Difference between revisions of "42Q Labor Tracking"

| Line 162: | Line 162: | ||

| | ||

| − | = <span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F">How does Labor Tracking Work?</span></span></span></span></span></span></span> = | + | |

| + | = <span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F"><span class="mw-headline" id="How_does_Labor_Tracking_Work.3F">How does Labor Tracking Work ?</span></span></span></span></span></span></span></span> = | ||

Tracking time for operations in the manufacturing process is an important KPI as it is a major component of the product's final cost. 42Q’s Labor Tracking feature tracks a variety of direct and indirect labor activities using automated processes when applicable to make this data collection as non intrusive as possible. | Tracking time for operations in the manufacturing process is an important KPI as it is a major component of the product's final cost. 42Q’s Labor Tracking feature tracks a variety of direct and indirect labor activities using automated processes when applicable to make this data collection as non intrusive as possible. | ||

Revision as of 14:27, 18 May 2021

Labor Tracking

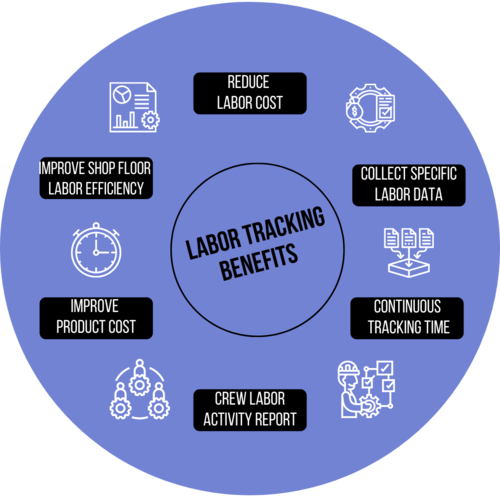

One of the most common concerns in the manufacturing world is the capturing and using of labor data. Manual data collection is inherently error-prone, and automated processes are often difficult to configure. Many companies strive to track and collect accurate information to enhance their production cycles. Having flexible and simple labor tracking can really help to track costs and time.

42Q Labor Tracking can help collect information about the labor involved in the build process, providing visibility to the amount and type of labor used. Engineers and planners can use that data to efficiently plan their build schedule, as well as to optimize the use of one of their most key resources - the operators.

Contents

What Is Labor Tracking ?

Labor Tracking is a capability within the 42Q Production Workbench, created to collect the labor so that the leadership can know the time that the employees of your company spent performing a process to build a product rather than guessing how long something will take. 42Q’s Labor Tracking allows operators to select orders and record their time as individuals or as members of a crew. Indirect labor (not part of the standard build process) can also be efficiently collected so that you know how much time is spent in training, meetings, or even lunchtime.

How can Labor Tracking Help Your Business ?

Labor Tracking stores the work time and indirect activities of those employees that are involved in the manufacturing process. Companies can take advantage of this information to explore strengths and improvement areas, making this a convenient tool to help save time and money.

Distinctive Features

Labor Tracking information comes from the operator(s) records, who are capable of:

|

Easily identify if a Shop Order or Serial Number is running at the moment. |

Have a time record of all the actions and activities that they execute to complete any job assigned to them, even indirect work. |

Switch between jobs while still having time control of each. |

Switch between different types of direct and indirect labor. |

|

Add employees to crews to measure overall performance.

|

Invite and add other employees to be part of a crew. |

Be able to work as a regular user or a crew user in the same standard client application. |

Pause, Resume, or Clock-Out jobs to make operators’ records easier to indicate when their efforts are paused or stopped, as well as to show if activities are active or not. |

Time tracking is more precise when it is done with an electronic system, even more, when it gathers information not only about employees’ performance as individuals but also about teamwork efforts because this can shorten the analysis of critical data and improve crew management. Labor Tracking works in collaboration with PWB (Product Workbench) which is the standard operation client to collect any type of manufacturing data, making it a one stop shop for manual data gathering in your factory.

Viewing Labor Tracking Reports

All the above features are summarized in reports provided by MESWeb Reports that can be considered solid gold for the company to identify where is necessary to enhance processes and decide how to overcome the improvement areas by having better and enough reasons to draw a successful strategy.

The following are some of the report features that can be searched by employee, order, part number, process, and indirect details: /> />

| |

| |

| |

| |

|

Users can access crew reports (such as crew activities) in MESWeb Reports where all the data collected is categorized and grouped so that teamwork can also be analyzed and evaluated. In this field, users are able to:

|

Access to the crew data. |

See the members of each crew. |

See when each member joins and leaves a crew. |

How does Labor Tracking Work ?

Tracking time for operations in the manufacturing process is an important KPI as it is a major component of the product's final cost. 42Q’s Labor Tracking feature tracks a variety of direct and indirect labor activities using automated processes when applicable to make this data collection as non intrusive as possible.

Operators play an important role in collecting the labor during the manufacturing process by performing these simple actions through Production Workbench where their progress is recorded:

- Clock-In and Clock-Out Direct/ Indirect labor: The system logs the date and time when operators begin to work on an order and serial numbers.

- Easy crew search and display to save time and make it easy for operators.

- Direct/Indirect Labor Type selection.

- Add Crew members.

- Profile pictures for the crew members list.

- 'Automatic 'Auto-tracking to ease continuous work update.

- Administrators can adjust operators' login and logout to crews.

Another advantage and distinguishing feature of Labor tracking is that any employee of the system can be added to a crew by using their credentials.

Please refer to the 42Q documentation for information concerning Labor Tracking and how it is used in the 42Q portal.

Document Revision History

| Date | Author | Title | Version | Change Reference | Approved by |

|---|---|---|---|---|---|

|

05/17/21 |

Julieta Jimenez |

Technical Writer |

A1 |

First version of the Labor Tracking Whitepaper at 15.69 | Juan Lopez |