|

|

| Line 1: |

Line 1: |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <div class="mw-parser-output">

| |

| − | <p><small><a href="42Q%20Cloud-Based%20MES%2FMOMS">42Q Home</a> >Production > 100% Traceability> PTS Mobile</small></p>

| |

| | | | |

| − | <p> </p> | + | <small>[[42Q_Cloud-Based_MES/MOMS|42Q Home]] >Production > 100% Traceability> PTS Mobile</small> |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <center><b>Production</b></center> | + | |

| | + | <center>'''Production'''</center> <center>'''100% Traceability'''</center> <center>'''PTS Mobile'''</center> <center>''' MES 15.78'''</center> |

| | + | <span class="mw-headline" id=""> </span> |

| | | | |

| − | <center><b>100% Traceability</b></center> | + | <span class="mw-headline" id=""> </span> |

| | | | |

| − | <center><b>PTS Mobile</b></center>

| + | |

| | | | |

| − | <center><b> MES 15.78</b></center> | + | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span></span></span></span></span> = |

| | | | |

| − | <p><span class="mw-headline" id=""> </span></p>

| + | The Part Traceability System (PTS) is an essential component of the MES suite of tools, designed specifically to meet the growing demands of customers. Its primary objective includes offering comprehensive traceability at the component level and ensuring strict quality controls. By automating production lines and enforcing rigorous product quality control, this system plays a pivotal role in enhancing overall productivity. its successful implementation has been witnessed across numerous plants worldwide. As technology continues to evolve and SMT process equipment tools become increasingly intricate and feature-rich, the PTS application and its accompanying features consistently advance. However, our commitment remains to provide support for all technology tools. 42Q prioritizes offering the necessary flexibility to accommodate various line types and deliver diverse levels of traceability that are crucial to the success of your business. |

| | | | |

| − | <p><span class="mw-headline" id=""> </span></p>

| + | |

| | | | |

| − | <p> </p> | + | = <span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile">PTS Mobile</span></span></span></span></span> = |

| | | | |

| − | <h1><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span></span></span></span></span></h1>

| + | PTS Mobile is specifically designed to be compatible with handheld devices, recognizing that operators may not always be in front of a computer and require the convenience of using a handheld device for operation. |

| | | | |

| − | <p>The Part Traceability System (PTS) is an essential component of the MES suite of tools, designed specifically to meet the growing demands of customers. Its primary objective includes offering comprehensive traceability at the component level and ensuring strict quality controls. By automating production lines and enforcing rigorous product quality control, this system plays a pivotal role in enhancing overall productivity. its successful implementation has been witnessed across numerous plants worldwide. As technology continues to evolve and SMT process equipment tools become increasingly intricate and feature-rich, the PTS application and its accompanying features consistently advance. However, our commitment remains to provide support for all technology tools. 42Q prioritizes offering the necessary flexibility to accommodate various line types and deliver diverse levels of traceability that are crucial to the success of your business.</p>

| + | |

| | | | |

| − | <p> </p> | + | To access PTS Mobile, navigate to '''Production > 100% Traceability > PTS Mobile'''<br/> <br/> |

| | | | |

| − | <h1><span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile"><span class="mw-headline" id="PTS_Mobile">PTS Mobile</span></span></span></span></span></h1>

| + | |

| | | | |

| − | <p>PTS Mobile is specifically designed to be compatible with handheld devices, recognizing that operators may not always be in front of a computer and require the convenience of using a handheld device for operation.</p> | + | == <span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material">Re-Validate Material</span></span></span></span></span></span></span></span> == |

| | | | |

| − | <p> </p>

| + | Whenever material is going to exhaust, splicing is required to ensure production can proceed without interruption. However, there is a small chance that splicing was mistakenly done to the wrong feeder slot and it can’t be detected by the normal part verification process. |

| | | | |

| − | <p>To access PTS Mobile, navigate to <b>Production > 100% Traceability > PTS Mobile</b><br />

| + | Therefore, a material re-validation is required to handle this scenario. By re-validate material (just re-scan material barcode, without interrupting the current production run), chances of splicing material to the wrong feeder slot can be avoided. The Re-Validate Material is a mobile solution (GUI) to handle the situation of Component Reset and Re-validation for traditional SMT Machines. The users can validate the materials with the Workstation, Material Barcode, Feeder Barcode, and Station. |

| − | <br />

| |

| − | </p> | |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <h2><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material"><span class="mw-headline" id="Re-Validate_Material">Re-Validate Material</span></span></span></span></span></span></span></span></h2>

| + | '''Figure 1: Re-Validate Material''' |

| | | | |

| − | <p>Whenever material is going to exhaust, splicing is required to ensure production can proceed without interruption. However, there is a small chance that splicing was mistakenly done to the wrong feeder slot and it can’t be detected by the normal part verification process.</p>

| + | [[File:PTSM RevalidateMaterial.png|900px|PTSM RevalidateMaterial.png]] |

| | | | |

| − | <p>Therefore, a material re-validation is required to handle this scenario. By re-validate material (just re-scan material barcode, without interrupting the current production run), chances of splicing material to the wrong feeder slot can be avoided. The Re-Validate Material is a mobile solution (GUI) to handle the situation of Component Reset and Re-validation for traditional SMT Machines. The users can validate the materials with the Workstation, Material Barcode, Feeder Barcode, and Station.</p>

| + | |

| | | | |

| − | <p> </p>

| + | The main screen will request the user to input or scan the Workstation, Material Barcode, Feeder Barcode, and Station Location. |

| | | | |

| − | <p><b>Figure 1: Re-Validate Material</b></p>

| + | |

| | | | |

| − | <p><img _fck_mw_filename="PTSM RevalidateMaterial.png" _fck_mw_origimgheight="683" _fck_mw_origimgwidth="1869" alt="PTSM RevalidateMaterial.png" src="/mes_wiki/images/a/a9/PTSM_RevalidateMaterial.png" style="vertical-align:middle;" title="PTSM RevalidateMaterial.png" width="900" /></p> | + | == <span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials">Load/ Unload Materials </span></span></span></span></span> == |

| | | | |

| − | <p> </p>

| + | It is mainly used for material loading and unloading, including the following submenus: |

| | | | |

| − | <p>The main screen will request the user to input or scan the Workstation, Material Barcode, Feeder Barcode, and Station Location.</p>

| + | *Load Material |

| | + | *Load SMT Tools |

| | + | *Material Queue |

| | + | *Scan Barcode |

| | + | *Prepare Material |

| | + | *Unload Material |

| | + | *Load Prepare Material |

| | | | |

| − | <p> </p> | + | <br/> <br/> '''Figure 2: Load / Unload Materials page''' |

| | | | |

| − | <h2><span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials"><span class="mw-headline" id="Load.2F_Unload_Materials">Load/ Unload Materials </span></span></span></span></span></h2>

| + | '''[[File:PTSM Load UnloadMaterials page.png|900px|PTSM Load UnloadMaterials page.png]]''' |

| | | | |

| − | <p>It is mainly used for material loading and unloading, including the following submenus:</p>

| + | |

| | | | |

| − | <ul>

| + | |

| − | <li>Load Material </li>

| |

| − | <li>Load SMT Tools </li>

| |

| − | <li>Material Queue </li>

| |

| − | <li>Scan Barcode </li>

| |

| − | <li>Prepare Material </li>

| |

| − | <li>Unload Material </li>

| |

| − | <li>Load Prepare Material </li>

| |

| − | </ul>

| |

| | | | |

| − | <p><br />

| + | |

| − | <br />

| |

| − | <b>Figure 2: Load / Unload Materials page</b></p> | |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM Load UnloadMaterials page.png" _fck_mw_origimgheight="607" _fck_mw_origimgwidth="1903" alt="PTSM Load UnloadMaterials page.png" src="/mes_wiki/images/e/e7/PTSM_Load_UnloadMaterials_page.png" style="vertical-align:middle;" title="PTSM Load UnloadMaterials page.png" width="900" /></b></p> | + | === <span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material">Load Material [[File:PTSM Logo1.png|PTSM Logo1.png]]</span></span></span></span></span> === |

| | | | |

| − | <p> </p> | + | <br/> This function is to prepare for the Scan board. |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 3: Load to Workstation ''' |

| | | | |

| − | <h3><span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material"><span class="mw-headline" id="Load_Material">Load Material <img _fck_mw_filename="PTSM Logo1.png" _fck_mw_origimgheight="100" _fck_mw_origimgwidth="95" alt="PTSM Logo1.png" src="/mes_wiki/images/8/87/PTSM_Logo1.png" style="vertical-align:middle;" title="PTSM Logo1.png" /></span></span></span></span></span></h3>

| + | '''[[File:PTSM LoadtoWorkstation.png|900px|PTSM LoadtoWorkstation.png]]''' |

| | | | |

| − | <p><br />

| + | |

| − | This function is to prepare for the Scan board.</p>

| |

| | | | |

| − | <p> </p> | + | === <span class="mw-headline" id="Load_SMT_Tools"><span class="mw-headline" id="Load_SMT_Tools"><span class="mw-headline" id="Load_SMT_Tools">'''Load SMT Tools [[File:PTSM Logo2.png|PTSM Logo2.png]]'''</span></span></span> === |

| | | | |

| − | <p><b>Figure 3: Load to Workstation </b></p> | + | This function is used to load and unload Jig.<br/> <br/> <br/> '''Figure 5: Load SMT Tools ''' |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM LoadtoWorkstation.png" _fck_mw_origimgheight="355" _fck_mw_origimgwidth="1911" alt="PTSM LoadtoWorkstation.png" src="/mes_wiki/images/2/21/PTSM_LoadtoWorkstation.png" style="vertical-align:middle;" title="PTSM LoadtoWorkstation.png" width="900" /></b></p>

| + | [[File:PTSM LoadSMTTools.png|900px|PTSM LoadSMTTools.png]] |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <h3><span class="mw-headline" id="Load_SMT_Tools"><span class="mw-headline" id="Load_SMT_Tools"><span class="mw-headline" id="Load_SMT_Tools"><b>Load SMT Tools <img _fck_mw_filename="PTSM Logo2.png" _fck_mw_origimgheight="103" _fck_mw_origimgwidth="109" alt="PTSM Logo2.png" src="/mes_wiki/images/6/6a/PTSM_Logo2.png" style="vertical-align:middle;" title="PTSM Logo2.png" /></b></span></span></span></h3>

| + | |

| | | | |

| − | <p>This function is used to load and unload Jig.<br />

| + | |

| − | <br />

| |

| − | <br />

| |

| − | <b>Figure 5: Load SMT Tools </b></p>

| |

| | | | |

| − | <p><img _fck_mw_filename="PTSM LoadSMTTools.png" _fck_mw_origimgheight="415" _fck_mw_origimgwidth="1909" alt="PTSM LoadSMTTools.png" src="/mes_wiki/images/9/97/PTSM_LoadSMTTools.png" style="vertical-align:middle;" title="PTSM LoadSMTTools.png" width="900" /></p> | + | === <span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue">Marial Queue [[File:PTSM Logo3.png|PTSM Logo3.png]]</span></span></span></span></span> === |

| | | | |

| − | <p> </p>

| + | This function is used to batch joint materials and prepare for automatic loading. |

| | | | |

| − | <p> </p> | + | <br/> '''Figure 6: Material Queue''' |

| | | | |

| − | <p> </p>

| + | [[File:PTSM MaterialQueue.png|900px|PTSM MaterialQueue.png]] |

| | | | |

| − | <h3><span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue"><span class="mw-headline" id="Marial_Queue">Marial Queue <img _fck_mw_filename="PTSM Logo3.png" _fck_mw_origimgheight="91" _fck_mw_origimgwidth="92" alt="PTSM Logo3.png" src="/mes_wiki/images/d/d6/PTSM_Logo3.png" style="vertical-align:middle;" title="PTSM Logo3.png" /></span></span></span></span></span></h3>

| + | |

| | | | |

| − | <p>This function is used to batch joint materials and prepare for automatic loading.</p>

| + | |

| | | | |

| − | <p><br />

| + | |

| − | <b>Figure 6: Material Queue</b></p>

| |

| | | | |

| − | <p><img _fck_mw_filename="PTSM MaterialQueue.png" _fck_mw_origimgheight="423" _fck_mw_origimgwidth="1911" alt="PTSM MaterialQueue.png" src="/mes_wiki/images/f/f3/PTSM_MaterialQueue.png" style="vertical-align:middle;" title="PTSM MaterialQueue.png" width="900" /></p> | + | === <span class="mw-headline" id="Scan_Barcode"><span class="mw-headline" id="Scan_Barcode"><span class="mw-headline" id="Scan_Barcode"><span class="mw-headline" id="Scan_Barcode">'''Scan Barcode [[File:PTSM Logo4.png|PTSM Logo4.png]]'''</span></span></span></span> === |

| | | | |

| − | <p> </p>

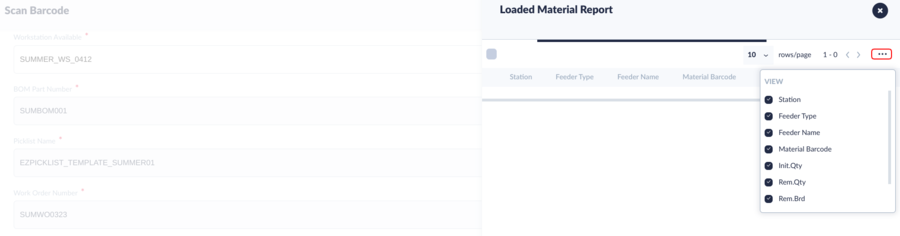

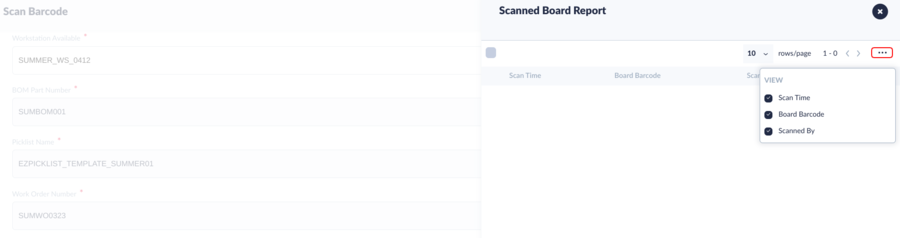

| + | After the production line has been activated the materials loaded in Traceability, go to the Scan Barcode module. |

| | | | |

| − | <p> </p> | + | <br/> <br/> '''Figure 7: Scan Barcode ''' |

| | | | |

| − | <p> </p>

| + | '''[[File:PTSM ScanBarcode.png|900px|PTSM ScanBarcode.png]]''' |

| | | | |

| − | <h3><span class="mw-headline" id="Scan_Barcode"><span class="mw-headline" id="Scan_Barcode"><span class="mw-headline" id="Scan_Barcode"><span class="mw-headline" id="Scan_Barcode"><b>Scan Barcode <img _fck_mw_filename="PTSM Logo4.png" _fck_mw_origimgheight="99" _fck_mw_origimgwidth="96" alt="PTSM Logo4.png" src="/mes_wiki/images/5/56/PTSM_Logo4.png" style="vertical-align:middle;" title="PTSM Logo4.png" /></b></span></span></span></span></h3>

| + | |

| | | | |

| − | <p>After the production line has been activated the materials loaded in Traceability, go to the Scan Barcode module.</p>

| + | |

| | | | |

| − | <p><br />

| + | '''Figure 8: Loaded Material Report ''' |

| − | <br />

| |

| − | <b>Figure 7: Scan Barcode </b></p>

| |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM ScanBarcode.png" _fck_mw_origimgheight="747" _fck_mw_origimgwidth="1897" alt="PTSM ScanBarcode.png" src="/mes_wiki/images/d/d3/PTSM_ScanBarcode.png" style="vertical-align:middle;" title="PTSM ScanBarcode.png" width="900" /></b></p>

| + | [[File:PTSM LoadedMaterialReport .png|900px|PTSM LoadedMaterialReport .png]] |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 9: Scanned ''' |

| | | | |

| − | <p><b>Figure 8: Loaded Material Report </b></p>

| + | [[File:PTSM Scanned.png|900px|PTSM Scanned.png]] |

| | | | |

| − | <p><img _fck_mw_filename="PTSM LoadedMaterialReport .png" _fck_mw_origimgheight="500" _fck_mw_origimgwidth="1908" alt="PTSM LoadedMaterialReport .png" src="/mes_wiki/images/a/ab/PTSM_LoadedMaterialReport_.png" style="vertical-align:middle;" title="PTSM LoadedMaterialReport .png" width="900" /></p>

| + | |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p><b>Figure 9: Scanned </b></p>

| + | |

| | | | |

| − | <p><img _fck_mw_filename="PTSM Scanned.png" _fck_mw_origimgheight="504" _fck_mw_origimgwidth="1905" alt="PTSM Scanned.png" src="/mes_wiki/images/5/5c/PTSM_Scanned.png" style="vertical-align:middle;" title="PTSM Scanned.png" width="900" /></p>

| + | |

| | | | |

| − | <p> </p> | + | === <span class="mw-headline" id="Prepare_Material"><span class="mw-headline" id="Prepare_Material"><span class="mw-headline" id="Prepare_Material"><span class="mw-headline" id="Prepare_Material">Prepare Material [[File:PTSM Logo5.png|PTSM Logo5.png]]</span></span></span></span> === |

| | | | |

| − | <p> </p>

| + | To prepare material in advance while the production line is either in offline mode or online mode. |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 10: Prepare Material ''' |

| | | | |

| − | <h3><span class="mw-headline" id="Prepare_Material"><span class="mw-headline" id="Prepare_Material"><span class="mw-headline" id="Prepare_Material"><span class="mw-headline" id="Prepare_Material">Prepare Material <img _fck_mw_filename="PTSM Logo5.png" _fck_mw_origimgheight="89" _fck_mw_origimgwidth="111" alt="PTSM Logo5.png" src="/mes_wiki/images/f/f7/PTSM_Logo5.png" style="vertical-align:middle;" title="PTSM Logo5.png" /></span></span></span></span></h3>

| + | '''[[File:PTSM PrepareMaterial .png|900px|PTSM PrepareMaterial .png]]''' |

| | | | |

| − | <p>To prepare material in advance while the production line is either in offline mode or online mode.</p>

| + | |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p><b>Figure 10: Prepare Material </b></p> | + | === <span class="mw-headline" id="Unload_Material"><span class="mw-headline" id="Unload_Material"><span class="mw-headline" id="Unload_Material">Unload Material [[File:PTSM Logo6.png|PTSM Logo6.png]]</span></span></span> === |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM PrepareMaterial .png" _fck_mw_origimgheight="851" _fck_mw_origimgwidth="1904" alt="PTSM PrepareMaterial .png" src="/mes_wiki/images/8/8f/PTSM_PrepareMaterial_.png" style="vertical-align:middle;" title="PTSM PrepareMaterial .png" width="900" /></b></p>

| + | Unload Feeder/Material from Workstation. |

| | | | |

| − | <p> </p> | + | <br/> '''Figure 11: Unload Material''' |

| | | | |

| − | <p> </p>

| + | '''[[File:PTSM UnloadMaterial.png|900px|PTSM UnloadMaterial.png]]''' |

| | | | |

| − | <h3><span class="mw-headline" id="Unload_Material"><span class="mw-headline" id="Unload_Material"><span class="mw-headline" id="Unload_Material">Unload Material <img _fck_mw_filename="PTSM Logo6.png" _fck_mw_origimgheight="89" _fck_mw_origimgwidth="107" alt="PTSM Logo6.png" src="/mes_wiki/images/f/fd/PTSM_Logo6.png" style="vertical-align:middle;" title="PTSM Logo6.png" /></span></span></span></h3>

| + | |

| | | | |

| − | <p>Unload Feeder/Material from Workstation.</p>

| + | |

| | | | |

| − | <p><br /> | + | === <span class="mw-headline" id="Load_Prepare_Material"><span class="mw-headline" id="Load_Prepare_Material"><span class="mw-headline" id="Load_Prepare_Material"><span class="mw-headline" id="Load_Prepare_Material">Load Prepare Material [[File:PTM Logo7.png|PTM Logo7.png]]</span></span></span></span> === |

| − | <b>Figure 11: Unload Material</b></p> | |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM UnloadMaterial.png" _fck_mw_origimgheight="893" _fck_mw_origimgwidth="1920" alt="PTSM UnloadMaterial.png" src="/mes_wiki/images/7/79/PTSM_UnloadMaterial.png" style="vertical-align:middle;" title="PTSM UnloadMaterial.png" width="900" /></b></p>

| + | Load prepared material sing. <br/> <br/> '''Figure 12: Load Prepare Material ''' |

| | | | |

| − | <p> </p>

| + | '''[[File:PTSM LoadPrepareMaterial .png|900px|PTSM LoadPrepareMaterial .png]]''' |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <h3><span class="mw-headline" id="Load_Prepare_Material"><span class="mw-headline" id="Load_Prepare_Material"><span class="mw-headline" id="Load_Prepare_Material"><span class="mw-headline" id="Load_Prepare_Material">Load Prepare Material <img _fck_mw_filename="PTM Logo7.png" _fck_mw_origimgheight="87" _fck_mw_origimgwidth="103" alt="PTM Logo7.png" src="/mes_wiki/images/c/cb/PTM_Logo7.png" style="vertical-align:middle;" title="PTM Logo7.png" /></span></span></span></span></h3>

| + | |

| | | | |

| − | <p>Load prepared material sing. <br /> | + | == <span class="mw-headline" id="Solder_Paste"><span class="mw-headline" id="Solder_Paste"><span class="mw-headline" id="Solder_Paste">'''Solder Paste'''</span></span></span> == |

| − | <br /> | |

| − | <b>Figure 12: Load Prepare Material </b></p> | |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM LoadPrepareMaterial .png" _fck_mw_origimgheight="515" _fck_mw_origimgwidth="1901" alt="PTSM LoadPrepareMaterial .png" src="/mes_wiki/images/4/43/PTSM_LoadPrepareMaterial_.png" style="vertical-align:middle;" title="PTSM LoadPrepareMaterial .png" width="900" /></b></p>

| + | Solder Paste Mainly used to manage solder paste, including the following submenus: |

| | | | |

| − | <p> </p>

| + | *Refrigeration In |

| | + | *Refrigeration out |

| | + | *Thaw Start |

| | + | *Thaw End |

| | + | *Stirring |

| | + | *Open Jar |

| | + | *Solder-Paste Scrap |

| | | | |

| − | <p> </p> | + | <br/> <br/> '''Figure 13: Solder Paste''' |

| | | | |

| − | <h2><span class="mw-headline" id="Solder_Paste"><span class="mw-headline" id="Solder_Paste"><span class="mw-headline" id="Solder_Paste"><b>Solder Paste</b></span></span></span></h2>

| + | '''[[File:PTSM SolderPaste.png|900px|PTSM SolderPaste.png]]''' |

| | | | |

| − | <p>Solder Paste Mainly used to manage solder paste, including the following submenus:</p>

| + | |

| | | | |

| − | <ul>

| + | |

| − | <li>Refrigeration In </li>

| |

| − | <li>Refrigeration out </li>

| |

| − | <li>Thaw Start </li>

| |

| − | <li>Thaw End </li>

| |

| − | <li>Stirring </li>

| |

| − | <li>Open Jar </li>

| |

| − | <li>Solder-Paste Scrap </li>

| |

| − | </ul>

| |

| | | | |

| − | <p><br /> | + | === <span class="mw-headline" id="Refrigeration_In"><span class="mw-headline" id="Refrigeration_In"><span class="mw-headline" id="Refrigeration_In"><span class="mw-headline" id="Refrigeration_In">Refrigeration In [[File:PTSM Logo8.png|PTSM Logo8.png]]</span></span></span></span> === |

| − | <br /> | |

| − | <b>Figure 13: Solder Paste</b></p> | |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM SolderPaste.png" _fck_mw_origimgheight="655" _fck_mw_origimgwidth="1912" alt="PTSM SolderPaste.png" src="/mes_wiki/images/c/cd/PTSM_SolderPaste.png" style="vertical-align:middle;" title="PTSM SolderPaste.png" width="900" /></b></p>

| + | This function is used to put the solder paste into the refrigerator. |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 14: Refrigeration In''' |

| | | | |

| − | <h3><span class="mw-headline" id="Refrigeration_In"><span class="mw-headline" id="Refrigeration_In"><span class="mw-headline" id="Refrigeration_In"><span class="mw-headline" id="Refrigeration_In">Refrigeration In <img _fck_mw_filename="PTSM Logo8.png" _fck_mw_origimgheight="93" _fck_mw_origimgwidth="99" alt="PTSM Logo8.png" src="/mes_wiki/images/7/78/PTSM_Logo8.png" style="vertical-align:middle;" title="PTSM Logo8.png" /></span></span></span></span></h3>

| + | '''[[File:PTSM RefrigerationIn.png|900px|PTSM RefrigerationIn.png]]''' |

| | | | |

| − | <p>This function is used to put the solder paste into the refrigerator.</p>

| + | |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p><b>Figure 14: Refrigeration In</b></p> | + | === <span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out">Refrigeration Out [[File:PTSM Logo9.png|PTSM Logo9.png]]</span></span></span></span> === |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM RefrigerationIn.png" _fck_mw_origimgheight="883" _fck_mw_origimgwidth="1904" alt="PTSM RefrigerationIn.png" src="/mes_wiki/images/3/3f/PTSM_RefrigerationIn.png" style="vertical-align:middle;" title="PTSM RefrigerationIn.png" width="900" /></b></p>

| + | This function is used to take the solder paste out of the refrigerator. |

| | | | |

| − | <p> </p> | + | <br/> '''Figure 15: Refrigeration Out''' |

| | | | |

| − | <p> </p>

| + | '''[[File:PTSM RefrigerationOut.png|900px|PTSM RefrigerationOut.png]]''' |

| | | | |

| − | <h3><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out"><span class="mw-headline" id="Refrigeration_Out">Refrigeration Out <img _fck_mw_filename="PTSM Logo9.png" _fck_mw_origimgheight="92" _fck_mw_origimgwidth="103" alt="PTSM Logo9.png" src="/mes_wiki/images/1/1a/PTSM_Logo9.png" style="vertical-align:middle;" title="PTSM Logo9.png" /></span></span></span></span></h3>

| + | |

| | | | |

| − | <p>This function is used to take the solder paste out of the refrigerator.</p>

| + | |

| | | | |

| − | <p><br />

| + | |

| − | <b>Figure 15: Refrigeration Out</b></p>

| |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM RefrigerationOut.png" _fck_mw_origimgheight="880" _fck_mw_origimgwidth="1884" alt="PTSM RefrigerationOut.png" src="/mes_wiki/images/0/08/PTSM_RefrigerationOut.png" style="vertical-align:middle;" title="PTSM RefrigerationOut.png" width="900" /></b></p> | + | === <span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start">Thaw Start [[File:PTSM Logo10.png|PTSM Logo10.png]]</span></span></span> === |

| | | | |

| − | <p> </p>

| + | This function is used to start thawing Solder Paste. |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 16: Thaw Start ''' |

| | | | |

| − | <h3><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start"><span class="mw-headline" id="Thaw_Start">Thaw Start <img _fck_mw_filename="PTSM Logo10.png" _fck_mw_origimgheight="88" _fck_mw_origimgwidth="96" alt="PTSM Logo10.png" src="/mes_wiki/images/b/be/PTSM_Logo10.png" style="vertical-align:middle;" title="PTSM Logo10.png" /></span></span></span></h3>

| + | [[File:PTSM ThawStart.png|900px|PTSM ThawStart.png]] |

| | | | |

| − | <p>This function is used to start thawing Solder Paste.</p>

| + | |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p><b>Figure 16: Thaw Start </b></p> | + | === <span class="mw-headline" id="Thaw_End"><span class="mw-headline" id="Thaw_End"><span class="mw-headline" id="Thaw_End">Thaw End [[File:PTSM Logo11.png|PTSM Logo11.png]]</span></span></span> === |

| | | | |

| − | <p><img _fck_mw_filename="PTSM ThawStart.png" _fck_mw_origimgheight="836" _fck_mw_origimgwidth="1895" alt="PTSM ThawStart.png" src="/mes_wiki/images/c/c1/PTSM_ThawStart.png" style="vertical-align:middle;" title="PTSM ThawStart.png" width="900" /></p>

| + | This function is used to end the thawed solder paste. |

| | | | |

| − | <p> </p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 17: Thaw End''' |

| | | | |

| − | <h3><span class="mw-headline" id="Thaw_End"><span class="mw-headline" id="Thaw_End"><span class="mw-headline" id="Thaw_End">Thaw End <img _fck_mw_filename="PTSM Logo11.png" _fck_mw_origimgheight="89" _fck_mw_origimgwidth="103" alt="PTSM Logo11.png" src="/mes_wiki/images/a/ac/PTSM_Logo11.png" style="vertical-align:middle;" title="PTSM Logo11.png" /></span></span></span></h3>

| + | '''[[File:PTSM ThawEnd.png|900px|PTSM ThawEnd.png]]''' |

| | | | |

| − | <p>This function is used to end the thawed solder paste.</p>

| + | |

| | | | |

| − | <p> </p> | + | === <span class="mw-headline" id="Stirring"><span class="mw-headline" id="Stirring">Stirring [[File:PTSM Logo12.png|PTSM Logo12.png]]</span></span> === |

| | | | |

| − | <p><b>Figure 17: Thaw End</b></p>

| + | This function is used to stir the solder paste. |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM ThawEnd.png" _fck_mw_origimgheight="667" _fck_mw_origimgwidth="1888" alt="PTSM ThawEnd.png" src="/mes_wiki/images/a/af/PTSM_ThawEnd.png" style="vertical-align:middle;" title="PTSM ThawEnd.png" width="900" /></b></p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 18: Stirring ''' |

| | | | |

| − | <h3><span class="mw-headline" id="Stirring"><span class="mw-headline" id="Stirring">Stirring <img _fck_mw_filename="PTSM Logo12.png" _fck_mw_origimgheight="95" _fck_mw_origimgwidth="107" alt="PTSM Logo12.png" src="/mes_wiki/images/5/56/PTSM_Logo12.png" style="vertical-align:middle;" title="PTSM Logo12.png" /></span></span></h3>

| + | '''[[File:PTSM Stirring.png|900px|PTSM Stirring.png]]''' |

| | | | |

| − | <p>This function is used to stir the solder paste.</p>

| + | |

| | | | |

| − | <p> </p> | + | === <span class="mw-headline" id="Open_Jar"><span class="mw-headline" id="Open_Jar">'''Open Jar [[File:PTSM 13.png|PTSM 13.png]]'''</span></span> === |

| | | | |

| − | <p><b>Figure 18: Stirring </b></p> | + | This function is used to open the solder paste and prepare it for use.<br/> |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM Stirring.png" _fck_mw_origimgheight="653" _fck_mw_origimgwidth="1901" alt="PTSM Stirring.png" src="/mes_wiki/images/9/94/PTSM_Stirring.png" style="vertical-align:middle;" title="PTSM Stirring.png" width="900" /></b></p>

| + | '''Figure 19: Open Jar ''' |

| | | | |

| − | <p> </p>

| + | '''[[File:PTSM OpenJar .png|900px|PTSM OpenJar .png]]''' |

| | | | |

| − | <h3><span class="mw-headline" id="Open_Jar"><span class="mw-headline" id="Open_Jar"><b>Open Jar <img _fck_mw_filename="PTSM 13.png" _fck_mw_origimgheight="101" _fck_mw_origimgwidth="97" alt="PTSM 13.png" src="/mes_wiki/images/a/ac/PTSM_13.png" style="vertical-align:middle;" title="PTSM 13.png" /></b></span></span></h3>

| + | |

| | | | |

| − | <p>This function is used to open the solder paste and prepare it for use.<br /> | + | === <span class="mw-headline" id="Solder_Paste_Scrap"><span class="mw-headline" id="Solder_Paste_Scrap">Solder Paste Scrap [[File:PTSM Logo14.png|PTSM Logo14.png]]</span></span> === |

| − | </p> | |

| | | | |

| − | <p><b>Figure 19: Open Jar </b></p>

| + | This function is used to scrap expired or unusable solder paste. |

| | | | |

| − | <p><b><img _fck_mw_filename="PTSM OpenJar .png" _fck_mw_origimgheight="615" _fck_mw_origimgwidth="1915" alt="PTSM OpenJar .png" src="/mes_wiki/images/4/46/PTSM_OpenJar_.png" style="vertical-align:middle;" title="PTSM OpenJar .png" width="900" /></b></p>

| + | |

| | | | |

| − | <p> </p>

| + | '''Figure 20: Solder Paste Scrap''' |

| | | | |

| − | <h3><span class="mw-headline" id="Solder_Paste_Scrap"><span class="mw-headline" id="Solder_Paste_Scrap">Solder Paste Scrap <img _fck_mw_filename="PTSM Logo14.png" _fck_mw_origimgheight="84" _fck_mw_origimgwidth="103" alt="PTSM Logo14.png" src="/mes_wiki/images/4/42/PTSM_Logo14.png" style="vertical-align:middle;" title="PTSM Logo14.png" /></span></span></h3>

| + | '''[[File:PTSM SolderPasteScrap.png|900px|PTSM SolderPasteScrap.png]]''' |

| | | | |

| − | <p>This function is used to scrap expired or unusable solder paste.</p>

| + | |

| | | | |

| − | <p> </p>

| + | ---- |

| − | | |

| − | <p><b>Figure 20: Solder Paste Scrap</b></p>

| |

| − | | |

| − | <p><b><img _fck_mw_filename="PTSM SolderPasteScrap.png" _fck_mw_origimgheight="533" _fck_mw_origimgwidth="1897" alt="PTSM SolderPasteScrap.png" src="/mes_wiki/images/d/d0/PTSM_SolderPasteScrap.png" style="vertical-align:middle;" title="PTSM SolderPasteScrap.png" width="900" /></b></p>

| |

| − | | |

| − | <p> </p>

| |

| − | | |

| − | <hr /></div>

| |

| − | </div>

| |

| − | </div>

| |

| − | </div>

| |

| − | </div>

| |

| − | </div>

| |

| − | </div>

| |

| − | </div>

| |

| − | </div>

| |

42Q Home >Production > 100% Traceability> PTS Mobile

Production 100% Traceability PTS Mobile MES 15.78

Introduction

The Part Traceability System (PTS) is an essential component of the MES suite of tools, designed specifically to meet the growing demands of customers. Its primary objective includes offering comprehensive traceability at the component level and ensuring strict quality controls. By automating production lines and enforcing rigorous product quality control, this system plays a pivotal role in enhancing overall productivity. its successful implementation has been witnessed across numerous plants worldwide. As technology continues to evolve and SMT process equipment tools become increasingly intricate and feature-rich, the PTS application and its accompanying features consistently advance. However, our commitment remains to provide support for all technology tools. 42Q prioritizes offering the necessary flexibility to accommodate various line types and deliver diverse levels of traceability that are crucial to the success of your business.

PTS Mobile

PTS Mobile is specifically designed to be compatible with handheld devices, recognizing that operators may not always be in front of a computer and require the convenience of using a handheld device for operation.

To access PTS Mobile, navigate to Production > 100% Traceability > PTS Mobile

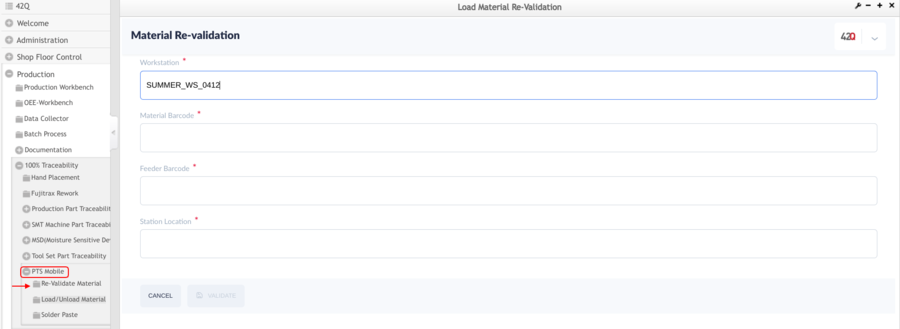

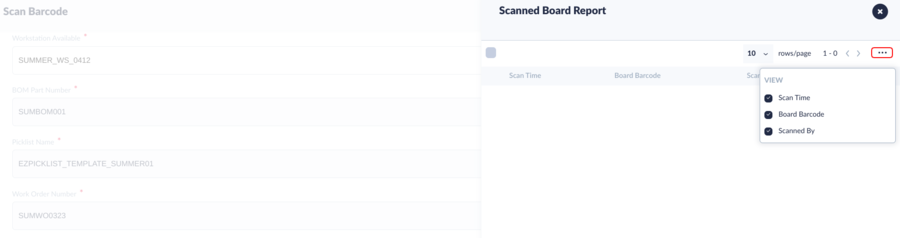

Re-Validate Material

Whenever material is going to exhaust, splicing is required to ensure production can proceed without interruption. However, there is a small chance that splicing was mistakenly done to the wrong feeder slot and it can’t be detected by the normal part verification process.

Therefore, a material re-validation is required to handle this scenario. By re-validate material (just re-scan material barcode, without interrupting the current production run), chances of splicing material to the wrong feeder slot can be avoided. The Re-Validate Material is a mobile solution (GUI) to handle the situation of Component Reset and Re-validation for traditional SMT Machines. The users can validate the materials with the Workstation, Material Barcode, Feeder Barcode, and Station.

Figure 1: Re-Validate Material

The main screen will request the user to input or scan the Workstation, Material Barcode, Feeder Barcode, and Station Location.

Load/ Unload Materials

It is mainly used for material loading and unloading, including the following submenus:

- Load Material

- Load SMT Tools

- Material Queue

- Scan Barcode

- Prepare Material

- Unload Material

- Load Prepare Material

Figure 2: Load / Unload Materials page

PTSM Load UnloadMaterials page.png

Load Material

This function is to prepare for the Scan board.

Figure 3: Load to Workstation

PTSM LoadtoWorkstation.png

Load SMT Tools

This function is used to load and unload Jig.

Figure 5: Load SMT Tools

PTSM LoadSMTTools.png

Marial Queue

This function is used to batch joint materials and prepare for automatic loading.

Figure 6: Material Queue

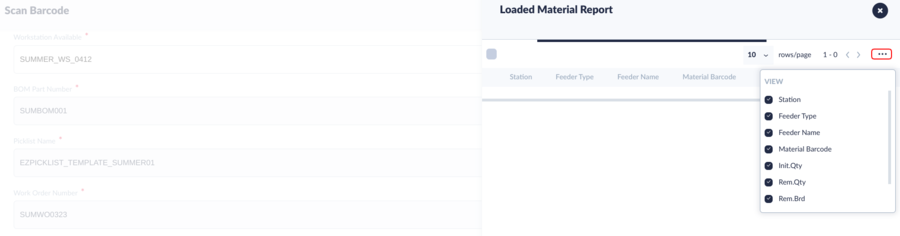

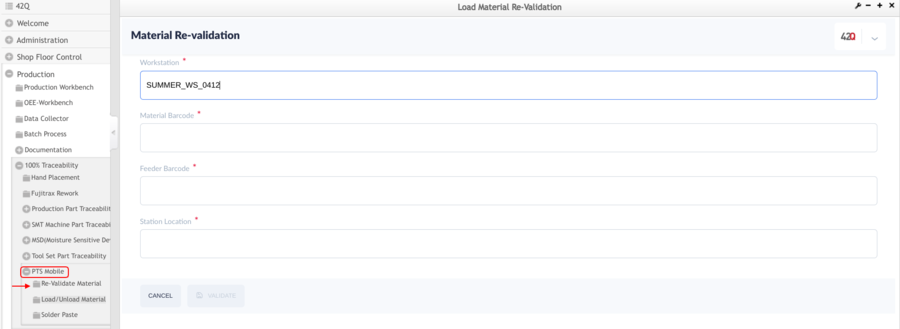

Scan Barcode

After the production line has been activated the materials loaded in Traceability, go to the Scan Barcode module.

Figure 7: Scan Barcode

PTSM ScanBarcode.png

Figure 8: Loaded Material Report

Figure 9: Scanned

To prepare material in advance while the production line is either in offline mode or online mode.

Figure 10: Prepare Material

Unload Feeder/Material from Workstation.

Figure 11: Unload Material

PTSM UnloadMaterial.png

Load prepared material sing.

Figure 12: Load Prepare Material

PTSM LoadPrepareMaterial .png

Solder Paste

Solder Paste Mainly used to manage solder paste, including the following submenus:

- Refrigeration In

- Refrigeration out

- Thaw Start

- Thaw End

- Stirring

- Open Jar

- Solder-Paste Scrap

Figure 13: Solder Paste

PTSM SolderPaste.png

This function is used to put the solder paste into the refrigerator.

Figure 14: Refrigeration In

PTSM RefrigerationIn.png

This function is used to take the solder paste out of the refrigerator.

Figure 15: Refrigeration Out

PTSM RefrigerationOut.png

This function is used to start thawing Solder Paste.

Figure 16: Thaw Start

PTSM ThawStart.png

This function is used to end the thawed solder paste.

Figure 17: Thaw End

PTSM ThawEnd.png

This function is used to stir the solder paste.

Figure 18: Stirring

PTSM Stirring.png

This function is used to open the solder paste and prepare it for use.

Figure 19: Open Jar

PTSM OpenJar .png

This function is used to scrap expired or unusable solder paste.

Figure 20: Solder Paste Scrap

PTSM SolderPasteScrap.png