Difference between revisions of "42Q-MES0085-C Conduit Command Appendix"

| Line 2,254: | Line 2,254: | ||

| | ||

| − | == <span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M">'''<span class="mw-headline" id="M">M</span>'''</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | + | |

| + | == <span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M"><span class="mw-headline" id="M">'''<span class="mw-headline" id="M">M</span>'''</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | ||

| | ||

| − | === <span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial">'''<span class="mw-headline" id="MergeBatchSerial">MergeBatchSerial</span>'''</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === | + | === <span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial"><span class="mw-headline" id="MergeBatchSerial">'''<span class="mw-headline" id="MergeBatchSerial">MergeBatchSerial</span>'''</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === |

'''Description: '''Merge the provided batch serial number into the scanned batch unit. | '''Description: '''Merge the provided batch serial number into the scanned batch unit. | ||

| Line 2,270: | Line 2,271: | ||

|- | |- | ||

| style="width:330px" | | | style="width:330px" | | ||

| − | + | Merge Serial Number? | |

| − | | style="width:396px" | <span style="color:#c0392b;"> | + | | style="width:396px" | <span style="color:#c0392b;">merge_serial_number*</span> |

|} | |} | ||

| + | | ||

| | ||

| − | === '''<span class="mw-headline">MOVE</span>''' === | + | === <span class="mw-headline" id="MOVE">'''<span class="mw-headline">MOVE</span>'''</span> === |

'''Description: '''Moves the scanned unit to the specified workstation. The move to the workstation can be supplied in shorter style (e.g., COMP) or long formats (e.g., COMP Complete). | '''Description: '''Moves the scanned unit to the specified workstation. The move to the workstation can be supplied in shorter style (e.g., COMP) or long formats (e.g., COMP Complete). | ||

| Line 2,292: | Line 2,294: | ||

|- | |- | ||

| style="width: 191px;" | | | style="width: 191px;" | | ||

| − | + | Workstation? | |

| − | | style="width: 250px;" | <span style="color:#c0392b;"> | + | | style="width: 250px;" | <span style="color:#c0392b;">workstation*</span> |

| style="width: 226px;" | | | style="width: 226px;" | | ||

| − | + | Move Password? | |

| − | | style="width: 227px;" | | + | | style="width: 227px;" | move_password |

|} | |} | ||

| − | | + | |

| + | | ||

| + | |||

| | ||

| − | === '''MoveFromHold''' === | + | === <span class="mw-headline" id="MoveFromHold">'''MoveFromHold'''</span> === |

'''Description: '''Conduit implementation of MOVEFROMHOLD. | '''Description: '''Conduit implementation of MOVEFROMHOLD. | ||

| Line 2,315: | Line 2,319: | ||

|- | |- | ||

| style="width:330px" | | | style="width:330px" | | ||

| − | + | Serials To Move? | |

| − | | style="width:396px" | | + | | style="width:396px" | <span style="color:#c0392b;">serialsToMove*</span> |

|} | |} | ||

<br/> | <br/> | ||

| − | === '''MoveIfAttributeData''' === | + | === <span class="mw-headline" id="MoveIfAttributeData">'''MoveIfAttributeData'''</span> === |

| + | |||

| + | '''Description:''' Conduit implementation of MOVEIFATT. | ||

| + | |||

| + | '''Parameters: '''ParametersFields that can be passed to Move If Attribute Data calls. | ||

| + | /> /> /> /> /> /> | ||

| + | {| | ||

| + | |- | ||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | '''Attribute Name To Check?''' | ||

| + | |||

| + | | | ||

| + | '''checkAttrName*''' | ||

| + | |||

| + | | | ||

| + | '''Expected Attribute Value?''' | ||

| + | |||

| + | | | ||

| + | '''checkAttrData*''' | ||

| + | |||

| + | | | ||

| + | '''Move Location?''' | ||

| + | |||

| + | | | ||

| + | '''moveLoc*''' | ||

| − | + | |} | |

| | ||

| − | + | | |

| − | If the command does not find an active component with ref_designator matching ref param, then it moves the unit to the location specified in moveloc param. | + | === '''MoveIfComponentAt''' === |

| + | |||

| + | '''Description: '''Moves the scanned unit to the specified destination when the specified reference designator exists as a component. | ||

| + | |||

| + | '''Parameters: '''ParametersFields that can be passed to Move If Component At calls. | ||

| + | |||

| + | {| border="1" class="wikitable" style="font-size: 13px; width: 909px;" | ||

| + | |- | ||

| + | | style="width: 191px; text-align: center;" | '''Prompt ''' | ||

| + | | style="width: 250px; text-align: center;" | '''Value to be entered''' | ||

| + | | style="width: 226px;" | <p style="text-align: center;"> '''Prompt''' </p> | ||

| + | | style="width: 227px; text-align: center;" | '''Value to be entered''' | ||

| + | |- | ||

| + | | style="width: 191px;" | | ||

| + | '''Reference Designator?''' | ||

| + | |||

| + | | style="width: 250px;" | '''ref_designator*''' | ||

| + | | style="width: 226px;" | | ||

| + | '''Destination Workstation?''' | ||

| + | |||

| + | | style="width: 227px;" | '''destination*''' | ||

| + | |} | ||

| + | |||

| + | <br/> | ||

| + | |||

| + | === <span class="mw-headline" id="Move_If_MissingComponent"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component"><span class="mw-headline" id="Move_If_Missing_Component">'''MoveIfMissingComponent'''</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> === | ||

| + | |||

| + | '''Description: '''Conduit implementation of MOVEIFNOREF. | ||

| + | |||

| + | '''If the command does not find an active component with ref_designator matching ref param, then it moves the unit to the location specified in moveloc param.''' | ||

| + | |||

| + | '''Parameters: '''ParametersFields that can be passed to Move If Missing Component calls. | ||

| + | /> /> /> /> | ||

| + | {| | ||

| + | |- | ||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | '''Reference Designator To Check?''' | ||

| + | |||

| + | | | ||

| + | '''refDesignatorToCheck*''' | ||

| + | |||

| + | | | ||

| + | '''Move Location?''' | ||

| + | |||

| + | | | ||

| + | '''moveLoc*''' | ||

| + | |||

| + | |} | ||

| + | |||

| + | | ||

| + | |||

| + | | ||

| + | |||

| + | == '''MoveIfRef''' == | ||

| + | |||

| + | '''Description: Conduit implementation of MOVEIFREF.''' | ||

| + | |||

| + | '''Parameters: ParametersFields that can be passed to Move If Ref calls.''' | ||

| + | /> /> /> /> | ||

| + | {| | ||

| + | |- | ||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | '''Ref Designator To Check?''' | ||

| + | |||

| + | | | ||

| + | '''refDesignatorToCheck*''' | ||

| + | |||

| + | | | ||

| + | '''Move Location?''' | ||

| + | |||

| + | | | ||

| + | '''moveLoc*''' | ||

| + | |||

| + | |} | ||

| + | <br/> | ||

| + | == '''MoveUnitTo''' == | ||

| + | |||

| + | '''Description: Moves the units to the specified workstation. The move to workstation can be supplied in shorter style (e.g., COMP) or long formats (e.g., COMP Complete).''' | ||

| + | |||

| + | '''Parameters: ParametersFields that can be passed to Move Unit To calls.''' | ||

| + | /> /> /> /> /> /> | ||

| + | {| | ||

| + | |- | ||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | | | ||

| + | '''Prompt''' | ||

| + | |||

| + | | | ||

| + | '''Value to be entered ''' | ||

| + | |||

| + | |- | ||

| + | | | ||

| + | '''Workstation?''' | ||

| + | |||

| + | | | ||

| + | '''workstation*''' | ||

| + | |||

| + | | | ||

| + | '''Move Password?''' | ||

| + | |||

| + | | | ||

| + | '''move_password''' | ||

| + | |||

| + | | | ||

| + | '''Unit Serial Number?''' | ||

| + | |||

| + | | | ||

| + | '''unit_serial_number*''' | ||

| + | |||

| + | |} | ||

== <span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O">'''<span class="mw-headline" id="O">O</span>'''</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | == <span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O"><span class="mw-headline" id="O">'''<span class="mw-headline" id="O">O</span>'''</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | ||

Revision as of 18:17, 12 January 2022

42Q Home > Conduit > Conduit Command Appendix

Contents

- 1 Command Appendix Registry

- 1.1 A

- 1.1.1 AddAttribute

- 1.1.2 AddAttributeTo

- 1.1.3 AddAttributeToUnits

- 1.1.4 AddComment

- 1.1.5 AddCommentTo

- 1.1.6 AddConsumableBatchComponent

- 1.1.7 AddConsumableNon-TrackedComponent

- 1.1.8 AddCustomerReportTimeStamp

- 1.1.9 AddDefect

- 1.1.10 AddDefinedAttribute

- 1.1.11 AddMeasurementKey

- 1.1.12 AddMeasurementKeyTo

- 1.1.13 AddNon-SerializedToContainer

- 1.1.14 AddNon-TrackedAssemblyComponent

- 1.1.15 AddNontrackedComponent

- 1.1.16 AddNon-TrackedComponentTo

- 1.1.17 AddToContainer

- 1.1.18 AddToLot

- 1.1.19 AddToShopOrder

- 1.1.20 AddTrackedAssemblyComponent

- 1.1.21 AddTrackedComponent

- 1.1.22 AddTrackedComponentTo

- 1.1.23 AddUniqueAssemblyComponent

- 1.1.24 AddUniqueComponent

- 1.1.25 AddUnitToContainer

- 1.1.26 AddUnitToLot

- 1.1.27 AdvancedShopOrderUnits

- 1.1.28 AppendMeasurement

- 1.1.29 ApplyAlgorithmToUnit

- 1.1.30 ApplyMeo

- 1.1.31 ApplyMfgEngineeringOrder

- 1.1.32 AssertAttribute

- 1.1.33 AssertScanningUnit

- 1.1.34 AssertStationUnitCount

- 1.1.35 AssertValue

- 1.1.36 AssignDistinctNon-TrackedComponent

- 1.1.37 AssignIPV4MacAddress

- 1.1.38 AssignMacAddresses

- 1.1.39 AssignUnitsToNextShopOrder

- 1.2 B

- 1.3 C

- 1.3.1 ChangePartNumber

- 1.3.2 ChangeRevision

- 1.3.3 ChangeSerialAlgorithm

- 1.3.4 ChangeSerialNumber

- 1.3.5 ChangeSerialToComponentId

- 1.3.6 ChangeUnitShopOrder

- 1.3.7 CheckAlgorithmOrderPoint

- 1.3.8 CheckDefectBoardLocCount

- 1.3.9 CheckComponentCount

- 1.3.10 CheckDefectCount

- 1.3.11 CheckFailureCount

- 1.3.12 CheckFromLocation

- 1.3.13 CheckIn

- 1.3.14 CheckOut

- 1.3.15 CheckProcessExits

- 1.3.16 CheckShopOrderLocationIfExpired

- 1.3.17 CheckStationCycles

- 1.3.18 ClearMatchingAttributes

- 1.3.19 ClearNon-MatchingAttributes

- 1.3.20 CloseContainer

- 1.3.21 CloseLot

- 1.3.22 ConditionalContainerization

- 1.3.23 ConsumeAlgorithm

- 1.3.24 ConsumeNon-SerializedBatch

- 1.3.25 ConsumeSitBatch

- 1.3.26 CreateBatchSerial

- 1.3.27 CreateContainer

- 1.3.28 CreateGeneratedBatchSerial

- 1.3.29 CreateLot

- 1.3.30 CreateUnit

- 1.4 D

- 1.5 E

- 1.6 F

- 1.7 H

- 1.8 I

- 1.9 K

- 1.10 L

- 1.11 M

- 1.12 MoveIfRef

- 1.13 MoveUnitTo

- 1.14 O

- 1.15 P

- 1.16 R

- 1.16.1 ReconcileComponentMFGHolds

- 1.16.2 RecordDefect

- 1.16.3 RecordMedia

- 1.16.4 RegexMatch

- 1.16.5 RegexReplace

- 1.16.6 RejectIfDefective

- 1.16.7 RejectIfMissingAttribute

- 1.16.8 RejectIfMissingAttributes

- 1.16.9 RejectIfMissingComponents

- 1.16.10 RejectIfMissingProcessAttributes

- 1.16.11 RemoveAllComponents

- 1.16.12 RemoveAttribute

- 1.16.13 RemoveComponent

- 1.16.14 RemoveComponentFrom

- 1.16.15 RemoveProcesAttributes

- 1.16.16 RemoveProcessComponents

- 1.16.17 RemoveUnitFromContainer

- 1.16.18 RemoveUnitFromLot

- 1.16.19 RenderLabel

- 1.16.20 RepairDefect

- 1.16.21 ReplaceAttribute

- 1.16.22 ReplaceAttributeOn

- 1.16.23 ReplaceComponent

- 1.16.24 ReplaceComponentAt

- 1.16.25 ReplaceConsumedNonSerializedBatch

- 1.16.26 ReplaceNontrackedAssemblyComponent

- 1.16.27 ReplaceNontrackedComponent

- 1.16.28 ReplaceNontrackedComponentAt

- 1.16.29 ReplaceNontrackedComponentOn

- 1.16.30 ReplaceOnBoardPtsComponent

- 1.16.31 ReplaceTrackedAssemblyComponent

- 1.16.32 ReplaceTrackedComponent

- 1.16.33 ReplaceTrackedComponentAt

- 1.16.34 ReplaceTreeComponent

- 1.16.35 ReplaceUniqueComponent

- 1.16.36 ReplaceUniqueComponentAt

- 1.16.37 ReplaceUnitTreeComponent

- 1.16.38 RestoreLegacyArchiveUnit

- 1.17 S

- 1.18 T

- 1.19 U

- 1.20 V

- 1.1 A

- 2 Conduit Command Listing

Command Appendix Registry

The commands defined within the Conduit Command Registry represent the core functionality of the Conduit system. Unlike with legacy systems, Conduit commands are full words, generally Pascal case (though technically command names are case insensitive.)

In addition to the more extensive names, Conduit Commands tend to be more focused on a single concept. Most Conduit commands expect all of their data to be provided upfront, leaving the work of gathering that data to the various client implementations in conjunction with the CCRS.

The commands referencing Assembly or Defined components and attributes respectively are designed for use with the Scanning Template mechanism in Conduit. The basic concept is that the actual command to use (tracked, unique, non tracked, etc.) will be provided by Conduit. Individual clients only need to prompt for the appropriate piece of data to satisfy the scan template then construct a Client Command from the Scan Template + user input.

The full list of commands and a short explanation of each are given below:

A

AddAttribute

Description: Adds an attribute to the scanned unit. This command will produce an error if the attribute already exists, no replacement will occur.

Parameters: ParametersFields that can be passed to Add Attribute calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Attribute Name? |

attr_name* | Attribute Value? | attr_data* |

Mask? |

mask |

AddAttributeTo

Description: Adds an attribute to the specified unit serial number. This command will produce an error if the attribute already exists, no replacement will occur.

Parameters: ParametersFields that can be passed to Add Attribute To calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Unit Serial Number? |

unit_serial_number* | Attribute Name? | attr_name* | Attribute Value? | attr_data* | Mask? | mask |

AddAttributeToUnits

Description: Adds an attribute to the specified unit serial number(s). This command will produce an error if the attribute already exists, no replacement will occur.

Parameters: ParametersFields that can be passed to Add Attribute To Units calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

Unit Serial Number? |

unit_serial_number* | Attribute Name? | attr_name* | Attribute Value? | attr_data* | Mask? | mask |

AddComment

Description: Adds a comment checked against an optional mask to the scanned unit.

Parameters: ParametersFields that can be passed to Add Comment calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Comment Text? |

comment_text* |

Mask? |

mask |

AddCommentTo

Description: Adds a comment checked against an optional mask to the specified unit.

Parameters: ParametersFields that can be passed to Add Comment To calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Unit Serial Number? |

unit_serial_number* | Unit Part Number? | unit_part_number | Comment Text? | comment_text* | Mask? | mask |

AddConsumableBatchComponent

Description: ParametersFields that can be passed to Add Consumable Batch Component calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt |

|

Reference Designator? |

ref_designator* | Batch Serial Number? | primary_batch_number* | Batch Quantity? | component_quantity* | Component Id Mask? | comp_id_mask | Component Part Number? |

AddConsumableNon-TrackedComponent

Description: ParametersFields that can be passed to Add Consumable Non-Tracked Component calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Reference Designator? |

ref_designator* | Batch Serial Number? | component_id* | Batch Quantity? | component_quantity* | Component Id Mask? | comp_id_mask | Component Part Number? | comp_part_mask |

AddCustomerReportTimeStamp

Description: Creates a timestamp to have serial info sent to the customer.

Parameters: ParametersFields that can be passed to Add Customer Report TimeStamp calls.

Prompt |

Value to be entered |

|

Customer? |

customer* |

AddDefect

Description: Records a defect against the scanned unit. More streamlined input requirements than RecordDefect.

Parameters: ParametersFields that can be passed to Add Defect calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Defect Code? |

defect_code* | Ref Designator or N/A? | ref_designator |

Repair Code YES/NO/NFF/Code? |

repair_code |

AddDefinedAttribute

Description: Add Defined Attribute is equivalent to ATTADD in SFDC. Unlike SFDC it is designed to be used with the Conduit “Scanning Template” construct for units that have active/unreconciled Assembly / Attr_Def entries. AddMeasurementKey Add Measurement Key is equivalent to MEASKEY in SFDC.

AddMeasurementKey

Description: Adds a measurement key to the scanned unit.

AddMeasurementKeyTo

Description: Adds a measurement key to the specified unit.

Parameters: ParametersFields that can be passed to Add Measurement Key To calls.

Prompt |

Value to be entered |

|

Unit Serial Number? |

unit_serial_number* |

AddNon-SerializedToContainer

Description: Adds provided Non-Serialized to the scanned container serial.

Parameters: ParametersFields that can be passed to Add Non-Serialized To Container calls.

AddNon-TrackedAssemblyComponent

Description: Add Nontracked Assembly Component is a “Scanning Template” specific command for adding a non-tracked component based on an unreconciled assembly record for a unit. It is equivalent to ADCMP

AddNontrackedComponent

Description: Adds a non-tracked component to the scanned unit. This command will not replace an existing unremoved component with that component id but it will mark a previously removed component as replaced.

Parameters: ParametersFields that can be passed to Add Non-Tracked Component calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Reference Designator? |

ref_designator* | Component Part Number? | component_part_number | Component Id? | component_id* | Component Id Mask? | comp_id_mask |

AddNon-TrackedComponentTo

Description: Adds a non-tracked component to the specified unit. Unlike Add Non-Tracked Component this does not require a scanned unit. This command will not replace an existing unremoved component with that component id but it will mark a previously removed component as replaced.

Parameters: ParametersFields that can be passed to Add Non-Tracked Component To calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Unit Serial Number? |

unit_serial_number* | Reference Designator? | ref_designator* | Component Part Number? | component_part_number | Component Id? | component_id* | Component Id Mask? | comp_id_mask |

Warning: Using either of these AddNontrackedComponent/To commands multiple times for a given serial and ref_designator can result in multiple active components with the same ref_designator. In order to remove and replace an existing component for a serial/ref_designator, so that only one is active, you must use the ReplaceNontrackedComponent/To the version of these commands.

AddToContainer

Description: Adds scanned unit serial number to the specified container serial.

Parameters: ParametersFields that can be passed to Add To Container calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Container Serial Number? |

container_serial_number* |

Container Part Number? |

container_part_number |

AddToLot

Description: Adds the scanned unit serial number to the specified lot.

Parameters: ParametersFields that can be passed to Add To Lot calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Lot Serial Number? |

lot_serial_number* |

Lot Part Number? |

lot_part_number |

AddToShopOrder

Description: Assign the scanned unit to a shop order.

Parameters: ParametersFields that can be passed to Add to Shop Order calls.

Prompt |

Value to be entered |

|

New Shop Order Number? |

new_shop_order_number* |

AddTrackedAssemblyComponent

Description: Add Tracked Assembly Component is the tracked version of the Scanning Template enabled ADCMP command in SFDC.

AddTrackedComponent

Description: Adds a tracked or standard component to the scanned unit. This command will not replace an existing unremoved component with a matching <component id> but it will mark a previously removed component as replaced.

Parameters: ParametersFields that can be passed to Add Tracked Component calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Reference Designator? |

ref_designator* | Component Id? | component_id* | Component Workstation? | workstation | Component Part Number? | component_part_number | Component Id Mask? | comp_id_mask |

AddTrackedComponentTo

Description: Adds a tracked or standard component to the specified unit. This command will not replace an existing unremoved component with a matching <component id> but it will mark a previously removed component as replaced.

Parameters: ParametersFields that can be passed to Add Tracked Component To calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Unit Serial Number? |

unit_serial_number* | Reference Designator? | ref_designator* |

Component Id? |

component_id* |

| Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

| Component Workstation? | workstation | Component Part Number? | component_part_number | Component Id Mask? | comp_id_mask |

Warning: Using either of these AddTrackedComponent/To commands multiple times for a given serial and ref_designator can result in multiple active components with the same ref_designator. In order to remove and replace an existing component for a serial/ref_designator, so that only one is active, you must use theReplaceTrackedComponent/To the version of these commands.

AddUniqueAssemblyComponent

Description: Add Unique Assembly Component is the unique component version of the Scanning Template enabled ADCMP command in SFDC. AddUniqueComponent Add Unique Component has no corollary in SFDC today. It is designed to add a unique component without a predefined assembly record just like ADCMP2 (non-tracked) or ADCMP3 (tracked). AddUnitToContainer Add Unit To Container has no equivalent command in SFDC. SFDC Containerization essentially does the same thing via complicated mini-sessions executed after NEWCNTNR / OPENCNTNR.

AddUniqueComponent

Description: Creates and adds a unique component to the scanned unit. This command will not replace an existing unremoved component with a matching <component id> but it will mark a previously removed component as replaced.

Parameters: ParametersFields that can be passed to Add Unique Component calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Reference Designator? |

ref_designator* | Component Id? | component_id* | Component part number? | component_part_number | Component Id Mask? | comp_id_mask |

AddUnitToContainer

Description: Adds provided unit serial number to the scanned container serial.

Parameters: ParametersFields that can be passed to Add Unit To Container calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Unit Serial Number? |

unit_serial_number* |

Unit Part Number? |

unit_part_number |

AddUnitToLot

Description: Adds the provided unit serial number to the scanned lot.

Parameters: ParametersFields that can be passed to Add Unit To Lot calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Unit Serial Number? |

unit_serial_number* |

Unit Part Number? |

unit_part_number |

AdvancedShopOrderUnits

Description: Ends up to <unit limit> units for the supplied shop order number at the provided workstation. Units are chosen in FIFO order for the specified workstation. This command can be executed without a transaction unit.

Parameters: ParametersFields that can be passed to Advance Shop Order Units calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Shop Order Number? |

shop_order_number* | Workstation? | workstation* |

Unit Limit? |

unit_limit |

AppendMeasurement

Description: Find the most recent measurement key for the scanning process or add a new one if none exists and then record a measurement against it.

Parameters: ParametersFields that can be passed to Append Measurement calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Group? |

groups_2* | Step Name? | steps_2* |

Measurement? |

values_2* |

ApplyAlgorithmToUnit

Description: Change the provided unit serial number by applying the specified algorithm number to it.

Parameters: ParametersFields that can be passed to Apply Algorithm To Unit calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Unit Serial Number? |

unit_serial_number* |

Unit Part Number? |

unit_part_number |

ApplyMeo

Description: Applying Meo is equivalent to ADMEO.

ApplyMfgEngineeringOrder

Description: Adds a Manufacturing Engineering Order number to the scanned unit.

Parameters: ParametersFields that can be passed to Apply Mfg Engineering Order calls.

Prompt |

Value to be entered |

|

MEO Number? |

meo_number* |

AssertAttribute

Description: AssertAtribute validates that the attribute exists.

Parameters: The parameters to execute are:

- Attribute Name: This is the name of the defined attribute to be compared.

- No Op If Missing: This validates whether the attribute exists in the scanned serial number or not.

Note: If the attribute does not exist Conduit will send an error message.

- Expression Operator: Logic Expressions can be:

- EQ Equals to the expected value.

- NE No equal to the expected value.

- GT Greater than the low limit.

- LT Less than the high limit.

- GE Greater than or equal to the low limit.

- LE Less than or equal to the high limit.

- GTLT Greater than the low limit and less than the high limit.

- GELE Greater than or equal to the low limit and less than or equal to the high limit.

- GTLE Greater than the low limit and less than or equal to the high limit.

- GELT Greater than or equal to the low limit and less than the high limit.

- LTGT Less than the low limit and greater than the high limit.

- LEGE Less than or equal to the low limit and greater than or equal to the high limit.

- LTGE Less than the low limit and greater than or equal to the high limit.

- LEGT Less than or equal to the low limit and greater than the high limit.

- CONTAINS Check if the tested value is within the expected item list.

- First Comparator: The first value to compare with the current value.

- Remaining Comparators: The list of the other values to be compared with the current value.

- Error Message: The message that returns when the comparison between the value and the first comparator is not true.

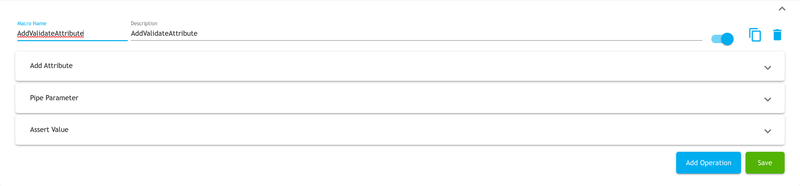

Note: This command should not be used directly in Production Workbench, to execute this command, a Macro and an AutoCommand must be created previously at the Command Register.

The Figure below shows the AssertAttribute Macro calling the AutoCommand.

Figure 1: AssertAttribute Macro calling the AutoCommand

AssertScanningUnit

Description: Helper operation to confirm the scanned serial number matches the checked serial number, typically a box label.

Parameters: ParametersFields that can be passed to Assert Scanning Unit calls.

Prompt |

Value to be entered |

|

Checked Serial Number? |

unit_serial_number* |

AssertStationUnitCount

Description: Counts the units at a specific location (Use packing stations to limit units to avoid mixing labels).

Conduit implementation of'VERQTY

Parameters: ParametersFields that can be passed to Assert Station Unit Count calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Check Location? |

stationToCheck* |

Unit Count Limit? |

countLimit* |

AssertValue

Description: Assert Value compares set values.

Parameters: The parameters to execute are:

- Value: The current value to be compared.

- Expression Operator: Logic Expressions can be:

- EQ Equals to the expected value.

- NE No equal to the expected value.

- GT Greater than the low limit.

- LT Less than the high limit.

- GE Greater than or equal to the low limit.

- LE Less than or equal to the high limit.

- GTLT Greater than the low limit and less than the high limit.

- GELE Greater than or equal to the low limit and less than or equal to the high limit.

- GTLE Greater than the low limit and less than or equal to the high limit.

- GELT Greater than or equal to the low limit and less than the high limit.

- LTGT Less than the low limit and greater than the high limit.

- LEGE Less than or equal to the low limit and greater than or equal to the high limit.

- LTGE Less than the low limit and greater than or equal to the high limit.

- LEGT Less than or equal to the low limit and greater than the high limit.

- CONTAINS Check if the tested value is within the expected item list.

- First Comparator: The first value to compare with the current value.

- Remaining Comparators: The list of the other values to be compared with the current value.

- Error Message: The message that returns when the comparison between the value and the first comparator is not true.

Note: This command should not be used directly in Production Workbench, to execute this command, a Macro and an AutoCommand must be created previously at the Command Register.

The following Figures show how this attribute works in Command Register.

Figure 2: Create a Macro

Figure 3: Create an Auto Command in a Prepend to call the previously created Macro (Figure 1)

AssignDistinctNon-TrackedComponent

Description: Generate a component id from a specified algorithm number and add it as a non tracked component with a specified ref designator.

Parameters: ParametersFields that can be passed to Assign Distinct Nontracked Component calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Algorithm Number? |

algo_number* |

Reference Designator? |

ref_des* |

AssignIPV4MacAddress

Description: Generate IPV4 MAC address from specified algorithm number and add as non tracked component with specified ref designator.

Parameters: ParametersFields that can be passed to Assign IPV4 Mac Address calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Algorithm Number? |

algo_number* |

Reference Designator? |

ref_des* |

AssignMacAddresses

Description: Generate one or more MAC addresses using the specified algorithm number and add them as nontracked components on the scanned unit.

Parameters: ParametersFields that can be passed to Assign Mac Addresses calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Algorithm Number? |

algorithm_number* |

Count? |

count* |

AssignUnitsToNextShopOrder

Description: Assign the specified set of unit serial numbers to the oldest eligible shop orders.

Parameters: ParametersFields that can be passed to Assign Units To Next Shop Order calls.

Prompt |

Value to be entered |

|

Serial Number? |

unit_serial_numbers* |

B

BackgroundPrintLabel

Description: Schedules background printing of the specified label name for the scanned unit serial number to the specified print queue.

Parameters: ParametersFields that can be passed to Background Print Label calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Label Name? |

label_name* |

Print Queue? |

print_queue* |

C

ChangePartNumber

Description: Changes the part number of the scanned unit.

Parameters: ParametersFields that can be passed to Change Part Number calls.

Prompt |

Value to be entered |

|

New Part Number? |

new_part_number* |

ChangeRevision

Description: Changes the revision for the scanned unit.

Parameters: ParametersFields that can be passed to Change Revision calls.

Prompt |

Value to be entered |

|

New Revision? |

new_revision |

ChangeSerialAlgorithm

Description: Generates a new unit id with the specified algorithm and changes the serial number of the scanned unit.

Parameters: ParametersFields that can be passed to Change Serial Algorithm calls.

Prompt |

Value to be entered |

|

Algorithm Number? |

algorithm_number* |

ChangeSerialNumber

Description: Changes the serial number of the scanned unit.

Parameters: ParametersFields that can be passed to Change Serial Number calls.

Prompt |

Value to be entered |

|

New Serial Number? |

new_serial_number* |

ChangeSerialToComponentId

Description: Conduit implementation of CHGIDREF

Verifies one component matching a specified reference designator is assigned to a serial number and runs a duplicate check on the component. If there is a component error, the command records a specified component error defect code against the component.

If there is no component error then the serial number is changed to the component id found at the specified reference designator.

Parameters: ParametersFields that can be passed to Change Serial To Component Id calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Component Reference Designator? |

refDesignatorToCheck* |

Error Defect Code? |

errorDefectCode* |

ChangeUnitShopOrder

Description: Removes the non-wip unit from its existing shop order and adds it to specified shop order.

Parameters: ParametersFields that can be passed to Change Unit Shop Order calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Unit Serial Number? |

unit_serial_number* | New Shop Order Number? | new_shop_order_number* |

Source Unit Status? |

source_unit_status_key* |

| Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

| Move To Location? | destination* | Source Workstation? | source_workstation | Force Common Shop Order Part Number? | flag |

CheckAlgorithmOrderPoint

Description: Check if the order point threshold for the specified algorithm number has been achieved and initiate notification email(s) if necessary.

Parameters: ParametersFields that can be passed to Check Algorithm Order Point calls.

Prompt |

Value to be entered |

|

Algorithm Number? |

algorithm_number* |

CheckDefectBoardLocCount

Description: Records a defect and moves the unit if the specified board location has more than the provided limit/count defect(s).

Parameters: ParametersFields that can be passed to Check Defect Board Loc Count calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Fail Limit? |

fail_limit* | Board Location? | board_loc* | Move To Location? | destination* | Defect Code? | defect_code* |

CheckComponentCount

Description: Conduit implementation of CHKCMPQT.

Counts the number of components assigned to a serial number and compares that count to a specified count parameter. If the values do not match, the command passes the unit to a specified Fail location and records a W999 defect against the unit, else returns END to pass the unit to the next station.

Parameters: ParametersFields that can be passed to Check Component Count calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Expected Component Quantity? |

expectedCount* | Move Location? | moveLoc* |

Failure Defect Code? |

failureDefectCode* |

CheckDefectCount

Description: Count the number of defects matching the specified defect code and move to the Move To Location if the count matches or exceeds the specified max quantity.

Parameters: ParametersFields that can be passed to Check Defect Count calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

| Defect Code? | defect_code* | Max Qty? | max_qty* | Count NFF? (Y/N) |

CheckFailureCount

Description: Count the number of failures and move to the Move To Location if the count matches or exceeds the specified max quantity.

Parameters: ParametersFields that can be passed to Check Failure Count calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Max Qty? |

max_qty* |

Move To Location? |

move_to_loc* |

CheckFromLocation

Description: Conduit implementation of CHECKFROM. Verifies the last location movement activity of the scanned serial number matches the specified check location.

Parameters: ParametersFields that can be passed to Check From Location calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Check Location? |

stationToCheck* |

Defect Code? |

defectCode* |

CheckIn

Description: Moves the units to the specified workstation. The move to the workstation can be supplied in shorter style (e.g., COMP) or long formats (e.g., COMP Complete).

Parameters: ParametersFields that can be passed to Check Incalls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Workstation? |

workstation* | Move Password? | move_password |

Unit Serial Number? |

unit_serial_number |

CheckOut

Description: Moves the units to the previous workstation, before check-in.

Parameters: ParametersFields that can be passed to Check Outcalls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Move Password? |

move_password |

Unit Serial Number? |

unit_serial_number* |

CheckProcessExits

Description: Conduit implementation of CHKPROCQ. Checks the quantity of pass/fail activities at all locations for a group of processes. The command requires a string specifying the processes to be checked. If the quantity of pass and fail activities equals or is greater than the value specified by the moveqty parameter, the unit is moved to the location specified by the moveloc parameter.

Parameters: ParametersFields that can be passed to Check Process Exits calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Threshold Reached Move Location? |

moveLoc* | Process To Check? | processToCheck* |

Pass/Fail Limit? |

passFailLimit* |

CheckShopOrderLocationIfExpired

Description: If there is no activity for that unit at the specific process/location or expired based on the duration refuse to add to the container.

Parameters: ParametersFields that can be passed to Check Shop Order Location If Expired calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Check Location? |

workstation* |

Delay Period? |

duration* |

CheckStationCycles

Description: Check the specified station for the number of trips through that station and compare it to the specific max and move it to the specified move to location when the value is exceeded.

Parameters: ParametersFields that can be passed to Check Station Cycles calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Check Location? |

workstation* | Move To Location? | move_to_loc* |

Max Qty? |

max_qty |

ClearMatchingAttributes

Description: Removes attributes that match the provided name/pattern from the scanned unit.

Parameters: ParametersFields that can be passed to Clear Matching Attributes calls.

Prompt |

Value to be entered |

|

Attribute Name? |

attr_name* |

ClearNon-MatchingAttributes

Description: Removes any attributes not matching the provided name/pattern from the scanned unit.

Parameters: ParametersFields that can be passed to Clear Non-Matching Attributes calls.

Prompt |

Value to be entered |

|

Attribute Name? |

attr_name* |

CloseContainer

Description: Changes the status of the scanned container serial number to Closed. Roughly equivalent to CLOSECNTNR.

Parameters: ParametersFields that can be passed to Close Container calls.

Prompt |

Value to be entered | Prompt |

Value to be entered |

|

Container Serial Number? |

container_serial_number* |

Container Part Number? |

container_part_number |

CloseLot

Description: Changes the status of the scanned lot serial to Closed.

Parameters: ParametersFields that can be passed to Close Lot calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Lot Serial Number? |

lot_serial_number |

Lot Part Number? |

lot_part_number |

ConditionalContainerization

Description: Check process activity and optionally verify the presence of the specified reference designator.

Parameters: ParametersFields that can be passed to Conditional Containerization calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Check Reference Designator(s)? |

value | Component Missing Defect Code? | value_1 | Process Missing Defect Code? | value_2* | Processes To Check? | value_3* |

ConsumeAlgorithm

Description: Invokes the specified algorithm number and returns the generated value.

Parameters: ParametersFields that can be passed to Consume Algorithm calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Algorithm Number? |

algorithm_number* |

Product Number? |

unit_part_number |

ConsumeNon-SerializedBatch

Parameters: ParametersFields that can be passed to ConsumeNonSerializedBatch calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Batch Serial Number? |

primary_batch_number* | Base Reference Designator? | ref_designator* |

Batch Quantity? |

batch_quantity |

ConsumeSitBatch

Description: Consume the specified quantity from the provided Sit Batch serial and add a non-tracked component matching the sit batch serial number to the scanned unit at the specified reference designator.

Parameters: ParametersFields that can be passed to Consume Sit Batch calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Reference Designator? |

ref_designator* | Batch Serial Number? | primary_batch_number* |

Consume Quantity? |

consume_quantity* |

CreateBatchSerial

Description: Creates a Batch Serial number with the provided serial number, batch quantity, and shop order number. Can be executed in place of a transaction unit.

Parameters: ParametersFields that can be passed to Create Batch Serial calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Shop Order Number? |

shop_order_number* | Batch Quantity? | batch_quantity* | Batch Serial Number? | unit_serial_number* | Revision? | new_revision |

CreateContainer

Description: Create a container with the provided serial number using supplied the c_level and part definition. This command can be supplied in place of a transaction unit.

Parameters: ParametersFields that can be passed to Create Container calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

Container Level? |

c_level* | Container Part Number? | container_part_number | Container Serial Number? | container_serial_number | Project Id? | proj_id |

CreateGeneratedBatchSerial

Description: Creates a batch serial using the supplied quantity and shop order number. The actual batch serial number will be generated using provided algorithm. Can be executed in place of a transaction unit.

Parameters: ParametersFields that can be passed to Create Generated Batch Serial calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt |

|

Shop Order Number? |

shop_order_number* | Batch Quantity? | batch_quantity* | Algorithm Number? | algorithm_number* | Revision? | new_revision | Execute as Unit |

CreateLot

Description: Create a lot with the provided serial number using supplied the c_level and part definition. This command can be supplied in place of a transaction unit.

Parameters: ParametersFields that can be passed to Create Lot calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Lot Part Number? |

lot_part_number | Lot Serial Number? | lot_serial_number |

Project Id? |

proj_id |

CreateUnit

Description: Creates and scans a unit serial number using the specified serial number generation algorithm.

Parameters: ParametersFields that can be passed to Create Unit calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Algorithm Number? |

algorithm_number* | Unit Part Number? | unit_part_number* |

Revision? |

new_revision |

D

DeallocateStationMaterial

Description: Deallocate any material for the specified part number at the specified location or the scanning location.

DeferUnitPrompts

Description: Answer NEXT to all assembly and attribute prompts relevant to the scanned unit at the scanning station/process.

E

END

Description: END is effectively identical to END in SFDC.

F

FindActiveShopOrder

Description: Identify the active shop order for the mfg line associated with the location.

FindAttribute

Description: Find an attribute matching the specified name for the scanned unit. By default not finding the attribute is an ERROR condition but that can be overridden via parameter.

Parameters: ParametersFields that can be passed to Find Attribute calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Attribute Name? |

attr_name* |

No Op If Missing? |

no_op_if_missing |

FindClientStations

Description: Finds client stations.

FindNextStationUnit

Description: Finds the oldest unit at a station matching an optional part number and shop order number. The most recent unit at a station can be returned if LIFO (Last in, First out) is specified for the final parameter.

FindParent

Description: Finds the immediate parent of the provided component serial number.

Parameters: ParametersFields that can be passed to Find Parent calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Component Serial Number? |

component_serial_number |

Error If Not Found? |

error_if_not_found |

FindPrinters

Description: Identify the printers currently available to the label engine.

FindUnitActivity

Description: Attempts to find the unit activity for the provided serial number and optional part number.

FindUnitAttribute

Description: Find an attribute matching the specified name for the scanned unit. By default not finding the attribute is an ERROR condition but that can be overridden via parameter

FindUnitStation

Description: Finds the workstation at which the specified unit resides (if any.)

Prompt |

Value to be entered |

|

Unit Serial Number? |

unit_serial_number* |

H

hpeftpComponentsExtractionOperation

Description: Extract the components in two different orders displayed into the generated file.

Parameters: ParametersFields that can be passed to hpeftp Components Extraction Operation calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Levels Deep? |

levels_deep* |

Order Display? |

order_display* |

I

IncreaseNon-SerializedBatchQuantity

Description: Increase quantity of a non serialized batch.

Parameters: ParametersFields that can be passed to Increase Non-Serialized Batch Quantity calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt |

|

Unit Serial Number? |

unit_serial_number* | Unit Part Number? | part_number | Employee Number? | employee* | New Quantity? | new_quantity* | Execute as Unit |

IncrementaNumericalRevision

Description: Increment a numerical revision for the scanned unit.

Parameters: ParametersFields that can be passed to Increment numerical Revision calls.

Prompt |

Value to be entered |

|

New Revision? |

new_revision |

InitializeMeasurementKey

Description: Find the most recent measurement key for the scanning process or add a new one if none exists.

InitializePrinter

Description: Initializes printer graphics for all labels of the specified label type.

Parameters: ParametersFields that can be passed to Initialize Printer calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Label Type? |

label_type* |

Print Queue? |

print_queue* |

InitiateMaterialNon-Conformance

Description: Creates a non-conforming material against the specified material part number and optional serial number defect.

Parameters: ParametersFields that can be passed to Initiate Material Non Conformance calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Material Part Number? |

material_part_number* | Material Identifier? | material_id |

Defect Serial Number? |

unit_serial_number |

| Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

| Defect Sequence? | unit_defect_seq | Parent Serial Number? | parent_serial_number | External Reference Number? | external_reference_number |

InsuletPrintLabel

Description: Print Label from Label Engine Print History if any it was already printed based on the LOT#, if not then print label getting values from Target Maintenance.

Parameters: ParametersFields that can be passed to Insulet Print Label calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt |

Value to be entered |

|

Lot Number? |

lot_number* | Flex Field? | flex_field* |

Print Queue? |

print_queue* |

K

KillIfDuplicated

Description: Move the unit into the specified kill location if the first <match_size> characters of the scanned unit id match any existing or archived serial numbers.

Parameters: ParametersFields that can be passed to Kill If Duplicated calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Kill Location? |

workstation* |

Match Size? |

match_size |

L

LinkDefect

Description: Associates or links a defect from the specified serial number to another defect on the same or alternate serial number if the link does not already exist.

Parameters: ParametersFields that can be passed to Link Defect calls.

Prompt |

Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered | Prompt | Value to be entered |

|

From Serial Number? |

from_serial_number* | From Defect Sequence? | from_defect_seq* | To Serial Number? | to_serial_number | To Defect Sequence? | to_defect_seq* |

LinkMedia

Description: Links a media reference identifier to an existing activity for a serial number.

M

MergeBatchSerial

Description: Merge the provided batch serial number into the scanned batch unit.

Parameters: ParametersFields that can be passed to Merge Batch Serial calls.

Prompt |

Value to be entered |

|

Merge Serial Number? |

merge_serial_number* |

MOVE

Description: Moves the scanned unit to the specified workstation. The move to the workstation can be supplied in shorter style (e.g., COMP) or long formats (e.g., COMP Complete).

Parameters: ParametersFields that can be passed to Move calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Workstation? |

workstation* |

Move Password? |

move_password |

MoveFromHold

Description: Conduit implementation of MOVEFROMHOLD.

Parameters: ParametersFields that can be passed to Move From Hold calls.

Prompt |

Value to be entered |

|

Serials To Move? |

serialsToMove* |

MoveIfAttributeData

Description: Conduit implementation of MOVEIFATT.

Parameters: ParametersFields that can be passed to Move If Attribute Data calls. /> /> /> /> /> />

|

Prompt |

Value to be entered |

Prompt |

Value to be entered |

Prompt |

Value to be entered |

|

Attribute Name To Check? |

checkAttrName* |

Expected Attribute Value? |

checkAttrData* |

Move Location? |

moveLoc* |

MoveIfComponentAt

Description: Moves the scanned unit to the specified destination when the specified reference designator exists as a component.

Parameters: ParametersFields that can be passed to Move If Component At calls.

| Prompt | Value to be entered | Prompt |

Value to be entered |

|

Reference Designator? |

ref_designator* |

Destination Workstation? |

destination* |

MoveIfMissingComponent

Description: Conduit implementation of MOVEIFNOREF.

If the command does not find an active component with ref_designator matching ref param, then it moves the unit to the location specified in moveloc param.

Parameters: ParametersFields that can be passed to Move If Missing Component calls. /> /> /> />

|

Prompt |

Value to be entered |

Prompt |

Value to be entered |

|

Reference Designator To Check? |

refDesignatorToCheck* |

Move Location? |

moveLoc* |

MoveIfRef

Description: Conduit implementation of MOVEIFREF.

Parameters: ParametersFields that can be passed to Move If Ref calls. /> /> /> />

|

Prompt |

Value to be entered |

Prompt |

Value to be entered |

|

Ref Designator To Check? |

refDesignatorToCheck* |

Move Location? |

moveLoc* |

MoveUnitTo

Description: Moves the units to the specified workstation. The move to workstation can be supplied in shorter style (e.g., COMP) or long formats (e.g., COMP Complete).

Parameters: ParametersFields that can be passed to Move Unit To calls. /> /> /> /> /> />

|

Prompt |

Value to be entered |

Prompt |

Value to be entered |

Prompt |

Value to be entered |

|

Workstation? |

workstation* |

Move Password? |

move_password |

Unit Serial Number? |

unit_serial_number* |

O

OpenContainer

Changes the status of a container to Open. Do not initiate container serial scanning like OPENCNTR.

OpenLot

Changes the status of a lot to Open. Does not initiate lot serial scanning like OPEN LOT.

P

PrepareUnitContainer

Depending on the type of unit provided either create a container and add the specified unit to it or open the container in preparation for adding more units. This command can be supplied in place of a transaction unit.

PrintDemoLabel

Print a demo label name for the currently scanned unit serial number to the specified print queue.

PrintLabel

Print HPE label.

Print Legacy Label

Prints MES labels.

R

ReconcileComponentMFGHolds

Traverses the entire component tree and checks to see if a component serial is on hold. RecordDefect Records a defect against a unit. Equivalent to RCDFC in SFDC.

RecordDefect

Records a defect against the scanned unit. Equivalent to RCDFC in SFDC.

RecordMedia

Records a media activity against the scanned unit with the specified media reference identifier.

RegexMatch

Applies the provided regular expression to the specified value returning OK if it matches and either or NO-OP as specified.

RegexReplace

Replaces substrings that match the regular expression with the replacement string.

RejectIfDefective

Moves scanned unit to the relevant failure location if any unrepaired defects exist on that unit at all, otherwise, do nothing.

RejectIfMissingAttribute

Fails a unit that is missing the provided attribute. Equivalent to VERATT.LIST.

RejectIfMissingAttributes

Fails a unit that is missing any configured attributes. Equivalent to VERATT.ALL.

RejectIfMissingComponents

Fails a unit that is missing any assembly components. Unlike VERCMP this command has to be provided with a failure location just like Reject if Missing Attribute[s] (VERATT).

RejectIfMissingProcessAttributes

Fails a unit that is missing any attributes matching the current scanning location’s process. Effectively equivalent to VERATT.PROC.

RemoveAllComponents

Removes all components from a unit. Equivalent to RMCMPALL.

RemoveAttribute

Removes an attribute. Similar to ATTREMOVE but the specific attribute must be provided.

RemoveComponent

Removes a component. Similar to RMCMP2.

RemoveComponentFrom

Removes a component of any type matching the provided <component id> from the specified unit.

RemoveProcesAttributes

Removes any attributes defined for addition at the provided process from the scanned unit.

RemoveProcessComponents

Removes any components defined for addition at the provided process from the scanned unit.

RemoveUnitFromContainer

Removes a unit from a container. Equivalent to RMVFRMCNTNR.

RemoveUnitFromLot

Removes a unit from a lot. Equivalent to RMVFRMLOT.

RenderLabel

Signal the label engine service to render a printable label and download it to a local temporary file. Note: the downloaded file is only guaranteed to exist for the duration of the request session.

RepairDefect

Repair a defect on a unit. Similar to RCRPR but the defect sequence to be repaired must be provided.

ReplaceAttribute

Replace an existing attribute with a new attribute.

ReplaceAttributeOn

Replaces an attribute (if one exists) and adds one to the specified unit serial number. Similar to ADCMP2 for non-tracked components in SFDC this command does not require an existing attribute definition.

ReplaceComponent

Replaces a component at the provided <component id> on the scanned unit with a new component. Equivalent to RPCMP2 in SFDC.

ReplaceComponentAt

Replaces a component at the provided <reference designator> on the scanned unit with a new component.

ReplaceConsumedNonSerializedBatch

Replaces consumed non serialized batches.

ReplaceNontrackedAssemblyComponent

Replace a previously existing “Scanning Template” non-tracked component with a new one.

ReplaceNontrackedComponent