Difference between revisions of "42Q-MES0168 NetSuite Adapter"

| Line 10: | Line 10: | ||

| | ||

<center style="text-align: left;"> </center> <center style="text-align: left;"> | <center style="text-align: left;"> </center> <center style="text-align: left;"> | ||

| − | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

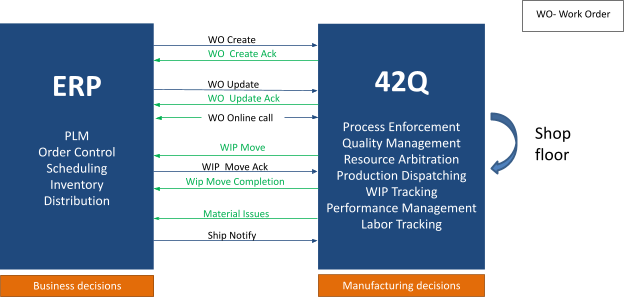

<br/> The '''NetSuite Adapter''' is a middleware software that has been developed for customers to seamlessly integrate their NetSuite systems with 42Q. This adapter can be installed to the customer’s NetSuite system in order to allow NetSuite users to monitor and iterate with 42Q. | <br/> The '''NetSuite Adapter''' is a middleware software that has been developed for customers to seamlessly integrate their NetSuite systems with 42Q. This adapter can be installed to the customer’s NetSuite system in order to allow NetSuite users to monitor and iterate with 42Q. | ||

| Line 111: | Line 111: | ||

| | ||

| − | = <span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup">Assembly Item / Product Setup</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup"><span class="mw-headline" id="Assembly_Item_.2F_Product_Setup">Assembly Item / Product Setup</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| | ||

| Line 120: | Line 120: | ||

| | ||

| − | '''Figure | + | '''Figure 8: Assembly/Bill of Materials: 42Q-MUG''' |

[[File:NA Assembly-Bill of Materials- 42Q-MUG.png|700px|NA Assembly-Bill of Materials- 42Q-MUG.png]] | [[File:NA Assembly-Bill of Materials- 42Q-MUG.png|700px|NA Assembly-Bill of Materials- 42Q-MUG.png]] | ||

| Line 139: | Line 139: | ||

| | ||

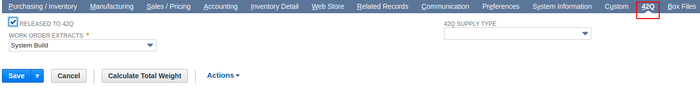

| − | '''Figure | + | '''Figure 9: 42Q Tab''' |

'''[[File:NA 42Q Tab.png|700px|NA 42Q Tab.png]]''' | '''[[File:NA 42Q Tab.png|700px|NA 42Q Tab.png]]''' | ||

| Line 153: | Line 153: | ||

| | ||

| − | = <span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order">Create a Work Order</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order">Create a Work Order</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| | ||

| Line 191: | Line 191: | ||

| | ||

| − | '''Figure | + | '''Figure 12: Schedule Priority Value''' |

[[File:NA Schedule Priority Value.png|700px|NA Schedule Priority Value.png]] | [[File:NA Schedule Priority Value.png|700px|NA Schedule Priority Value.png]] | ||

| Line 203: | Line 203: | ||

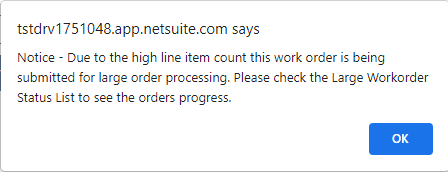

'''Figure 13: Large BOM Work Order Example''' | '''Figure 13: Large BOM Work Order Example''' | ||

| − | '''https://lh4.googleusercontent.com/zaRN7IFV6B2JDIybRZ7pPTAhGbqViKgkIKAfrF_HxHgmCWnOyDguU2R5L5SWDhMBD5WDtfuCCX7e1x9WIFLUgehs6r7UUTyjb12dGCmewPVsh218C-XZ4AF6zvBKoILnyDaEC6FvufYO0lvczvyeX4w''' | + | '''[https://lh4.googleusercontent.com/zaRN7IFV6B2JDIybRZ7pPTAhGbqViKgkIKAfrF_HxHgmCWnOyDguU2R5L5SWDhMBD5WDtfuCCX7e1x9WIFLUgehs6r7UUTyjb12dGCmewPVsh218C-XZ4AF6zvBKoILnyDaEC6FvufYO0lvczvyeX4w https://lh4.googleusercontent.com/zaRN7IFV6B2JDIybRZ7pPTAhGbqViKgkIKAfrF_HxHgmCWnOyDguU2R5L5SWDhMBD5WDtfuCCX7e1x9WIFLUgehs6r7UUTyjb12dGCmewPVsh218C-XZ4AF6zvBKoILnyDaEC6FvufYO0lvczvyeX4w]''' |

| | ||

| Line 221: | Line 221: | ||

'''Mass Create Work Order:'''<br/> To mass create a Work Orders, navigate to: '''Transactions > Manufacturing > Mass Create Work Orders'''.<br/> Work orders are generated when the assembly backorder quantities are equal and greater than to build point. After reaching the build point, a work order is added in the Mass Create Work Orders queue. After submitting the record, the work order is automatically generated. | '''Mass Create Work Order:'''<br/> To mass create a Work Orders, navigate to: '''Transactions > Manufacturing > Mass Create Work Orders'''.<br/> Work orders are generated when the assembly backorder quantities are equal and greater than to build point. After reaching the build point, a work order is added in the Mass Create Work Orders queue. After submitting the record, the work order is automatically generated. | ||

| − | <br/> '''Figure | + | <br/> '''Figure 15: Recorder Point Items Tab''' |

[[File:NA Recorder Point Items Tab.png|700x700px|NA Recorder Point Items Tab.png]] | [[File:NA Recorder Point Items Tab.png|700x700px|NA Recorder Point Items Tab.png]] | ||

| Line 227: | Line 227: | ||

| | ||

| − | '''Figure | + | '''Figure 16: Process Status Form''' |

'''[[File:NA Process Status Form.png|700x700px|NA Process Status Form.png]]''' | '''[[File:NA Process Status Form.png|700x700px|NA Process Status Form.png]]''' | ||

| Line 235: | Line 235: | ||

| | ||

| − | '''Figure | + | '''Figure 17: Processed Items Form''' |

[[File:NA Processed Items Form.png|700x700px|NA Processed Items Form.png]] | [[File:NA Processed Items Form.png|700x700px|NA Processed Items Form.png]] | ||

| Line 243: | Line 243: | ||

| | ||

| − | '''Figure | + | '''Figure 18: Created Work Order''' |

'''[[File:NA Created Work Order.png|700x700px|NA Created Work Order.png]]''' | '''[[File:NA Created Work Order.png|700x700px|NA Created Work Order.png]]''' | ||

| Line 255: | Line 255: | ||

| | ||

| − | '''Figure | + | '''Figure 19: Released Work Order''' |

'''[[File:NA Released Work Order.png|700x700px|NA Released Work Order.png]]'''<br/> | '''[[File:NA Released Work Order.png|700x700px|NA Released Work Order.png]]'''<br/> | ||

| Line 261: | Line 261: | ||

| | ||

| − | '''Figure | + | '''Figure 20: Work Order Received In 42Q''' |

[[File:NA Work Order Received In 42Q.png|700x700px|NA Work Order Received In 42Q.png]] | [[File:NA Work Order Received In 42Q.png|700x700px|NA Work Order Received In 42Q.png]] | ||

| Line 271: | Line 271: | ||

<br/> | <br/> | ||

| − | '''Figure | + | '''Figure 21: 'Mark Work Order Released' Form Page In NetSuite''' |

[[File:NA 'Mark Work Order Released' Form Page In NetSuite.png|700x700px|NA 'Mark Work Order Released' Form Page In NetSuite.png]] | [[File:NA 'Mark Work Order Released' Form Page In NetSuite.png|700x700px|NA 'Mark Work Order Released' Form Page In NetSuite.png]] | ||

| Line 277: | Line 277: | ||

<br/> | <br/> | ||

| − | '''Figure | + | '''Figure 22: 'Mark Work Order Released' Process Status Page (In Progress)''' |

[[File:NA 'Mark Work Order Released' Process Status Page (In Progress).png|700x700px|NA 'Mark Work Order Released' Process Status Page (In Progress).png]] | [[File:NA 'Mark Work Order Released' Process Status Page (In Progress).png|700x700px|NA 'Mark Work Order Released' Process Status Page (In Progress).png]] | ||

| Line 285: | Line 285: | ||

| | ||

| − | '''Figure | + | '''Figure 23: 'Mark Work Order Released' Process Status Page (Complete)''' |

[[File:NA 'Mark Work Order Released' Process Status Page (Complete).png|700x700px|NA 'Mark Work Order Released' Process Status Page (Complete).png]] | [[File:NA 'Mark Work Order Released' Process Status Page (Complete).png|700x700px|NA 'Mark Work Order Released' Process Status Page (Complete).png]] | ||

| Line 293: | Line 293: | ||

| | ||

| − | '''Figure | + | '''Figure 24: Work Order Create and Ack Monitoring Screen''' |

'''[[File:NA Work Order Create and Ack Monitoring Screen.png|700x700px|NA Work Order Create and Ack Monitoring Screen.png]]''' | '''[[File:NA Work Order Create and Ack Monitoring Screen.png|700x700px|NA Work Order Create and Ack Monitoring Screen.png]]''' | ||

| Line 301: | Line 301: | ||

| | ||

| − | '''Figure | + | '''Figure 25: Work Order Create and Ack Monitoring Screen''' |

[[File:NA Work Order Create and Ack Monitoring Screen.png|700x700px|NA Work Order Create and Ack Monitoring Screen.png]] | [[File:NA Work Order Create and Ack Monitoring Screen.png|700x700px|NA Work Order Create and Ack Monitoring Screen.png]] | ||

| Line 309: | Line 309: | ||

| | ||

| − | '''Figure | + | '''Figure 26: Work Orders Successfully Received On 42Q''' |

'''[[File:NA Work Orders Successfully Received On 42Q.png|700x700px|NA Work Orders Successfully Received On 42Q.png]]''' | '''[[File:NA Work Orders Successfully Received On 42Q.png|700x700px|NA Work Orders Successfully Received On 42Q.png]]''' | ||

| Line 317: | Line 317: | ||

| | ||

| − | = <span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates">Monitoring Work Order Updates</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates"><span class="mw-headline" id="Monitoring_Work_Order_Updates">Monitoring Work Order Updates</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| − | == <span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change">Update / Change</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change">Update / Change</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

<br/> Users can update or change the information of a work order (e. g. change the quantity) by following the next steps: | <br/> Users can update or change the information of a work order (e. g. change the quantity) by following the next steps: | ||

| Line 329: | Line 329: | ||

| | ||

| − | '''Figure | + | '''Figure 27: Work Order Monitor and Acknowledge Monitor Screen''' |

[[File:NA Work Order Monitor and Acknowledge Monitor Screen.png|700px|NA Work Order Monitor and Acknowledge Monitor Screen.png]] | [[File:NA Work Order Monitor and Acknowledge Monitor Screen.png|700px|NA Work Order Monitor and Acknowledge Monitor Screen.png]] | ||

| Line 340: | Line 340: | ||

| | ||

| − | '''Figure | + | '''Figure 28: Work Order Create and Ack Table''' |

'''[[File:NA Work Order Create and Ack Table.png|700px|NA Work Order Create and Ack Table.png]]''' | '''[[File:NA Work Order Create and Ack Table.png|700px|NA Work Order Create and Ack Table.png]]''' | ||

| Line 351: | Line 351: | ||

</ol> | </ol> | ||

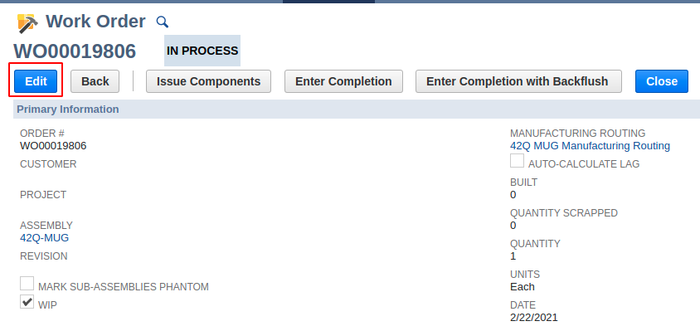

| − | <br/> <br/> '''Figure | + | <br/> <br/> '''Figure 29: Edit Work Order''' |

[[File:NA Edit Work Order.png|700px|NA Edit Work Order.png]] | [[File:NA Edit Work Order.png|700px|NA Edit Work Order.png]] | ||

| Line 362: | Line 362: | ||

| | ||

| + | | ||

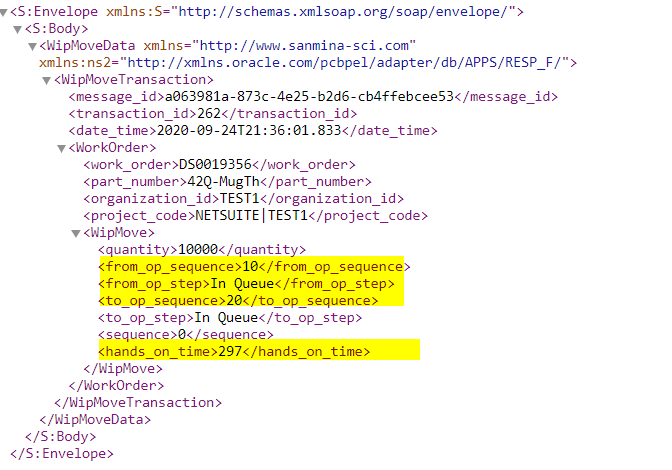

| − | == <span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions">WIP Move Transactions</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions"><span class="mw-headline" id="WIP_Move_Transactions">WIP Move Transactions</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

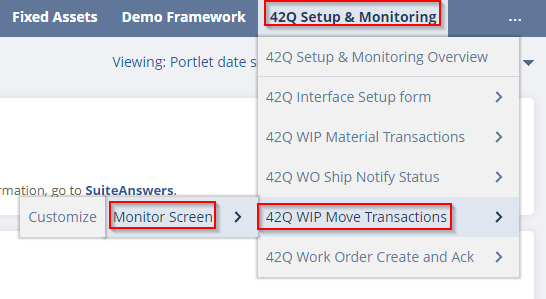

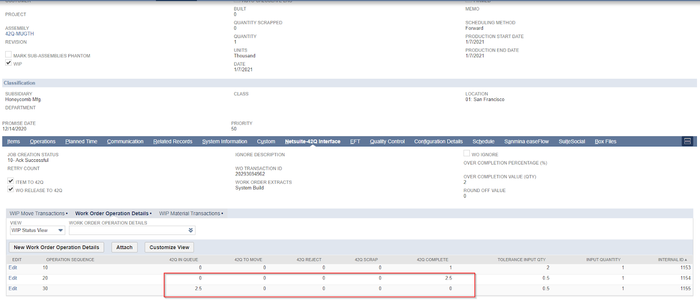

Users can view Work Order '''WIP Move Transactions''' by following the next steps: | Users can view Work Order '''WIP Move Transactions''' by following the next steps: | ||

| Line 371: | Line 372: | ||

<br/> '''Figure 30: 42Q WIP Move Transactions Monitor Screen''' | <br/> '''Figure 30: 42Q WIP Move Transactions Monitor Screen''' | ||

| − | [[File:NA 42Q WIP Move Transactions Monitor Screen.png]] | + | [[File:NA 42Q WIP Move Transactions Monitor Screen.png|NA 42Q WIP Move Transactions Monitor Screen.png]] |

| | ||

| Line 382: | Line 383: | ||

'''Figure 31: WIP Move Transactions Table''' | '''Figure 31: WIP Move Transactions Table''' | ||

| − | [[File:NA WIP Move Transactions Table.png|700px]] | + | [[File:NA WIP Move Transactions Table.png|700px|NA WIP Move Transactions Table.png]] |

| | ||

| Line 391: | Line 392: | ||

</ol> | </ol> | ||

| − | <br/> '''Figure | + | <br/> '''Figure 32: WIP Move Transactions NetSuite 42Q Interface''' |

[[File:NA WIP Move Transactions NetSuite 42Q Interface.png|700px|NA WIP Move Transactions NetSuite 42Q Interface.png]] | [[File:NA WIP Move Transactions NetSuite 42Q Interface.png|700px|NA WIP Move Transactions NetSuite 42Q Interface.png]] | ||

| Line 397: | Line 398: | ||

| | ||

| − | <br/> '''Figure | + | <br/> '''Figure 33: Save WIP Move Transactions Changes''' |

'''[[File:NA Save WIP Move Transactions Changes.png|700px|NA Save WIP Move Transactions Changes.png]]''' | '''[[File:NA Save WIP Move Transactions Changes.png|700px|NA Save WIP Move Transactions Changes.png]]''' | ||

| Line 406: | Line 407: | ||

</ol> | </ol> | ||

| + | | ||

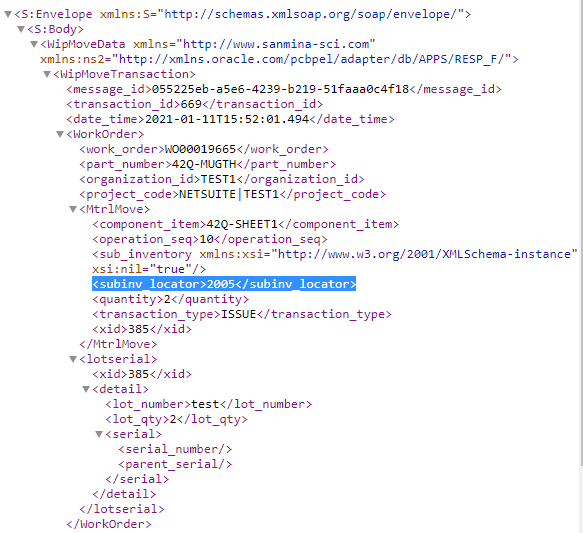

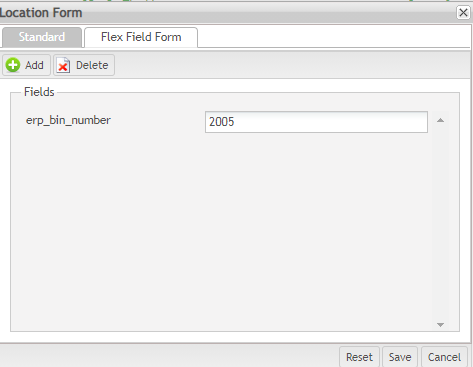

| − | == <br/> <br/> <span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions">WIP Material Transactions</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | + | == <br/> <br/> <span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions"><span class="mw-headline" id="WIP_Material_Transactions">WIP Material Transactions</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

There are two types of Materials (BOM Components): | There are two types of Materials (BOM Components): | ||

| Line 437: | Line 439: | ||

#'''Non Serialized Batch:''' This type of component item only sends a lot number back to NetSuite on material consumption. | #'''Non Serialized Batch:''' This type of component item only sends a lot number back to NetSuite on material consumption. | ||

| − | <br/> '''Figure | + | <br/> '''Figure 35: Material Lot And Quantity Consumed On 42Q''' |

'''[[File:NA Material Lot And Quantity Consumed On 42Q.png|700x700px|NA Material Lot And Quantity Consumed On 42Q.png]]'''<br/> | '''[[File:NA Material Lot And Quantity Consumed On 42Q.png|700x700px|NA Material Lot And Quantity Consumed On 42Q.png]]'''<br/> | ||

| Line 443: | Line 445: | ||

| | ||

| − | '''Figure | + | '''Figure 36: Material Transaction Received on NetSuite''' |

| − | + | [[File:NA Material Transaction Received on NetSuite.png|700px]] | |

| | ||

| Line 453: | Line 455: | ||

| | ||

| − | '''Figure | + | '''Figure 37: Used In Build Values''' |

| − | + | [[File:NA Used In Build Values.png|700px]] | |

| | ||

| Line 463: | Line 465: | ||

| | ||

| − | '''Figure | + | '''Figure 38: Recorded Quantity And Lot Number''' |

'''[[File:NA Recorded Quantity And Lot Number.png|700x700px|NA Recorded Quantity And Lot Number.png]]''' | '''[[File:NA Recorded Quantity And Lot Number.png|700x700px|NA Recorded Quantity And Lot Number.png]]''' | ||

| Line 477: | Line 479: | ||

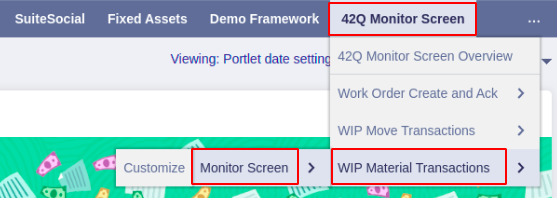

#On the menu bar, go to: '''42Q Monitor Screen > WIP Material Transactions > Monitor Screen'''. | #On the menu bar, go to: '''42Q Monitor Screen > WIP Material Transactions > Monitor Screen'''. | ||

| − | <br/> '''Figure | + | <br/> '''Figure 39: 42Q WIP Material Transactions Monitor Screen''' |

'''[[File:NA WIP Material Transactions Monitor Screen.png|NA WIP Material Transactions Monitor Screen.png]]''' | '''[[File:NA WIP Material Transactions Monitor Screen.png|NA WIP Material Transactions Monitor Screen.png]]''' | ||

| Line 488: | Line 490: | ||

| | ||

| − | '''Figure | + | '''Figure 40: 42Q WIP Material Transactions Table''' |

| − | [[File:NA WIP Material Transactions Table.png|700px | + | [[File:NA 42Q WIP Material Transactions Table.png|700px]] |

| | ||

| Line 499: | Line 501: | ||

</ol> | </ol> | ||

| − | <br/> <br/> '''Figure | + | <br/> <br/> '''Figure 41: WIP Material Transactions NetSuite 42Q Interface''' |

'''[[File:NA WIP Material Transactions NetSuite 42Q Interface.png|700px|NA WIP Material Transactions NetSuite 42Q Interface.png]]''' | '''[[File:NA WIP Material Transactions NetSuite 42Q Interface.png|700px|NA WIP Material Transactions NetSuite 42Q Interface.png]]''' | ||

| Line 510: | Line 512: | ||

| | ||

| − | <br/> '''Figure | + | <br/> '''Figure 42: Save WIP Material Transactions Changes''' |

'''[[File:NA Save WIP Material Transactions Changes.png|700px|NA Save WIP Material Transactions Changes.png]]''' | '''[[File:NA Save WIP Material Transactions Changes.png|700px|NA Save WIP Material Transactions Changes.png]]''' | ||

| Line 516: | Line 518: | ||

| | ||

| − | '''Phantom Items as Component Item (Bill of Material):'''<br/> To send phantom details in the component list to 42Q use the ''' | + | '''Phantom Items as Component Item (Bill of Material):'''<br/> To send phantom details in the component list to 42Q use the '''‘SHOW_PHANTOM’''' field in the: '''42Q Global and Plant Setup Form > 42Q Plant Setup tab > Show Phantom field'''. |

If the '''SHOW_PHANTOM''' is set as ‘'''YES’''', the Phantom item and Phantom Child items details in the component list will be sent to 42Q. | If the '''SHOW_PHANTOM''' is set as ‘'''YES’''', the Phantom item and Phantom Child items details in the component list will be sent to 42Q. | ||

| − | <br/> '''Figure | + | <br/> '''Figure 43: SHOW_PHANTOM Value Set To ‘YES’''' |

| − | ''' | + | '''https://lh6.googleusercontent.com/qdadOL_Pce987VY56Hc-oRCsJl_SQ5K9x_O9NUy6uICsv9VTcYZzGBPu2hdxRR9irbHD9Dpx-WRjB2bxQTWRRQtg09VkrVWcHtqnHEYin-ElVys5l0_cXEhlaoqb4k8-yk1YzpV5ajgVXFgArn_hDXQ''' |

| | ||

| − | '''Figure | + | '''Figure 44: Component List On 42Q''' |

'''[[File:NA Component List On 42Q.png|700x700px|NA Component List On 42Q.png]]''' | '''[[File:NA Component List On 42Q.png|700x700px|NA Component List On 42Q.png]]''' | ||

| Line 532: | Line 534: | ||

If the '''SHOW_PHANTOM''' is set as '''‘NO’''', only the Phantom child item details in the component list will be sent to 42Q. | If the '''SHOW_PHANTOM''' is set as '''‘NO’''', only the Phantom child item details in the component list will be sent to 42Q. | ||

| − | + | The Phantom Item is not sent in the BOM, only the phantom child’s are sent: | |

| − | |||

| − | |||

| − | |||

| − | |||

| | ||

| − | + | '''Figure 45: BOM Data Sent to 42Q''' | |

| − | |||

| − | |||

| − | |||

| − | '''Figure | ||

'''[[File:NA BOM Data Sent to 42Q.png|700x700px|NA BOM Data Sent to 42Q.png]]'''<br/> | '''[[File:NA BOM Data Sent to 42Q.png|700x700px|NA BOM Data Sent to 42Q.png]]'''<br/> | ||

| Line 552: | Line 546: | ||

| | ||

| − | == <span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates">Routing Updates</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates"><span class="mw-headline" id="Routing_Updates">Routing Updates</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

The updates supported under Routing from NetSuite to 42Q are the following: | The updates supported under Routing from NetSuite to 42Q are the following: | ||

| Line 567: | Line 561: | ||

| | ||

| − | = <span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs">Key Value Pairs</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs">Key Value Pairs</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

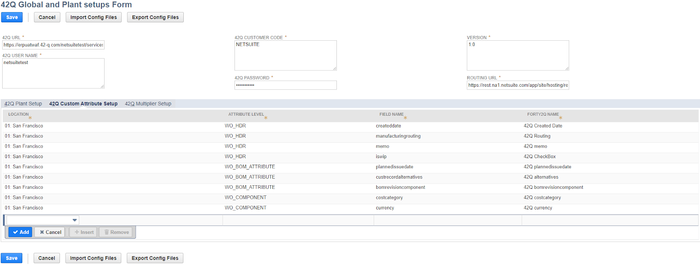

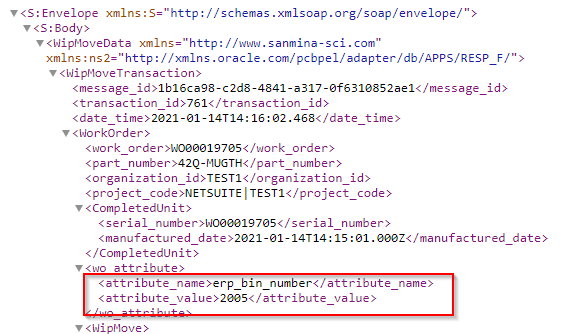

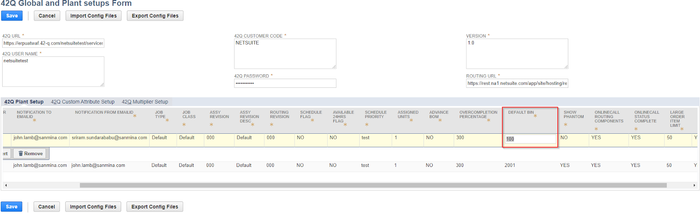

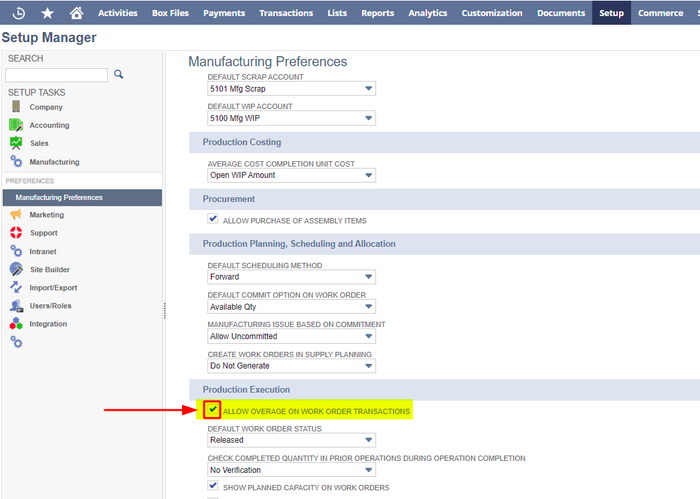

'''Key Value Pairs''' (Custom Attributes) allows users to send custom fields or native fields, which are not part of the standard adapter from ERP to 42Q. | '''Key Value Pairs''' (Custom Attributes) allows users to send custom fields or native fields, which are not part of the standard adapter from ERP to 42Q. | ||

| Line 580: | Line 574: | ||

| | ||

| − | To send these custom attributes, users need to follow the next steps: & | + | To send these custom attributes, users need to follow the next steps: |

| + | |||

| + | #'''Go''' to: '''42Q Setup & Monitoring > 42Q Interface Setup Form > 42Q Interface Setup Form > 42Q Custom Attribute Setup'''. | ||

| + | #'''Select''' '''Location''' for which the custom attribute should be sent with the work order created. | ||

| + | #'''Select''' an '''Attribute Level''', and choose from the 4 levels defined. | ||

| − | + | <br/> <br/> '''Figure 46: ''''''Choose an Attribute Level''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | + | [[File:NA Choose an Attribute Level.png|700px]] |

| + | |||

| + | | ||

| + | <ol start="4"> | ||

| + | <li>To perform the mapping of the custom attribute field, set '''FIELD_NAME = Field ID from NetSuite''' as in Figure 47.</li> | ||

| + | <li>Set the 42Q generic field name called '''FORTY2Q_NAME = Field name to be displayed on 42Q''' as in Figure 47.</li> | ||

| + | </ol> | ||

| − | + | | |

| | ||

| − | + | '''Figure 47: Custom Attributes Setup''' | |

| + | |||

| + | [[File:NA Custom Attributes Setup.png|700px]] | ||

| + | |||

| + | | ||

| − | If custom fields have multiple inputs, the adapter comma separates them and sends them to 42Q. | + | <u>'''Note:'''</u> If custom fields have multiple inputs, the adapter comma separates them and sends them to 42Q. |

| | ||

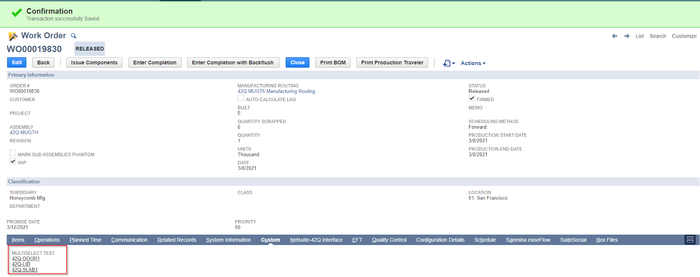

| − | '''Figure | + | '''Figure 48: Custom Tab''' |

[[File:NA Custom Tab.png|700x700px|NA Custom Tab.png]] | [[File:NA Custom Tab.png|700x700px|NA Custom Tab.png]] | ||

| Line 607: | Line 610: | ||

| | ||

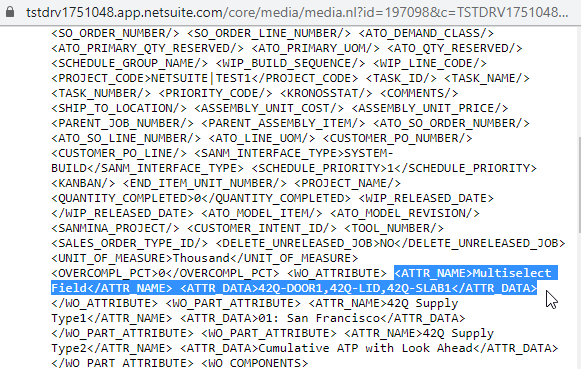

| − | '''Figure | + | '''Figure 49: Custom Data Sent to 42Q''' |

'''[[File:NA Custom Data Sent to 42Q.png|NA Custom Data Sent to 42Q.png]]''' | '''[[File:NA Custom Data Sent to 42Q.png|NA Custom Data Sent to 42Q.png]]''' | ||

| Line 613: | Line 616: | ||

| | ||

| − | '''Figure | + | '''Figure 50: Data Received By 42Q''' |

'''[[File:NA Data Received By 42Q.png|700x700px|NA Data Received By 42Q.png]]''' | '''[[File:NA Data Received By 42Q.png|700x700px|NA Data Received By 42Q.png]]''' | ||

| Line 623: | Line 626: | ||

<u>'''Note:'''</u> '''COMPONENT_PART_ATTRIBUTE''' and '''WO_BOM_ATRIBUTE''' attributes are not sent to 42Q when the BOM item list has more than 500 line items. | <u>'''Note:'''</u> '''COMPONENT_PART_ATTRIBUTE''' and '''WO_BOM_ATRIBUTE''' attributes are not sent to 42Q when the BOM item list has more than 500 line items. | ||

| − | = <span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time">Standard Cycle Time and Hands on Time</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time">Standard Cycle Time and Hands on Time</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| | ||

| Line 629: | Line 632: | ||

| | ||

| − | == <span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time">Standard Cycle Time</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time"><span class="mw-headline" id="Standard_Cycle_Time">Standard Cycle Time</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

| | ||

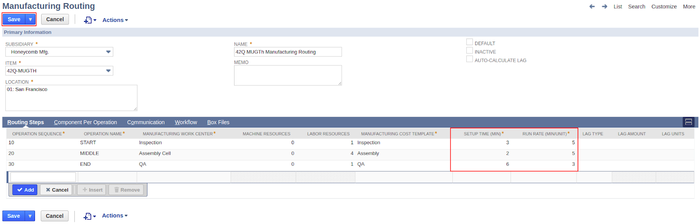

| Line 642: | Line 645: | ||

#'''RUN RATE (MIN/UNIT)''' also known as machine run time (Basis type is item). | #'''RUN RATE (MIN/UNIT)''' also known as machine run time (Basis type is item). | ||

| − | <br/> <br/> '''Figure | + | <br/> <br/> '''Figure 51: Work Order Operations''' |

[[File:NA Work Order Operations.png|700px|NA Work Order Operations.png]] | [[File:NA Work Order Operations.png|700px|NA Work Order Operations.png]] | ||

| Line 656: | Line 659: | ||

#Add the standard baselines for each operation in the '''SETUP TIME (MIN)''' and '''RUN RATE (MIN/UNIT)''' columns. | #Add the standard baselines for each operation in the '''SETUP TIME (MIN)''' and '''RUN RATE (MIN/UNIT)''' columns. | ||

| − | <br/> '''Figure | + | <br/> '''Figure 52: Manufacturing Routing Edition''' |

[[File:NA Manufacturing Routing Edition.png|700px|NA Manufacturing Routing Edition.png]]<br/> <br/> <br/> | [[File:NA Manufacturing Routing Edition.png|700px|NA Manufacturing Routing Edition.png]]<br/> <br/> <br/> | ||