|

|

| Line 2: |

Line 2: |

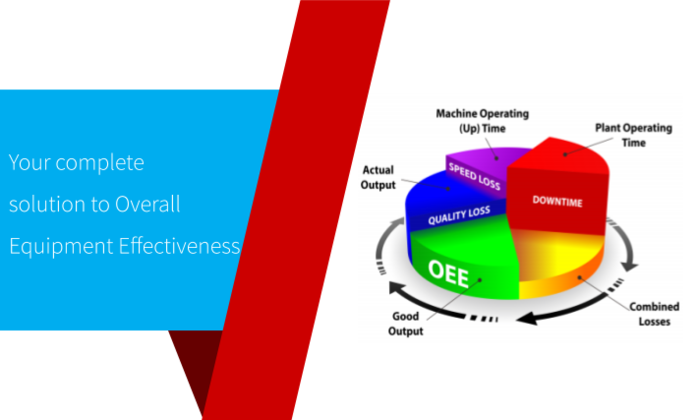

| | <span style="color:#FF0000;"><span style="font-size:xx-large;">OEE (Overall Equipment Effectiveness)</span></span> | | <span style="color:#FF0000;"><span style="font-size:xx-large;">OEE (Overall Equipment Effectiveness)</span></span> |

| | | | |

| − | <span style="color:#808080;"><span style="font-size:large;">Improving your factory's production process</span></span><br/> | + | <font color="#808080" size="4">Your factory's blood pressure, heart rate, and blood oxyen level monitored in real time.</font><br/> |

| | | | |

| | '''[[File:OEEIntro.png|700px|OEEIntro.png]]''' | | '''[[File:OEEIntro.png|700px|OEEIntro.png]]''' |

| − |

| |

| − | By definition OEE is the cumulative measure of three separate factors: Availability, Performance and Quality and together they can provide you with a good measure of how well your production line is running. Such information is critical when trying to determine benchmarking in order to improve your company's efficiency.<br/> <br/>

| |

| − |

| |

| − |

| |

| − |

| |

| − | = <span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F"><span class="mw-headline" id="What_Is_OEE.3F">What Is OEE?</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> =

| |

| − |

| |

| − | OEE ('''Overall Equipment Effectiveness''') is known as the gold standard for measuring manufacturing productivity. To simply put it, it identifies the percentage of manufacturing time that is truly productive. By measuring OEE, manufacturing businesses will gain important insights into how to systematically improve the manufacturing process.

| |

| − |

| |

| − | By implementing a system that can measure and analyze OEE, manufacturers can improve equipment performance, operating procedures, and maintenance processes.

| |

| − |

| |

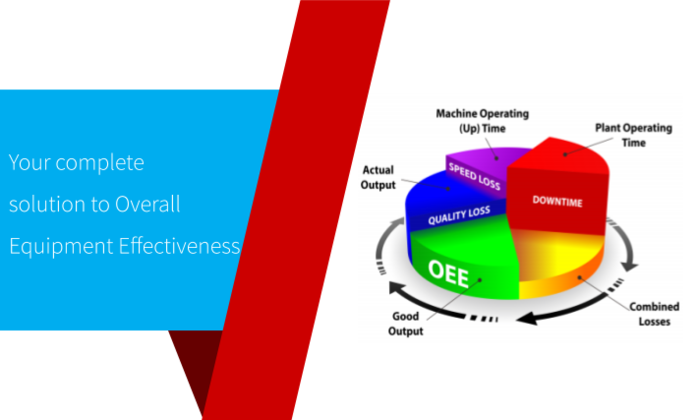

| − | Measuring OEE is the manufacturing best practice and metric for identifying losses, benchmarking progress, and improving the productivity of manufacturing equipment (i.e., OEE takes into consideration the cumulative impact of three factors: the equipment’s '''''availability''''', its '''''performance''''' rate, and the '''''quality''''' of its output.<br/> <br/>

| |

| − |

| |

| − | '''[[File:APQDefine.png|700px|QAPQDefine.png]]'''

| |

| − |

| |

| − | = <span class="mw-headline" id="Overall_Equipment_Effectiveness_Factors_:"><span class="mw-headline" id="Overall_Equipment_Effectiveness_Factors_:"><span class="mw-headline" id="Overall_Equipment_Effectiveness_Factors_:"><span class="mw-headline" id="Overall_Equipment_Effectiveness_Factors_:">'''Overall Equipment Effectiveness Factors ''':</span></span></span></span> =

| |

| − |

| |

| − | '''O'''verall '''E'''quipment '''E'''ffectiveness :

| |

| − |

| |

| − | '''OEE''' uses all three factors to give you a single metric that is used to help you identify the percentage of manufacturing time that is truly productive :

| |

| − |

| |

| − | '''[[File:APQEquation.png|700px|APQEquation.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − | = <span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example"><span class="mw-headline" id="OEE_Calculation_Example">OEE Calculation Example</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> =

| |

| − |

| |

| − | OEE scores provide a very valuable insight into an accurate picture of how effectively your manufacturing process is running. It also makes it possible to track improvements easily within the process over time.

| |

| − |

| |

| − | Here are some interesting examples that capture the fundamental nature of each of the three losses '''(Availability, Performance''', and '''Quality)''' :

| |

| − |

| |

| − | '''<u>A</u>vailability''' = Operating Time / Scheduled Time

| |

| − |

| |

| − | '''[[File:A-Example.png|400px|A-Example.png]]'''

| |

| − |

| |

| − | '''''Availability''''' = 420 minutes Operating / 450 minutes Scheduled = '''93.3%'''<br/> <br/> <br/>

| |

| − |

| |

| − | '''<u>P</u>erformance''' = Time to Produce Units / Operating Time

| |

| − |

| |

| − | '''[[File:P-Example.png|400px|P-Example.png]]'''

| |

| − |

| |

| − | ''' Performance''' = 400 minutes / 420 minutes = '''95.2%'''

| |

| − |

| |

| − |

| |

| − |

| |

| − | '''<u>Q</u>uality''' = Good Units / Total Units Produced

| |

| − |

| |

| − | '''[[File:Q-Example.png|400px|Q-Example.png]]'''

| |

| − |

| |

| − | ''''' Quality'''''= 380 Good Units / 400 Units Produced = '''95.0%'''<br/> <br/>

| |

| − |

| |

| − | Finally, OEE is calculated by multiplying the Three OEE Factors :

| |

| − |

| |

| − | '''Availability''' (93.3%) x '''Performance ('''95.2%) x '''Quality '''(95.0%) = '''OEE''' (84.3%)

| |

| − |

| |

| − |

| |

| − |

| |

| − | = <span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses"><span class="mw-headline" id="Six_Big_Losses">Six Big Losses </span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> =

| |

| − |

| |

| − | One of the major goals of '''OEE''' (Overall Equipment Effectiveness) is to reduce and eliminate what is called the '''Six Big Losses''' – the most common causes of equipment-based productivity loss in manufacturing.

| |

| − |

| |

| − | Below is a chart demonstration defining the Six Big Losses. Let’s take a look at each one of the six in more detail and how digital capabilities can help to minimize them for greater effectiveness and efficiency upon the manufacturing floor.<br/> <br/> '''Six Big Losses: '''

| |

| − |

| |

| − | '''[[File:SixBigLosses.png|700px|SixBigLosses.png]]'''

| |

| − |

| |

| − | <u>'''Availability Losses:'''</u>

| |

| − |

| |

| − | #'''Equipment Failure '''

| |

| − |

| |

| − | *The first big loss is caused by equipment that is not running despite being scheduled to do so within production. This results in an unplanned down due to machine breakdowns, tooling failure, and/or emergency maintenance stops.

| |

| − |

| |

| − |

| |

| − | <ol start="2">

| |

| − | <li>'''Setup and Adjustments'''</li>

| |

| − | </ol>

| |

| − |

| |

| − | *The second big loss is caused by downtime when equipment is not running due to changeover, machine, and tooling adjustments or planned maintenance as well as setup time and quality inspections.

| |

| − |

| |

| − | IoT connected devices can help to minimize possible downtime while also improving the effectiveness of changeovers and adjustment. One possible way of reducing downtime can be by pushing a reminder or alert to workers’ mobiles or wearables about upcoming changeover as well as step-by-step guidance on how to perform it.

| |

| − |

| |

| − |

| |

| − |

| |

| − | <u>'''Performance Losses:'''</u>

| |

| − | <ol start="3">

| |

| − | <li>'''Idling and Minor Stops '''</li>

| |

| − | </ol>

| |

| − |

| |

| − | *Also known as small stops, idling, and minor stops account for short periods of time when equipment stops operating. These can be caused by material jams or product flow obstructions.

| |

| − |

| |

| − |

| |

| − | <ol start="4">

| |

| − | <li>'''Reduced Speed '''</li>

| |

| − | </ol>

| |

| − |

| |

| − | *Equipment can sometimes run more slowly than the Ideal Cycle Time. Reduced speed can be due to poorly maintained or slow equipment.

| |

| − |

| |

| − | Technology can help to address performance losses by helping to improve training and provide operators with relevant information for the point of action. For example, management can take a photo of the machine as evidence of complying with the standard operating procedure (SOP).

| |

| − |

| |

| − |

| |

| − |

| |

| − | '''<u>Quality Losses:</u>'''

| |

| − | <ol start="5">

| |

| − | <li>'''Quality Losses '''</li>

| |

| − | </ol>

| |

| − |

| |

| − | *Both quality losses account for the production of defective parts, including scrapped parts and parts that can be re-worked.

| |

| − |

| |

| − |

| |

| − | <ol start="6">

| |

| − | <li>'''Reduced Yield'''</li>

| |

| − | </ol>

| |

| − |

| |

| − | *Reduced yield accounts for the defective parts produced in the warm-up stage of production. It is caused by poorly executed changeovers, wrong settings, or equipment generating waste after startup.

| |

| − |

| |

| − | Analyzing data captured on the shop floor can help to identify the root causes and communicate with workers the best corrective action to take.

| |

| − |

| |

| − | = <span class="mw-headline" id="What_OEE_Benefits"><span class="mw-headline" id="What_OEE_Benefits"><span class="mw-headline" id="What_OEE_Benefits"><span class="mw-headline" id="What_OEE_Benefits"><span class="mw-headline" id="What_OEE_Benefits"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F"><span class="mw-headline" id="What.E2.80.99s_Benefits.3F">What OEE Benefits</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> =

| |

| − |

| |

| − | *With Overall Equipment Effectiveness (OEE), you are able to accurately and effectively measure your manufacturing productivity. Overall Equipment Effectiveness (OEE) identifies areas of production time that are efficient, how efficient they are, and offers thorough insight within your operation.

| |

| − |

| |

| − |

| |

| − |

| |

| − | *Return on Investment (ROI) - Machinery is a large investment that companies make in order to achieve maximum return on investment. Operators are able to prove the amount of financial value of these investments, conducted through measurable data provided by overall equipment effectiveness (OEE). With even a small increase in production, this can add up in time in small increments and become monumental progress for a production facility.

| |

| − |

| |

| − |

| |

| − |

| |

| − | *Increase Competitiveness - For manufacturing operations, it is a must to reduce losses within production and push toward greater competitiveness. If production line is lacking efficiency, there are procedures and methods needed to help maximize the facility. With OEE data, operators and analysts are able to identify any constraints or bottlenecks within production. Cloud-based OEE can easily identify any weaknesses and opportunities within production.

| |

| − |

| |

| − |

| |

| − |

| |

| − | *Visualizing Performance - OEE enables you to visualize performance with ease. This is conducted by utilizing calculations and observing any production losses. This is then assigned into three different categories of availability, performance, and quality and then are filtered into a single metric, ultimately showing current production status and areas of improvement.

| |

| − |

| |

| − |

| |

| − |

| |

| − | *Reducing Machinery Cost - Understanding actual performance of machinery correlates directly with knowing whether or not the machine is working efficiently. It also identifies whether there are issues that may lead to the need for future repair. With OEE, you are able to anticipate events that represent massive savings of cost - preventative maintenance, machine failure, etc.

| |

| − |

| |

| − |

| |

| − |

| |

| − | *Production Insight - You can not understand what to improve without it being measured, which is why utilizing live data of equipments status can efficiently provide the knowledge to reduce any unplanned downtime and increase speed time on planned stops. This analysis of the correlation between performance and performance loss may reveal potential for improvements within maintenance in the future, ultimately leading to lower cost within the facility.

| |

| − |

| |

| − |

| |

| − |

| |

| − | = <span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:"><span class="mw-headline" id="OEE_Functionality_in_42Q_Module:">OEE Functionality in 42Q Module:</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> =

| |

| − |

| |

| − | The functionality provided by the 42Q OEE system includes:

| |

| − |

| |

| − | *Automatic or manual acquisition of downtime, quantity

| |

| − | *Downtime classification via reason/error code

| |

| − | *Downtime management and analysis support

| |

| − | *Data contextualization against meaningful production data as well as custom data

| |

| − | *High visibility panel/TV/Web operator pages

| |

| − | *Supervisor pages for detailed analysis

| |

| − | *Downtime reports & dashboards with drill-down capability

| |

| − |

| |

| − | <br/> OEE is completed within several 42Q modules :

| |

| − |

| |

| − | *The '''OEE Configuration''' modules are used by engineers to define '''''Shift, Plant Calendar, Work Center, Root Cause/Root Cause Category, Tap Mapping, Up/Down Threshold, Target UPH, Repair''''', also the mapping parameters to connect the MES101 and Fuji.

| |

| − | *'''OEE Production''' modules are used to report the Machine Down and to report work manually, also associates MES 101 data (Shop Floor Asset Mapping) with OEE, in order for 42Q OEE to get the production data auto backend.

| |

| − | *'''OEE Operation Dashboard '''/42Q live/MESWeb are OEE reports that inform your team just how close you are to that target and which aspects of your operations are holding you back from exceeding it.

| |

| − |

| |

| − | = <span class="mw-headline" id="OEE_Use_Case_Example:"><span class="mw-headline" id="OEE_Use_Case_Example:"><span class="mw-headline" id="OEE_Use_Case_Example:"><span class="mw-headline" id="OEE_Use_Case_Example:"><span class="mw-headline" id="OEE_Use_Case_Example:">OEE Use Case Example:</span></span></span></span></span> =

| |

| − |

| |

| − | Let’s take a look at an OEE “Use Case” example that will become beneficial within the manufacturing business world.

| |

| − |

| |

| − | For this example, let’s assume that a new product was developed such as a thermos for a new seller. To make this product, there are four assets involved: Sheet Metal Cutter, Metal Forming Machine, Labeling Machine, and OPtical INspections Machine. All the machines, however, are connected within the 42 system and each of these processes can be done within 10 seconds.

| |

| − |

| |

| − |

| |

| − |

| |

| − | '''[[File:OEEUseCase.png|700px|OEEUseCase.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − | As the Ideal Performance --- Each asset should be measured at one unit per 10 seconds. Expect availability for the machines to be 8 hours, for one single shift with the ideal theory of 100% quality. By setting these idea measures, we can observe our OEE charts. Through the first trial, engineers notice some metal pieces are coming out of the sheet metal cutter wrinkled and/or damaged which results in those pieces being scrapped. The next step for this process will be to adjust the ideal quality to 99% to save time and performance.

| |

| − |

| |

| − |

| |

| − |

| |

| − | = <span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:"><span class="mw-headline" id="OEE_Modules_within_42Q:">OEE Modules within 42Q:</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> =

| |

| − |

| |

| − | All data is collected in one central location. OEE modules are located within Shop Floor Control > Configuration > OEE Configuration.

| |

| − |

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="1._Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts"><span class="mw-headline" id="Shifts">1. Shifts </span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==

| |

| − |

| |

| − | The supervisor defines days and times of operation to the various shifts operating in their plants in order to accurately measure OEE availability. Administrators assign Shift Names and Shift Codes to scheduled shifts, and then add/edit shifts as needed.Shifts are configured in OEE > Shift.

| |

| − |

| |

| − |

| |

| − |

| |

| − | '''[[File:Shifts01.png|700px|Shifts01.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="2._Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar"><span class="mw-headline" id="Plant_Calendar">2. Plant Calendar</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==

| |

| − |

| |

| − | The Plant Calendar is a planning tool that allows administrators to add or remove special shifts from the work schedule (such as holidays, or extra workdays- e.g. Sundays), without affecting the regular work shift calendar.

| |

| − |

| |

| − | '''[[File:PlantCalendar.png|700px|PlantCalendar.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="3._Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center"><span class="mw-headline" id="Work_Center">3. Work Center</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==

| |

| − |

| |

| − | The Work Center defines a group of machines that build the same product on a production line or shop floor. Work Center is a configuration tool used by managers to:

| |

| − |

| |

| − | #Designate the Work Center Name

| |

| − | #Assign an Asset to the Work Center

| |

| − |

| |

| − |

| |

| − |

| |

| − | '''[[File:WorkCenter.png|700px|WorkCenter.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="4._Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause"><span class="mw-headline" id="Root_Cause_Category_.26_Root_Cause">4. Root Cause Category & Root Cause</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==

| |

| − |

| |

| − | <br/> Root Cause Categories are broad descriptions of machine downtime problems. Possible manufacturing Root Cause Category examples include: Process, Energy, System, and Maintenance. Users may add and edit root causes directly from the [https://docs.google.com/document/d/1F2c5M3uWYHLAnAhYlOwthfjAnHo1V1XqDCigAYpIwnM/edit#heading=h.j3t32e7o6zg7 Root Cause Category submodule], or within the Root Cause submodule of OEE. Examples of root causes pertaining to a manufacturing environment include: Material Issues, Shortage of Operators, Unscheduled Maintenance, Change Over, End of Shift Cleaning, and Tool Change.

| |

| − |

| |

| − | '''[[File:AddNewRootCause.png|AddNewRootCause.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="5._Repair_Code_Category_.26_Repair_Code"><span class="mw-headline" id="5._Repair_Code_Category_.26_Repair_Code"><span class="mw-headline" id="5._Repair_Code_Category_.26_Repair_Code">5'''.''' Repair Code Category & Repair Code</span></span></span> ==

| |

| − |

| |

| − | Sometimes the production line’s low OEE value may be caused by worn out, misaligned, or broken parts on the asset itself. To resume producing a good quality product, the repair team must replace or refurbish the asset’s parts or calibrate the asset itself. The management team may also want to view the asset’s repair history according to reported [https://docs.google.com/document/d/12dAE7A8QBYGBfbER79xWGxfdhL5NWRVHvHSAY0oLnfk/edit#heading=h.y10vhmg9elq0 Problems] and/or most commonly reported repairs ([https://docs.google.com/document/d/1S_TM4W5R9idM8lNskc2JWI2f0dXmyG5anjo1BgEis0g/edit#heading=h.y10vhmg9elq0 Top Repair Codes]). All repair details are compiled into reports that are available on the factory’s shop floor via [https://docs.google.com/document/d/12dAE7A8QBYGBfbER79xWGxfdhL5NWRVHvHSAY0oLnfk/edit Operation Dashboard]. Overall, OEE’s Repair Code feature is a valuable tool that helps management teams to determine the root cause of poor OEE scores.<br/>

| |

| − |

| |

| − | '''[[File:OEERepair.png|700px|OEERepair.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="6._Up.2FDown_Threshold"><span class="mw-headline" id="6._Up.2FDown_Threshold"><span class="mw-headline" id="6._Up.2FDown_Threshold"><span class="mw-headline" id="6._Up.2FDown_Threshold"><span class="mw-headline" id="6._Up.2FDown_Threshold">6'''.''' Up/Down Threshold</span></span></span></span></span> ==

| |

| − |

| |

| − | The '''Up/Down Threshold''' submodule of OEE allows engineers to set a grace period (threshold time) before assets are officially flagged as down or up in the 42Q MES.

| |

| − |

| |

| − | '''Up/Down Thresholds''' are configured according to Asset Type, and depend upon that machine’s unique running patterns and idiosyncrasies. The time selected will determine how long the system allows before machine stoppages and starts are recorded as down/up times. Time intervals are available in minutes, seconds, or milliseconds.

| |

| − |

| |

| − | '''[[File:OEEUpDown.png|500px|OEEUpDown.png]]'''

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="7._Tag_Mapping"><span class="mw-headline" id="7._Tag_Mapping"><span class="mw-headline" id="7._Tag_Mapping"><span class="mw-headline" id="7._Tag_Mapping">7'''.''' Tag Mapping</span></span></span></span> ==

| |

| − |

| |

| − | The '''Tag Mapping''' feature links (tags) assets to the OEE reporting system. This mapping process allows 42Q’s MES to automatically capture asset downtimes and problems from CMMS, and eliminates the need to manually input downtime events. Once a downtime event is received, the system creates a new repair Work Order or closes the corresponding Work Order in CMMS.<br/>

| |

| − |

| |

| − | '''[[File:OEETagMap.png|700px|OEETagMap.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection"><span class="mw-headline" id="OEE_Data_Collection">OEE Data Collection</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==

| |

| − |

| |

| − | 42Q OEE provides two ways for plants to collect Production Data.

| |

| − |

| |

| − | #Report production data (downtimes, work time) manually in the OEE Data Collection module.

| |

| − | #Collect production data backend automatically from MES 101,Fuji, and PLC using the OEE tools, 42Q's API, and a preferred client.

| |

| − |

| |

| − |

| |

| − |

| |

| − | '''[[File:OEEDataCollection.png|700px|OEEDataCollection.png]]'''

| |

| − |

| |

| − | '''[[File:ReportWork.png|500px|ReportWork.png]]'''

| |

| − |

| |

| − |

| |

| − | == <span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports"><span class="mw-headline" id="OEE_Reports">OEE Reports </span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==

| |

| − |

| |

| − | Users are able to see the final OEE, TEEP, performance, quality and availability metrics on reports, 42Q Live Operational Dashboard (3x3) and 42Q Live Layout.

| |

| − |

| |

| − | Our 42Q OEE system provides reports as following:

| |

| − |

| |

| − | *OEE/TEEP,A,P,Q Status report

| |

| − | *Top 5 Problems/Repairs report

| |

| − | *Availability,Performance, and Quality report

| |

| − | *Downtime Trend report

| |

| − | *Uptime Trend report

| |

| − | *Downtime Root Cause Analysis report

| |

| − | *Downtime Problem Analysis report

| |

| − | *MTBF AND MTTR report

| |

| − |

| |

| − |

| |

| − |

| |

| − | === <span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard"><span class="mw-headline" id="Operation_Dashboard">Operation Dashboard </span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ===

| |

| − |

| |

| − | 42Q’s dashboard application, [https://42qrpt1.42-q.com/mes_wiki/index.php/42Q-MES0107-CRA1_Operation_Dashboard Operation Dashboard], provides a real time view of production line status, allowing plant managers to quickly troubleshoot critical problems in real time. Presently, factories can monitor the throughput and yield of any given production line as compared to expected target results. Read about 42Q Live

| |

| − |

| |

| − | '''[[File:OperationDashboard.png|700px|OperationDashboard.png]]'''

| |

| − |

| |

| − |

| |

| − |

| |

| − | === <span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets"><span class="mw-headline" id="OEE_Widgets">OEE Widgets </span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ===

| |

| − |

| |

| − | The addition of OEE (Overall Equipment Effectiveness) widgets to the Operations Dashboard provides displays a different kind of productivity metric. With one quick glance at their shop floor monitors, plant managers can now answer broader questions: How well does my machinery work? How are my lines moving? What is causing delays and downtimes? What time of day do problems occur? And more. <br/> <br/>

| |

| − |

| |

| − | '''[[File:OEEWidgets.png|OEEWidgets.png]]'''

| |

| − |

| |

| − | '''[[File:WidgetCOnfiguration.png|700px|WidgetConfiguration.png]]'''

| |

| | | | |

| | <br/> | | <br/> |

| | | | |

| | + | An essential part of manufacturing is the ability to quantify the productivity and efficiency of production processes and assets. Everything that can be measured, monitored, and managed can likely be optimized. This, by itself, is already a great reason for implementing OEE-based continuous improvement programs. |

| | | | |

| − | === <span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates"><span class="mw-headline" id="42Q_Live_Updates">42Q Live Updates</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ===

| + | OEE''' '''is a tremendous benefit to organizations by helping with '''early detection''' and provide '''actionable intelligence''' to different user bases across the enterprise, whenever '''availability''', '''performance''', or '''quality''' aren’t looking as good as they should. OEE is considered a gold standard measurement of how well production lines and assets are running, and this information is critical to determining benchmarks and identifying areas for improvement. |

| | | | |

| − | [https://docs.google.com/document/d/1ecf9ekqFdTm7eVOxRX5YZaavkD7tIwBaLB4fqtB8pLA/edit 42Q Live] provides real time data on shop floor activity in an intuitive dashboard format. 42Q Live currently offers 3 Layers of data:

| + | Businesses can monitor and compare the actual effectiveness of production processes and assets and quickly identify issues, allowing troubleshooting and optimizations to resolve the underlying causes of availability, performance and quality problems. |

| | + | |

| | + | = '''What Is OEE?''' = |

| | | | |

| − | *'''Machine''': displays cycle time status (Machine status is determined by comparing scanning activity (throughput and cycle time) during a set period of time to target yield values predefined in target maintenance.

| + | ---- |

| | | | |

| − | | + | OEE '''(Overall Equipment Effectiveness),''' in simple terms, is an index that measures how effective any piece of equipment is. You can think of it as a medical monitor that gathers and computes your asset’s blood pressure, heart rate and temperature continuously displaying and keeping history of these KPIs and raising alerts when things are out of control. |

| | | | |

| − | *'''TP/Yield''': shows throughput and yield values for the selected level, and the current status of each production line (ok, acknowledged, on hold, critical, and idle.)

| + | When a well-rounded, integrated OEE system such as 42Q is implemented, operations can quickly unleash the power of clusters of OT information that were previously isolated and very difficult to make sense of. The losses are related to the three main factors that link to poor OEE and can be investigated by any organizational level you desire. The chart below shows the six big losses that manufacturing leaders keep their eyes on for their production lines and processes. |

| | | | |

| − | | + | Monitoring and taking actions on these metrics is one of the key differentiators between world-class manufacturers and the rest of the pack. Don't you worry, though. Help is on the way. If you’re reading this, you’ve already taken the first few steps towards the answer that will help visualize issues and improvement opportunities. |

| | + | |

| | + | Overall Equipment Effectiveness is the product of the 3 KPIs/metrics above:<br/> |

| | | | |

| − | *'''OEE''': shows OEE statistics for the specific asset;

| + | '''OEE = Availability * Performance * Quality''' |

| | | | |

| − | | + | <br/> An effective analysis of the underlying causes for losses in any of those 3 main process indicators is a science that requires readily available information; flexibility to quickly and easily interpret business intelligence and monitoring capabilities while controlling the cost of acquiring all that data, processing it into valuable information and making it available anywhere at any time.<br/> <br/> An OEE system that acts on the backstage in a nearly transparent fashion to the operations is the holy grail manufacturers all over the world have been looking for. 42Q can deliver all of that and more. |

| | | | |

| | | | |

| | | | |

| − | === <span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb"><span class="mw-headline" id="MESWeb">MESWeb</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === | + | = '''The OEE components: Availability, Performance and Quality.''' = |

| − | | |

| − | OEE MESWeb reports include all historical data as it relates to current OEE activity.

| |

| − | | |

| − | '''[[File:MESWEb.png|700px|MESWeb.png]]''' | |

| | | | |

| | | | |

| | | | |

| − | '''[[File:DowntimeAnalysis.png|700px|DowntimeAnalysis.png]]'''

| + | Each underlying variable in OEE corresponds to a specific type of loss. Knowing with confidence each of these potential production losses will lead to accurate calculations, which in turn will lead to better decision-making, saving time and resources. |

| − | | |

| − |

| |

| | | | |

| − | = <span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solution"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solutions"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solutions"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solutions"><span class="mw-headline" id="Highlight_questions_and_Our_42Q_OEE_Solutions">Highlight questions and Our 42Q OEE Solution</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | == '''https://lh6.googleusercontent.com/XIQesjU1nOYfu5gbLYLOfpAiSG_z2f0HXgu0gjA_QChbe2GGFRDtJbD6whWkU76vREHlx4ZFybF-hQ1OZVAM-iIwQ_7EXJbWlaY7XBg1OSTYEgY-Bb9Vm8pTKoXZQPCGgxSADfmaDjTYXgD-XEaxfM4Availability''' == |

| | | | |

| − | | + | This KPI compares the time that an asset was operating against the time that it was stopped. It is the relationship between the actual production time (planned production time minus every stoppage, including scheduled and unscheduled downtimes) and the original planned production time.<br/> <br/> Scheduled downtimes are usually personnel breaks, mealtimes, and other planned events when there isn’t intended production happening, such as shift changeovers. OEE systems should allow for categorization of downtimes. |

| | + | |

| | + | '''Availability = Actual Production Time / Planned Production Time''' |

| | | | |

| − | = <span class="mw-headline" id="Question_1:_Integration_with_MES_101.2C_retrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2C_retrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2C_retrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2C_retrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2C_retrieve_the_real_production_data_from_production_line."><span style="font-size:large;"><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line."><span class="mw-headline" id="Question_1:_Integration_with_MES_101.2Cretrieve_the_real_production_data_from_production_line.">Question 1: Integration with MES 101, retrieve the real production data from production line.</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | == == |

| | | | |

| | + | == '''Performance''' == |

| | | | |

| − | === <span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:"><span class="mw-headline" id="42Q_Solution:">'''42Q Solution''':</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ===

| + | This KPI provides information about how fast a part is being produced. It compares the total count against the theoretical target. Performance is affected by minor stops and slowdowns making production run at less than the ideal cycle time. |

| − | | + | |

| − | 42Q provides MES 101 API/Web services to get real production data automatically from the backend.

| + | '''Performance = (Ideal Cycle Time × Total Count) / Actual Production Time''' |

| − | | |

| − | MES 101 allows OEE to gather Performance & Quality data from MES automatically, thus avoiding possible human errors resulting from manual entry. The process saves labor time and ensures data (e.g. Finished Qty, Good Qty, Target UPHs, shop order, Start/End Intervals, etc.) is accurate and up-to-date. The automatic data retrieval also reduces the need for operation training, thereby simplifying implementation, and reducing costs.

| |

| − | | |

| − | *The MES 101 system provides an API to feed performance & quality data to the OEE system.

| |

| − | **OEE retrieves specific location/machine hourly throughput & yield from MES 101 interface.

| |

| − | **OEE system collects target HPU & yield rates as well as quality, OEE and TEEP from MES 101 backend.

| |

| − | **The user can set the target OEE, Performance, Quality and Availability at the MES 101 Target Maintenance. It takes care of the ERP Shop Order Target OEE value as well.

| |

| | | | |

| | | | |

| | | | |

| − | ==== <span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps"><span class="mw-headline" id="Configuration_Steps">Configuration Steps</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==== | + | == '''Quality''' == |

| | | | |

| − | In order for the system to get the Production data and target data, users must map the Asset to the Location in the OEE system ('''Shop Floor Control > Configuration > CMMS Asset > Asset Mapping'''). <br/>

| + | The quality variable shows how many good units were produced versus the total count. It is affected by rejected products. This calculation takes into account good manufactured parts that go through the process for the first time without any rework and divides it by the total number of parts processed. |

| | + | |

| | + | '''Quality = Good Units / Total Count''' |

| | + | |

| | + | == '''Practical example ''' == |

| | | | |

| − | '''[[File:SFAssetMapping.png|700px|SFAssetMapping.png]]'''

| + | Let’s say that each Friday the operations manager and his team review a weekly OEE trend by manufacturing line or asset.<br/> During their last meeting, they identified the current top five OEE downtime reason codes. The next step was to detect the specific downtime root causes and which machines are experiencing unplanned downtimes due to equipment failure. Afterwards, they might want to also drill down even further to find detailed repair information to figure out the most common causes, problems and repair actions that are resulting in assets downtime. |

| | | | |

| − | | + | This type of analysis allows operations management and maintenance teams to make informed decisions and take corrective action to prevent or reduce downtimes. In the upcoming OEE weekly meeting, the team can review the trends and compare them with previous periods (i.e.before and after corrective action plans, supplier changes, staff training and other potential actions). |

| | | | |

| − | = <span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time"><span class="mw-headline" id="Question_2:_Key_in.2FReceive_the_UPH_or_Cycle_Time">Question 2: Key in/Receive the UPH or Cycle Time</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> =

| + | The following is a simple example that helps to explain how OEE is calculated. |

| − | | |

| − | The OEE standalone user needs to be able to key in the expected Cycle Time or UPH, eliminating the mandatory ERP dependency. | |

| | | | |

| | | | |

| | | | |

| − | Use Case

| + | PICTURE |

| − | | + | |

| − | #The user can key in the Shop Order with the expected Cycle Time or UPH.

| + | '''Note: '''This is fictional data used to explain how OEE calculation may help build the underlying variable(s) that are used to display improvement opportunities. |

| − | #Alternatively, The OEE system will calculate the OEE based on the performance target value.

| |

| − | #*If ERP order integration is available, the system should be able to use it.

| |

| − | #The user should be able to see the final OEE, TEEP, performance, quality and availability metrics on reports, 42Q Live Operational Dashboard (3x3) and 42Q Live Layout/Monocle.

| |

| | | | |

| | | | |

| | + | |

| | + | = '''What can monitoring OEE do for your factory?''' = |

| | | | |

| − | | + | ---- |

| | + | |

| | + | * |

| | + | '''Measure accurately and effectively.'''<br/> Production constraints and bottlenecks can be quickly identified through OEE data analysis, uncovering opportunities to rectify weaknesses thereby improving your processes and machinery. For example, if a production line is capable of producing 100 pieces per hour, but it is producing less than that, OEE systems will point that out. |

| | | | |

| − | == <span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:"><span class="mw-headline" id="42Q_Solution_:">42Q Solution : </span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ==

| + | |

| | + | * |

| | + | '''Improve Return on Investment (ROI).'''<br/> Assets are expensive. Using them to the fullest can represent an important step towards operational excellence and profitability. OEE provides measurable KPIs that can be used to gauge and monitor efficiency over time, directly supporting decision-making on maintenance plans, material supply processes, staff training, machine purchases and more. |

| | | | |

| − | To meet the requirements/questions of a wide variety of plants, OEE offers several ways to configure target data/Target UPH.

| + | |

| | + | * |

| | + | '''Cost savings.'''<br/> By utilizing OEE and analyzing the underlying metrics, teams can identify losses and work on minimizing defective products and reworks, machine slowdowns and unplanned downtimes, whichtranslates into cost savings. |

| | | | |

| − | #Plants using MES 101 can set target values at the [https://docs.google.com/document/d/1F2c5M3uWYHLAnAhYlOwthfjAnHo1V1XqDCigAYpIwnM/edit#heading=h.enk0qi7iov6q Target Maintenance] module; the system automatically saves data into CMMS and OEE databases.

| + | |

| − | #Plants that utilize Oracle’s ERP to transfer data define target values in Oracle; 42Q sends data via the Oracle Work Order to 42Q’s Shop Order.

| + | * |

| | + | '''Predict/Prevent breakdowns.'''<br/> As OEE provides real time machinery efficiency information, it helps companies to prevent or control machine failures. This could lead to less unscheduled downtimes, especially when it is integrated with a Computerized Maintenance Management System (CMMS) that calculates mean time between failures (MTBF) and mean time to repair (MTTR).'''<br/> |

| | | | |

| − | === <span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants"><span class="mw-headline" id="Target_Configuration_for_MES_101_Plants">Target Configuration for MES 101 Plants</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === | + | |

| | + | = = |

| | | | |

| − | Plants using OEE in conjunction with MES101 will set target UPH values in 42Q’s [https://42qrpt1.42-q.com/mes_wiki/index.php/SOP-5-I-MES0084-C_Target_Maintenance Target Maintenance] module. Once defined, target data will be saved into the plant’s MES database. The OEE application then calls 42Q’s API call (automatically auto) to send target data from the MES database to the CMMS/OEE database .

| + | = '''OEE in 42Q''' = |

| | | | |

| − | '''[[File:TargetMaintenance.png|700px|TargetMaintenance.png]]'''

| + | ---- |

| | | | |

| − |

| + | The set of functionality provided by 42Q’s OEE system includes several features around data collection, analysis, and reporting through a clear and intuitive user interface. Additionally, it is easy to implement machine connectivity through 42Q’s IIoT modules. |

| | + | /> /> /> /> |

| | + | {| |

| | + | |- |

| | + | | <p dir="ltr" style="text-align: center;">'''https://lh4.googleusercontent.com/kTaEv24UM0p1kWQ11skMjwEDMr0vMzTt_1Bq6e8xdy0W6x0NjZXpVj043cjQIEsP_bCEI8EKCYWaOMpgFT0Tpxs9zi6OaUw-kNpCjUDFO8htdNFH0zhXwT4alH8FxDdaDB9VKrW8fB-mtURUeBIP2oQ'''</p> |

| | + | '''Automatic or manual data acquisition fully integrated with MES 101’s track and trace (Production Workbench)''' |

| | | | |

| − |

| + | | <p dir="ltr" style="text-align: center;">'''https://lh4.googleusercontent.com/m_i1pHMJikZvqVhXFCN60hPK21TI5oLdowjWCRDeWEyMa0Yy_PwDAQDnVflctDITjoC8VOAM2DzlTqVzDp4pXZCjJfsG3JKlr4maQGHSTcUZGq6xAzYgr3FnecQW8fqMCOKBk8yiIOLOgAwEpDmbha8'''</p> |

| | + | '''Downtime classification and root cause analysis''' |

| | | | |

| − | === <span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets"><span class="mw-headline" id="OEE_Target:_Define_UPH_For_Assets">OEE Target: Define UPH For Assets</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ===

| + | | <p dir="ltr" style="text-align: center;">'''https://lh5.googleusercontent.com/FghuMuNsymS-fcnITAclXO67SBI-jn0_YhXyxV8ca30WSAl3mZeyHVhGz4SXpQljt99W8_I8jW4a-WOC8OG9SEOQ-Uz6sbhwIINHweIygeMB_qhOw6sgP4PcsFT6PVlXHGQ0chMeBiq_UHtIWHRZzO4'''</p> |

| | + | '''OEE (Overall Equipment Effectiveness) and TEEP (Total Effective Equipment Performance) metrics and underlying variables''' |

| | | | |

| − |

| + | | <p dir="ltr" style="text-align: center;">'''https://lh5.googleusercontent.com/EH-MLckEgTI0sDCcqkowDfY4J4GFnY5xvDkhrqrBvSR5hk8VNb4MFTeh06o1qxS3jDfPoa4GHaHb9SVfiujaAdT6aISHIMDIY3nyOlfPp1TigLsPb8F8s2PGrRm6pRMvR3J-FcwH0RvNlg7pseivzFQ'''</p> |

| | + | '''CMMS integration:<br/> Asset Management and Repair Work Order sync''' |

| | | | |

| − | '''[[File:DefineUPH.png|700px|DefineUPH.png]]''' | + | |- |

| | + | | <p dir="ltr" style="text-align: center;">'''https://lh3.googleusercontent.com/U2JNURrQ9-ym1zF_w1xzMb_2KtFAqCv9XHuZ1ov96tho0uLEvyZFnbQfzV52lGJx6MnWuVhAuk8ol5hmdhsE_KBu9sXDG5v0KOqNmfr6n11EeKHlPrX6ertkuI6mGYlyuCvQANahWmCFBA0pmCP0Ew8'''</p> |

| | + | '''IIoT - Machine signals/error code contextualization and mappings''' |

| | | | |

| − |

| + | | <p dir="ltr" style="text-align: center;">'''https://lh6.googleusercontent.com/lPJQuzhuGoy6ZLtT-icf42eLxjrfsG4Zjkugq8gWqNIO9_nm1v8_tYrdQ5oZSieLv_U5XsiYzR_bEX351iYIITCKNqBxSn-R4kIdHBKgjPVlD9zyFb1m8z7MmlqRxosaDPpQzFJV4NOk1rHljsTBYFc'''</p> |

| | + | '''Digital signage:<br/> Fully configurable, TV-friendly factory layout infographic''' |

| | | | |

| − | === <span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines"><span class="mw-headline" id="SOMS_Target:_Define_Target_for_Mfg._Lines">SOMS Target: Define Target for Mfg. Lines</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> ===

| + | | <p dir="ltr" style="text-align: center;">'''https://lh5.googleusercontent.com/2NEOHI241dklv3QAqeQPftbOPoHL5P58HL3PfljrvsklrtPfWaIyWNhat9-U8ww0jhngItxDqtSHkIIeyZbe2dST5ol0pQTIOPViNpbJZEUFD7eH3Vx8xjSsWo4QNK8WHl3wEKFSadIOj8dGWz3JAVY'''</p> |

| | + | '''Report asset events with bulk upload capability''' |

| | | | |

| − | The SOMS Target is used to configure target data according to Manufacturing line, Process, and Part Number. The configuration also determines how MES 101 data (e.g. target yields, throughputs, top defects, etc.) will be displayed in Operation Dashboard and 42Q Live.

| + | | <p dir="ltr" style="text-align: center;">'''https://lh3.googleusercontent.com/lfWQCmRKoJTnTHMWzmX4afL3Ag7Hv6LCumt_Kav3OPDA0kKqht6nYgRggMS_-BGaGfkLrYmdgZRe3vprlotg5vqYj11ebtr6f68v6_cDrsF7souEpbR5gtOD27OqoOyb2OdNcJO_dSgIZEOWxjNuh7g'''</p> |

| | + | '''Reports & dashboards: with drill-down capability for troubleshooting and trend analysis''' |

| | | | |

| − | '''[[File:SOSTarget.png|700px|SOSTarget.png]]''' | + | |} |

| | + | <br/> |

| | + | = '''The benefits of an automated data collection''' = |

| | | | |

| − |

| + | ---- |

| | | | |

| − |

| + | 42Q’s OEE system allows manual or automatic data collection and interpretation.<br/> Although automated data collection might require some larger initial effort, it is a much more powerful and less error-prone strategy delivering more accurate and consistent information. |

| | | | |