Difference between revisions of "SOP-42Q-MES0025 Serialized Item Tracker"

Dane parker (talk | contribs) |

|||

| Line 1: | Line 1: | ||

| + | <small>[http://hsvmeswiki.sanmina-sci.com/mes_wiki/index.php/Cirrus#Categories Cirrus] > [http://hsvmeswiki.sanmina-sci.com/mes_wiki/index.php/Shop_Floor_Control Shop Floor Control] > [http://hsvmeswiki.sanmina-sci.com/mes_wiki/index.php/Production_Control Production] > Serialized Item Tracker</small> | ||

| + | |||

[[Image:Sanmina logo.png|130px|Sanmina logo.png]] | [[Image:Sanmina logo.png|130px|Sanmina logo.png]] | ||

| Line 298: | Line 300: | ||

'''Figure 10: Operation Summary''' | '''Figure 10: Operation Summary''' | ||

| − | [[Image:Figure 10 Operation Summary.jpg|left|500px|Figure 10 Operation Summary.jpg]]<br> | + | [[Image:Figure 10 Operation Summary.jpg|left|500px|Figure 10 Operation Summary.jpg]]<br> |

<br> | <br> | ||

| Line 320: | Line 322: | ||

<br> | <br> | ||

| + | <br> In this summary you can see all returned/obsolete/damaged serial number (Passed status) otherwise, the fail reason. | ||

| − | + | A new line with the new status is created in the serialized list. | |

| − | |||

| − | A new line with the new status is created in the serialized list. | ||

| − | |||

| − | |||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

==== Resend ==== | ==== Resend ==== | ||

| Line 1,235: | Line 1,237: | ||

| Review and format for WIKI | | Review and format for WIKI | ||

|} | |} | ||

| − | + | ||

| + | </font> | ||

<font color="#FF0000"></font> | <font color="#FF0000"></font> | ||

Revision as of 20:19, 13 March 2014

Cirrus > Shop Floor Control > Production > Serialized Item Tracker

This edition applies to MES15 Portal 1.0 Application and all subsequent releases and modifications until otherwise indicated in new revisions.'

Contents

- 1 Serialized Item Tracker

- 1.1 Functionalities Executed from Serialized Items ListHeader

- 1.1.1 Accessing SIT Application

- 1.1.2 Serialized Item Tracker List

- 1.1.3 Edit (Update)

- 1.1.4 Process (Return/Obsolete/Damage)

- 1.1.5 Resend

- 1.1.6 Additional Information

- 1.1.7 Print/Export or Print/Export Filtered

- 1.1.8 SIT Batch Traveler

- 1.1.9 Receive

- 1.1.10 Receive PTS

- 1.1.11 Part x Sit Type

- 1.1.12 Location x Sit Type

- 1.1 Functionalities Executed from Serialized Items ListHeader

- 2 Appendix A

- 3 Appendix B

- 4 Document Revision History

Serialized Item Tracker

The Serialized Item Tracker (SIT) is a Cirrus module designed for effectively creating and importing large numbers of serialized components to be used in the manufacturing process. It eliminates much of the overhead of creating serial numbers one at a time. The serialized components can be created based on a starting serial number and algorithm or from a list of serial numbers scanned or copied from a text file.

The SIT can receive, return, and make obsolete a range of serialized items. Serialized Item Ranges will be stored in a new SIT_Range table in the database. Each item in the range is exploded into the serial table as tracked components. The assignment of these items to units will be done with standard SFDC technology. There are reports and EDI extracts that will be written to support SIT. These reports and extracts are not been defined in this document as they will most likely be written outside MDS.

SIT also manages and sends e-mail alerts of the serialized items consumption by low and very low watermarks.

Functionalities Executed from Serialized Items ListHeader

Accessing SIT Application

To access the SIT Serialized Item Tracker, navigate toShop Floor Control > Production Control > Serialized Item Tracker.

Figure 1: Serialized Item Tracker

To list and search Serialized Items, click onSerialized Item.

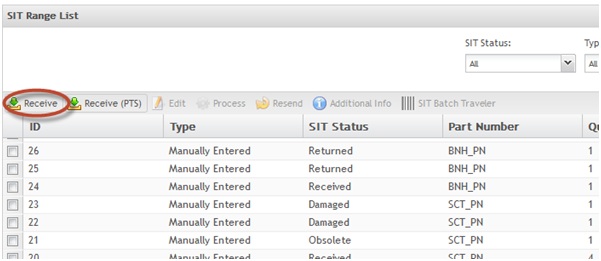

The SIT Range List displays:

Figure 2: SIT Range List

The user is able to perform the following actions from the SIT Range List: Receive, Receive (PTS), Edit, Process, Resend, Additional Info, SIT Batch Traveler, Print/Export, and Print/Export Filtered Ranges.

Figure 3: Search Using "Filter" Button

There are three available fields by which to search: Status, Type and Filter By. Enter the information and click Filter.

Figure 4: Searching by Status

The serialized items created by SIT have a status. The current statuses are Received, Returned, Damaged and Obsolete. See the following descriptions for each:

- Received: Serial number created (SFDC status is the same as the location where the serial was created)

- Returned: Returns a range of serials, a specific serial or all serials (change SFDC status to "50-Killed")

- Damaged: Serial item damaged (change SFDC status to "50-Killed")

- Obsolete: Serial will not be used anymore but continues to exist. No longer in use or valid (change SFDC status to "50-Killed")

1. To search, select a status and click Filter.

Figure 5: Searching by Type

There are four types available: COA label, EUI-48-Intel-MAC, Manually Entered and Non-SN Batch. Selecting a type will display serial number ranges already created for all statuses (receive, obsolete, damage, return).

1. To perform a search, select a type and click on Filter.

Figure 6: Searching by "Filter by":

1. To perform a search using the "Filter by" field, select one of the available options (Part Number, Serial Number, PO,PO Line, Packing List or Created User) and enter the information into the value field accordingly.

2. Select Filter.

Serialized Item Tracker List

The Serialized Item Tracker main page shows a list of locations that are based on the actual SFDC Configuration,

Figure 7: Serialized Item Tracker Range List

Edit (Update)

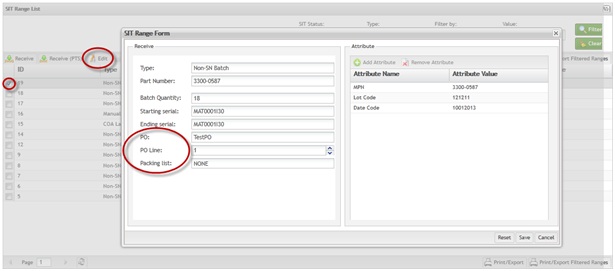

The Edit portlet can be used to make changes to the PO, PO line, and Packing List information.

1. To use the edit portlet, select the serial number and click Edit. The SIT Range Form displays.

Figure 8: SIT Range Form

2. Enter new values for:

- PO: The Purchase Order of the range being received.

- PO Line: The Line Number of the Purchase Order above.

- Packing List: The shipping number of the range being received.

3. Select Save. The updates are saved and the list is refreshed.

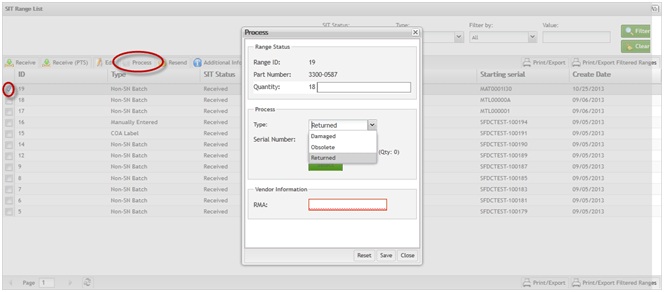

Process (Return/Obsolete/Damage)

For Return, an RMA (Return Material Authorization) number is required for the new range. The application saves this information for historical reporting.

This portlet allows the user to return a range, all available units, or a single serial item number to a vendor according to the chosen option in the Process page. The range is stored in the SIT_Range table as "Returned" for Return, "Obsolete" for Obsolete and "Damaged" for Damage.

1. To modify an existing serial, select a serial number and click Process. The Process pop-up window appears.

2. In the Process section of the Process window, select a Type from the drop-down box.

Figure 9: Process

The following information can be entered in the page, Range ID, Part Number and Available Units associated to the

percent of the available units to be returned.

Return/Obsolete/Damage "All Available Units"

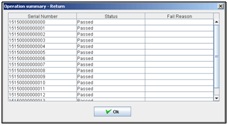

An Operation Summary page is displayed with the result of the operation. All available units must be returned/obsolete/damaged and must be inserted in the Serialized Items List with a new status and serial range information. After any operation, the serial numbers do not have to appear as available units.

Result: An Operation Summary page is displayed with the result of the operation. All available units are returned/damage or obsolete and a new line on "Serialized Items List" with the new status is inserted. After any operation, the serial numbers do not appear as "available units".

Return/Obsolete/Damage "Single Serial"

An Operation Summary page is displayed with the result of the operation. The single unit must be returned/obsolete/damaged and must be inserted as a new line on "Serialized Items List" with the new status and the serial number information. After any operation, the serial number does not have to appear as "available units".

Result: An Operation Summary page is displayed with the result of the operation. The Single Serial is returned/obsolete/damaged and a new line on "Serialized Items List" with the new status is inserted. After a return operation, the returned serial numbers do not appear as "available units".

Return/Obsolete/Damage "Serial Range"

An Operation Summary page is displayed with the result of the operation. The serial range filled in must be returned/obsolete/damaged and must be inserted as a new line on "Serialized Items List" with the new status and the serial range information. After any operation, the serial range returned does not have to appear as "available units".

Result: An Operation Summary page is displayed with the result of the operation. Serial range units are returned/obsolete/damaged and a new line on "Serialized Items List, with the new status is inserted. After any operation, the serial numbers do not appear as "available units".

Choose one of the available options to return/obsolete or damage (all available units, single serial, or a range (starting and ending serials).

An operation summary is returned.

Figure 10: Operation Summary

In this summary you can see all returned/obsolete/damaged serial number (Passed status) otherwise, the fail reason.

A new line with the new status is created in the serialized list.

Resend

This functionality allows the user to create an attribute for an SIT Range. This triggers another process to send an EDI file to the vendor.

Figure 11: Serialized Item Tracker List - Resend

1. To resend a serial range, check the box of a range and select Resend. A confirmation message is displayed.

2. Select Yes to complete the action, (or No to cancel). A confirmation message displays, and the serialized items have been resent.

Additional Information

This Topic discusses the basic information of a selected range as Range ID, Part Number, Quantity and Serial Number List.

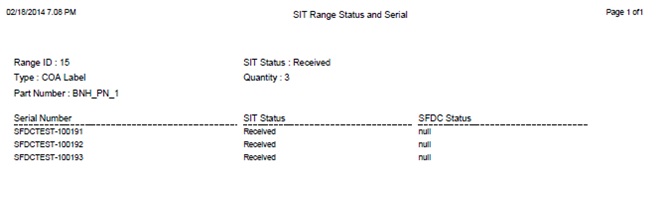

Figure 12: Serialized Tracker List - Received

1. To use the Additional Info portlet, check the box of a serial range with a Received status from the list and select Additional Info. The information of the selected range will be displayed, including Range ID, Part Number, Quantity and Serial Number List.

2. Select Print/Export Serial Numbers to display the page that will allow the user to select the status desired. The Print Label option is available. The following report is displayed:

Figure 13: Export Serial Numbers Report Viewer

Print/Export or Print/Export Filtered

This section covers the print/export portlet on the main SIT Range List page. This portlet is used toPrint or Export a selected range or a single serial number.

Figure 14: Serialized Items List – Print/Export

1. Select Print/Export or Print/Export Filtered Ranges in the Serialized Items Tracker list.

2. A PDF report is generated that the user may print or save.

Figure 15: Print/Export Report

Figure 16: Print/Export Filtered Ranges Report

SIT Batch Traveler

This section instructs users about the SIT Batch Traveler portlet. This portlet prints all the serial numbers that make up a selected range.

Figure 17: Serialized Tracker List - SIT Batch Traveler

1. To use the SIT batch traveler, select SIT Batch Traveler from the SIT Range List main page. This generates a PDF batch report that the user may save or print.

Figure 18: Batch Report

Receive

This portlet allows a user to receive (create) a range of serialized items. The user specifies the beginning and ending serial number, part number, and other miscellaneous attribute data. The range is stored in the SIT_Range table as "received" SIT status and has the same status as the location where it was created (see Location x SIT Type). Individual items are created in the database as tracked components. A serial number algorithm for the part number needs to be created and released to support generating serial numbers for the defined range.

NOTE:

SIT works with just with two algorithm types:

1. Shop Order Algorithm (created using the Algorithm Tool).

2. Algorithm manually encoded.

The serial numbers are created and associated to the location (and unit status) that was defined on Location x Sit Type. The following attributes are linked to each serial number:

- SIT Range Pointer

- SIT Serial Number

- SIT Date Code

- SIT Lot Code

- SIT Manufacturer Part Number

- SIT PTS ID (only in case of a PTS receive)

The algorithm is updated with the last serial number received.

1. To start the receive process, select Receive from the SIT Range List main page.

Figure 19: Receive

2. Click on Receive button.

Figure 20: SIT Range Form for Non SN Batch, COA Label and EUI-48 types

3. Complete the Type,Part Number, Quantity,andStarting Serial fields.

NOTE: After entering the mandatory fields, the Print Label pop-up for receive units is displayed. The user can fill the mandatory fields to print the label or cancel to proceed with the receive task. When Manually Entered is selected, the Quantity, Starting serial and Ending serial fields are disabled. A multi-line text box appears to be filled with the serials. Paste in a list of serial numbers in the text box, one per line. The quantity field will be automatically updated with the number of serial numbers in the text box. Then select Ok. These serial numbers will be used instead of calculating serial numbers from an algorithm.

Figure 21: Manually Entered Type

Part Number: The user selects one part number from the drop-down list, depending on the selected type.

Batch Quantity: Calculated if the starting and ending serial fields are populated. If the Starting serial and a specific quantity are entered, the system calculates the ending serial. If the starting serial and ending serial are populated, the quantity field is disabled.

PO: The Purchase Order of the range being received.

PO Line: The Line Number of the Purchase Order above.

Packing List: The shipping number of the range being received.

4. After all fields are populated, a confirmation message is displayed.

5. Click on Yes to confirm the range creation or No to cancel. The created range is displayed in the SIT list.

Non-SN Batch

Always create a batch serial number. The batch serial number quantity is determined by the receive quantity.

If the part number is assigned to an algorithm, the serial number will be validated accordingly; otherwise no validation will occur.

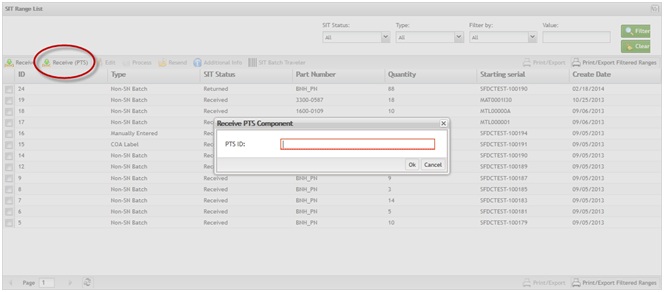

Receive PTS

This functionality is used by the plants that need traceability. This is controlled using a new set of screens and portlets in profile management, so only users with access to this screen can see or use it. Conversely, if the existing screen should not be shown in a specific project, it should not be assigned to any profile.

Receive PTS Steps:

1. Check Receive (PTS) in the SIT Range List page. The Receive PTS Component pop-up appears.

Figure 22: Receive PTS

2. Enter a PTS ID.

3. If the PTS ID information is not stored in the MDS tables, then jMDS tries to connect to the PTS database and imports PTS information for the PTS ID (like PTS ID’s Part Number, Date Code, Lot Code, MPN). The next time that same PTS ID is entered, jMDS will not have to connect to the PTS database.

NOTE: The process to import PTS ID data is as follows:

- jMDS checks if the PTS ID is on MDS database.

- If found, the PTS information in MDS database will be displayed.

- If not found, jMDS will try to get connect to the PTS database.

- If PTS records are found, the information will be imported (i.e., copied) to MDS database.

- If no PTS records are found, a warning message will be displayed stating that the PTS ID is invalid.

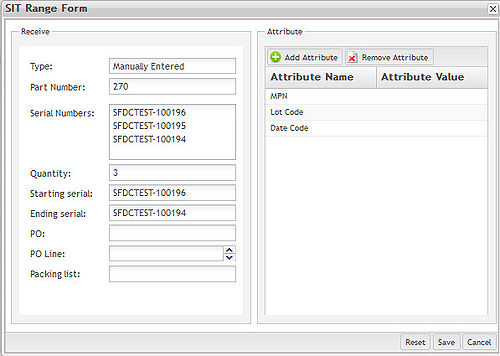

4. Select Ok using a valid PTS ID. The Sit Range screen will open showing the imported data.

Figure 23: SIT Range

NOTE: The Range Type is always Manually Entered. Because of this, the combo box is disabled. The Part Number, Date Code, Lot Code, and MPN will contain the imported PTS information and is disabled for editing.

5. Use the Edit portlet is available for PTS to update the PO, PO Line and Packing List information. If the generic attribute update_pts_data is defined as "Yes," the Date Code, Lot Code and MPN information will be available for editing as well.

Part x Sit Type

This section covers how a part number can be assigned or unassigned to an SIT type. To access the Part x Sit Type module navigate to the Serialized Item Tracker main page (Shop Floor Control > Production Control > Serialized Item Tracker) and select Part x Sit Type.

Figure 24: Part SIT Type

The SIT Type List page displays:

Figure 25: SIT Type List

1. To edit a SIT type, check the box of a SIT type from the list and click Edit. The Part x Type list is displayed.

Figure 26: Add Part x SIT Type

2. To add an association, click on Add Part x SIT Type in the Tasks panel.

Figure 27: Add Part x SIT Type

3. Select a part number to be associated and click on Save. The selected part number will disappear from this list and will be displayed in the SIT type list, for the previously selected type. To cancel this action, select Cancel.

Editing a SIT Type:

The rules for editing SIT Types are the same for COA, MAC or Manually Entered:

1. Select Edit to edit a MAC Address or COA Label Type. The Edit page is displayed.

Figure 28: Part x Type List – Edit Part SIT Type

Figure 29: Part x SIT Type Form

NOTE: Unless the user checks the check box "Do you want to manage the LVM and VLVM?" this page will not be available for editing.

- Low Water Mark: This is a value set by the user to trigger an alert when the available SN quantity for that part number is low and needs attention. This is defined when the user intends to manage the available quantity of SN. When the LWM is reached, e-mail alerts are sent for the registered addresses.

- Very Low Watermark: This is a value set by the user to trigger an alert when the available SN quantity is very low and has become a critical situation. When the VLWM is reached, e-mail alerts are sent for the registered addresses.

2. After checking the "Do you want manage the LVM and VLVM?" box, the data can be edited.

3. Type a user name and click on add icon for the LWM and VLWM CC E-mail. The e-mail list box is populated with the e-mail from the CC E-mail textbox. The user may also select Remove (All Items or Selected Items) for the LWM and VLWM CC E-mail. This removes the selected e-mail from the e-mail list.

NOTES:

- Selected users will receive e-mails frequently, unless they are removed from the list.

- ACRON job must be configured to send the emails.

Figure 30: Part x Type List - Disassociating Part Numbers

1. To delete a part x SIT type, select a part number to delete and click Delete.

NOTE: This selected part number will not be deleted from database per se; it will just be unassigned from the selected SIT type.

2. Select Yes to confirm, or No to cancel.

Location x Sit Type

This section covers how a location can be assigned or unassigned to a SIT type.

To access the Location x SIT Type module, navigate to Shop Floor Control > Production Control > Serialized Item Tracker and select Location x SIT Type from the SIT main page.

Figure 31: Location x SIT Type

1. To edit the Location, check the box of an SIT type in the list and select Edit.

Figure 32: SIT Type List

2. Edit the location and select Save to confirm the updates, or Cancel to abort.

Figure 33: SIT Type Form

NOTE: If the SIT Type already has received SIT Range, it will not be possible to change its location (see the image above).

Appendix A

Acronyms

Acronyms are abbreviations, such as LDAP, MDS, and SFDC, written as the initial letter or letters of words, and pronounced on the basis of this abbreviated written form. By developing these acronyms, it is not necessary to write the complete name all the time in the guide.

| COA Certificate of Authenticity |

Appendix B

Glossary

This glossary is a list of terms with the definitions for them.

Administrator

The System Administration has full access - all plants, all reports, all users.

Component

A component is a specific piece of data that appears on a label, for example: bar code, part numbers, graphic images, line or text. Hence, label components are broken down into several different types: text, graphic images, MDS database values, or a combination of text and database values.

Framework

In software development, a framework is a defined support structure in which another software project can be organized and developed. A framework may include support programs, code libraries, a scripting language, or other software to help develop and glue together the different components of a software project.

LVM

Low water mark – this is a value set by the user to alert when the available SN for that part number are low and it needs attention. It’s defined when the user intends to manage the available quantity of SN. Always when the LWM is reached, e-mail alerts are sent for the registered addresses.

Packing List

Packing List is the shipping number of the range being received

PO

PO is the Purchase Order of the range being received

PO Line

PO Line is the Line Number of the Purchase Order above

SFDC Configuration

The rules used to define how SFDC collects data, provides analysis, controls processing and maintains unit histories

Site Minder

Universal login of Sanmina-SCI

Username

The username is the site minder username (or a partial string)

VLVM

Very low watermark - this is a value set by the user to alert when the available SN are very low and this is a critical situation.

Appendix C

| Name | Type | Required | Min length / Min value | Max length / Max value |

Notes |

| Type | alpha-numeric | x | 1 | 30 | |

| Part Number | alpha-numeric | x | 1 | 25 | |

| Quantity | numeric | 1 | 999999999 | ||

| Starting | alpha-numeric | x | 14 | 14 | mask: AAAAA######### / The last 9 numbers must be minor to the Ending value |

| Ending | alpha-numeric | 14 | 14 | mask: AAAAA######### / The first 5 characters must be equals to the Starting value | |

| PO | alpha-numeric | 1 | 30 | ||

| PO Line | numeric | 1 | 9999999 | ||

| Packing List | alpha-numeric | 1 | 30 |

Document Revision History

| Date | Author | Title | Version | Change Reference |

| 14/01/06 | Elaine Fonaro | Tech Writer | 1.0 | Initial User’s Guide |

| 02/17/14 | Dane Parker | Tech Writer | 1.0 | General review and new screen capture |

| 02/28/14 | Elaine Fonaro | Tech Writer | 1.0 | Review and format for WIKI |

</font>