Difference between revisions of "How to Leak Scan Board"

| Line 1: | Line 1: | ||

| − | = <span class="mw-headline" id="Background"><span class="mw-headline" id="Background"><span class="mw-headline" id="Background">Background</span></span></span> = | + | = <span class="mw-headline" id="Background"><span class="mw-headline" id="Background"><span class="mw-headline" id="Background"><span class="mw-headline" id="Background">Background</span></span></span></span> = |

42Q PTS production scanning has a strong process(need scan the board at the previous workstation first, can not skip workstation when scan board ) that can avoid scanning board records missing. Most PTS plants are fine with this function. | 42Q PTS production scanning has a strong process(need scan the board at the previous workstation first, can not skip workstation when scan board ) that can avoid scanning board records missing. Most PTS plants are fine with this function. | ||

| Line 6: | Line 6: | ||

But some plants use two PTS production lines to produce the PCB board top & bottom side separately (In different lines). | But some plants use two PTS production lines to produce the PCB board top & bottom side separately (In different lines). | ||

| − | For example, a Product has B and T two sides. Plants need to create two workstations separately for the B / T side. Sometimes they already processed the B side in another production line(Line1) and then they just need to process the T side in the current line(Line2) and the current workstation with | + | For example, a Product has B and T two sides. Plants need to create two workstations separately for the B / T side. Sometimes they already processed the B side in another production line(Line1) and then they just need to process the T side in the current line(Line2) and the current workstation with other workstations not scan board. |

| | ||

| − | = <span class="mw-headline" id="Detailed_production_lines_setting:"><span class="mw-headline" id="Detailed_production_lines_setting:"><span class="mw-headline" id="Detailed_production_lines_setting:">Detailed production lines setting:</span></span></span> = | + | = <span class="mw-headline" id="Detailed_production_lines_setting:"><span class="mw-headline" id="Detailed_production_lines_setting:"><span class="mw-headline" id="Detailed_production_lines_setting:"><span class="mw-headline" id="Detailed_production_lines_setting:">Detailed production lines setting:</span></span></span></span> = |

| | ||

| Line 32: | Line 32: | ||

Before this enhancement, production will prompt a "Previous WS not scanned." error message when scan the board in line2. | Before this enhancement, production will prompt a "Previous WS not scanned." error message when scan the board in line2. | ||

| − | = <span class="mw-headline" id="Solution"><span class="mw-headline" id="Solution"><span class="mw-headline" id="Solution">Solution</span></span></span> = | + | = <span class="mw-headline" id="Solution"><span class="mw-headline" id="Solution"><span class="mw-headline" id="Solution"><span class="mw-headline" id="Solution">Solution</span></span></span></span> = |

#First, supply a new configuration item ‘'''Allow Leak Scanning Board'''‘ in '''PTS System Setting''' function. | #First, supply a new configuration item ‘'''Allow Leak Scanning Board'''‘ in '''PTS System Setting''' function. | ||

| Line 38: | Line 38: | ||

#Improve the Scan Board function, and only when switch ''''Allow Leak Scanning Board'''' in '''System Setting '''function and switch ''''Allow Leak Scanning Board '''' in '''Workstation Setup''' function are all in opened status(Value is '''Yes''') the scanning board allows leak scanning for the current workstation. | #Improve the Scan Board function, and only when switch ''''Allow Leak Scanning Board'''' in '''System Setting '''function and switch ''''Allow Leak Scanning Board '''' in '''Workstation Setup''' function are all in opened status(Value is '''Yes''') the scanning board allows leak scanning for the current workstation. | ||

| − | = <span class="mw-headline" id="How_to_operate_in_42Q"><span class="mw-headline" id="How_to_operate_in_42Q"><span class="mw-headline" id="How_to_operate_in_42Q">How to operate in 42Q</span></span></span> = | + | = <span class="mw-headline" id="How_to_operate_in_42Q"><span class="mw-headline" id="How_to_operate_in_42Q"><span class="mw-headline" id="How_to_operate_in_42Q"><span class="mw-headline" id="How_to_operate_in_42Q">How to operate in 42Q</span></span></span></span> = |

'''<span class="mw-headline" id="System_Setting"><span class="mw-headline" id="System_Setting">System Setting</span></span>''' | '''<span class="mw-headline" id="System_Setting"><span class="mw-headline" id="System_Setting">System Setting</span></span>''' | ||

| Line 50: | Line 50: | ||

| | ||

| − | == <span class="mw-headline" id="Workstation_Setup"><span class="mw-headline" id="Workstation_Setup"><span class="mw-headline" id="Workstation_Setup">Workstation Setup</span></span></span> == | + | == <span class="mw-headline" id="Workstation_Setup"><span class="mw-headline" id="Workstation_Setup"><span class="mw-headline" id="Workstation_Setup"><span class="mw-headline" id="Workstation_Setup">Workstation Setup</span></span></span></span> == |

Go to: '''Shop Floor Control > Production Control > Traceability Setup.''' | Go to: '''Shop Floor Control > Production Control > Traceability Setup.''' | ||

| Line 68: | Line 68: | ||

| | ||

| − | After setting all the workstations, please set the lines | + | After setting all the workstations, please set the lines online. |

This is an example of the two production lines with three workstations each. | This is an example of the two production lines with three workstations each. | ||

| Line 80: | Line 80: | ||

| | ||

| − | == <span class="mw-headline" id="Touch"><span class="mw-headline" id="Touch"><span class="mw-headline" id="Touch">Touch</span></span></span> == | + | == <span class="mw-headline" id="Touch"><span class="mw-headline" id="Touch"><span class="mw-headline" id="Touch"><span class="mw-headline" id="Touch">Touch</span></span></span></span> == |

#Load all the materials to all workstations at the '''Load material''' function. | #Load all the materials to all workstations at the '''Load material''' function. | ||

| Line 99: | Line 99: | ||

| | ||

| + | |||

| + | ---- | ||

| | ||

| − | |||

| − | |||

| | ||

Revision as of 22:42, 21 January 2022

Contents

Background

42Q PTS production scanning has a strong process(need scan the board at the previous workstation first, can not skip workstation when scan board ) that can avoid scanning board records missing. Most PTS plants are fine with this function.

But some plants use two PTS production lines to produce the PCB board top & bottom side separately (In different lines).

For example, a Product has B and T two sides. Plants need to create two workstations separately for the B / T side. Sometimes they already processed the B side in another production line(Line1) and then they just need to process the T side in the current line(Line2) and the current workstation with other workstations not scan board.

Detailed production lines setting:

PTS Production Line 1

First Workstation: L1 SP (Scanned By Later Workstation)

Second Workstation: L1 AIMEX_B (Scan For Previous Workstation) First Scanning

Third workstation: L1 AIMEX_T (Scan For the Previous Workstation)

PTS Production Line 2

First Workstation: L2 SP (Scanned By Later Workstation)

Second Workstation: L2 AIMEX_B (Scan For the Previous Workstation)

Third workstation: L2 AIMEX_T (Scan For the Previous Workstation) Second Scanning

Before this enhancement, production will prompt a "Previous WS not scanned." error message when scan the board in line2.

Solution

- First, supply a new configuration item ‘Allow Leak Scanning Board‘ in PTS System Setting function.

- PTS Workstation Setup function to add a new configuration switch item named 'Allow Leak Scanning Board'.

- Improve the Scan Board function, and only when switch 'Allow Leak Scanning Board' in System Setting function and switch 'Allow Leak Scanning Board ' in Workstation Setup function are all in opened status(Value is Yes) the scanning board allows leak scanning for the current workstation.

How to operate in 42Q

System Setting

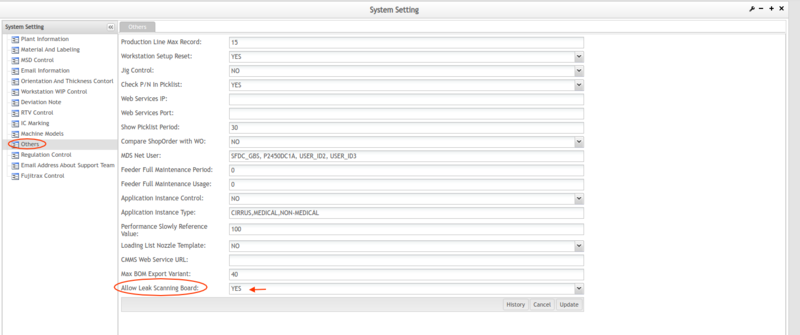

Go to Administration > Traceability Administration > System Setting, at the Others tab, set the Allow Leak Scanning Board =YES

Figure: System Setting - Allow Leak Scanning Board

Workstation Setup

Go to: Shop Floor Control > Production Control > Traceability Setup.

At the module, manage the Production lines and workstations.

For a Leak scanning board, this setting is important for all workstations.

Right-click on the workstation to open the menu, then select Workstation Setup to set the workstation configuration.

Figure: Workstation Setup

After setting all the workstations, please set the lines online.

This is an example of the two production lines with three workstations each.

Figure: An Example Leak scanning Production Line

Touch

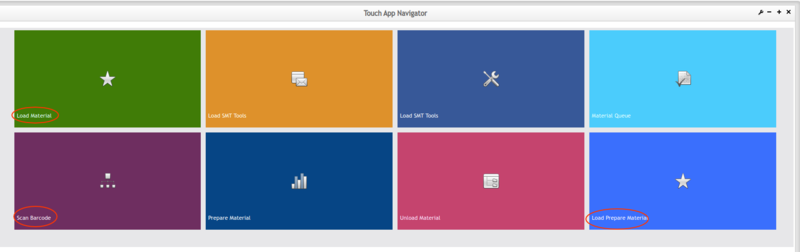

- Load all the materials to all workstations at the Load material function.

Figure: Touch Main Page

- Scan one Board for the B side at the station L1AIMEX-B (Production Line1 TestLine1, B side) at the Scan board function.

- Scan one Board with the same barcode of the B side for the T side at the station L2 AIMEX-T (Production Line2 TestLine2, T side) at the scan board function.

- Go to the Load material report to check the material quantity for the Production line2(TestLine2), the quantity of the material for station L2 AIMEX-T is reduced, but the quantity of the material for the other two stations (L2 SP, L2 AIMEX-B) is not reduced. This step is optional.

Figure: An example for scan board