Difference between revisions of "42Q-MES0186-A-PTS Mobile"

| Line 508: | Line 508: | ||

| − | |||

| − | + | === <span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out">Refrigeration Out [[File:PTSM Logo9.png|PTSM Logo9.png]]</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === | |

| − | | ||

| − | |||

| − | |||

| − | + | '''This function is used to take the solder paste out of the refrigerator.''' | |

| − | |||

| − | ''' | ||

| − | |||

| − | |||

| − | + | #Select '''Refrigeration Out '''Icon | |

| − | ''' | ||

| − | + | | |

| − | ''' | + | <ol start="2"> |

| + | <li>'''I'''nput the following information according to the field:</li> | ||

| + | </ol> | ||

| − | * | + | *'''Refrigerator ID: '''Scan or (input manually) the Refrigerator ID |

| − | '''Solder-Paste Material SN: '''Scan or (input manually) the Solder-Paste Material PN | + | *'''Solder-Paste Material PN: '''Scan or (input manually) the Solder-Paste Material PN |

| + | *'''Solder-Paste Material SN: '''Scan or (input manually) the Solder-Paste Material PN | ||

| + | *'''Solder-Paste Material SN List: ''' Scan or (input manually) the Solder-Paste Material SN List | ||

| + | *'''Reference Work Order Comment: '''Scan or (input manually) the Reference Work Order Comment | ||

| − | + | | |

| − | ''' | + | <ol start="3"> |

| + | <li>Select'''Submit.'''</li> | ||

| + | </ol> | ||

| − | + | <br/> '''Figure 19: Refrigeration Out''' | |

| − | ''' | ||

| − | + | [[File:PTSM RefrigirationOut.png|900px|PTSM RefrigirationOut.png]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[File:PTSM RefrigirationOut.png|900px]] | ||

'''<u>Note:</u>''' | '''<u>Note:</u>''' | ||

| Line 550: | Line 539: | ||

*'''Employee Number: '''The ID/number of employees, this employee number is called the login user information automatically. On the pad/Touch side, it can be used to scan the user code. Employee Number can not be empty and must be valid. | *'''Employee Number: '''The ID/number of employees, this employee number is called the login user information automatically. On the pad/Touch side, it can be used to scan the user code. Employee Number can not be empty and must be valid. | ||

*'''Refrigeration ID: '''The number of refrigeration can not be empty and must be valid. | *'''Refrigeration ID: '''The number of refrigeration can not be empty and must be valid. | ||

| − | *This refrigeration ID is an managed by the CMMS system. | + | *This refrigeration ID is an [[SOP-MES0074_CMMS_Asset|Asset ID]] managed by the CMMS system. |

| | ||

| Line 569: | Line 558: | ||

'''‘Employee Number’, ‘Refrigerator ID’, ‘Solder Paste Material PN’, and ‘Solder Paste Material SN’ '''can not be empty, and if the value is invalid, the system will pop up an error message. | '''‘Employee Number’, ‘Refrigerator ID’, ‘Solder Paste Material PN’, and ‘Solder Paste Material SN’ '''can not be empty, and if the value is invalid, the system will pop up an error message. | ||

| − | '''Reference Work Order '''can be null, if it is null, it will map to the N/A level solder paste control. If it is not Null, it must exist in the system. If the solder-paste material PN has been changed, it must input the refrigerator ID first. | + | '''Reference Work Order '''can be null, if it is null, it will map to the N/A level solder paste control. If it is not Null, it must exist in the system. If the solder-paste material PN has been changed, it must input the refrigerator ID first. The system supports taking out more than 1 solder paste material of the refrigeration at one time. Once users change the value of ‘Solder Paste Material PN’ (must input ‘Refrigerator ID’ first) then the further refrigeration in value of '''‘Solder Paste Material SN'''’ can be displayed first automatically according to the FIFO rule. |

| − | | ||

| − | The system supports taking out more than 1 solder paste material of the refrigeration at one time. Once users change the value of ‘Solder Paste Material PN’ (must input ‘Refrigerator ID’ first) then the further refrigeration in value of '''‘Solder Paste Material SN'''’ can be displayed first automatically according to the FIFO rule. | ||

| | ||

| Line 582: | Line 569: | ||

| | ||

| − | |||

| − | |||

| − | |||

=== <span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start">Thaw Start [[File:PTSM Logo10.png|PTSM Logo10.png]]</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === | === <span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start">Thaw Start [[File:PTSM Logo10.png|PTSM Logo10.png]]</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === | ||

Revision as of 22:09, 21 May 2024

42Q Home > Production > 100% Traceability> PTS Mobile

Contents

- 1 Introduction

- 2 PTS Mobile

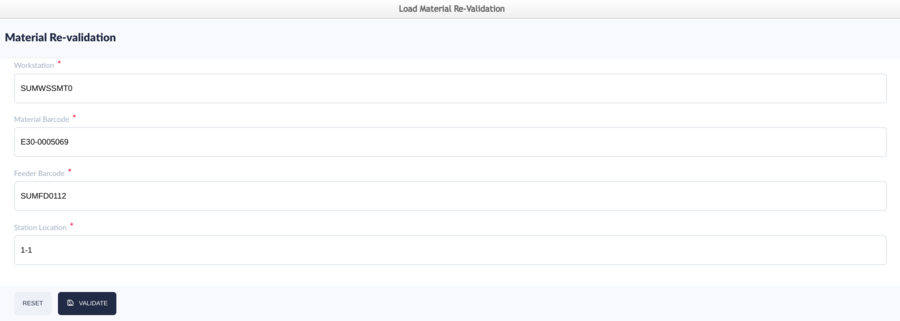

- 3 Re-Validate Material

- 4 Load/ Unload Materials

Introduction

The Part Traceability System (PTS) is an essential component of the MES suite of tools, designed specifically to meet the growing demands of customers. Its primary objective includes offering comprehensive traceability at the component level and ensuring strict quality controls. By automating production lines and enforcing rigorous product quality control, this system plays a pivotal role in enhancing overall productivity. its successful implementation has been witnessed across numerous plants worldwide.

As technology continues to evolve and SMT process equipment tools become increasingly intricate and feature-rich, the PTS application and its accompanying features consistently advance. However, our commitment remains to provide support for all technology tools. 42Q prioritizes offering the necessary flexibility to accommodate various line types and deliver diverse levels of traceability that are crucial to the success of your business.

PTS Mobile

PTS Mobile is specifically designed to be compatible with handheld devices, recognizing that operators may not always be in front of a computer and require the convenience of using a handheld device for operation.

To access PTS Mobile, navigate to Production > 100% Traceability > PTS Mobile

Re-Validate Material

Whenever material is going to be exhausted, splicing is required to ensure production is able to proceed without interruption. However, there is a small chance that splicing was mistakenly done to the wrong feeder slot and it can’t be detected by the normal part verification process.

Therefore, a material re-validation is required to handle this scenario. By re-validate material (just re-scan material barcode, without interrupting the current production run), chances of splicing material to the wrong feeder slot can be avoided. The Re-Validate Material is a mobile solution (GUI) to handle the situation of Component Reset and Re-validation for traditional SMT Machines. The users can validate the materials with the Workstation, Material Barcode, Feeder Barcode, and Station.

To access Re-validate, navigate to theProduction > 100% Traceability > PTS Mobile > Re-validate Material

The main screen will request the user to input or scan theWorkstation, Material Barcode, Feeder Barcode, and Station Location.

Figure 1: Re-validate Materials

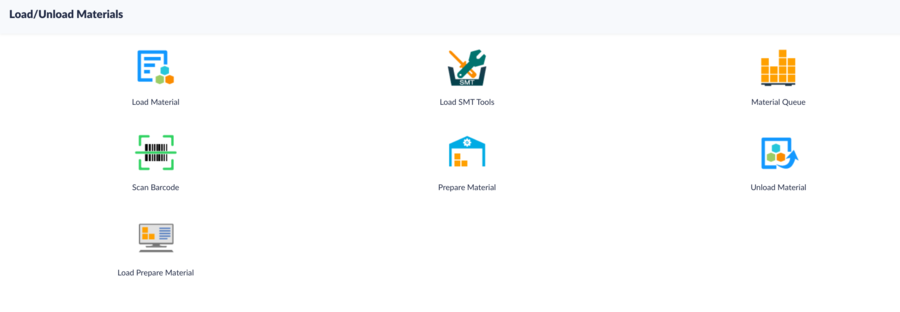

Load/ Unload Materials

It is mainly used for material loading and unloading materials and SMT tools, including the following subpages:

- Load Material

- Load SMT Tools

- Material Queue

- Scan Barcode

- Prepare Material

- Unload Material

- Load Prepare Material

Figure 2: Load / Unload Materials page

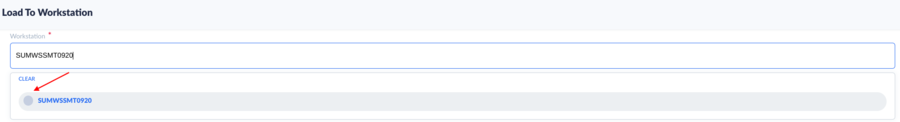

Load Material

This function is used to load material to the workstation.

- Input the Workstation name and select a workstation, and the detailed items for load material will display.

Figure 3: Load to Workstation

AI Workstation

For the AI workstation, the fields will contain the Material barcode and station

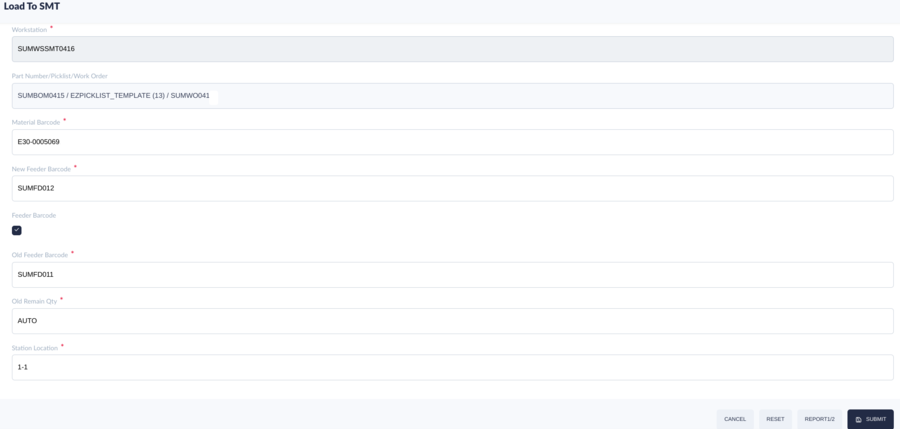

SMT Workstation

For the SMT workstation, the fields displayed will contain the Material barcode, feeder barcode, and station;

- Input the following information according to the field:

Figure 4: Load Material to an SMT Workstation

- Material Barcode: Scan (or Input manually) the material barcode.

- New Feeder Barcode: Scan (or Input manually) New Feeder Barcode. (Apply to the feeder which will be loaded to the defined SMT machine slot).

- Feeder Barcode: The Feeder Barcode checkbox is unchecked by default. If the "Feeder Barcode" checkbox is checked, then the "Old Feeder Barcode" and "Old Remaining Quantity" input boxes will be displayed.

- Old Feeder Barcode: Scan (or Input manually) Old Feeder Barcode.

- Old Remain Qty: Input Old Remain Qty.

- Station Location: Scan the station barcode. gram.)

- Select Submit. “ Load Material Successfully” will display after the material loads successfully. Detailed information can be seen on the “Load Material Report” page.

- To close the current page, select theCancel button. To see the loaded detailed information, select the Report button. To clear the content of the input box by selecting the Reset button.

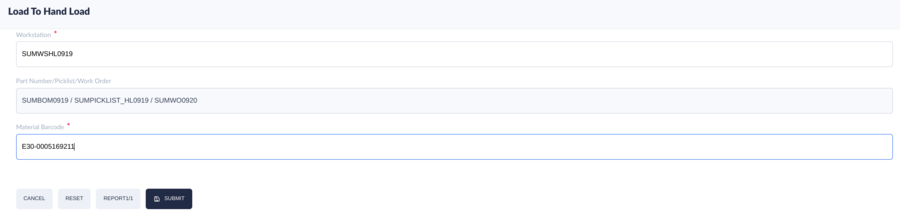

HL Workstation

For the HL workstation, the fields will contain a Material barcode.

- Input the Material Barcode, Scan (or Input manually) the material barcode.

Figure 5: Load Material to an HL Workstation

- Select Submit after the material barcode has been scanned or inputed manually, a “Load Material Successfully” will display after the material loads successfully.

- To close the current page, select the Cancel button. To see loaded detailed information, select the Report button. The information will be displayed on the “Load Material Report” page. To clear the content of the input box, select the Reset button.

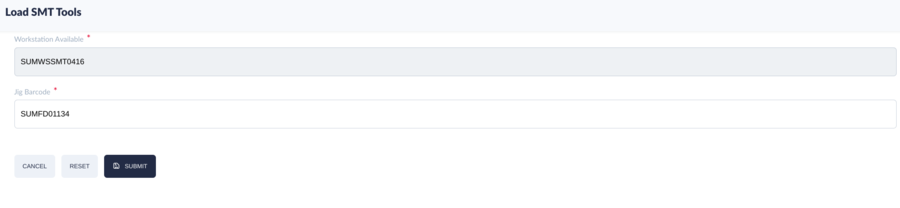

Load SMT Tools

This function is used to load and unload Jig.

Prerequisites

- Set Jig Control=Yes under the System Setting(Traceability) page

- A Jig barcode has been created

Figure 6: Load SMT Tools

- Input the Workstation name and select a Workstation Available.

- Input the corresponding jig barcode in the Jig Barcode textbox.

- Select Submit, “Load SMT Tool” will be displayed in the Load SMT Tools page.

- To close the current page by selecting the Cancel button. To clear the content of the input box by selecting the Reset button.

Note: The system will auto-verify whether the jig barcode can be loaded to the selected workstation based on the defined mapping. If the jig barcode is correct, it will then be loaded successfully. An error message will show up at the top side if the system fails to load the jig.

- If the JIG has been loaded to the workstation, then the user can enter the workstation and JIG barcode again to unload the Jig from this workstation.

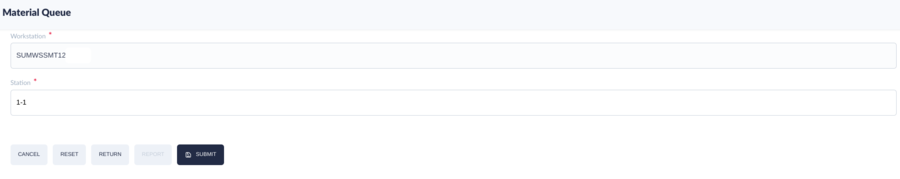

Marial Queue

This function is used to batch joint materials.

- Input a Workstation Name and Select the Workstation Available. Select a Station.

Figure 7: Material Queue Prerequisites

- Select Submit to finish inputting the following information according to the field:

- Workstation: Scan or (input manually) the Workstation name and select a Workstation Available

- Station: Scan or (input manually) the Station and press the enter key. The loaded material will show automatically.

- Last Material Barcode: Scan or (input manually) the Last Material Barcode

- Feeder Barcode: Scan or (input manually) the Feeder Barcode

- Remain Qty: Scan or (input manually) the quantity of the materials that have remained

- Confirm Qty: Scan or (input manually) the quantity of the materials that are going to change

Note: The portal will send a warning message, in case the quantity does not meet the Confirmed Quantity box.

- Confirm Material Barcode: Scan or (input manually) the Confirm Material Barcode

- New material Barcode: Scan or (input manually) the New material Barcode

- Select Submit, after the Workstation Station name

- Select the Cancel button, to close the current page. To clear the content of the input box, select theReset button. To return to the previous step by selecting theReturn button.

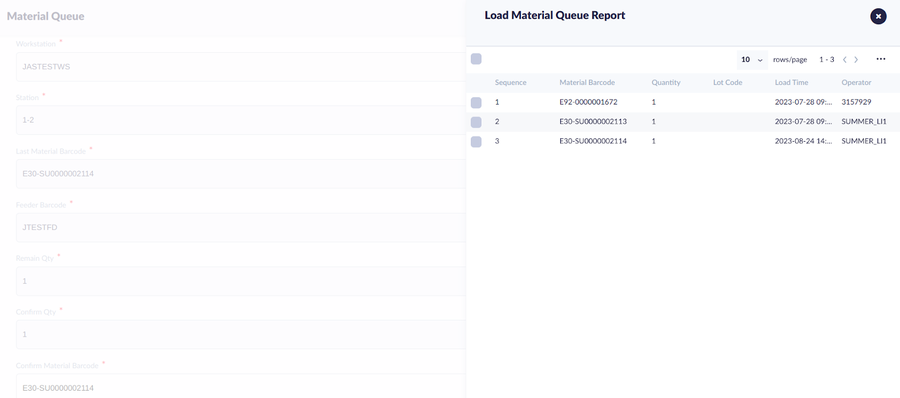

Figure 8: Material Queue

To view the Material Queue Report by selecting the Report button. To edit the Material Queue Report follow the following steps: Note: The first material cannot be deleted from the Material Queue Report.

- Select the box of the Material Barcode that needs to be edited.

- Select Delete to delete the material barcode that is no longer required.

Figure 9: Material Queue - Material Queue Report

Note: Material queue max reels and Material queue max Boards cannot be larger than the values set at the system settings page if Allow Material Queue isYES.

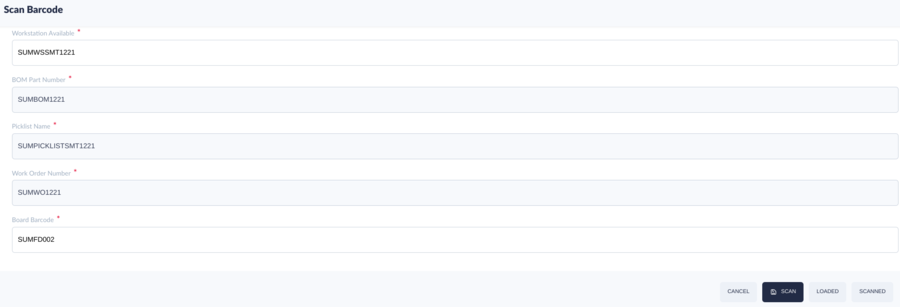

Scan Barcode

After the production line has been activated the materials loaded in Traceability, go to the Scan Barcode module.

Add the Workstation name and Select a Workstation.

- Input the following information according to the field:

BOM Part Number: Scan or (input manually) the BOM Part Number

Picklist Name: Scan or (input manually) the Picklist Name

Work Order Number: Scan or (input manually) the Work Order Number

Board Barcode: Scan or (input manually) the Board Barcode

- The PCB board/panel/serial barcode will need to be Scan as per Workstation Setup defined in the Production Setup module.“Scan board barcode successfully” will display after the scan barcode successfully.

Figure 10: Scan Barcode

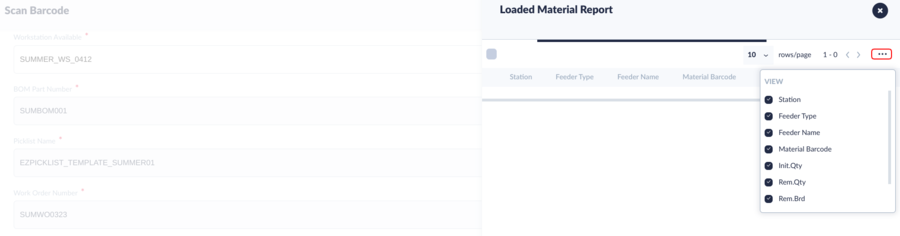

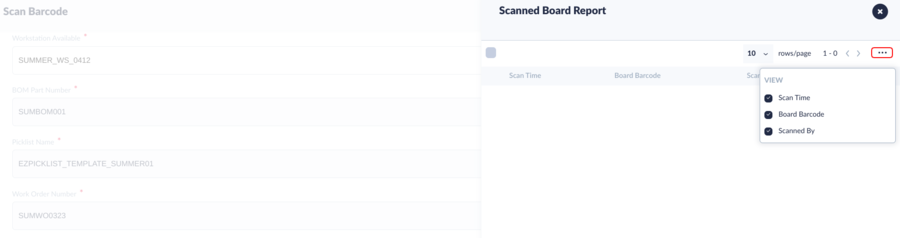

- To view the Loaded Material report, select theLoaded button and to view the Scanned Board Report select the Scanned button. To close the current page, select theCancel button.

Figure 11: Loaded Material Report

Figure 11: Scanned Board Report

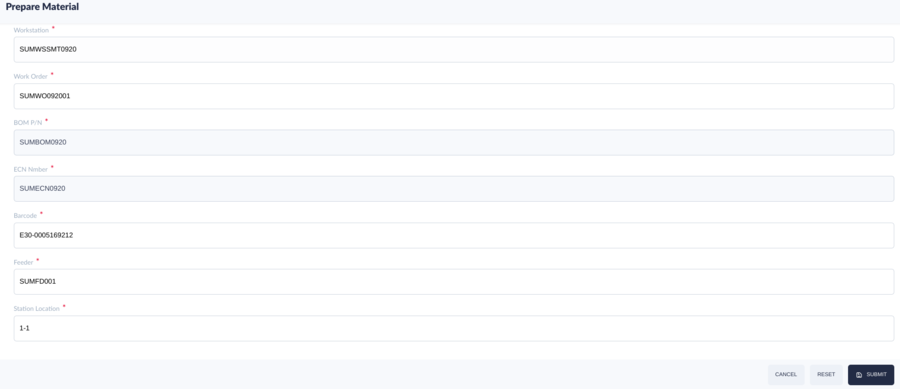

Prepare Material PTSM Logo5.png

To prepare material in advance while the production line is either in offline mode or online mode.

- Input the following information according to the field:

- Workstation: Scan or (input manually) the Workstation name and select a Workstation Available.

- Work Order: Scan or (input manually) the Work Order.

- BOM P/N, ECN Number: If the workstation and work order are correct, BOM P/N and ECN numbers will show automatically.

- Barcode: Scan or (input manually) the material barcode.

- Feeder: Scan or (input manually) the new feeder barcode.

- Station Location: Scan or (input manually) the station barcode. (I.e. SMT machine slot, as formatted in SMT placement program.)

Figure 13: Prepare Material

- Select Submit to send the material. If prepared successfully, the user can search for the information on the “Prepare Material Report” page.

- To close the current page, select the Cancel button. To clear the content of the input box select the Reset button.

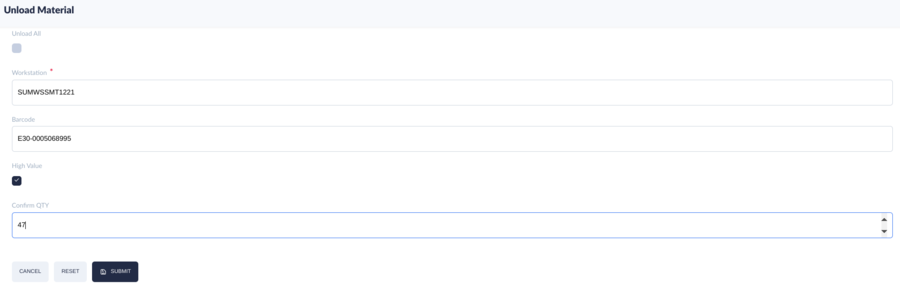

Unload Material PTSM Logo6.png

Unload Material from Workstation. To Unload a specific item of the material, make sure the Unload All is not checked.

- Input the following information according to the field:

- Workstation: Scan or (input manually) the Workstation name and select a Workstation Available.

- Barcode: Scan or (input manually) the Barcode

- High-Value: Check the High-Value box to input the Confirm QTY if needed.

- Select Submit to unload material.

Figure 14: Unload Material

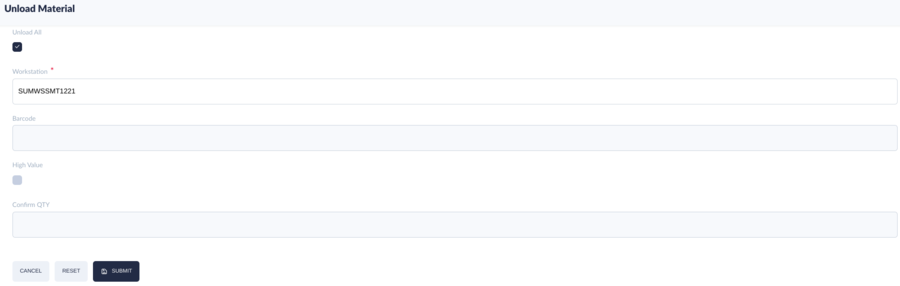

To Unload All the Material, make sure the Unload All is checked.

- Input the Workstation name, Scan or (input manually)the Workstation name and select a Workstation Available.

- Select Submit to unload all materials.

Figure 15: Unload All Material from the Workstation

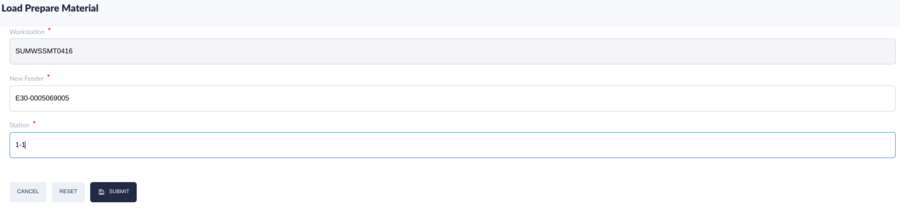

Load Prepare Material PTM Logo7.png

Load prepare material sing.

- Input the following information according to the field:

- Workstation: Scan or (input manually) the Workstation name and select a Workstation Available.

- New Feeder: Scan or (input manually) the New Feeder Barcode. (Apply to the feeder which will be loaded to the defined SMT machine slot).

- Station: Scan or (input manually) the Location number.

Figure 16: Load Prepare Material

- Select Submit. The successful prompt information will be displayed at the top of the page. The user could also go to the “Load Material Report” web page to check if the load material was successful by entering the same information as the preparation material. If load preparation material was successful, the information (before prepared material) will disappear from the “Prepare Material Report.”

Note: Prepare material before loading prepared material or the user can load the material directly.

Solder Paste

This module is used to manage solder paste, including the following subpages:

- Refrigeration In

- Refrigeration out

- Thaw Start

- Thaw End

- Stirring

- Open Jar

- Solder-Paste Scrap

Figure 17: Solder Paste

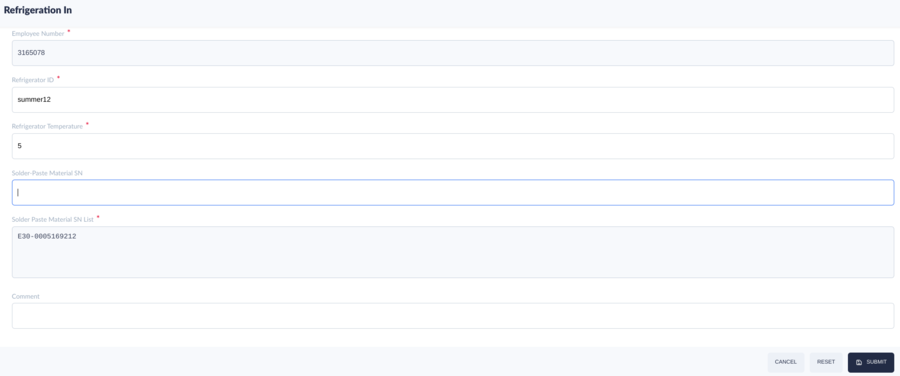

Refrigeration In PTSM Logo8.png

This function is used to put the solder paste into the refrigerator.

- Select Refrigeration In Icon

- Input the following information according to the field:

- Refrigerator ID: Scan or (input manually) the Refrigerator ID

- Refrigerator Temperature: Input the temperature

- Solder-Paste Material SN: Scan or (input manually) the Solder-Paste Material SN

- Comment: Input a comment

- SelectSubmit.

Figure 18: Refrigeration In

Note:

- Employee Number: The ID/number of employees, this employee number is to call the login user information automatically. On the pad/Touch side, it can be used to scan the user code. Employee Number can not be empty and must be valid.

- Refrigeration ID: The number of refrigeration. The refrigeration ID can not be empty and must be valid. This refrigeration ID is an Asset ID managed by the CMMS system.

Note: In order to get/verify the refrigeration ID/Asset ID, users need to set the CMMS web server information in the system setting (Others > CMMS Web Service URL).

- Refrigeration Temperature: The temperature of refrigeration.

- Solder Paste Material SN: The barcode of solder paste material.

- Solder Paste Material SN List: This application supports putting more than one solder paste material in refrigeration at one time. Once users scan/input the solder paste material barcode at the Solder-Paste Material SN text field and press the Enter key, the material barcode will show on this list line by line.

- Comment: Comment on the refrigeration in action.

Notes:

- If the value of ‘Refrigerator Temperature’ for the corresponding MPN is not between the value of ‘Optimal Storage Temp - Storage Temp Dev’ and ‘Optimal Storage Temp + Storage Temp Dev’ (Optimal Storage Temp and Storage Temp Dev can be configured in function ‘Solder Paste material Control’) then the system will prompt error message such as ‘Incorrect Storage Temperature’.

- If the shelf time of the current solder paste material is more than ‘Shelf-Life’ configured in the function ‘Solder Paste material Control’ then the system will prompt error messages such as ‘Shelf Time Expired’.

- If the count of ‘Thaw Cycle’ is more than ‘Max Allowed Thaw Cycle’ configured in function ‘Solder Paste MPN Control’ then the system will prompt error messages such as ‘Count of Max Allowed Thaw Cycle is reached’.

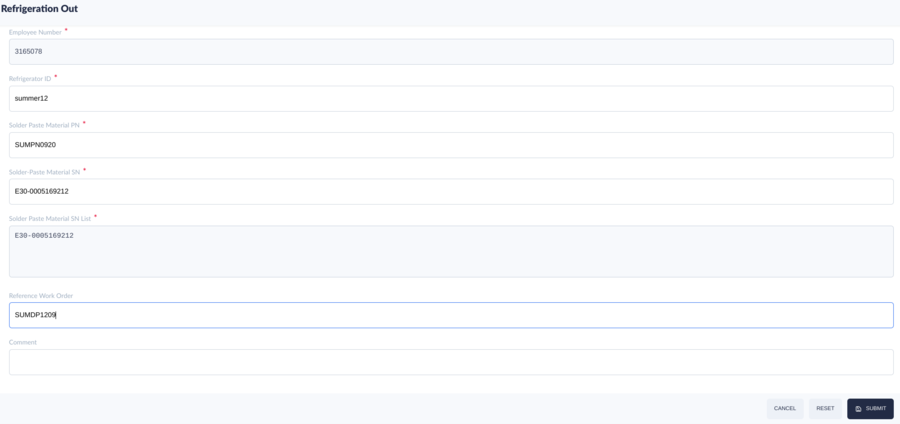

Refrigeration Out PTSM Logo9.png

This function is used to take the solder paste out of the refrigerator.

- Select Refrigeration Out Icon

- Input the following information according to the field:

- Refrigerator ID: Scan or (input manually) the Refrigerator ID

- Solder-Paste Material PN: Scan or (input manually) the Solder-Paste Material PN

- Solder-Paste Material SN: Scan or (input manually) the Solder-Paste Material PN

- Solder-Paste Material SN List: Scan or (input manually) the Solder-Paste Material SN List

- Reference Work Order Comment: Scan or (input manually) the Reference Work Order Comment

- SelectSubmit.

Figure 19: Refrigeration Out

Note:

- Employee Number: The ID/number of employees, this employee number is called the login user information automatically. On the pad/Touch side, it can be used to scan the user code. Employee Number can not be empty and must be valid.

- Refrigeration ID: The number of refrigeration can not be empty and must be valid.

- This refrigeration ID is an Asset ID managed by the CMMS system.

Note: In order to get/verify the refrigeration ID/Asset ID, users need to set the CMMS web server information in the system setting (Others > CMMS Web Service URL).

- Refrigeration Temperature: The temperature of refrigeration.

- Solder Paste Material PN: The part number of the solder paste material.

- Solder Paste Material SN: The barcode of solder paste material.

- Solder Paste Material SN List: This application supports putting more than one solder paste material out of refrigeration at one time. Once users scan/input the solder paste material barcode at the Solder-Paste Material SN text field and press the Enter key, the material barcode will show on this list line by line.

- Reference Work Order: The work order of the solder paste.

- Comment: Comment on the refrigeration in.

Note:

‘Employee Number’, ‘Refrigerator ID’, ‘Solder Paste Material PN’, and ‘Solder Paste Material SN’ can not be empty, and if the value is invalid, the system will pop up an error message.

Reference Work Order can be null, if it is null, it will map to the N/A level solder paste control. If it is not Null, it must exist in the system. If the solder-paste material PN has been changed, it must input the refrigerator ID first. The system supports taking out more than 1 solder paste material of the refrigeration at one time. Once users change the value of ‘Solder Paste Material PN’ (must input ‘Refrigerator ID’ first) then the further refrigeration in value of ‘Solder Paste Material SN’ can be displayed first automatically according to the FIFO rule.

- The ‘Reference Work Order’ item can be empty. If this is empty, it will map to the N/A level for the one Solder Paste MPN control.

- The ‘Reference Work Order’ item is related to the part configured in the ‘Solder Paste MPN Control’ function.

- If the shelf time of the current solder paste material is more than ‘Shelf-Life’ configured in the function ‘Solder Paste MPN Control’ then the system will prompt an error message such as ‘Shelf Time Expired’.

- If the storage time of the current solder paste material in the refrigerator is less than ‘Min Storage Time’ configured in the function ‘Solder Paste MPN Control’ then the system will prompt an error message such as ‘Not Reach Min Storage Time’.

- If the Solder Paste Refrigeration FIFO is ‘YES’, the solder paste was put into the same refrigerator earlier than that solder pastes with the same MPN will be allowed to take out from the same refrigerator. Otherwise, the system will prompt a warning message to remind the user to take out the earlier solder paste.

Thaw Start PTSM Logo10.png

This function is used to start thawing Solder Paste.

Once the Thaw Start icon is selected, users can complete the following fields: Solder-Paste Material SN, Reference Work Order, Thaw Humidity(%), Thaw Temperature (°c), Comment, and thenclick Submit.

Figure 19: Thaw Start

- ‘Employee Number’, and‘Solder Paste Material SN’ items can not be empty.

- The‘Reference Work Order’ item can be empty.

- If the previous step (Refrigerator Out) has already mapped ‘Solder-Paste Material SN’ and ‘Reference Work Order’ then the value of ‘Reference Work Order’ will display automatically after the user completes inputting the ‘Solder Paste Material SN’ item.

- If the shelf time of the current solder paste material is more than ‘Shelf-Life’ configured in the function ‘Solder Paste MPN Control’ then the system will prompt an error message such as‘Shelf Time Expired’.

- If the value of‘Thaw Humidity’ is not between the value of ‘Ambient Humidity Low Limit’ and the value of ‘Ambient Humidity High Limit’ (Ambient Humidity Low Limit and Ambient Humidity High Limit can be configured in the function ‘Solder Paste MPN Control’) then the system will prompt an error message such as ‘Incorrect Thaw Humidity’.

- If theSolder Paste Thawing FIFO is ‘YES’, the solder paste that is taken out from (or put into) the same refrigerator earlier than the solder pastes with the sam MPN will be allowed to do the ‘Thaw Start’ action, otherwise, the system will prompt a warning message such as ‘It is not the correct FIFO solder paste’ to remind the user.

Thaw End PTSM Logo11.png

This function is used to end the thawed solder paste.

Once the Thaw End icon is selected, users can complete the following fields: Solder-Paste Material SN, Thaw Humidity(%), Thaw Temperature (°c), Comment, and then click Submit.

Figure 20: Thaw End

- InputEmployee Number, Solder-Paste Material SN, thenpresstheEnter key

- Select Reference Work Order, input Comment, then click the Submit button

Notes:

- ‘Employee Number’, and‘Solder Paste Material SN’ can not be empty.

- The ‘Reference Work Order’ item can be empty.

- If the previous step has already mapped the‘Solder-Paste Material SN’ and ‘Reference Work Order’ then the value of ‘Reference Work Order’ will display automatically after users complete inputting the ‘Solder Paste Material SN’ item.

- If the shelf time of the current solder paste material is more than ‘Shelf-Life’ configured in the function‘Solder Paste MPN Control’ then the system will prompt an error message such as ‘Shelf Time Expired’.

- If the Thaw time of the current Solder Paste material is less than‘Min Thaw Time’ configured in the function ‘Solder Paste MPN Control’ then the system will prompt an error message such as‘Not Reach Min Thaw Time’.

If the Solder Paste Thawing FIFO is ‘YES’, the solder paste that is taken out from (or put into) the same refrigerator earlier than the solder pastes with the sam MPN will be allowed to do the ‘Thaw End’ action, otherwise, the system will prompt a warning message such as ‘It is not the correct FIFO solder paste’ to remind the user.

Stirring PTSM Logo12.png

This function is used to stir the solder paste.

Once the Stirring icon is selected, users can complete the following fields:Solder-Paste Material SN, Reference Work Order, Comment, and then click Submit.

Figure 21: Stirring

- Input Solder-Paste Material SN, then press the Enter key

- Select Reference Work Order, input Comment, then click the Submit button.

Notes:

- The‘Solder Paste Material SN’ item can not be empty.

- The ‘Reference Work Order’ item can be empty.

- If the previous step has already mapped the ‘Solder-Paste Material SN’ and ‘Reference Work Order’ then the value of ‘Reference Work Order’ will display automatically after the user completes inputting the‘Solder Paste Material SN’ item.

- If the shelf time of the current solder paste material is more than ‘Shelf-Life’ configured in the function ‘Solder Paste MPN Control’ then the system will prompt an error message such as ‘Shelf Time Expired’.

Open Jar PTSM 13.png

This function is used to open the solder paste and prepare it for use.

Once the Open Jar icon is selected, users can complete the following fields: Solder-Paste Material SN, Reference Work Order, Comment, and then click Submit.

Figure 22: Open Jar

- Input Solder-Paste Material SN, then press the Enter key.

- Select Reference Work Order, input Comment, then click the Submit button.

Notes:

- The Solder Paste Material SN item can not be empty.

- The ‘Reference Work Order’ item can be empty.

- If the previous step has already mapped the ‘Solder-Paste Material SN’ and ‘Reference Work Order’ then the value of ‘Reference Work Order’ will display automatically after the user completes inputting the ‘Solder Paste Material SN’ item.

- If the shelf time of the current solder paste material is more than ‘Shelf-Life’ configured in the function ‘Solder Paste MPN Control’ then the system will prompt an error message such as ‘Shelf Time Expired’.

Solder Paste Scrap PTSM Logo14.png

This function is used to scrap expired or unusable solder paste.

Once the Solder Paste Scrap icon is selected, users can complete the following fields: Solder-Paste Material SN, Scrap Reason, and then clickSubmit.

Figure 23: Solder Paste Scrap

- Input Solder-Paste Material SN, then press the Enter key

- Input Scrap Reason, then click the Submit button.

Note: ‘Solder Paste Material SN’ can not be empty.