Difference between revisions of "SOP-42Q-MES0005 Data Editor Maintenance"

| Line 7: | Line 7: | ||

| | ||

| − | <center>''' | + | <center>'''Shop Floor Configuration'''</center> <center>'''Data Editor'''</center> <center>'''Version MES15 Portal 1.0'''</center> <center>'''Work Instruction'''</center> |

| | ||

<center>This Work Instruction is 42Q's corporate standard.</center> <center>This document is under revision control. The latest revision is located on Intranet.</center> <center>Once printed it is an uncontrolled copy. All alterations to this work instruction require approval.</center> <center>Contact the IT Global Education and Training Department to submit suggested alterations and or updates.</center> | <center>This Work Instruction is 42Q's corporate standard.</center> <center>This document is under revision control. The latest revision is located on Intranet.</center> <center>Once printed it is an uncontrolled copy. All alterations to this work instruction require approval.</center> <center>Contact the IT Global Education and Training Department to submit suggested alterations and or updates.</center> | ||

| Line 14: | Line 14: | ||

| | ||

| + | | ||

| − | == | + | == Shop Floor Configuration == |

42Q’s powerful data collection system collects critical information from a plant’s shop floor, utilizing shop floor data collector, an intuitive tool developed by 42Q’s experienced manufacturing team. The aggregate information is stored in a cloud database, and available to MESWeb, where quality reports are generated. The 42Q system uses manual and automated barcode scanning to collect data for a product line or plant. Thus, 42Q plays an important role in maintaining unit histories and directing product movement on the manufacturing floor. The current version of 42Q includes configuration capabilities, which provide access to all sub-modules pages and their functionalities (view, add, edit, print/generate output files). | 42Q’s powerful data collection system collects critical information from a plant’s shop floor, utilizing shop floor data collector, an intuitive tool developed by 42Q’s experienced manufacturing team. The aggregate information is stored in a cloud database, and available to MESWeb, where quality reports are generated. The 42Q system uses manual and automated barcode scanning to collect data for a product line or plant. Thus, 42Q plays an important role in maintaining unit histories and directing product movement on the manufacturing floor. The current version of 42Q includes configuration capabilities, which provide access to all sub-modules pages and their functionalities (view, add, edit, print/generate output files). | ||

| − | To access | + | To access Shop Floor Configuration, navigate to '''Shop Floor Control'''>'''Configuration'''>'''Shop Floor Configuration'''. The main Shop Floor Configuration page is displayed: |

| − | The main | ||

| − | '''Figure 1: MES Portal – | + | '''Figure 1: MES Portal – Shop Floor Configuration Sub-modules''' |

[[File:Access Data Editor 01.jpg|700px|Access Data Editor 01.jpg]] | [[File:Access Data Editor 01.jpg|700px|Access Data Editor 01.jpg]] | ||

| Line 34: | Line 34: | ||

== Data Editor Maintenance == | == Data Editor Maintenance == | ||

| − | Data Editor Maintenance provides access to the | + | Data Editor Maintenance provides access to the Shop Floor configuration file that defines (but is not limited to) PCC ports, Options Lines, Auto Commands, Macros, Serial Input Masking, Passwords, and Device Numbers. |

| − | To access the Data Editor, select '''Data Editor '''in the | + | To access the Data Editor, select '''Data Editor '''in the Shop Floor Configuration main menu. |

The '''Setup Data Editor '''screen is displayed. | The '''Setup Data Editor '''screen is displayed. | ||

| Line 184: | Line 184: | ||

| | ||

| − | 2. Select the '''Restore Setup Data''' icon to restore the data or to save it locally, then select '''Download Setup Data''' icon. | + | 2. Select the '''Restore Setup Data''' icon to restore the data or to save it locally, then select the '''Download Setup Data''' icon. |

| | ||

| Line 218: | Line 218: | ||

'''''Component''''' | '''''Component''''' | ||

| − | A component is a specific piece of data that appears on a label, for example barcode, part numbers, graphic images, line or text. Hence, label components are broken down into several different types: text, graphic images, MES database values, or a combination of text and database values. | + | A component is a specific piece of data that appears on a label, for example, barcode, part numbers, graphic images, line, or text. Hence, label components are broken down into several different types: text, graphic images, MES database values, or a combination of text and database values. |

'''''Framework''''' | '''''Framework''''' | ||

| Line 224: | Line 224: | ||

In software development, a framework is a defined support structure in which another software project can be organized and developed. A framework may include support programs, code libraries, a scripting language, or other software to help develop and glue together the different components of a software project. | In software development, a framework is a defined support structure in which another software project can be organized and developed. A framework may include support programs, code libraries, a scripting language, or other software to help develop and glue together the different components of a software project. | ||

| − | ''''' | + | '''''Shop Floor Configuration''''' |

| − | The rules used to define how SFDC collects data provides analysis, controls processing and maintains unit histories | + | The rules used to define how SFDC collects data provides analysis, controls the processing and maintains unit histories |

'''''Site Minder''''' | '''''Site Minder''''' | ||

| Line 234: | Line 234: | ||

'''''Username''''' | '''''Username''''' | ||

| − | The username is the | + | The username is the SiteMinder username (or a partial string) |

| | ||

| Line 240: | Line 240: | ||

| | ||

| − | + | | |

= Document Revision History = | = Document Revision History = | ||

| Line 258: | Line 258: | ||

| v 1.0 | | v 1.0 | ||

| This is the first revision of MES Data Editor User’s Guide | | This is the first revision of MES Data Editor User’s Guide | ||

| − | | | + | | |

|- | |- | ||

| 03/17/14 | | 03/17/14 | ||

| Line 265: | Line 265: | ||

| v 1.0 | | v 1.0 | ||

| Review and added the new function Map Defect X Process | | Review and added the new function Map Defect X Process | ||

| − | | | + | | |

|- | |- | ||

| 03/17/14 | | 03/17/14 | ||

| Line 272: | Line 272: | ||

| v 1.0 | | v 1.0 | ||

| Review and format for WIKI | | Review and format for WIKI | ||

| − | | | + | | |

|- | |- | ||

| 04/3/17 | | 04/3/17 | ||

| Line 286: | Line 286: | ||

| v 1.0 | | v 1.0 | ||

| Updated images 02,03,04,10 to reflect the Conduit icon and updated Introduction for 42Q. | | Updated images 02,03,04,10 to reflect the Conduit icon and updated Introduction for 42Q. | ||

| − | | | + | | |

|- | |- | ||

| 04/10/18 | | 04/10/18 | ||

| Line 293: | Line 293: | ||

| v 1.0 | | v 1.0 | ||

| Applied new Template for formatting. | | Applied new Template for formatting. | ||

| − | | | + | | |

|- | |- | ||

| 07/04/18 | | 07/04/18 | ||

| Line 300: | Line 300: | ||

| v 1.0 | | v 1.0 | ||

| Updated images. | | Updated images. | ||

| − | | | + | | |

| + | |- | ||

| + | | 07/21/20 | ||

| + | | Elaine Fonaro | ||

| + | | Technical Writer | ||

| + | | v 1.0 | ||

| + | | Updated occurrences of SFDC Configuration to Shop Floor Configuration | ||

| + | | | ||

|} | |} | ||

Revision as of 19:55, 21 July 2020

42Q Home > Shop Floor Control > Configuration > Data Editor Maintenance

This edition applies to MES15 portal V1.0 and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

Shop Floor Configuration

42Q’s powerful data collection system collects critical information from a plant’s shop floor, utilizing shop floor data collector, an intuitive tool developed by 42Q’s experienced manufacturing team. The aggregate information is stored in a cloud database, and available to MESWeb, where quality reports are generated. The 42Q system uses manual and automated barcode scanning to collect data for a product line or plant. Thus, 42Q plays an important role in maintaining unit histories and directing product movement on the manufacturing floor. The current version of 42Q includes configuration capabilities, which provide access to all sub-modules pages and their functionalities (view, add, edit, print/generate output files).

To access Shop Floor Configuration, navigate to Shop Floor Control>Configuration>Shop Floor Configuration. The main Shop Floor Configuration page is displayed:

Figure 1: MES Portal – Shop Floor Configuration Sub-modules

NOTE: A user only has access to the modules assigned to his/her profile.

Data Editor Maintenance

Data Editor Maintenance provides access to the Shop Floor configuration file that defines (but is not limited to) PCC ports, Options Lines, Auto Commands, Macros, Serial Input Masking, Passwords, and Device Numbers.

To access the Data Editor, select Data Editor in the Shop Floor Configuration main menu.

The Setup Data Editor screen is displayed.

Figure 2: Setup Data Editor Shop Floor ID List

The user can edit, clear Data Editor, Publish History and Print/Export the data.

Filter Setup Data Editor by SFDC ID

This module enables the user to filter by SFDC ID.

1. Enter the desired SFDC ID into appropriate field, and then select Filter. The filtered Shop Floor ID is now displayed.

Figure 3: Shop Floor ID List - Find

Editing with the Setup Data Editor

This module enables the user to edit using the Setup Data Editor.

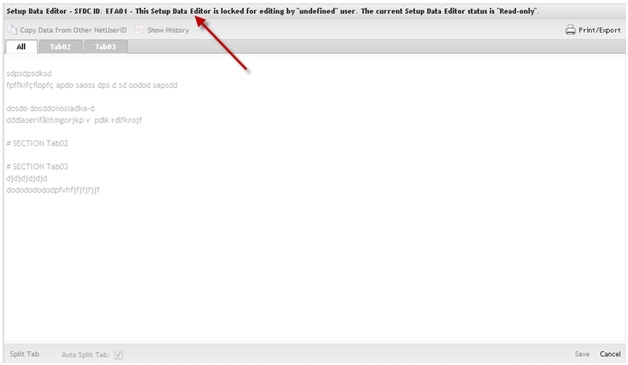

1. To edit using Setup Data Editor, select the data editor to be edited and select Edit. The Setup Data Editor Form for the selected Shop Floor ID is now displayed.

Figure 4: Shop Floor ID List – Edit Setup Data Editor

Figure 5: Setup Data Editor Form

NOTE: To add a new tab, create an entry line by entering "# SECTION"

+

section name.

For example: # SECTION MULTIPASS

2. Enter the desired modifications to the Setup Data Editor Form.

NOTE: If multiple users have opened the Setup Data Editor for the same SFDC PC line, only the first user to open the file has write access. Other users are notified that the SDE is locked for editing by another user and that read-only access is allowed.

Copy Setup Data Editor from Other Shop Floor ID

This module replaces the contents of the current Setup Data Editor Form with data copied from another Shop Floor ID.

1. To copy data from another Shop Floor ID, open the target Shop Floor ID ’

s Setup Data Editor and select Copy Data from Other Shop Floor ID in the Tasks window. The Choose a Shop Floor ID window is now displayed.

Figure 7: Copy Data from Other Shop Floor ID

Figure 7 Copy Data from Other Shop Floor ID.jpg

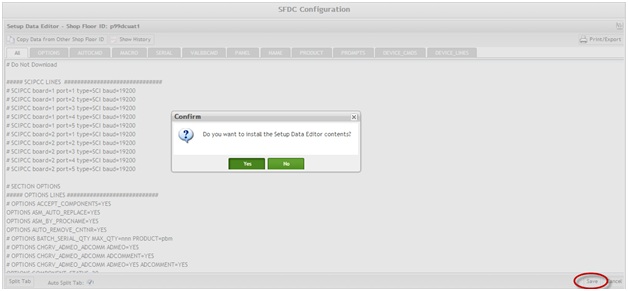

2. Select the Shop Floor ID to copy and select Save to install the Setup Data Editor. The Setup Data Editor is now updated with the data from the selected Shop Floor ID.

3. Select Yes to confirm the install, or select No to cancel.

NOTE: The application saves a backup file on the MES server every time user installs a Setup Data Editor.

Publish History

The Publish History functionality is used by permitted users to show and publish the action history of a Route. To use this functionality

- Select a route from the list. The Publish History function becomes available for selection.

- Select Publish History. The Publish History window pops up for the given route. This history shows the Action, Status, Time/Date, and User for each item.

- Select Publish, to publish the history to Conduit. Select Close to end or abort.

Figure 9: Publish History

SFID Publish History Function.png

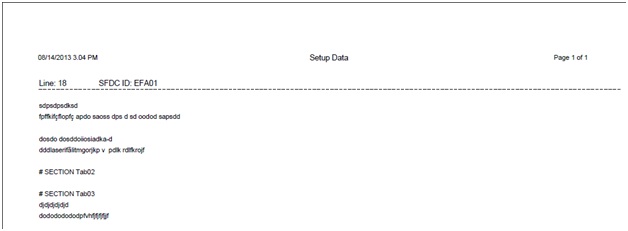

Print/Export Current Setup Data Editor

This module enables the user to print or export the current Setup Data Editor.

1. To print or export current Setup Data Editor Form, select Print/Export. A report PDF will be generated that the user may save or print.

Figure 10: Print/Export Current Editor

Figure 11: Print/Export Report

Show History

This module displays the Setup Data Editor history updates.

1. To show the history, select Show History. The Setup Data Backup Files pop-up is now displayed.

Figure 12: Show History

FIgure 11 Show History.jpg

2. Select the Restore Setup Data icon to restore the data or to save it locally, then select the Download Setup Data icon.

Save/Publish

The Save/Publish Conduit-based function at the bottom of the Attribute Step List screen is available to users with the appropriate permissions and can be used by selecting the down arrow adjacent to the Save button. Whereas Save gives the record a pending status relative to Conduit, Save/Publish saves the record and publishes it to Conduit.

Figure 13: Save/Publish - Conduit Function

Appendix A

COPS

Customer Order Processing System

FES

Factory Execution Systems

LDAP

Lightweight Directory Access Protocol

Mfg

Manufacturing

MES

Manufacturing Execution Systems

PRAC

Process Access

SFDC

Shop Data Floor Collection

SPC

Statistical Process Control

SQC

Statistical Quality Control

Appendix B

Glossary

Access Control

A module that will set the permissions for users and external customers of 42Q

Administrator

the System Administrator has full access - all plants, all reports, all users.

Component

A component is a specific piece of data that appears on a label, for example, barcode, part numbers, graphic images, line, or text. Hence, label components are broken down into several different types: text, graphic images, MES database values, or a combination of text and database values.

Framework

In software development, a framework is a defined support structure in which another software project can be organized and developed. A framework may include support programs, code libraries, a scripting language, or other software to help develop and glue together the different components of a software project.

Shop Floor Configuration

The rules used to define how SFDC collects data provides analysis, controls the processing and maintains unit histories

Site Minder

Universal login of 42Q

Username

The username is the SiteMinder username (or a partial string)

Document Revision History

| Date | Author | Title | Version | Change Reference | Approved by |

|---|---|---|---|---|---|

| 08/14/13 | Elaine Fonaro | Technical Writer | v 1.0 | This is the first revision of MES Data Editor User’s Guide | |

| 03/17/14 | Ashley Martin | Technical Writer | v 1.0 | Review and added the new function Map Defect X Process | |

| 03/17/14 | Elaine Fonaro | Technical Writer | v 1.0 | Review and format for WIKI | |

| 04/3/17 | Martha Jordan | Technical Writer | v 1.0 | Rewrite SFDC introductory paragraph according to current 42Q functionality | Bob Moss |

| 02/06/18 | Elaine Fonaro | Technical Writer | v 1.0 | Updated images 02,03,04,10 to reflect the Conduit icon and updated Introduction for 42Q. | |

| 04/10/18 | Elaine Fonaro | Technical Writer | v 1.0 | Applied new Template for formatting. | |

| 07/04/18 | Elaine Fonaro | Technical Writer | v 1.0 | Updated images. | |

| 07/21/20 | Elaine Fonaro | Technical Writer | v 1.0 | Updated occurrences of SFDC Configuration to Shop Floor Configuration |