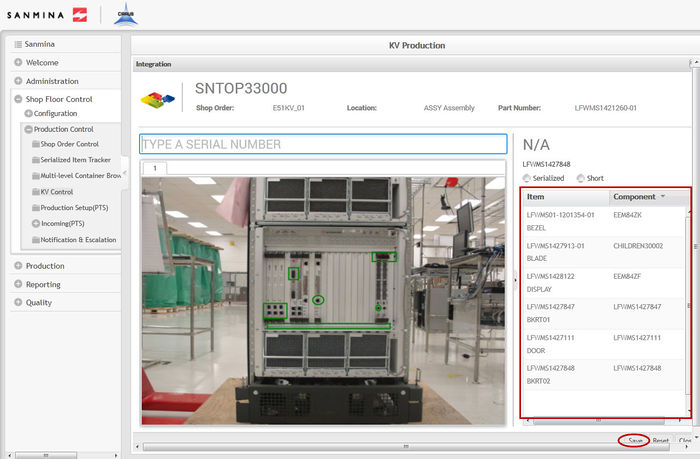

3. To integrate the components, select each item in the Item list and scan/enter the previously consolidated part number for non-serialized components or the serial that complies with the mask for serialized components.

NOTE: For non-serialized components with reference designators, the user will have to enter/scan the part number as many times as there are reference designators.

4. For short items, enter a serial that complies with the mask to integrate the component.

Figure 30: Integrated Kit

5. Once all items have been integrated, select Save to confirm.

6. "The record has been successfully saved" displays.

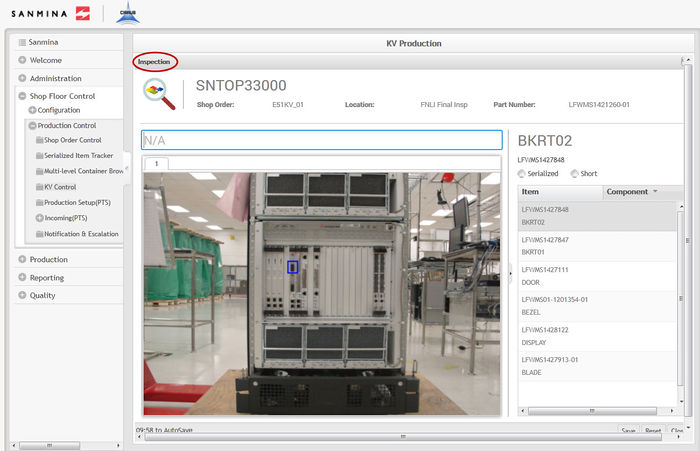

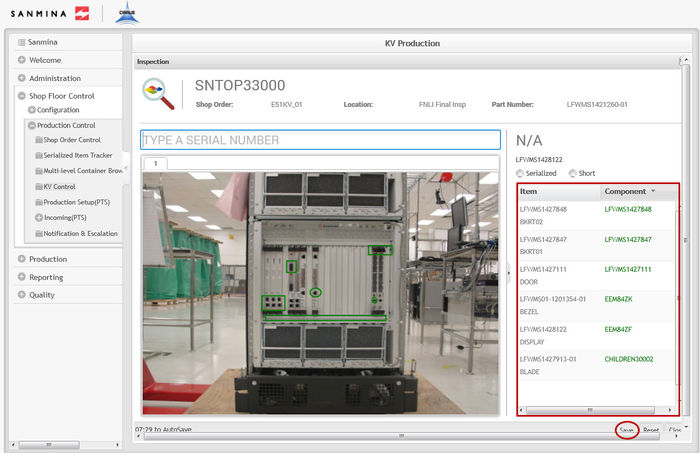

Inspection

The third step in the kitting process is Inspection. This step verifies that all previously integrated components are in the correct physical location.

1. To inspect a kit, enter the Top Level Assembly into the field provided

2. The Kit Processing portlet displays in the Inspection step.

Figure 31: Inspection

3. To inspect the components, select each item in the Item list and scan/enter the previously consolidated part number for non-serialized components or the serial that complies with the mask for serialized components.

NOTE: For non-serialized components with reference designators, the user will have to enter/scan the part number as many times as there are reference designators.

Figure 32: Inspected Kit

4. Once all items have been inspected, select Save to confirm.

5. "The record has been successfully saved" displays.

NOTE: If there are failed components in a kit, they will display in red when entered/scanned and the kit will be sent to Repair when saved.

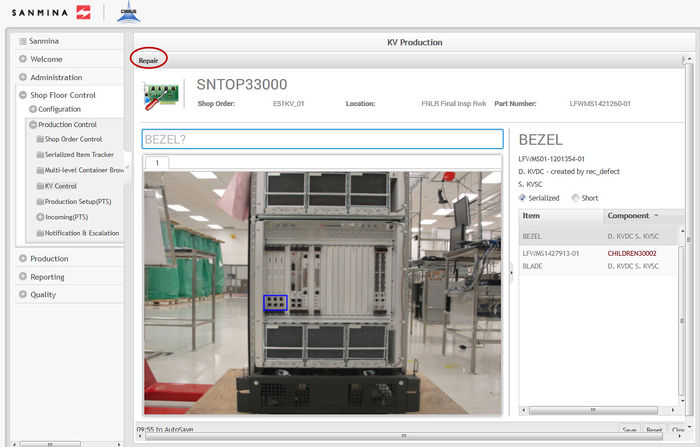

Repair

The fourth step in the kitting process is Repair. Repair allows for the repairing or replacing of failed components in the kit.

1. To repair a kit, enter the Top Level Assembly into the field provided

2. The Kit Processing portlet displays in the Repair step.

3. Only the components that have failed during the inspection step will display in the repair step.

Figure 33: Repair

4. To repair the components, select each item in the Item list and scan/enter the correct serial or part number that is displayed in the Component list.

5. Once all items have been repaired, select Save to confirm. This sends the kit back to the inspection step.

6. Complete the Inspection step again after repairing the failed items.

7. Once all items have been successfully inspected, the kit is complete and will no longer display in the Kit Processing portlet.

Document Revision History

| Date | Author | Title | Version | Change Reference |

| 09/04/15 | Ashley Martin | Technical Writer | v 1.0 | This is the first revision of the Kit Verify User Guide. |