Difference between revisions of "Configuration"

| Line 153: | Line 153: | ||

=== Shop Floor [[Image:2014-02-03_10-10-40.jpg]] === | === Shop Floor [[Image:2014-02-03_10-10-40.jpg]] === | ||

| − | === Data Editor<br> | + | === Data Editor[[Image:2014-02-03_10-10-08.jpg]]<br> === |

=== Location<br> === | === Location<br> === | ||

Revision as of 16:13, 3 February 2014

Contents

- 1 Introduction

- 1.1 SFDC Configuration

- 1.1.1 Misc. Config.

- 1.1.2 Shop Floor

- 1.1.3 Data Editor

- 1.1.4 Location

- 1.1.5 Data Collector

- 1.1.6 Defect Codes

- 1.1.7 Part Number

- 1.1.8 Product Route

- 1.1.9 Assembly

- 1.1.10 Attribute Def.

- 1.1.11 Traveler

- 1.1.12 MFG Line

- 1.1.13 MFG Hold

- 1.1.14 Revision Change

- 1.1.15 Record Components

- 1.1.16 Sampling Plan

- 1.2 Kit Verify Configuration

- 1.3 Multi-Level Container Configuration

- 1.3.1 Container List

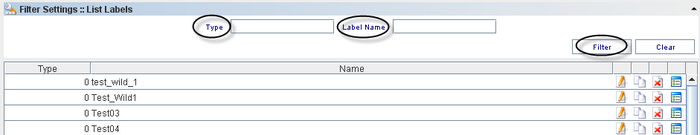

- 1.3.2 Filter Settings

- 1.3.3 Edit Container Configuration

- 1.3.4 Copy Container Configuration

- 1.3.5 Delete Container Configuration

- 1.3.6 View Container Configuration

- 1.3.7 Print/Export Container Configuration

- 1.3.8 Container Task Panel

- 1.3.9 Create Container Configuration: Level 99 (LOT) /Level 100 (Container)

- 1.3.10 Create Multi-Level Configuration Containers: Type > 100

- 1.3.11 Print/Export All Filtered Container Configuration

- 1.4 Employee Validation

- 1.5 SQC Configuration

- 1.5.1 Introduction

- 1.5.2 Statistic Quality Control Setup

- 1.5.3 SQC – Line List Functionalities

- 1.5.4 Managing HPU Lines

- 1.5.5 Adding HPU Baselines

- 1.5.6 Editing HPU Baselines

- 1.5.7 Deleting HPU Baselines

- 1.5.8 Importing HPU Lines

- 1.5.9 Printing HPU Lines

- 1.5.10 Load Target Parameters

- 1.5.11 Export Target Parameters

- 1.6 Labor Tracking Maintenance

- 1.7 Algorithm Tool

- 1.7.1 Introduction

- 1.7.2 Algorithm Tool

- 1.7.2.1 Algorithm Tool Main Page

- 1.7.2.2 Creating Algorithms

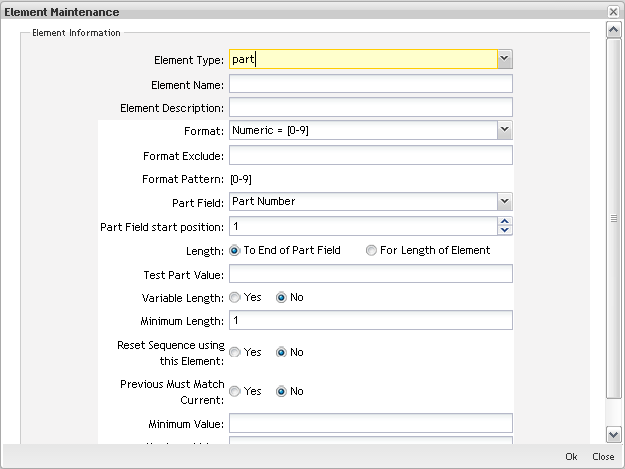

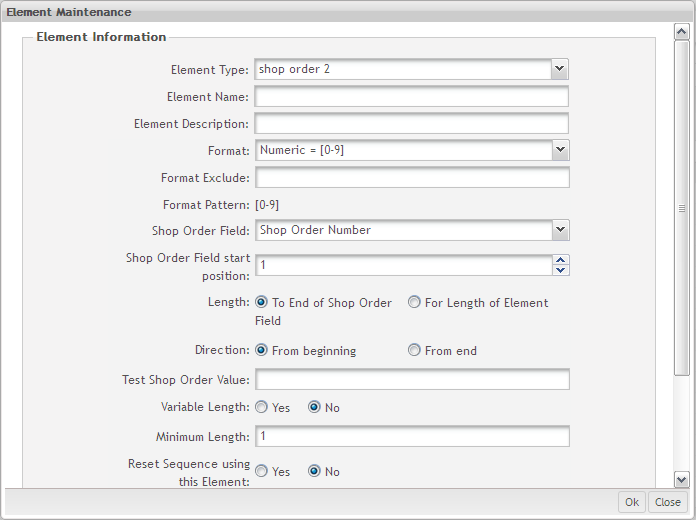

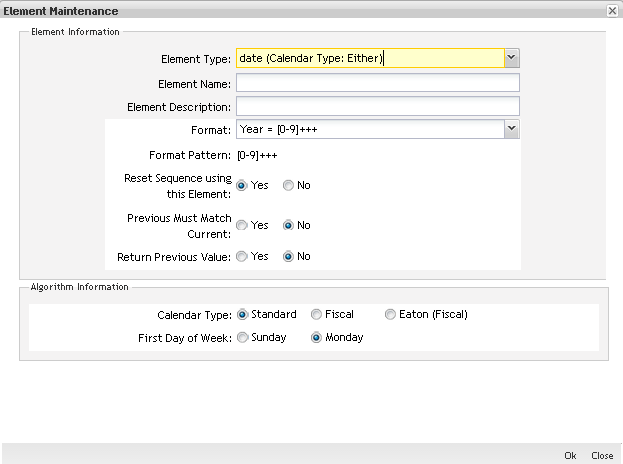

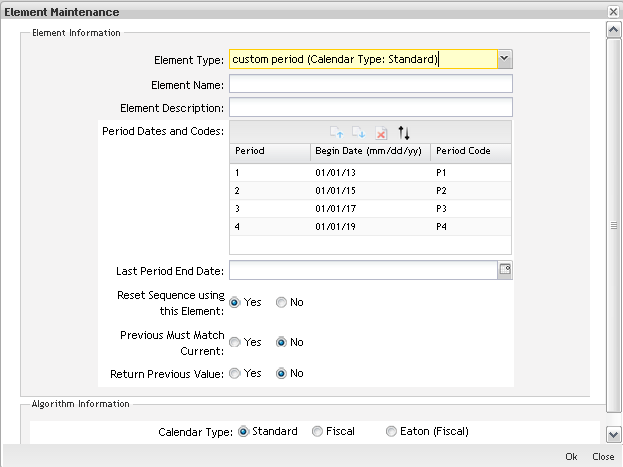

- 1.7.2.3 Create Element

- 1.7.2.4 Sequence Range / Increment Order:

- 1.7.2.5 MDS Parameters

- 1.7.2.6 Edit Algorithm

- 1.7.2.7 Copy Algorithm

- 1.7.2.8 Deleting an Algorithm

- 1.7.2.9 Exporting an Algorithm

- 1.7.2.10 View Customcode Record

- 1.7.2.11 Special Functionalities

- 1.7.2.12 Test Algorithm

- 1.7.2.13 Activate Algorithm

- 1.7.2.14 Select Enabled

- 1.7.2.15 Import Algorithm

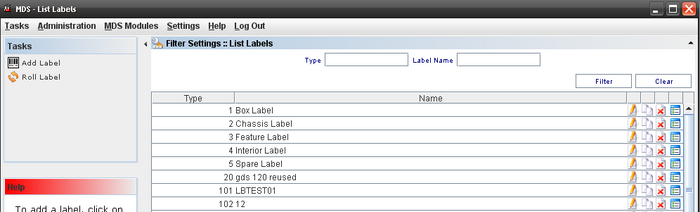

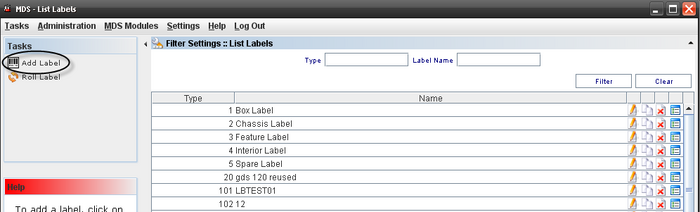

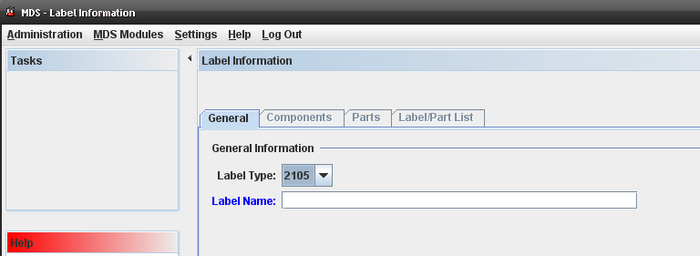

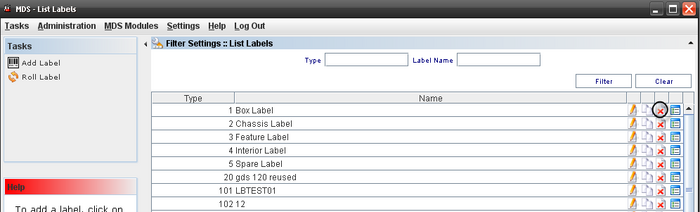

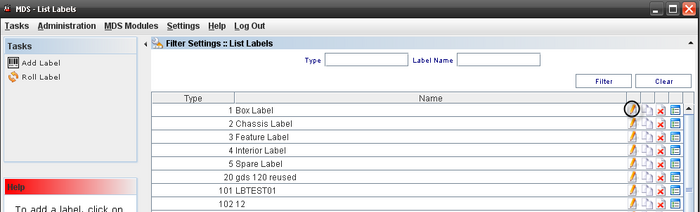

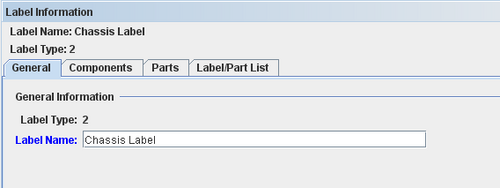

- 1.8 MDS Labels

- 1.1 SFDC Configuration

Introduction

The Shop Floor Data Collection System (SFDC) communicates interactively with the Customer Order Processing System (COPS), and Statistical Process Control/Statistical Quality Control (SPC/SQC). The Manufacturing Data System (MDS) makes the communication between these systems possible.

SFDC provides real-time information used by SPC/SQC and MESWeb to create quality control reports. The data configuration for SFDC PC is handled within the Manufacturing Data System (MDS), which is a complete factory automation system. The SFDC System uses barcode scanning, both manual and automated, to monitor and control a single product line or an entire plant. SFDC Configuration collects data, provides analysis, maintains unit histories, and controls product movement on the manufacturing floor.

The system provides Access Control between the modules of the application, including the functionalities of each screen. The current version has an SFDC Configuration screen which provides access to all screens and its functionalities (view, add, edit, delete, print and generate output file), and a View-Only mode screen which only supports view, print and output to file; to support these screen modes, the MDS user or group of users have specific profiles, which provides specific access to MDS screens and functionalities.

SFDC Configuration

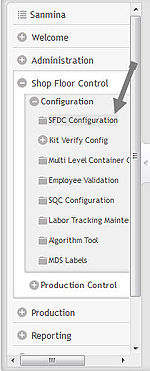

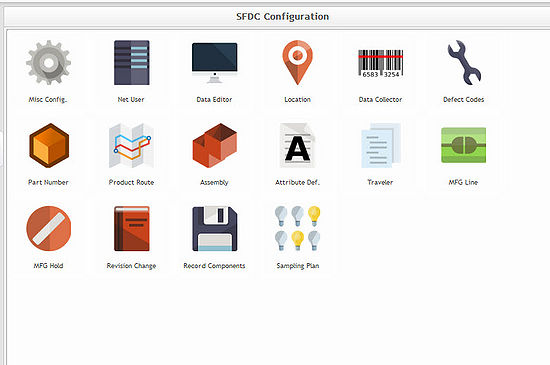

To access the SFDC Configuration module, expand the Shop Floor Control portlet, then expand the Configuration sub-heading, then select the SFDC Configuration Folder. The SFDC Configuration main screen contains 16 separate icons. Each icon contains separate functions.

GENERAL NOTES:

- A user only has access to the modules assigned to his/her profile.

- Profile permissions can only be granted by the Program Admin user.

- Any/all reports printed from jMDS modules will print to the default printer for the workstation.

Misc. Config.

This icon provides access to manage Miscellaneous Configurations, such as Net UserID, Line, Title Line, Screen Update Interval, Inactivity Days, SOMS Site ID, and Work Shift configuration.

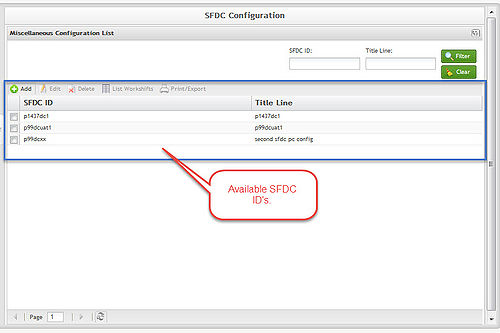

When the Misc. Config. icon is selected, a list of available SFDC ID's will appear in the following screen.

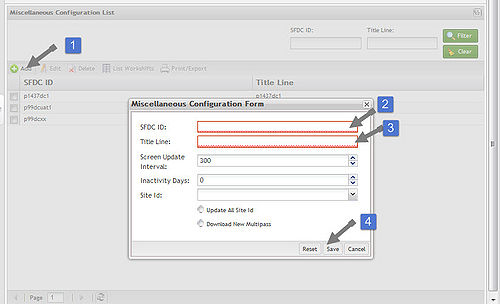

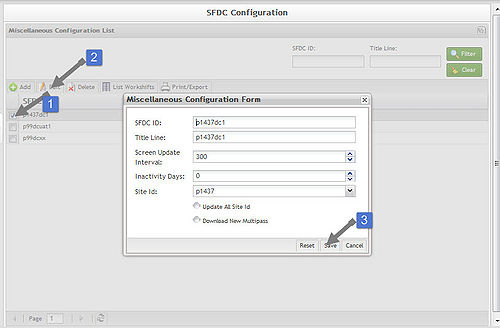

Add

To add a Miscellaneous Configuration, select the Add button located at the top left of the screen. A Miscellaneous Configuration form will pop-up. The SFDC ID and the Title Line are mandatory fields. Screen Update Interval, Inactivity Days, and Site ID are available to manipulate. Located at the bottom of the form boxes titled Update All Site ID andDownload New Multipass. Both boxes are available to be selected. When all necessary information is entered, select theSave button.

SFDC ID – This is a unique network ID to identify the SFDC PC to the network. Each Net UserID must be unique in the same database. Usually this is the the same name as the Line, without a description. i.e. p99dc1

Title Line – A brief description of the Line. i.e. Plant 99 PCBA

Screen Update Interval – The time interval used between updates to the SFDC PC display. This value is normally set to 300.

Inactivity Days – The number of calendar days a unit may remain at a location before it is listed as inactive on the SFDC PC Serial Number Display.

Site Id – SOMS Site ID i.e. E99

- Update All Site Id-

- Download New Multipass – Check box to flag the configuration when using Multipass functionality for SOMS.

Edit

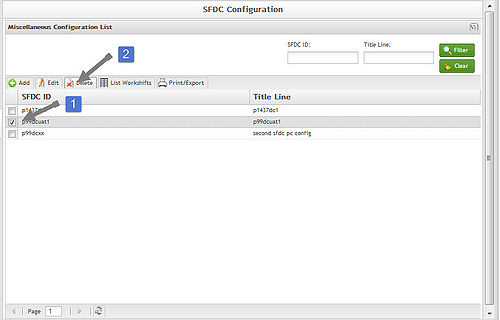

To edit an existing Miscellaneous Configuration, check the box to the left of the SFDC ID and then select Edit.

All fields are available to edit in the Miscellaneous Configuration Form. When all necessary information has been entered, select theSave button at the bottom of the form.

Delete

To delete a Miscellaneous Configuration, select the box next to the SFDC ID and then select Delete.

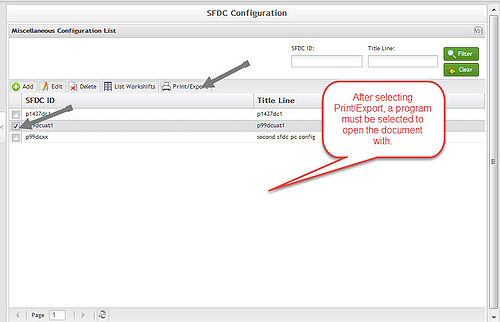

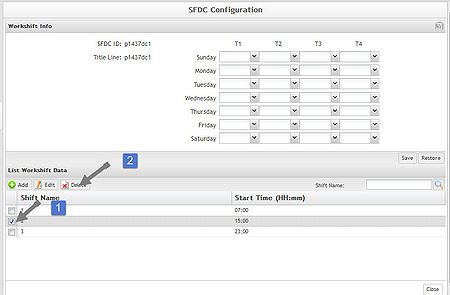

List Workshifts

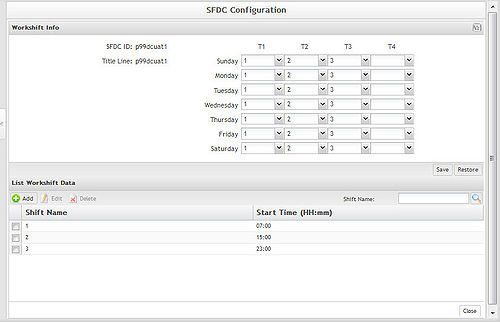

This functionality enables the user to manage Workshifts.

To access List Workshift, select the box to the left of the SFDC ID and then select theList Workshift button above the list.

On the following screen, a list of available workshifts is displayed.

From this screen, the user is able to Add, Edit, or Delete Available Shifts, manage Daily Workshift Assignments, and search for Available Shifts.

To exit the List Workshift Data screen, click the Close button at bottom right-hand corner of screen.

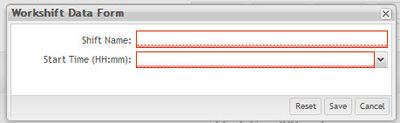

Add Workshift

This functionality enables the user to add new Workshift Data into the Miscellaneous Configuration.

Note: Shifts must be created prior to Daily Workshift Assignments can be made.

To add a new workshift data, select Add located in the List Workshift Data screen.

The Workshift Data Form screen is displayed:

Enter the following mandatory fields to define the Workshift.

Shift Name: The name of a Workshift with a 2-character maximum text string.

(Shift Name Examples: S1 for Shift 1, S2 for Shift 2, A for Shift A, B for Shift B, etc.)

Start Time: The time when the present yields are stored and zeroed. This usually occurs just before the start time of the next Workshift. The Start Time is 24 hour HH:MM format, with a time range of 00:00 to 23:59.

Click Save to save, or click Cancel to ignore.

The new Workshift is displayed in the Available Shifts section.

Edit Workshift

This functionality enables the user to modify an existing Workshift.

To edit an existing Workshift, click the box to the left of the name of the Workshift, then select Edit.

Perform the desired modifications to the Workshift Data.

Click Save to save, or click Cancel to ignore.

The modified Workshift is displayed in the Available Shifts section.

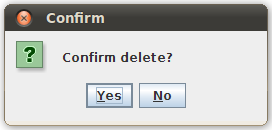

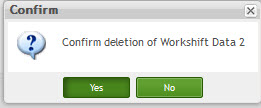

Delete Workshift

This functionality enables the user to delete an existing Workshift.

To delete an existing Workshift, select the box to the left of the desired workshift and select Delete.

Note: Be aware that it is possible to delete a Workshift even if it has a Daily Workshift Assignment.

Click Yes to confirm deletion, or No to ignore.

The Workshift Data is removed from the Available Shifts section.

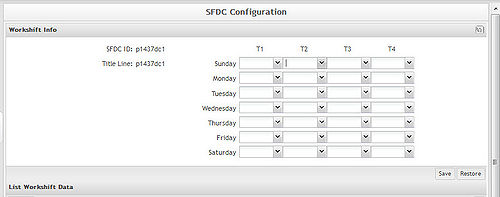

Daily Workshift Assignments

This functionality enables the user to manage Daily Workshift Assignments.

The Workshift Assignment table defines the starting shift times for the workshifts in the SFDC system. Workshift assignment definitions are used to configure the starting time for the SFDC database update performed at the end of a workshift (or prior to the start of the next workshift). The Workshift Assignment table provides up to twenty-eight entries for four workshifts (T1, T2, T3 and T4) assigned for each day of the week.

Note: Shifts must be created prior to Daily Workshift Assignments can be made.

To define a shift change, click the Workshift icon in the list for the desired Miscellaneous Configuration.

The List Workshift Data window is displayed:

Click the cell for desired day/shift assignment input field in the Workshift Info grid, then select the desired Shift.

Note: It is possible to assign only valid shift names displayed in the Available Shifts section.

Click Save to save the Daily Workshift Assignment, or Restore to cancel edits.

Print/Export

Shop Floor

Data Editor

Location

Data Collector

Defect Codes

Part Number

Product Route

Assembly

Attribute Def.

Traveler

MFG Line

MFG Hold

Revision Change

Record Components

Sampling Plan

Kit Verify Configuration

The Kit Verify consolidates or validates all of component that we have in a “Kit” that warehouse give to the floor versus the shop order, in order to know if we have missing component in the Kit.

This module is integrated to MDS Client Application and will be available to all Sanmina's Plants.

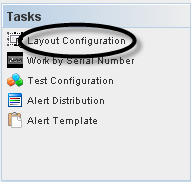

Layout Configuration

The function of this interface is to allow the user to Add, Copy or Edit an assembly layout in the Kit Verify MDS Database.

Note 1: If Oracle does not send the reference Designator information to MDS the system will allow entering it manually.

To access the Layout functionality, click on Layout Configuration at Tasks panel.

Figure 4: Choose Layout Configuration

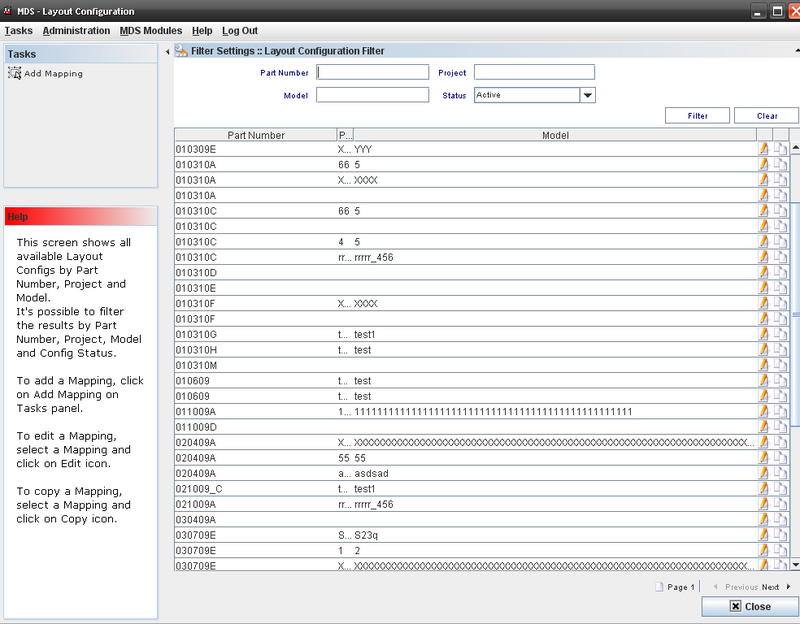

The Layout main window displays:

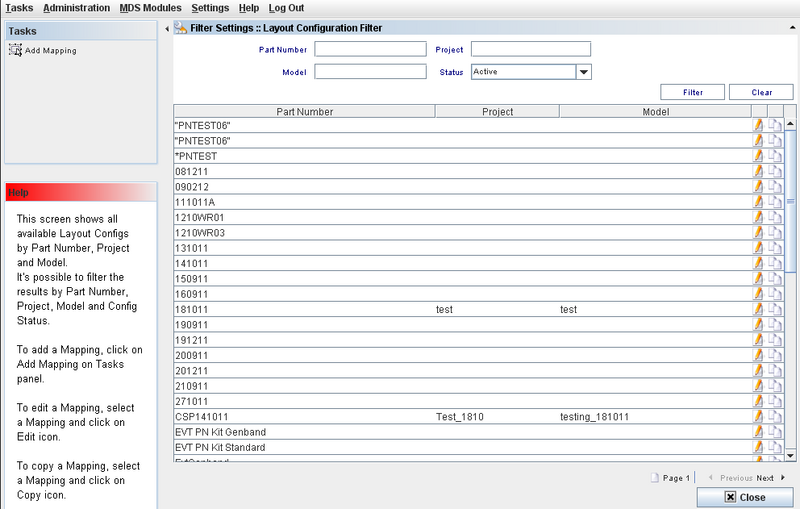

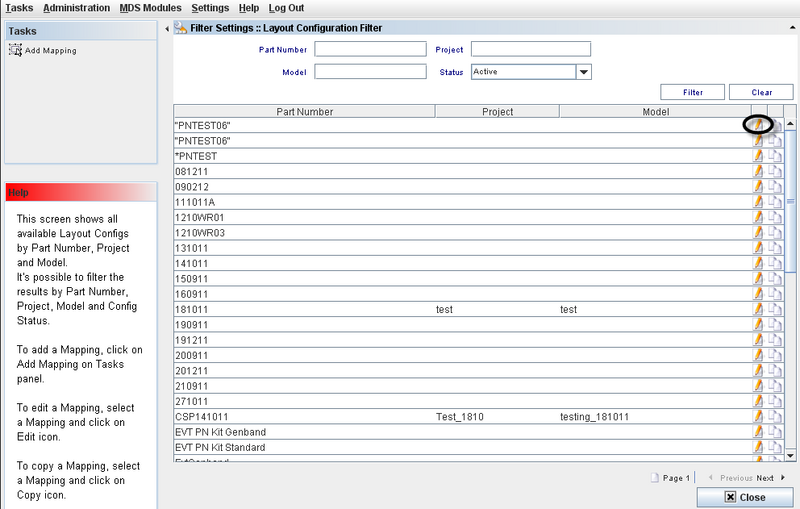

Figure 5: Layout Configuration Main Window

This screen will display all available Layout Configurations by Part Number, Project and Model.

Layout Configuration List

This screen displays all Layouts available and the user can edit or use the copy function.

Figure 6: Layout Configuration Filter

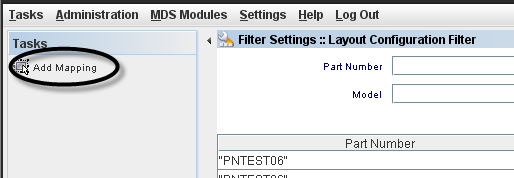

Adding a Mapping (Layout configuration)

To create a Control Config, the user must to click onCreate Control Config on Tasks panel.

Figure 7: Add Mapping from Tasks panel

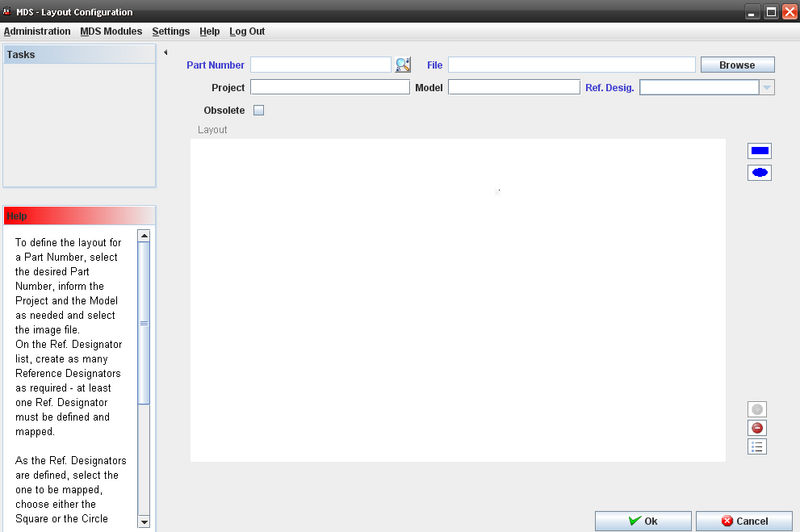

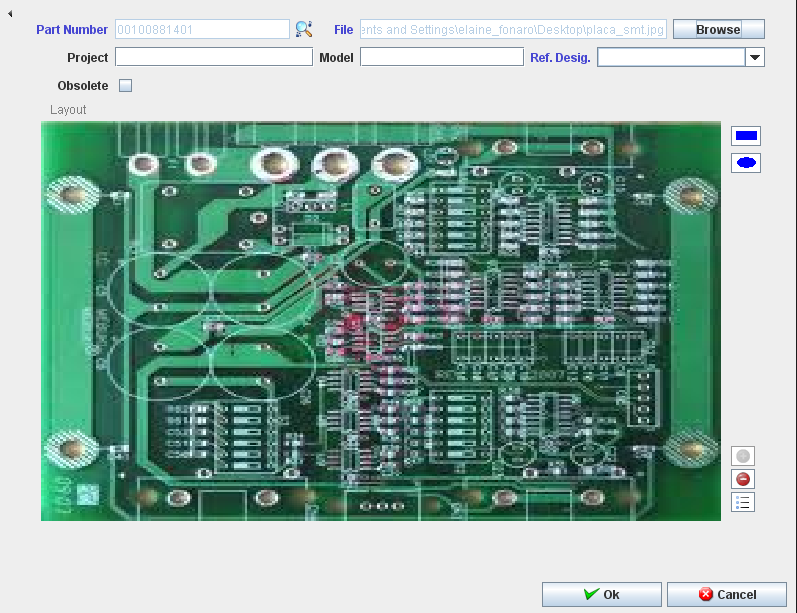

The Layout Configuration screen displays:

Figure 8: Layout Configuration screen

Note1: at least one Ref. Designator must be defined and mapped.

Fields that User can enter/select:

- Part Number;

- File

- Project;

- Model;

- Reference Designator;

- Browse to find the layout file;

Follow the steps below to define a layout for a part number:

- Select the desired Part Number; inform the Project and the Model as needed.

- Click on the “Browse” button to select the new assembly layout. The system will show the File Dialog window and the user can select the image. The system disables the button and the path text box and the image will appear in the layout box;

- On the Ref. Designator list, the user must to create as many Reference Designators as required which will then automatically appear as disabled;

- The user has to click in Square orCircle form Button and draw a Square or Rectangle in Layout;

- Click on the Add “+” button.

- At the same time a new row with the reference designator information will appear in the “UI control” box with the following variables:

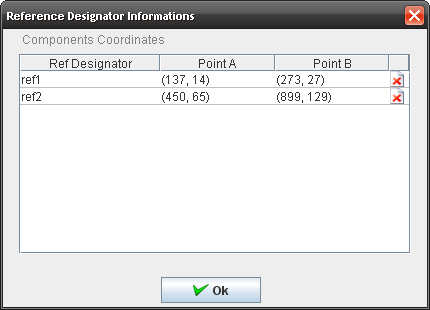

Figure 9: Components Designator

To view the Reference Designator Information, click on the View button in the Layout Configuration window.

a.X coordinate;

b.Y coordinate;

c.Width;

d.Height;

- To delete the component, click on Delete icon.

- After adding all reference designators the user has to click on the “OK” button and the system will insert all these rows into the MDS Database;

Editing a Layout Configuration

Figure 10: Edit Layout configuration

To edit a Mapping, the user must to select a Mapping and click on Edit icon.

The Layout Configuration window displays with the existing layout information.

Figure 11: Layout Configuration

Note that the following fields can not be updated:

- Part Number

- Layout

- Project

- Model.

The Ref Designator can be removed from the list or included in the list.

To obsolete a configuration, check the Obsolete box.

Copying a Layout Configuration (mapping)

This option allows the user to create a new layout based on a pre existing layout (this module allows the user to copy and modify an existing assembly layout).

Follow the steps bellow to copy a layout:

- The user must create a new relation between the project and the model;

- Select the layout in the list and click the “Copy” button;

- The image will appear in the layout box, and all records will appear in the “UI control” grid;

- Select the part number that will have the layout chosen;

- In case the user wants to change any reference designator he/she has to select it on the assembly layout and the reference designator row that was selected will appear in the “UI control” grid.;

- Once the modification has been finished, the user has to click onOK button;

The system updates the information into the MDS database.

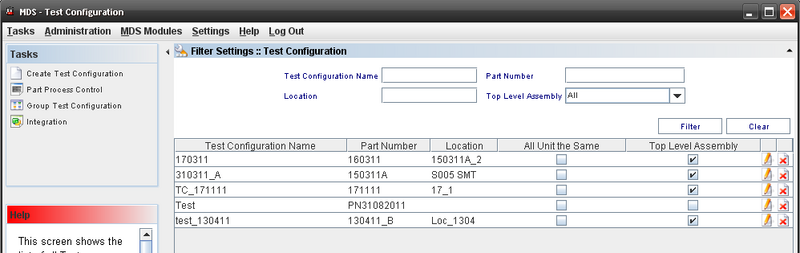

Test Configuration

Figure 25: Test Configuration window

This screen shows all Test Configurations.

Performing Searches

To perform searches, there are there are just one field available:

Filters Fields:

- Part Number;

- Test Configuration Name

- Top Level Assembly

- Location

Enter the information and click on Filter.

To clear the filter fields, click on Clear.

Adding/Editing Test Configuration;

See bellow the Add/Edit steps.

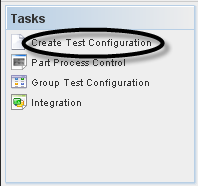

1. To add a Test Config, the user must to click on Add Test Config on Tasks panel.

Figure 26: Create Test Configuration

2. To edit or delete a Test Config, the user must to select the config in Test Config List and click on Edit or Delete icon.

3. Click on Create Test Configuration in the Tasks Panel. The Create Test Configuration window displays.

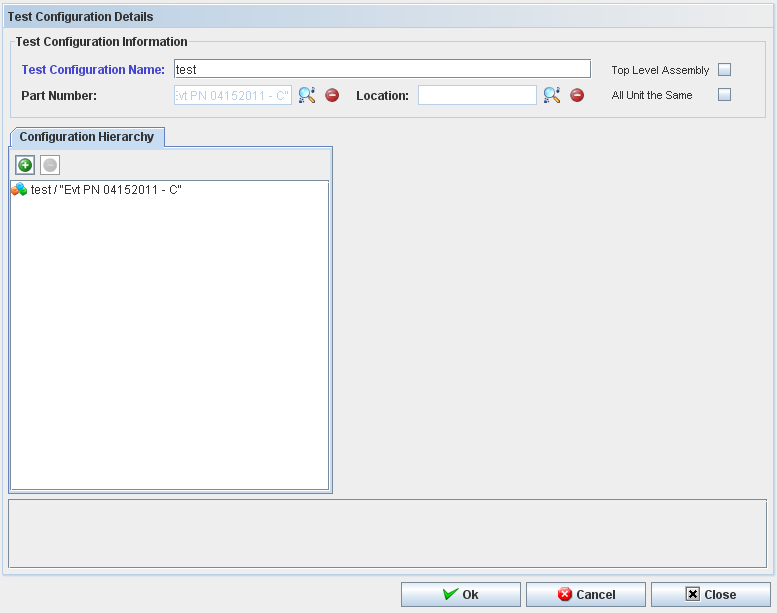

Figure 27: Test Configuration Details

To add a test configuration, the user must to follow the following steps:

1. To create or edit a test configuration it's required to inform the top level Part Number.

2. To add a part number, a test configuration or a test configuration group to the test configuration, click on the "+" icon.

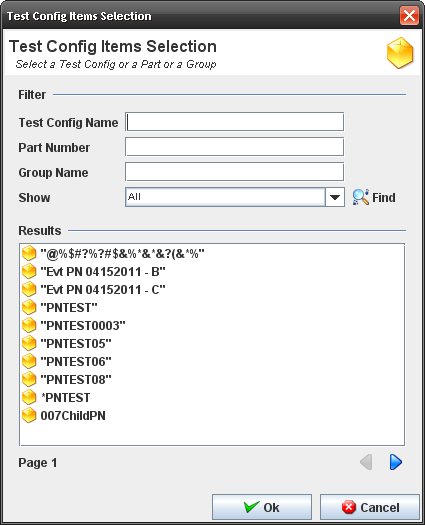

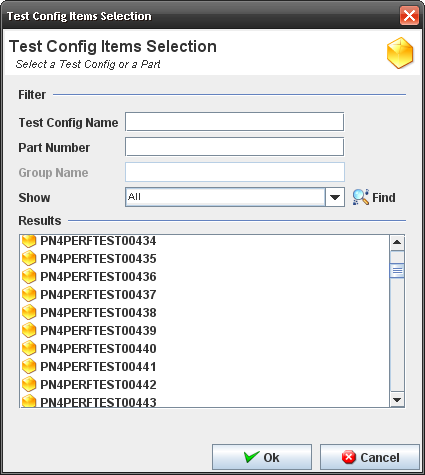

3. The Test Configuration Items Selection popup displays.

Figure 28: Test Config Items Selection

4. The user must enter a search item (your criteria: Part Number only, a Test Configuration Group or a Test Configuration only) and click on Find.

5. Double click on the result.

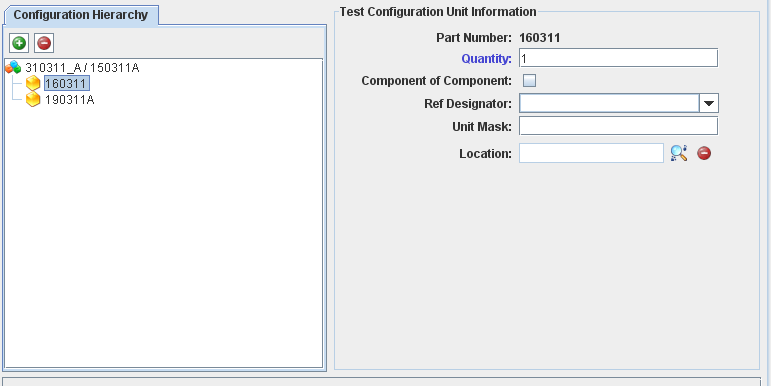

6. Fill mandatory fields (part number and quantity) in "Test Configuration Unit Information".

Figure 29: Test Configuration Details

7. Click on Ok button.

Note1: Obsolete Part Numbers do not display. The Part Number chosen will display in "Configuration Hierarchy".

The user can see the "Test Configuration Selection" window with "Test Configuration", "Part Number" and "Test Config Group"

Note2: It's possible to add more than one Test Configuration, Part Number or Test Config Group to create a Test Configuration.

8. The information is saved in the database.

9. The "Test Configuration" window closes and the Test Configuration created is displayed.

10. To delete a part number, a test configuration or a test configuration group from the control configuration, the user must select the item and click on the "-" icon.

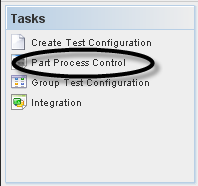

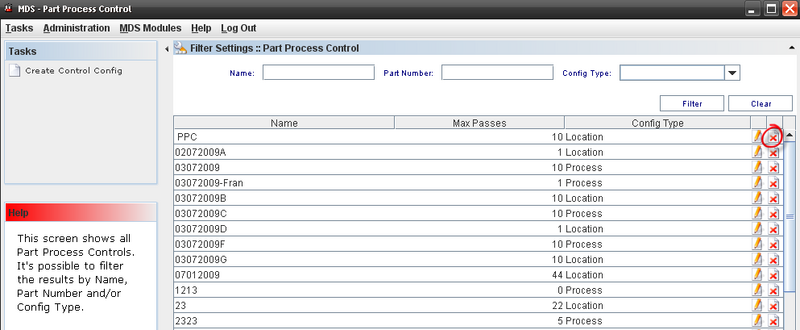

Part Process Control;

To manage Part Process Control, the user must to click on Part Process Control on Tasks panel.

Figure 30: Selecting Part Process Control

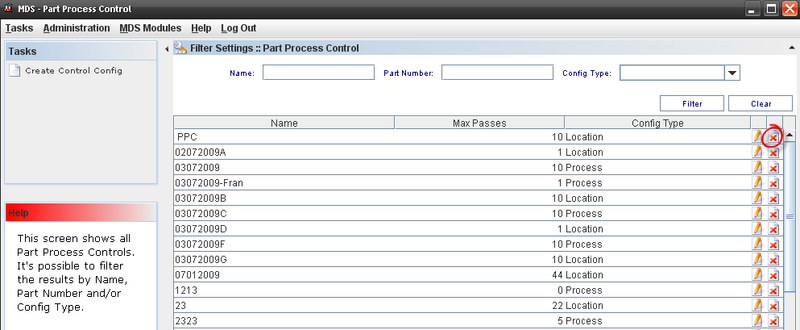

The Part Process control Window displays.

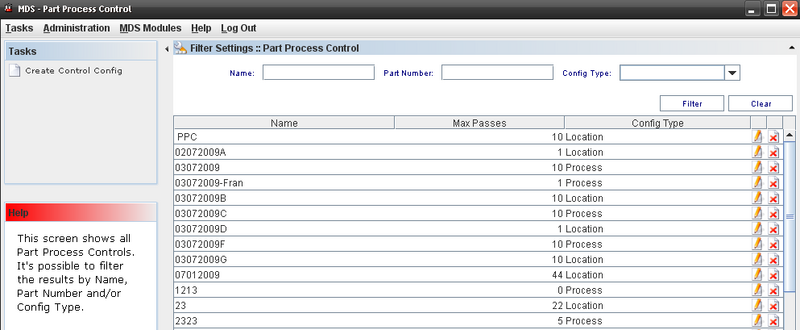

Figure 31: Part Process Control

This screen displays all Part Process Control available.

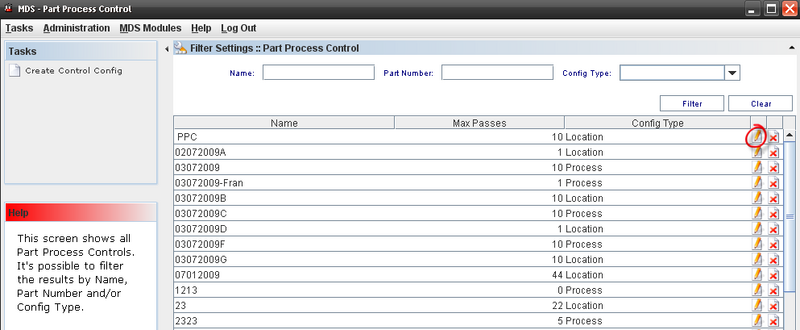

Editing or Deleting from Part Process Control List

Figure 32: Editing a configuration from Part Process Control List

To Edit a Control Config, the user must to click on edit icon in the list.

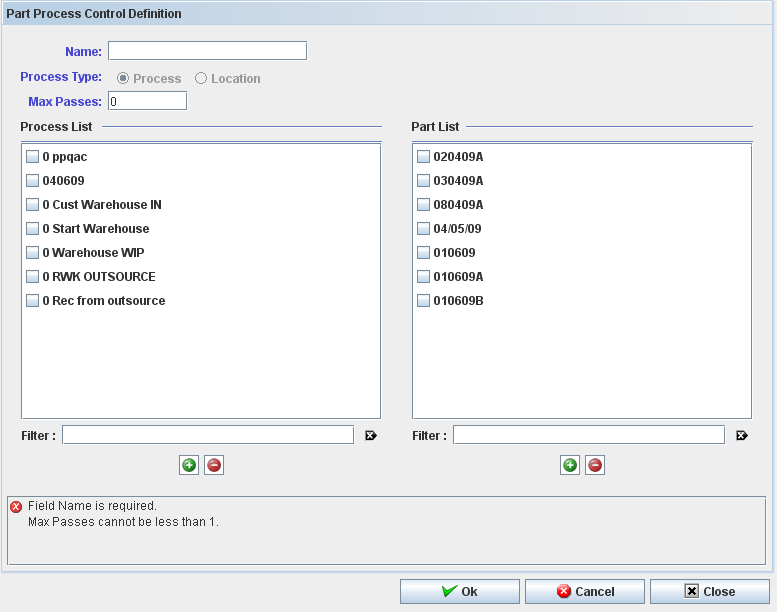

The edit page displays:

Figure 33: Part Process Control definition

Toupdate a part process control config it is required that the user type a unique name, the config type (process or location) and the max passes.

Note: All items of the control must be of the same type: process OR location.

At least one process or one location is required; the part number list is optional information.

To add a process or a location to the control config:

1. Click on the "+" icon below Process/Location list.

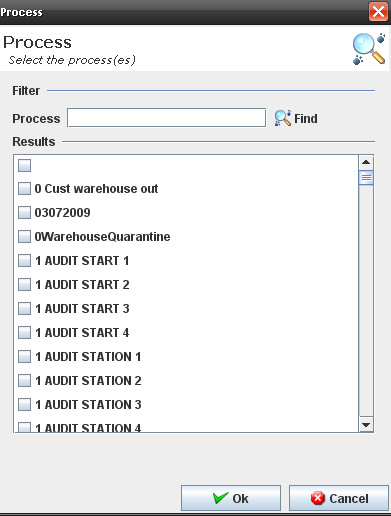

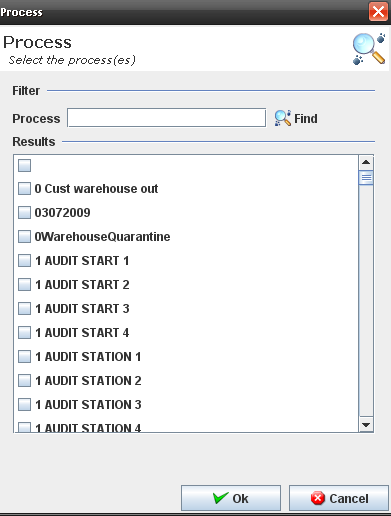

2. The Process popup displays:

Figure 34: Process Popup

3. Execute the filer to select an available process.

4. Click on OK button.

5. The selected process must display at the process list.

To delete a process or a location from the control config, select the process or location and click on the "-" icon below Process/Location list.

Click on Ok to confirm.

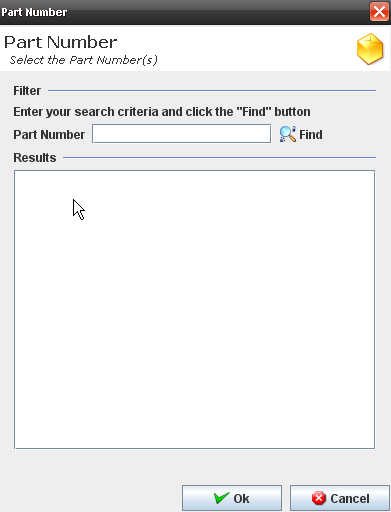

To add a part number to the control config, the steps are the same to add process:

1. Click on the "+" icon belowPart list.

2. The part Popup displays:

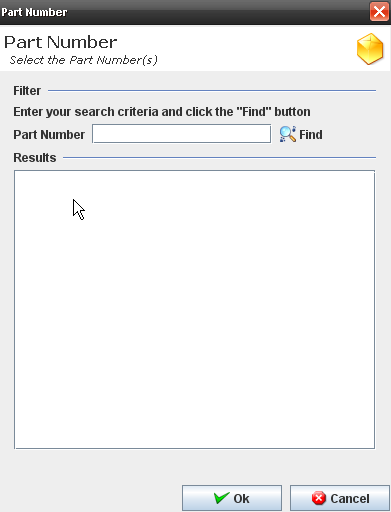

Figure 35: Part Number dialog

3. Execute the filer to select an available part number.

4. Click on OK button.

The selected part must display at the process list.

Figure 36: Deleting from Part Process Control List

To delete a Control Config, select the control and click on Delete icon in the main Part Process Control list window.

Click on Ok to confirm.

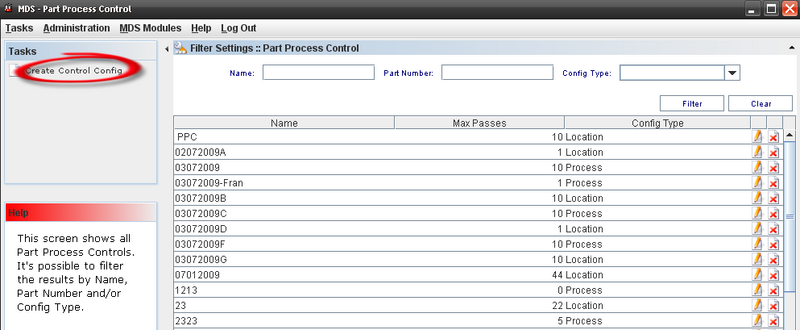

Creating a Control Configuration

To create a Control Config, the user must to click onCreate Control Config on Tasks panel.

Figure 37: Create a Control Config

The Part Process Control Definition displays:

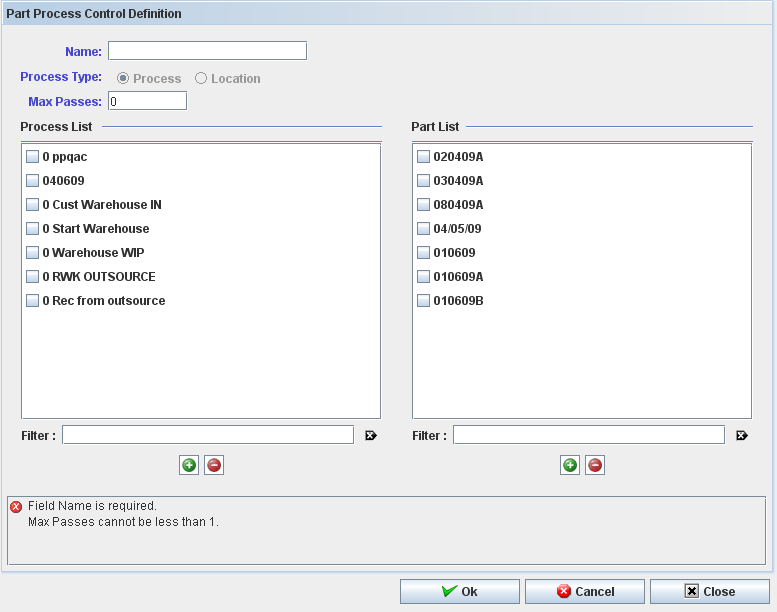

Figure 38: Part Process Control Definition

To create or edit a part process control config it is required to the user informs:

- Name;

- Config Type and

- Max Passes.

Note: All items of the control must be of the same type: process OR location.

At least one process or one location is required; the part number list is optional information.

To add a process or a location to the control config:

1. Click on the "+" icon below Process/Location list.

2. The process Popup displays:

Figure 39: Process Popup

3. Execute the filer to select an available process.

4. Click on OK button.

5. The selected process must display at the process list.

To delete a process or a location from the control config, select the process or location and click on the "-" icon below Process/Location list and click on Ok to confirm.

To add a part number to the control config, the steps are the same to add process:

1. Click on the "+" icon below Part list.

The part Popup displays:

Figure 40: Part Number

2. Execute the filer to select an available part number. 3. Click on OK button. 4. The selected part must display at the process list.

To delete a part number from the control config, select the part number and click on the "-" icon below Part list.

Figure 41: Deleting Control Config from Part Process Control List

To delete a Control Config, select the control and click on Delete icon in the main Part Process Control list window and click on Ok to confirm.

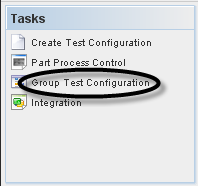

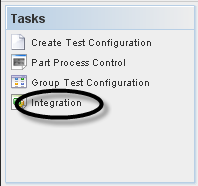

Group Test Configuration;

To manage Groups Test Config, the user must to click on Group Test Configuration on Tasks panel.

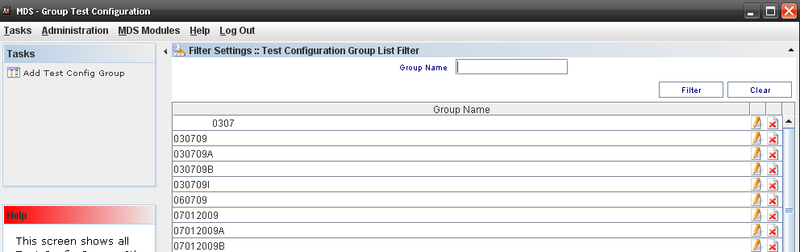

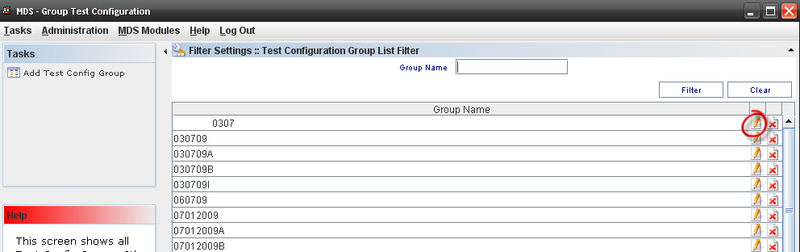

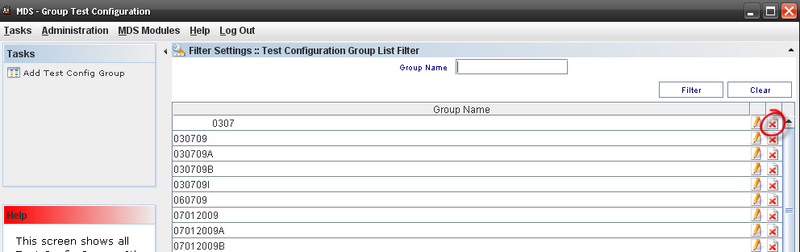

Figure 42: Test Configuration

To access the Group Test Config, click on Group Test Configuration in the Tasks panel.

Figure 43: Group Test Configuration List Filter

Sorting Colum

The application allows to sort all columns of the list (ascending or descending), including the multi-column sorting keeping the "control" key pressed.

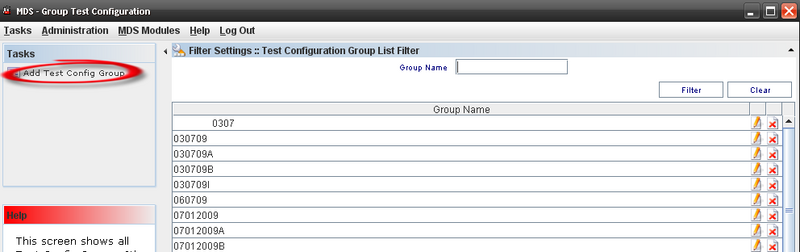

Adding a Test Config Group

Figure 44: Adding Test Config Group

To add a Group, click on Add Test Config Group on Tasks panel.

The Test Config Group window displays:

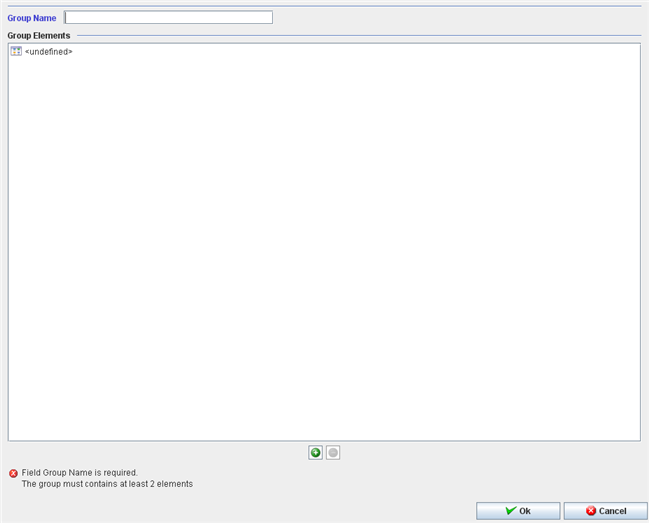

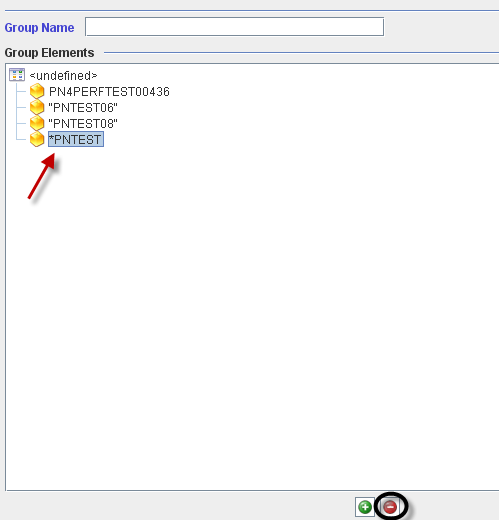

Figure 45: Adding Test Config Group

To create or edit a test config will be required to the user informs:

- Group Name;

To create or edit a test config group it will be required to the user to inform a unique group name.

All items of the group must be of the same type: test config OR part number.

To add a test config or a part number to the group:

1. Enter the new group name and click on the "+" icon.

2. The Test Config Items popup displays:

Figure 46: Config Items Popup

3. Execute the filter to select an available Test Config or part number.

4. Click on OK button.

5. The selected test config or part number must display at the group name element list.

To delete a test config or a part number from the group, the user must to select the test config or the part number and click on the "-" icon.

Figure 47: Deleting Group Elements

Click on Ok to confirm.

Editing a group name.

Figure 48: Deleting Group Elements

To edit a group, select the group and click on Edit icon.

The same window to create a group displays. The user is able to change the group name or add/delete part numbers/test groups clicking on “+” icon to add or “-” icon to delete.

For more information, see the topic [#_Adding_a_Test 2.8.4.2 - Adding a Test Config Group].

Deleting a group name.

Figure 49: Deleting Group Names

To delete a Group, select the group and click on Delete icon.

Click on Ok to confirm.

Integration

To integrate a Top Assembly, scan or type the Component Serial Number according to the requested Ref. Designator.

To integrate a Test Config, the user must to click on Integration on Tasks panel.

Figure 50: Test Configuration - Integration

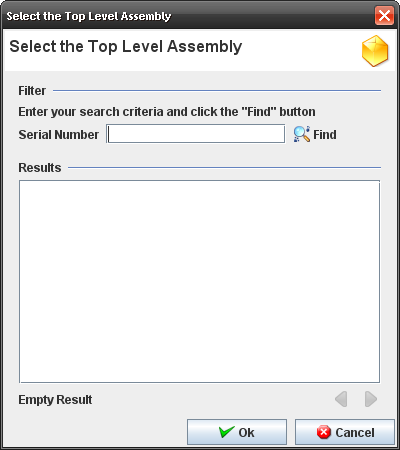

Finding Top Assemblies to Integrate

When the user clicks on "Integration" from Tasks panel, the screen to find and select the top assembly to integrate components is displayed.

Figure 51: Select the Top Assembly

Follow the steps below:

- Go to Kit Verify Test Configuration Integration, leave the Serial Number field empty or enter a S/N and click on Filter.

Note: Only top assembly serial numbers in status >=20 which have a test configuration created for the main part number must be displayed. The paginator buttons (previous and next) are displayed and 10 serial numbers are displayed per page.

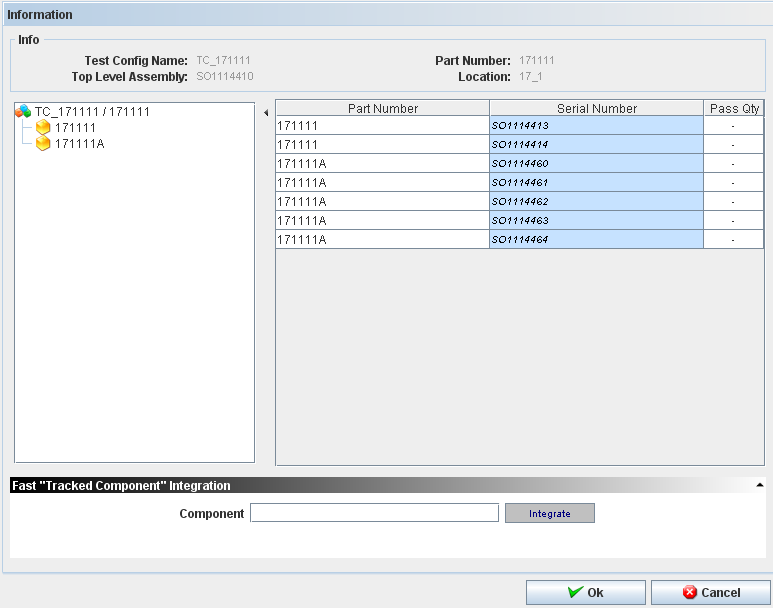

Showing Integration Information

Figure 52: Integration Information

Follow the steps below:

- Go to Kit Verify Test Configuration Integration, fill the Serial Number field with the top assembly;

- Double click on top assembly;

- The test configuration tree view which was created for the main part number is displayed and beside that the components to integrate to the serial numbers are displayed;

- Click on Serial Number for the related part number, fill with one of the serial numbers created according to the pre condition 2 and press enter;

- The serial number is recorded to the part number and the application points to the next serial number to be filled;

- Repeat the step 3 for the remaining serial numbers and click OK;

- The message "Are you sure you want to create a new component integration?" is displayed.

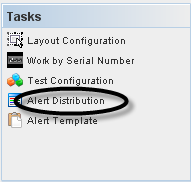

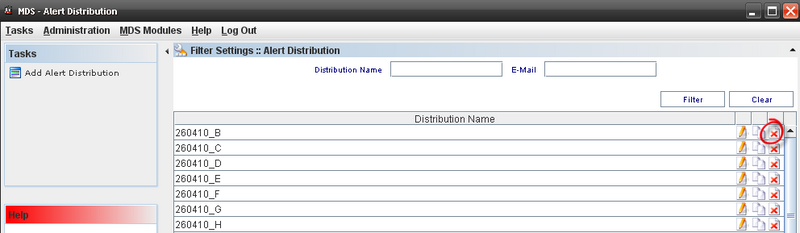

Alert Distribution

To access the Alert Distribution functionality, from Tasks panel, click on Alert Distribution.

Figure 53: Shop Order List

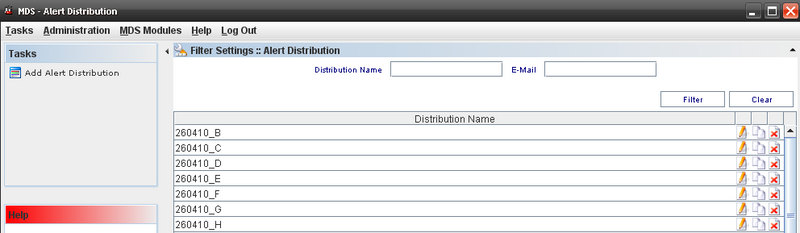

The alert distribution list should be like a profile. We can select the user for each program and these users will receive an email alert base on xml template.

The Alert Distribution list displays:

Figure 54: Alert Distribution

From this screen, the user is able to add, edit, copy or delete alerts distribution. See the next topics for more information.

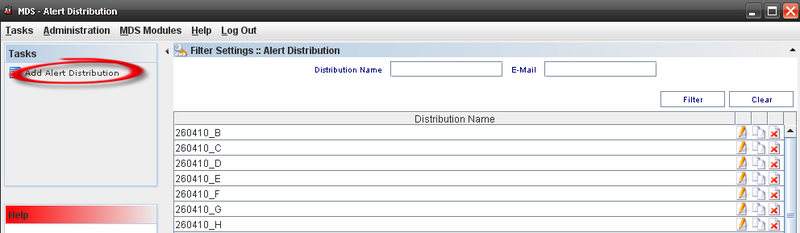

Adding Alert Distribution

Figure 55: Adding Alert Distribution

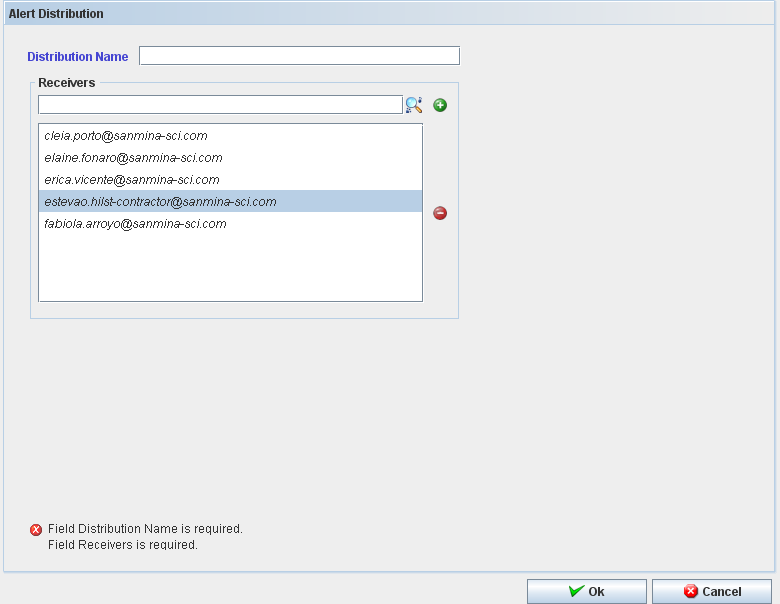

The Add Alert Distribution window displays:

Figure 56: Add Alert Distribution

To add an Alert Distribution, follow the steps bellow:

- In Task Panel click in "Add Alert Distribution" option;

- Fill the mandatory fields (Distribution Name and Receivers);

- Click in "Ok" button;

- Confirm the Alert Distribution creation.

The "Alert Distribution" window closes and the "Alert" is displayed with the recorded "Alert" in the table.

The user can search for receivers. Click on “+” to add or “-” to delete.

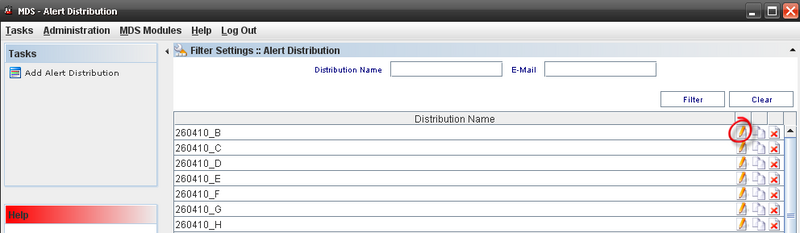

Editing Alert Distribution

Figure 57: Editing Alert Distribution.

Follow the steps bellow to edit an alert distribution:

- On the Alert Distribution list, select an existing Alert;

- Click the Edit icon; The Alert Distribution screen displays. It is the same for Add Distribution alert.

- Change the mandatory fields;

- Click "OK" button

- Confirm the Edit.

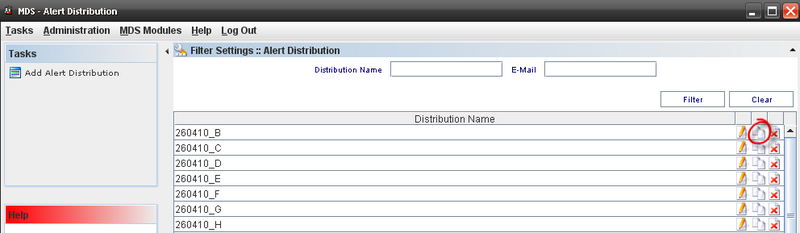

Copying Alert Distribution

Figure 58: Copying Alert Distribution

The copy feature allows the user to copy alert information. Follow the steps bellow:

- On the Alert Distribution List, select an existing Alert;

- Click the Copy Icon;

- Change the mandatory fields;

- Click "OK" button.

Deleting Alert Distribution

Figure 59: Deleting Alert Distribution

Follow the steps bellow to delete an Alert:

- On the Alert Distribution List, select an existing Alert;

- Click the Delete icon;

- Click "OK" button.

- A confirmation box displays.

- The Alert is deleted.

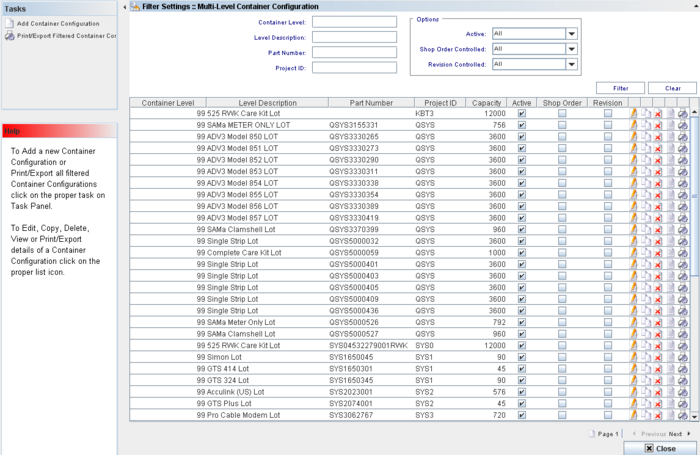

Multi-Level Container Configuration

This chapter describes how the user manages the Multi-Level Containerization MDS Module. It details all functionalities and actions that can be performed by users.

GENERAL NOTES:

- Most error and informational messages are displayed in a dialog box. Click OK or press Enter to dismiss the dialog window. Yes orNo buttons may also be provided to answer questions presented by the message dialog window.

- The user Profile defines what the user can access.

Figure 3: Multi-Level Container Configuration

The user is able to perform actions like create, print/export filtered results, edit, copy, delete, view or print/export containers configuration.

The next topics will describe all available Container Configuration functionalities.

Container List

The Container List displays all container levels and allows performing the following actions:

- Filter Data

- Edit a Container Configuration

- Copy a Container Configuration

- View a Container Configuration

- Delete a Container Configuration

- Print/Export details of a Container Configuration.

Note that it is possible to execute two actions from the Task Panel:

- Add a new Container Configuration

- Print/Export all Filtered Container Configurations

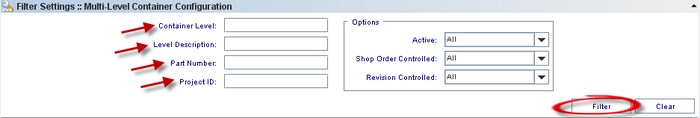

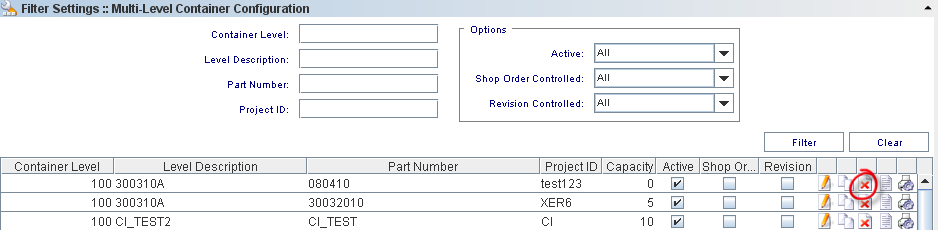

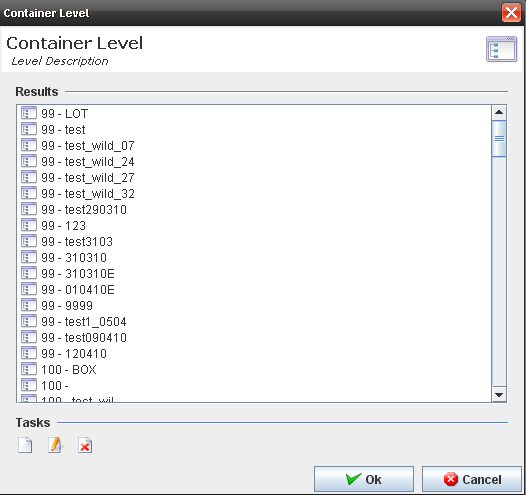

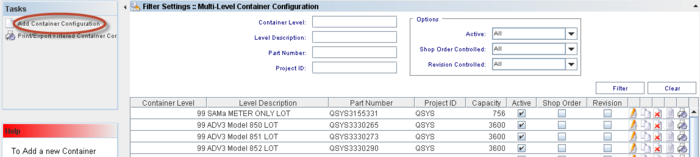

Filter Settings

To perform searches, there are four available fields:

Container Level: Predefined container levels are: “99 LOT”, “100 BOX”, “110 SKID” and “120 PALLET”; levels 101-999 are Multi-Level Containers and are handled only by MDS Client.

Level Description: The default description for the level.

Part Number: A number which serves to uniquely identify a part (product).

Project ID: The project identification number.

Also, the user can select additional options from the Options section:

Active (All, No, Yes): NO implies inactive for containerization. Default=YES;

Shop Order controlled (All, No, Yes): YES allows only units from a single shop order to be containerized together. Default=NO;

Revision Controlled (All, No, Yes): YES means only one revision can be containerized together. Please correct and check the default value.

Enter the information or combination of information and click on Find.

Figure 4: Filter Settings

To clear the fields’ contents, click on Clear button to start a new filter.

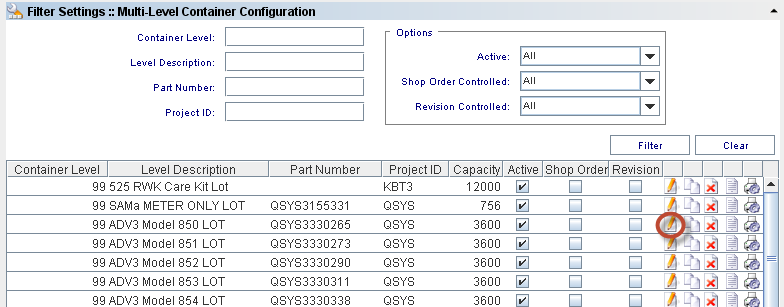

Edit Container Configuration

To edit a container configuration, go to MDS Client > Multi-Level Containerization > Container Configuration> Container Configuration list, select an existing Container Configuration and click on Edit Icon.

Figure 5: Multi-Level Container Configuration - Edit

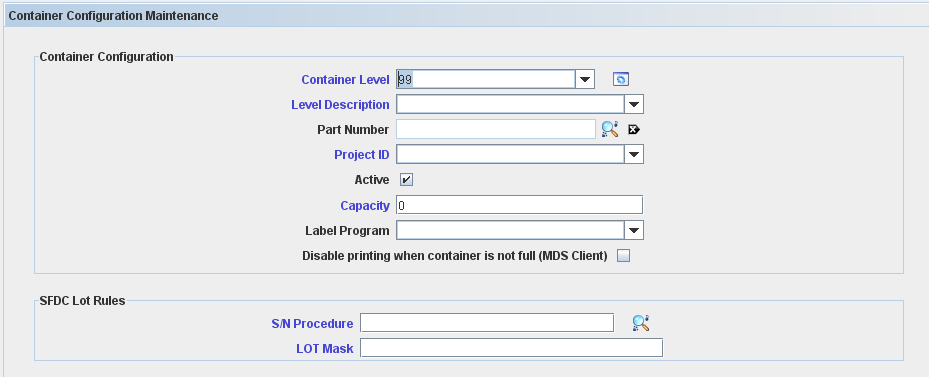

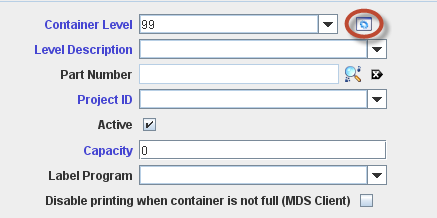

The Container Configuration Maintenance screen displays:

Figure 6: Container Configuration Maintenance - Edit

All the container configuration information is updated according to the updates applied and the container configuration is displayed in the container configuration's list.

Container Level, Part Number and Project ID cannot be edited, as they are the keys of the record.

Note: For more details about a field’s description, see the [#_5.1.2a_Create_Container Create Container Configuration] topic.

Copy Container Configuration

To copy Container Configuration definitions, go to Container Configuration> Container Configuration list, select an existing Container Configuration and click on the Copy icon.

The Container Configuration Maintenance window is displayed:

Figure 7: Container Configuration Maintenance - Copy

Change the necessary information and click on the "Ok" button. The new Container configuration created is displayed on Container Configuration List.

Delete Container Configuration

To delete a container configuration, go to Multi-Level Containerization > Container Configuration> Container Configuration list, select an existing Container Configuration and click on Delete Icon.

Figure 8: Multi-Level Container Configuration - Delete

A confirmation message displays. Click on Yes to confirm the deletion or No to cancel. The Container Configuration will be deleted from the containers list.

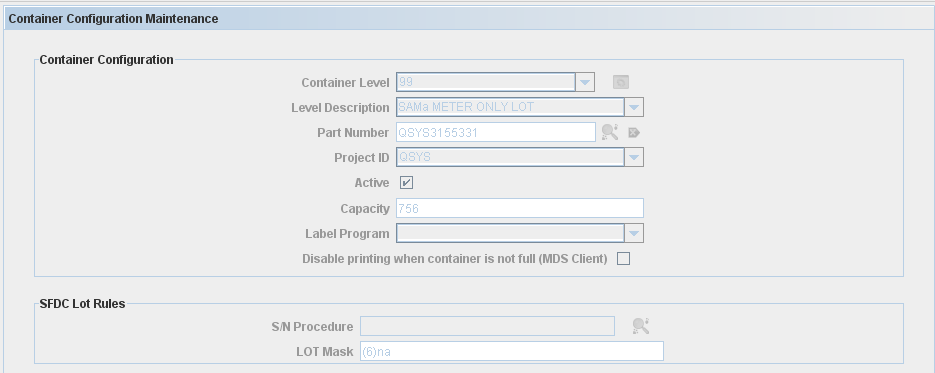

View Container Configuration

To view the container information, go to Multi-Level Containerization > Container Configuration> Container Configuration list, select an existing Container Configuration and click on the view Icon.

The container configuration maintenance window displays:

Figure 9: View Container Configuration Window

Note: all the fields are read only.

Print/Export Container Configuration

1) To print/export containers, go to Multi-Level Containerization > Container Configuration> Container Configuration list, select an existing Container Configuration and click on the Print/Export Container Configuration Icon.

A report is generated. In the viewer screen, click on "Save" or “Print” button to save or print the report result.

Container Task Panel

From the Task Panel the user is able to create a new container configuration and print/export all filtered container configuration created.

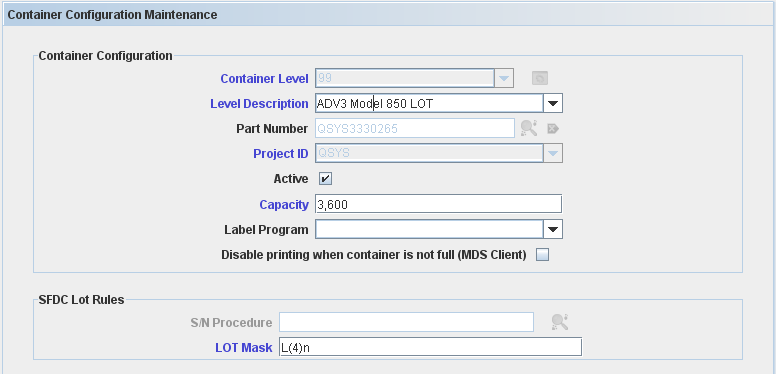

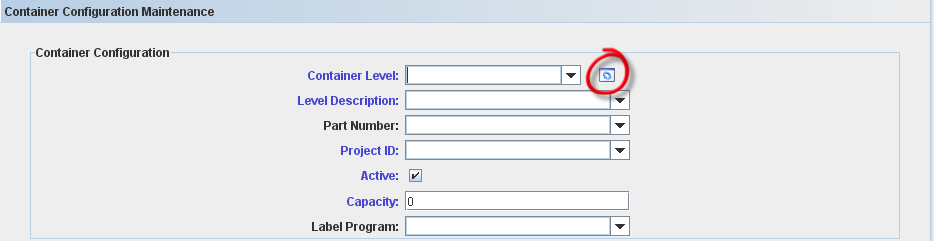

Create Container Configuration: Level 99 (LOT) /Level 100 (Container)

There are different configurations for Containers Level 99 (LOT) and level 100 (Container). See bellow the differences between them.

** Container Level = 99: Configuration

To create a container configuration, go to Multi-Level Containerization > Container Configuration > Task Panel and click on Add Container Configuration.

The Container Configuration Maintenance screen is displayed:

Figure 10: Container Configuration Maintenance

Container Configuration fields description:

Container Level: defines the container level (99 to 999) – default is Empty. For this topic, the level used is 99(LOT). The default Container Levels, 99 - LOT, 100 - CONTAINER, 110 - SKID and 120 - PALLET cannot be edited or deleted, it’s created automatically by the application.

SFDC Lot Rules:

- S/N Procedure: not used when Serial Mask is specified. The field can contain either (i) a predefined program filename or (ii) an algorithm number, if the algorithm was defined using the Algorithm Tool – default Empty;

- Lot Mask: not used when Serial Algorithm Procedure is specified. Up to 30 characters in length. The mask of the serial number for the container or lot. Using a serial mask, container serialization schemes can be different per part number – default Empty;

To manage the container levels click on Manage icon:

Figure 11: Container configuration Maintenance

The Manage Level screen is displayed:

Figure 12: Container Level Maintenance

The user is able to Add, Edit or Delete container levels.

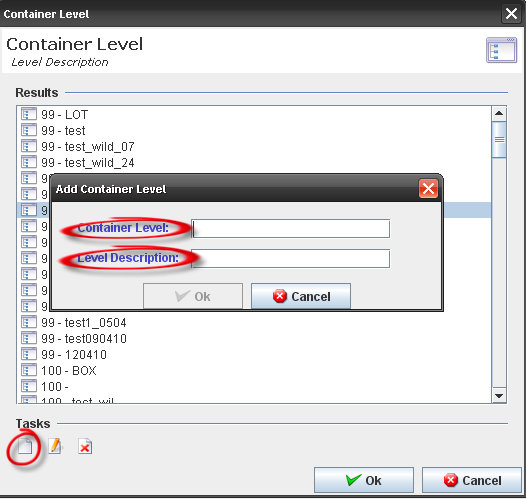

Create a new container level

To add a container level, click on the Add icon in the bottom of the window. The Add Container Level window displays.

Figure 13: Container Level - Add

Enter the "Container Level" with a value between 99 to 999 and the "Level Description" with a value that does not exist in the database. Click on OK to finish.

The new container level will be displayed in the containers level list and the user will be able to select it when creating/editing a container configuration.

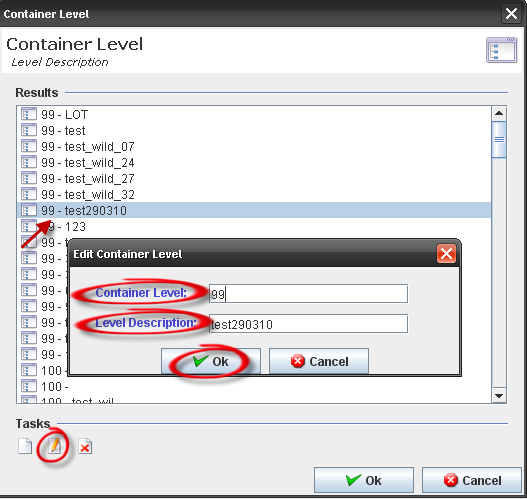

Edit/delete a container level

Edit/delete container level: (maintenance button) can be performed at any time except for a default value or a container definition that already exists for that level; otherwise, if there are no definitions, editing or deleting a container level is allowed. Type 99 (LOT) cannot be edited. Also, all types without a container configuration associated can be deleted. If a definition already exists, then the container level cannot be modified.

Figure 14: Container Level – Edit

Figure 15: Container Level - Delete

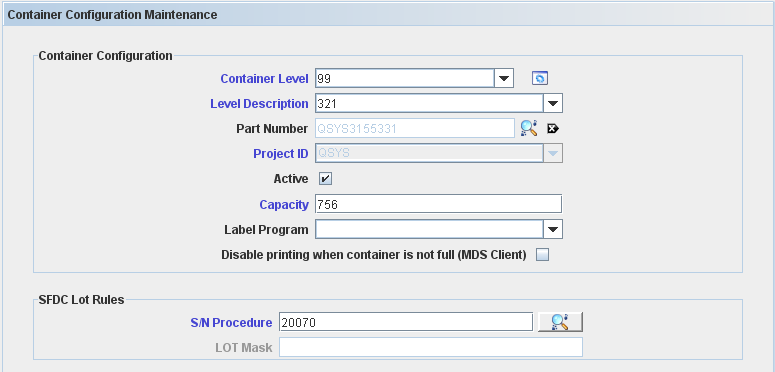

** Container Level = 100: SFDC Container Rules section

New configuration was added for level 100 and will run just in the MDS Client. Just configuration with algorithm type = Container will run in the SFDC.

It supports the following options:

- Revision Controlled;

- Shop Order Controlled;

- Auto Close;

- Dimensions (MDS Client only);

- Shipping Level

- Multi Part

- S/N Procedure

- Container Mask

General Rules:

After entering all mandatory fields, click on the "OK" button and confirm the configuration creation. The container configuration list is updated with the new container configuration, with the inserted data.

It is necessary to use the same "Level" for all records with the same "Description". For example, if you create a level 120 and say that the name is "Overpack Box", then any other record which is added later that has the description "Overpack Box" needs to be level 120.

Note: The application cannot show obsolete part numbers for selection during the creation of a container configuration.

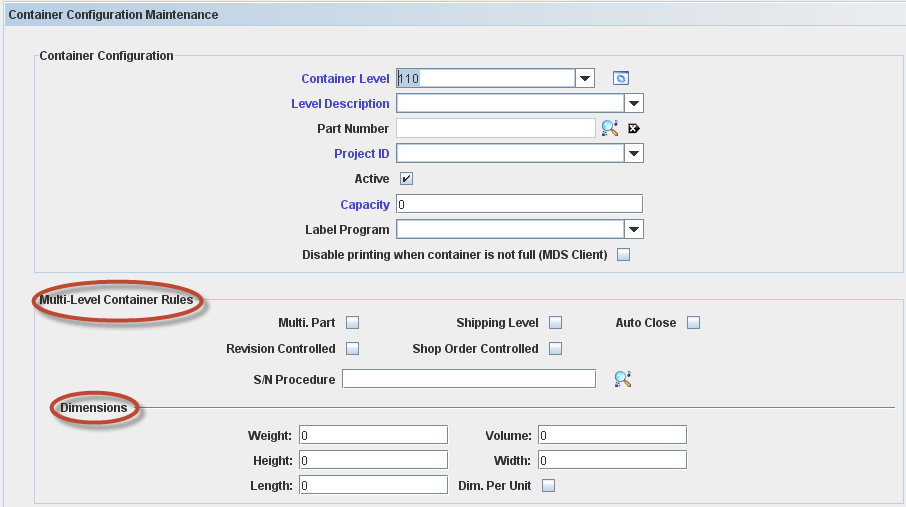

Create Multi-Level Configuration Containers: Type > 100

To create a new Container Configuration, click on Add Container Configuration button in the task panel.

Figure 16: Add Container Configuration

The Container Configuration Maintenance window is displayed:

Figure 17: Multi-Level Container Configuration Maintenance

The following fields are displayed just for containers >100: Container Level, Level Description, Part Number, Project ID, Active, Capacity, Label Program andDisable printing when container is not full (checking this option, the container configuration will print only when the container is full).

The following check boxes are displayed as Multi Level Container Rule:

- Revision Controlled: Revision Controlled (All, No, Yes): YES means only one revision can be containerized together. Please correct and check the default value.

- Shop Order Controlled: Yes / No. Yes allows only units from a single shop order to be containerized together – default No;

- Shipping Level: Yes / No. Yes defines that a specific container is the Shipping level of containerization – default No;

- Auto Close: Yes / No – default No;

- S/N Procedure: Show all “COPS Container” algorithms created in Algorithm Tool – default Empty. Not used when Serial Mask is specified. The field can contain either (i) a predefined program filename or (ii) an algorithm number, if the algorithm was defined using the Algorithm Tool – default Empty;

- Multi Part: Allow multiple part number in a container. It is possible to add elements from another part number, but it must have the same Project Id.

In Addition, the user can define the Container dimension filling the weight (kg), height (m), length (m), volume (m3) and width (m). Selecting the Dimension per Unit flag, it is possible to fill for each configuration container. If the dimension is in different measure, the data will be converted.

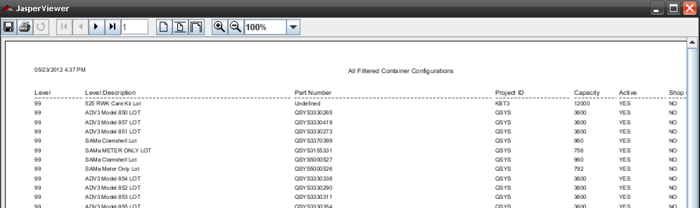

Print/Export All Filtered Container Configuration

To Print/Export all Filtered Container Configurations, click on Print/Export Container Configurations button in the tasks panel.

A report is generated:

Figure 18: Print All Filtered Container Configuration

The user can perform some actions (print, save, fit page…) by clicking on the buttons in the top of the report.

Employee Validation

Employee Validation Setup

This edition applies to MDS14-5 Application (Employee Validation Module) and all subsequent releases and modifications until otherwise indicated in new revisions.

This module is responsible for creating trainings that operators should perform to work in manufacturing processes. The whole operator control (registration and information maintenance) and trainings and certificates required for the operators work in shop floor (mainly in medical plants) will be administered by this feature.

Employee Validation is a manual input module that allows individuals working on the Employee other than those creating a new configuration and maintaining an existing one.

It provides a method of creating employee / password / training records that can be administered by non-SFDC personnel, and a method of identifying specific processes that must be controlled.

It will still support the traditional login methods for data collectors without controlled processes.

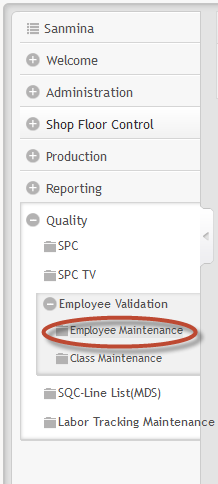

To access Employee Validation module, click onEmployee Validation Maintenance in the main MDS page:

Figure 1: MDS Modules

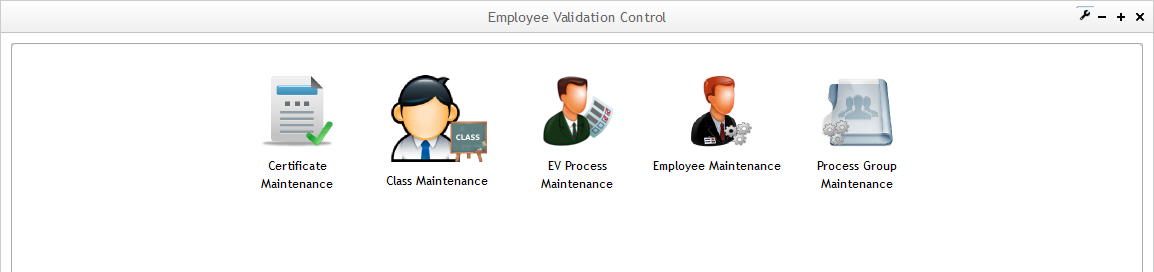

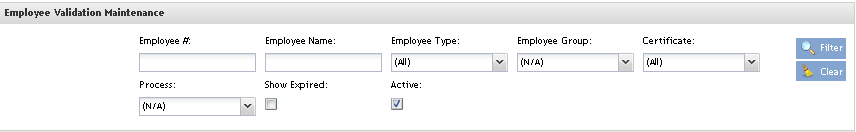

The Employee Validation Maintenance page is displayed as follow:

Figure 2: Employee Validation Maintenance

Employee Validation is composed by sub-modules and these work instructions will help users to understand each one.

- Certificate Maintenance: responsible for manage the certificates as well associate process and process groups to certificates;

- Class Maintenance:

- EV Process Maintenance:

- Employee Maintenance:

- Process Group Maintenance:

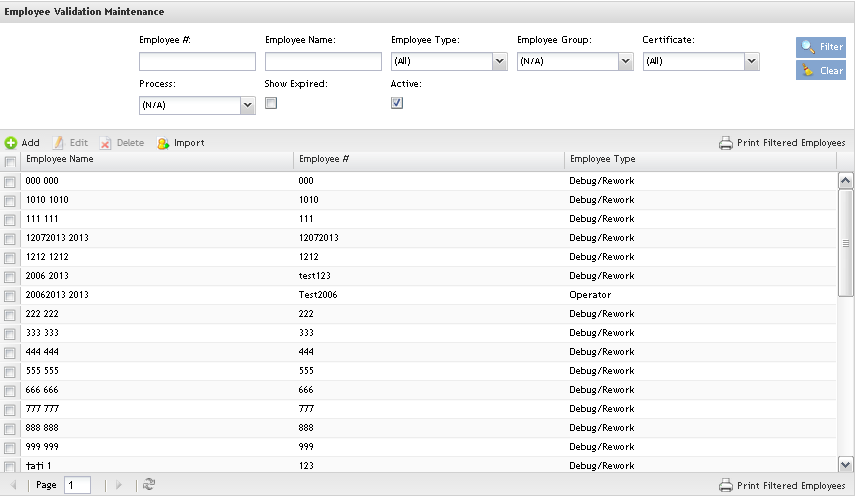

Employee Maintenance

To access Employee Maintenance, click on Employee Maintenance in the employee validation main page.

The first step in setting up Employee Validation is to define all the Employees in the Employee Maintenance module.

Listing employees

The Employee List displays all employees’ name, type and number and allows filtering data by entering data in the available field, edit employees by clicking on Edit icon and delete employees by clicking on Delete icon;

Figure 3: Employee Maintenance Page

This is the main Employee validation maintenance page and the users are able to perform searches, sort, add, edit, delete, import and print/export employees.

Performing Searches

To perform searches, there are four available fields: Employee #, Employee Name, Employee Type, Employee Group, Certificate, Process and the Active/Show Expired flags.

It’s possible to search by one field or a combination of those. Click on Filter button.

Figure 4: List and Search Employees

The search result is displayed in the Employee list.

Note: It is possible to list only the active employees by checking the Active check box.

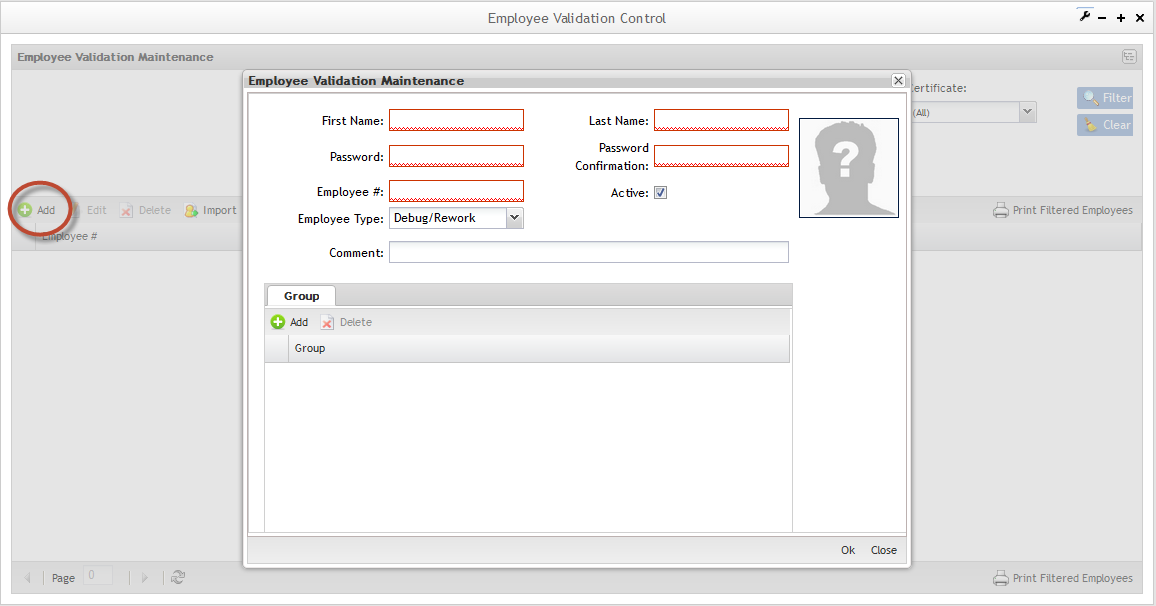

Adding Employee

This functionality allows adding employees in the application.

Employee records can be added individually clicking on Add ,or a number of records can be imported clicking on Import button.

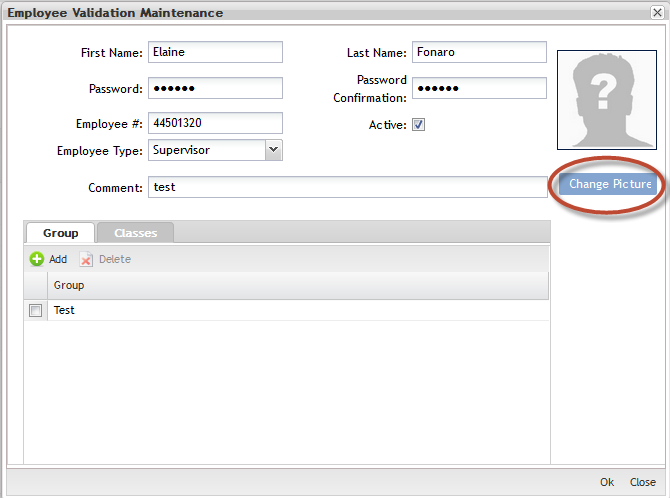

To Add Employees, click on Add.

The Employee validation page is displayed:

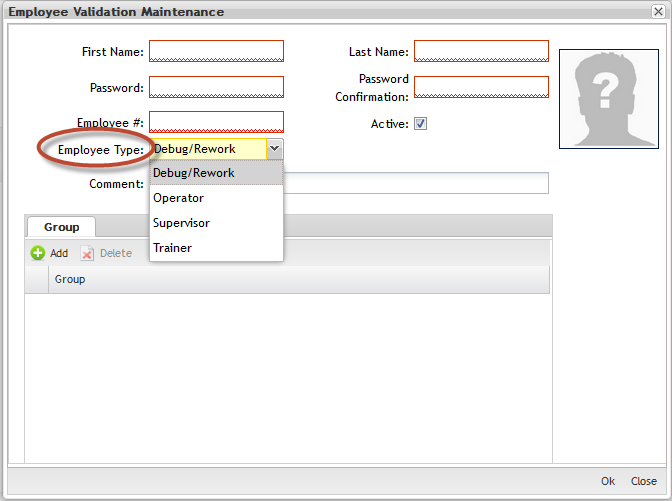

Figure 5: Adding Employee

Fill in all mandatory fields (in red):"First Name", "Last Name","Password", "Password Confirmation", "Employee#", "Employee Type" (operator, supervisor or trainer).

- Trainers are the people used to create a class. Someone has to be a designated trainer, in order to create a class in EV. They are also the people typically holding "classes" and performing any hands on training.

- Operators are the production folks who perform work. They either have the certification to perform a job or not. That is the EV control for processes.

- Supervisors are required to be in EV and have at least 1 certificate. They do not necessarily have to be in every certificate in order to be able to scan serial numbers through the processes. Effectively, they are "superusers" which can scan serial numbers through any process, without having the actual certification. They just must have 1 certification for something.

- Debug/Rework are the production folks who perform work with debug/rework roles;

- Click onChange Picture to add the Employee image.

Figure 6: Employee Validation - Employee Type

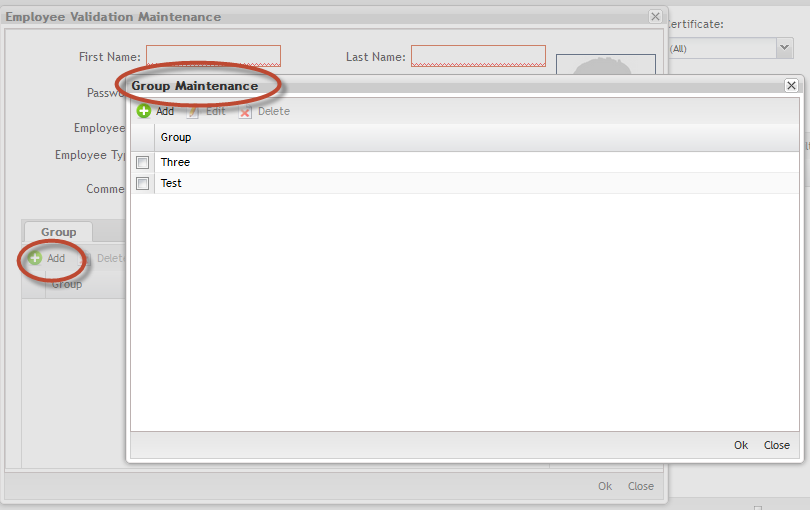

After Employee records have been created, each employee should be associated to at least one Group.

Group Maintenance:

To add, edit, delete and undo groups, go to group maintenance;

1. Click on Maintenance button to open the Groups Maintenance popup.

Figure 7: Groups Maintenance

After insert the employee data, the user is able to upload the employee image, or if prefer, upload the image in the future using the Edit Employee button.

Figure 8: Uploading Employee Image

Click on Yes to continue the upload or No to abort.

Click on Change Picture to upload and save the image.

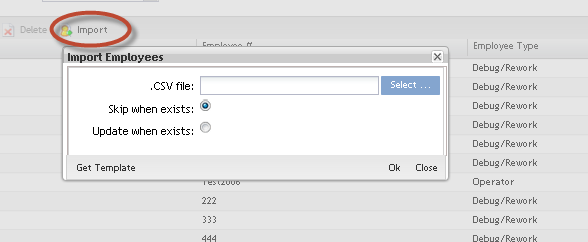

Importing Employees

To Import Employees from a CSV file, click on Import.

Figure 9: Import Employees

The Import employee is displayed.

Note: Selecting Skip when exists, the user will not be updated.

This functionality allows importing employees in mass.

The format of the .csv file for importing Employee records is:

| First Name | Last Name | Password | Employee # | Employee Type |

| Character | Character | Character | Character | Character |

After creating the spreadsheet, follow the steps below to import:

- Go toEmployee Maintenance page and click on "Import" button.

- Select the .CSV file already created.

- Click on "OK" button.

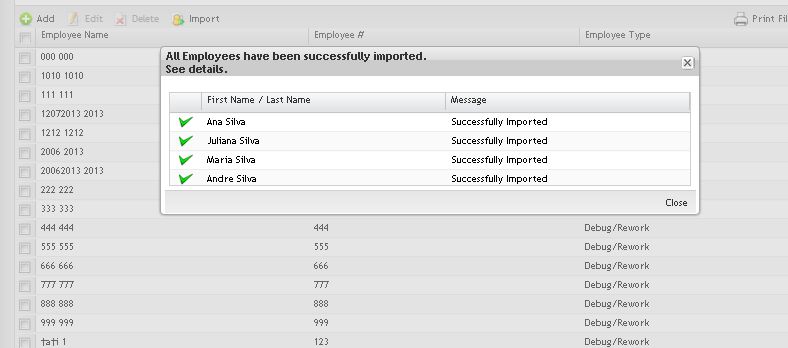

The"Import Employee Results" page with the import results is displayed:

Figure 10: Import Employees

- Click on "Close" button.

After the import process, a report is displayed with the employees successfully imported and with those who failed.

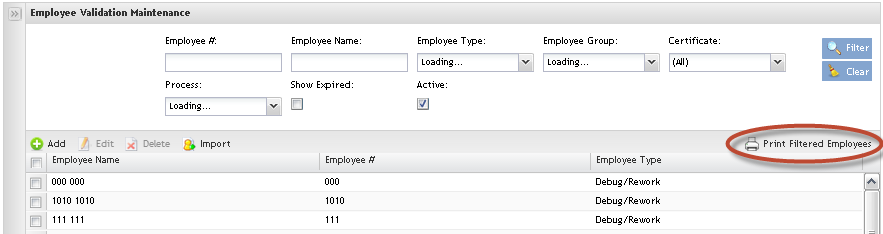

Print Filtered Employees

To Print Filtered Employees list, click on Print Filtered Employees button.

Figure 11: Exporting Employees

A .pdf report is generated with classes, certificates and processes. The user can save it and print.

Editing Employees Information

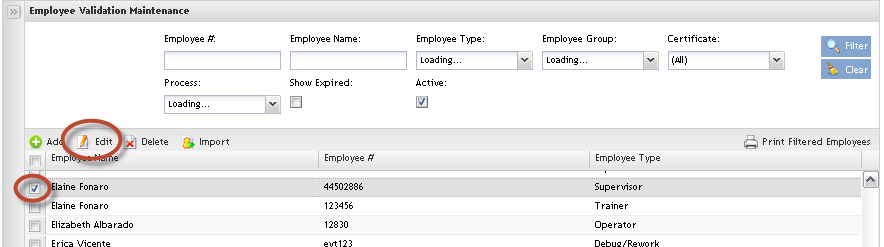

Figure 12: Editing Employee Information

It is possible to edit the employee information by selecting the employee and clicking on Edit button.

The steps to edit employees are the same as Add Employees. See Add Employee section for more information.

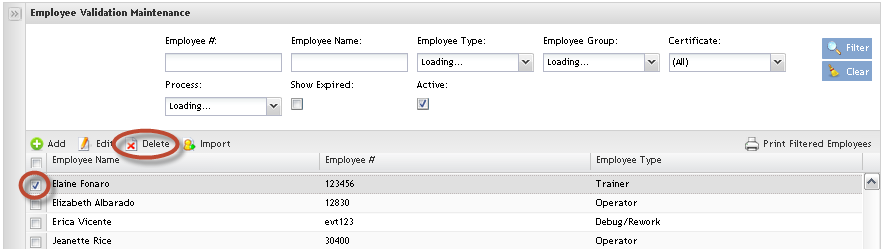

Deleting Employees Information

Delete the employee by selecting the employee and clicking on Delete button.

Figure 13: Deleting Employees

NOTE:

1. The deleted employees will be removed from classes also.

2. The application does not allow removing a Trainer that is assigned to a class.

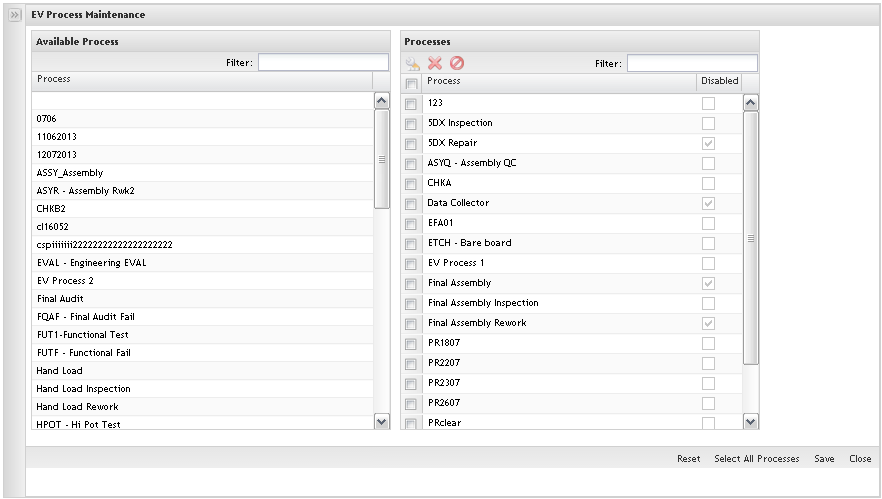

EV Process Maintenance

The processes are created in the SFDC Maintenance module. In EV, the user is able to Add Processes already created. The added Processes will be processes that EV will download to SFDC and check for Classes. In this step the user is able to add, edit, remove and re-add processes and process groups that will be managed inside the Employee Validation Module.

| To access the EV Processes Maintenance, click on EV Processes Maintenance. |

The Process list main page is displayed.

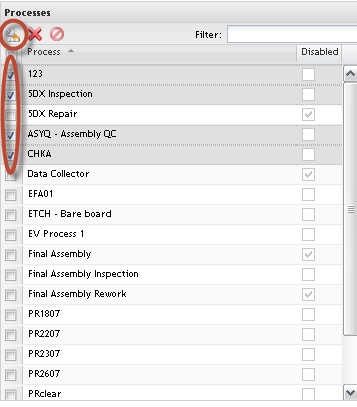

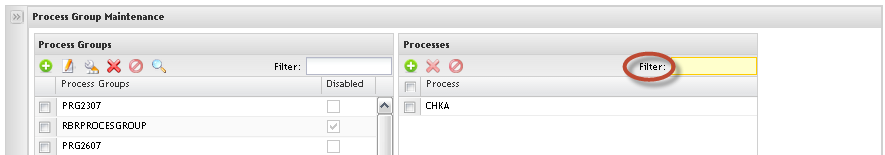

Listing Process

Figure 14: Processes List

In the Process List, the user can perform a filter by typing the process name in the Filter field. Click on Ok to confirm.

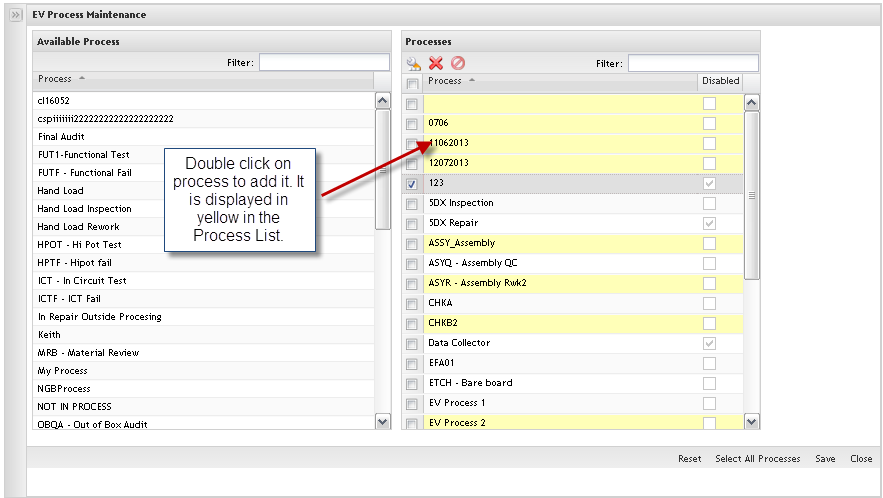

Adding Processes

Figure 15: Add Process List

The available processes are displayed to be added in EV.

1. To define the processes to be controlled by EV, double click on available process in the left application panel.

2. The new added process is displayed in the Process list highlighted in yellow.

To cancel, click on Reset before save.

To add all processes available, click on Select All Processes. Clicking on Reset

Click on Save to commit the updates.

If there are multiple processes that are to be controlled by Employee Validation, yet fall into the same certification, these processes can be grouped together by defining a Process Group. Click on the Process Group Maintenance module. Follow the steps defined in the Process Group Maintenance topic for specific instructions on how to create Process Groups.

Editing Processes

To Edit (Enable and Disable) Processes, follow the steps bellow:

Figure 16: Edit Processes

1. Select the process (es) to be updated and click on Enable/Disable icon.

2. Click on Yes to confirm the status change.

Note: The process will be disabled when it is not used, but it can be used anytime by enabling it.

After clicking on the edit icon, the process shows in dark gray. To commit this, click on Save.

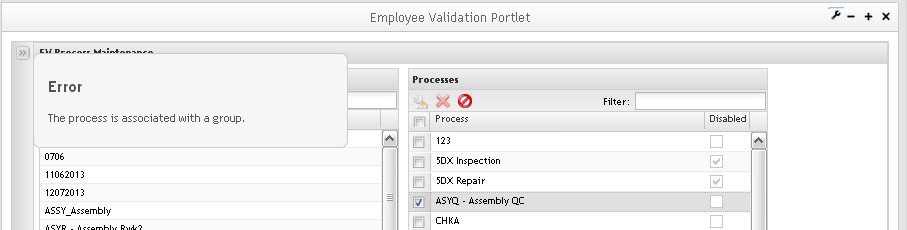

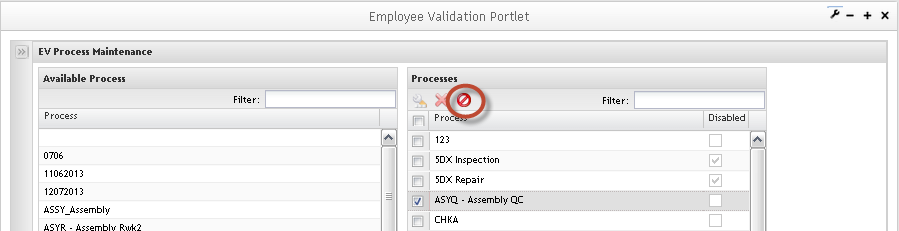

Removing Processes

To Remove Processes, follow the steps below:

Figure 17: Remove Processes

1. To Remove Processes from list, select the process and click onRemove button.

Note: If the selected process has any associated certificate(s), the application will not allow the user to remove it, displaying an error message, otherwise, the process is displayed in gray.

Re-add Processes

1. Tore-add processes, click on the Undo Delete button.

Figure 18: Undo Delete Processes

The selected process will change the color and continue displaying in the list.

Click on OK button to commit the changes or click on Cancel button to cancel the action.

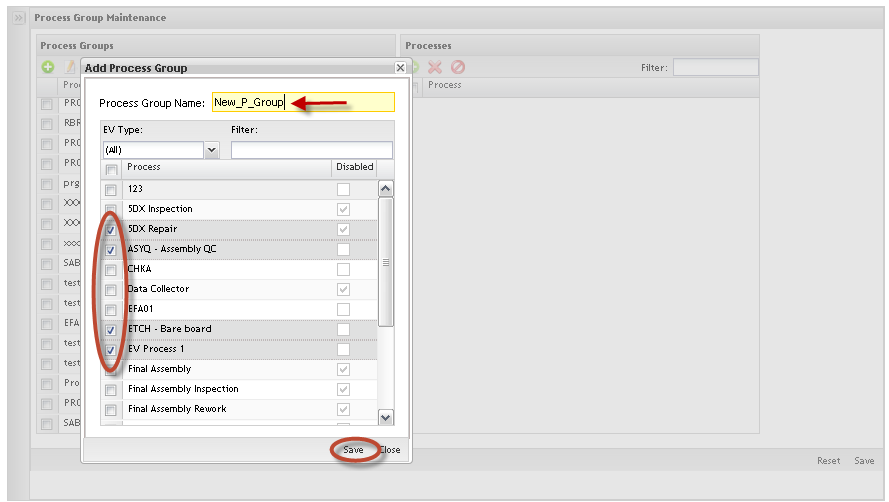

Process Group Maintenance

Toaccess theProcess Group Maintenance, click on Process Group Maintenance option.

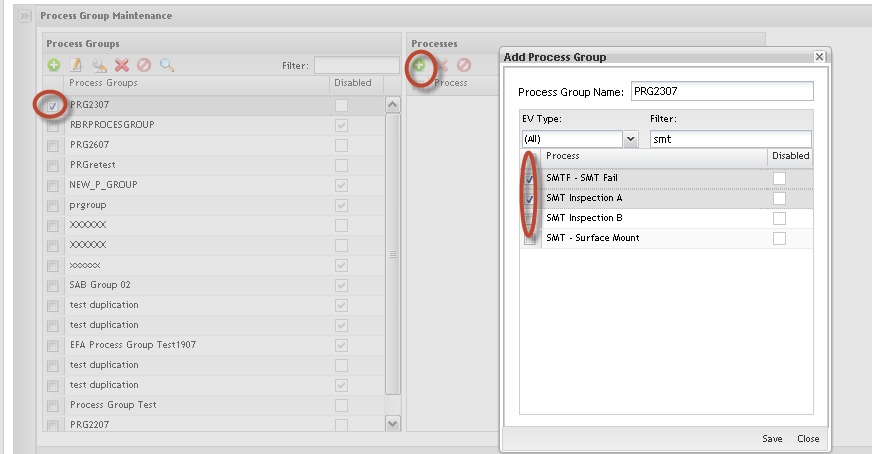

Adding Process Groups

To add process groups, follow the steps below:

Figure 19: Add Process Groups

1) ToAdd Process Groups, click on Add icon, fill in the Process Group Name field and select the processes to be added into the process group.

Note: Every time that a new process group is created, the user must associate at least one process to it.

Selecting a process group, the user can see all associated processes.

The selected Process Group will be displayed highlighted in yellow. Selecting the process group, the user can see all associated processes.

Click on OK button to save the changes.

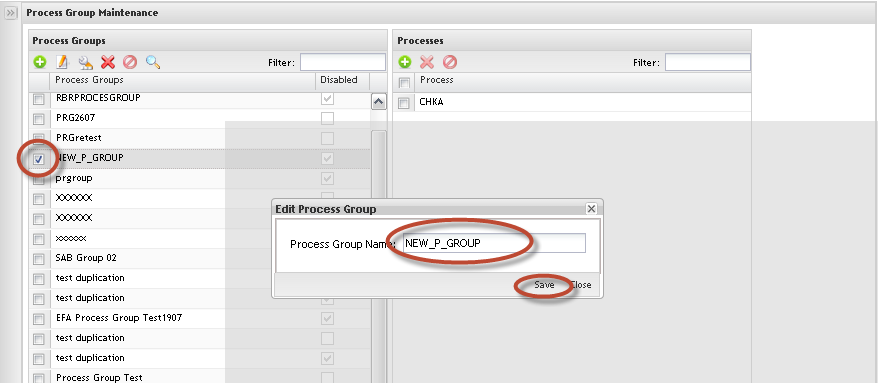

Editing Process Group Name

Figure 20: Edit Process Groups

1. To Edit Process Groups Name, select the process group and click on Edit icon.

Just the Process Group Name can be updated. Update the Process Group Name and click on OK to commit the change. To cancel, click on Cancel button.

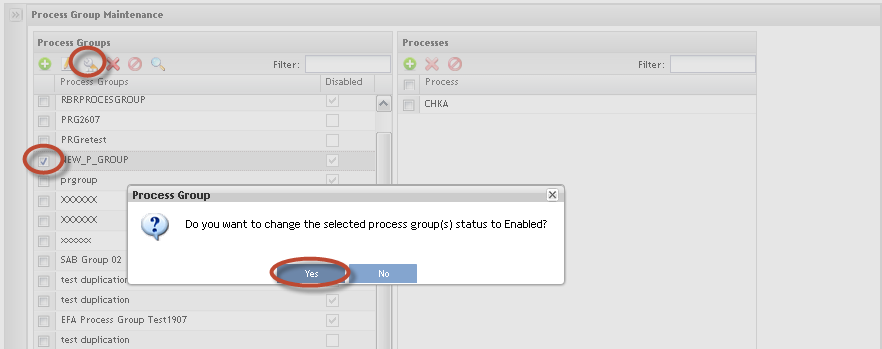

Editing Process Group Status

Figure 21: Change Process Group

1. To Change Process Group status, from list, select the item and click on Edit Status icon.

Note: The updated Process Group is displayed in red:

2. Click onYes button to commit the change.

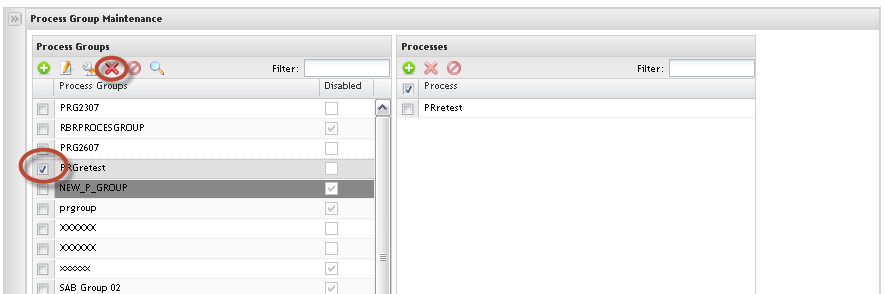

Removing Process Group

Figure 22: Remove Process Group

1. To Remove Process Group from list, select the process group and click on Remove icon.

Note: It is not possible to remove process groups if there are associated certificates. In this case, it is possible to only update the processes.

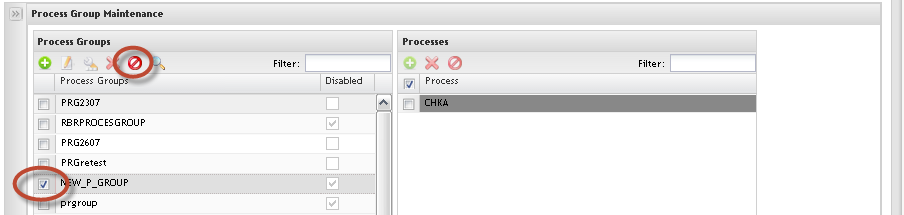

Undo Delete Process Group

Figure 23: Undo Delete Process

1. To undo delete a process group, click onUndo Delete icon.

The selected process group color will be changed and continue displaying in the list.

To commit the changes, click on Yes button. To cancel the changes, click onCancel button.

Process Maintenance:

Searching Process

Figure 24: Filter Processes

1. To Filter Processes already associated with a Process Group, enter the process name (at least 3 chars) in the Filter field. The process displays with the respective associated process group.

Adding Process

Figure 25: Add Process

1. To Add Process, select the Process Group and click on Add Process icon.

The available processes are displayed. Select the process and click on Save button.

The selected process (es) will be displayed in the Processes list highlighted in yellow.

This action could be affecting existing Certificates and the user is able to update it.

Note: A Process can only belong to a single Process Group.

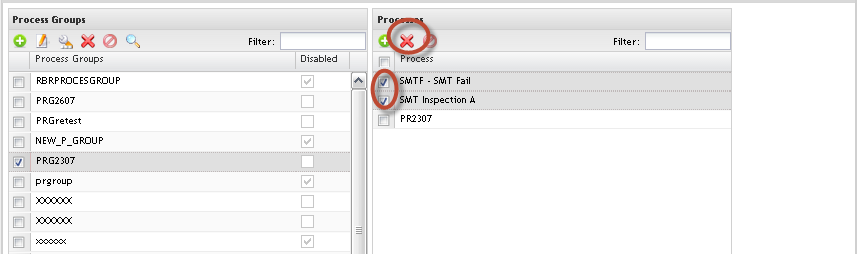

Removing Process

Figure 26: Remove Process

1. To Remove Process, select the Process Group, select the process to be removed and click on Remove Process icon.

If the update on the process group affects existing certificates, the user is alerted and has the possibility to change the certificate before committing the change.

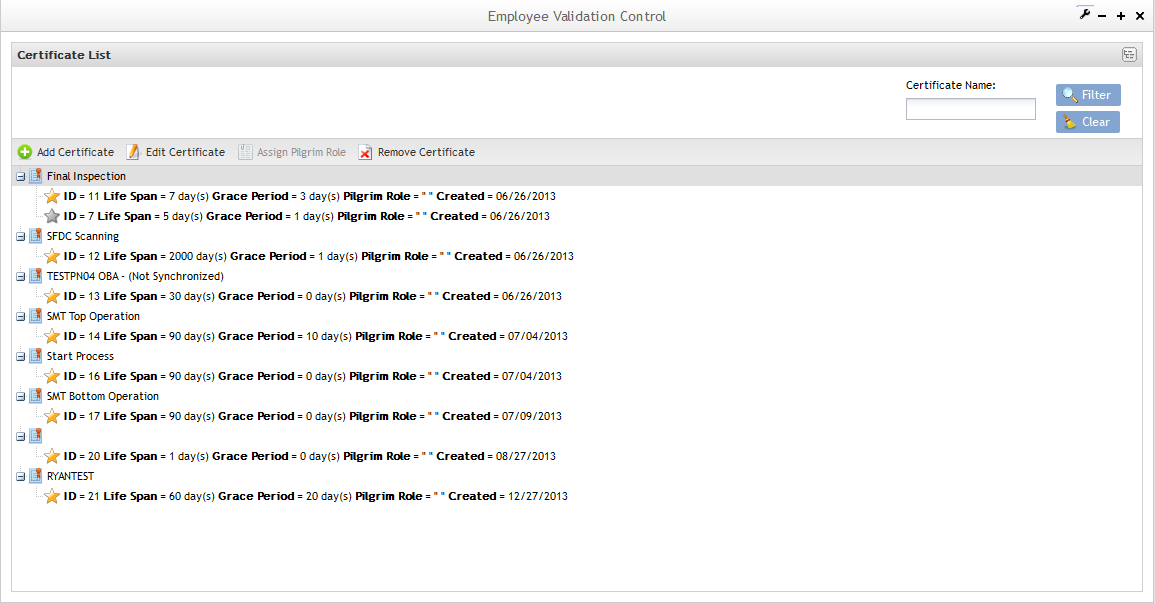

Certificate Maintenance

The next step to configuring Employee Validation is to create the Certificates. Toaccess theCertificates, click on Certificate Maintenance.

The main certificate maintenance page displays:

Certificate List

Figure 27: Certificate List

Note that in the Certificate list, it is possible to see some unsynchronized certificates, which means that it has at least one process group that is out of date. In the next steps, the user will be able to turn non synchronized certificates into synchronized certificates.

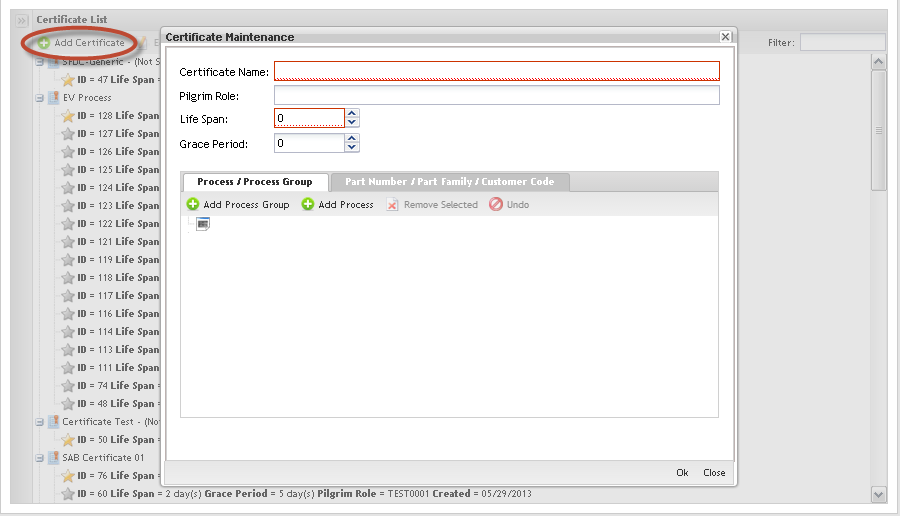

Adding Certificates

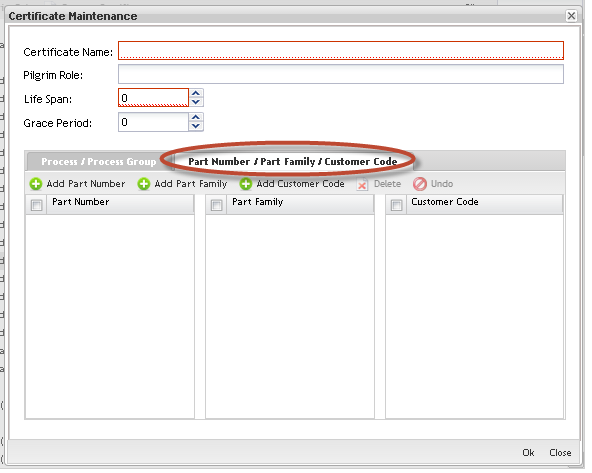

1. ToAdd Certificates and associate processes and process groups or Part/Family to Certificates, click on Add Certificate in the Tasks area.

Figure 28: Add Certificate

The Certificate Maintenance screen displays:

Follow the steps below to add a certificate:

1. Fill in the fields:

Certificate Name: The name of the new certificate;

Pilgrim Role: this field is used to associate the Certificate to a Pilgrim role. It was created to maintain a list of the ’Roles’ in Pilgrim that require training for EV purposes, linked to the EV certificate associated with that role.

Life Span: # of days the certificate is valid;

Grace Period: # of days allowed after expiration (can not be grater than 30);

2. Click on Ok to confirm. The new certificate must display in the Certificate list.

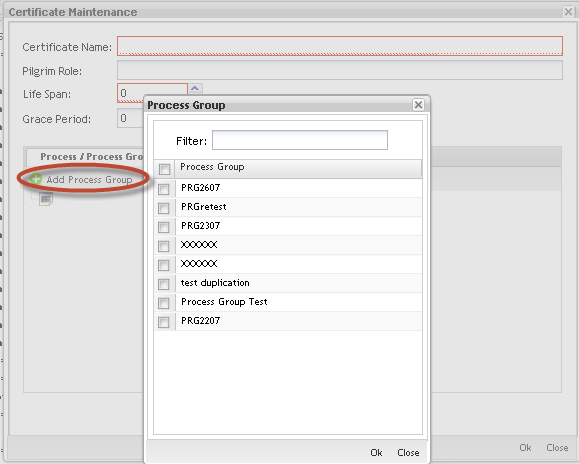

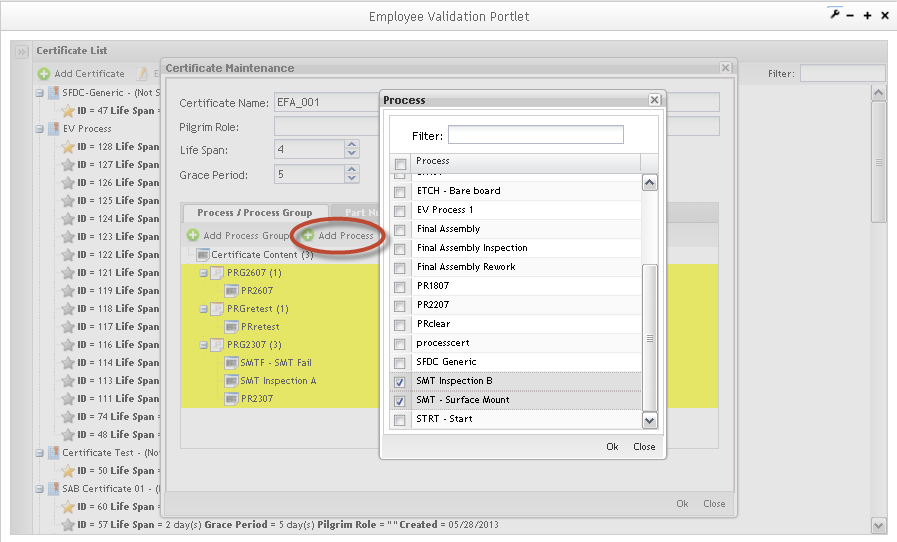

3. Click on the Add Process / Process Group button to define the process (es) and/or groups that are associated to the certificate.

Adding Process/Process Group to the certificate:

Figure 29: Certificate X Process/Process Group

The Certificate X Process / Process Group page displays:

Select the Process Groups check box to add process groups available in the list. Do the same steps to Processes and click on the Add button.

The inserted process/process group is displayed in the Process/Process Group tab.

NOTE: You cannot create a certificate without having at least one process or group assigned.

Figure 30: Certificate Maintenance Process/Process Group Tab

To add Process to the process groups, click on Add Process. The added processes/process groups are displaying highlighted.

a)Creating generic certificates.

If multi-pass device numbers are used in SFDC, then it is recommended to create a generic certificate and assign some process to it. The process does not have to exist in any route. An example would be SFDC Training for the process. The process is not used for any locations or in any route. The process is controlled by Employee Validation and a generic certificate is created for this process.

All employee numbers are associated to this certificate/process. The reason for this is to allow any employee to log into a device number that has one or more EV controlled processes. Without a generic certificate/process, employees would not be able to log into the device number to perform the non-EV controlled processes that are assigned to the multi-pass device number. Employee validation insures that serial numbers that are at a controlled process can only be scanned by employees that have the necessary certification for the controlled process. Without the generic certificate/process, non certified employees will not be able to log into multi-pass device numbers.

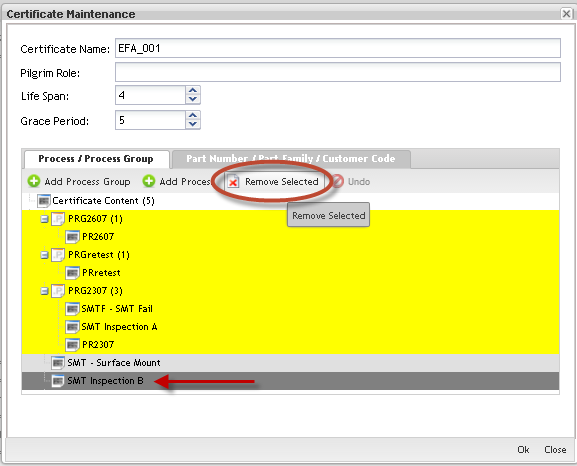

b) To Remove 'CERTIFICATE 'Process/Process Group:

Figure 31: Remove Process Group

Click the process/process group to select it and click on Remove Selected button. The removed process/process group displays in dark gray in the list. To Undo Delete 'CERTIFICATE 'Process/Process Group, select it from list and click on Undo button.

c)Adding Part Number/Part Family/Customer Code to the certificates:

Figure 32: Part Number/Part Family/Customer Code Tab

In addition, users can add Part Numbers/Family and Customer Codes to the Certificate. The rules to add, remove and undo remove are the same described for Process and Process Group.

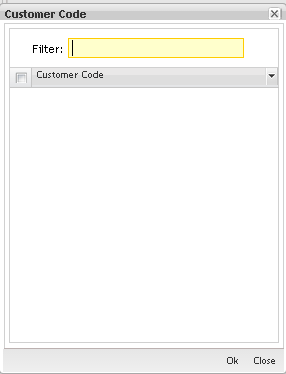

Figure 33: Customer Code

To add customer code, select the item (s) in the list and click on OK.

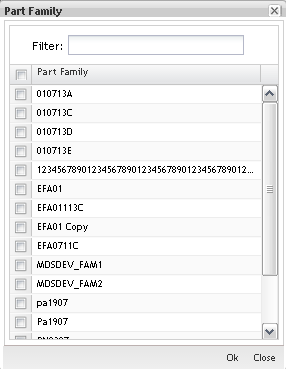

Figure 34: Part Family

To add part numbers/family, select the item (s) in the list and click on OK.

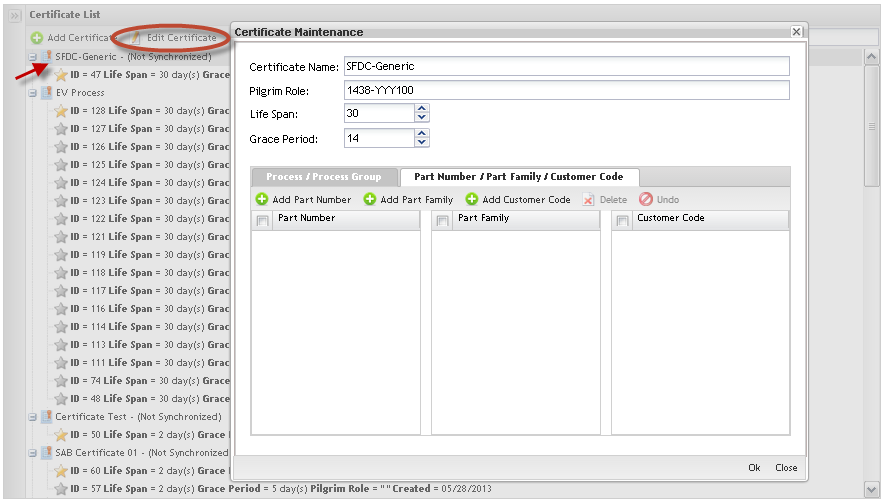

Editing Certificates

1. To Edit Certificates, select the certificate in the Certificate List and follow the same instructions to Add Certificates: update the mandatory fields and click on OK to commit the change.

Figure 35: Certificate Maintenance

NOTE: Every time the user adds a new Process on the Certificate, the application creates a new instance of that Certificate. All classes created before the Certificate changes will be linked to the old Certificate instance.

See the example:

1- Create Certificate CERT with process "A" and "B";

2- Create a Class for CERT with employee Y and Z;

3- Edit CERT and add the new Process "C";

On this example the employees Thomas and Keith will be trained only on the processes "A" and "B". If the certificate is changed, they need to be trained on "C", therefore another class will need to be created for the same CERT.

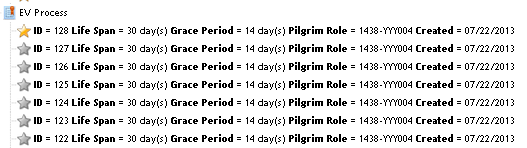

Figure 36: Certificate Instances

GOLD STAR represents the last update;

SILVER STARS are the old instances that are associated to the classes already created.

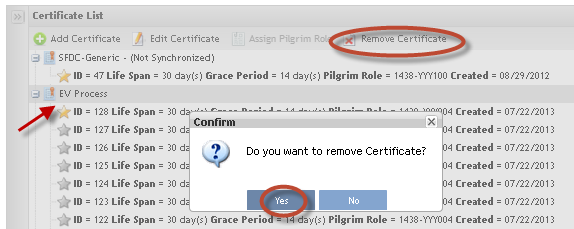

Removing Certificates

To Remove Certificates from the list, follow the steps below:

1. Select the certificate to be removed;

2. Click on Remove Certificate button. A popup message displays to confirm the certificate removal.

3. Click onYes to confirm or click on No to cancel the removal.

Figure 37: Remove Certificate from List

NOTE: Certificates already associated with classes can not be removed.

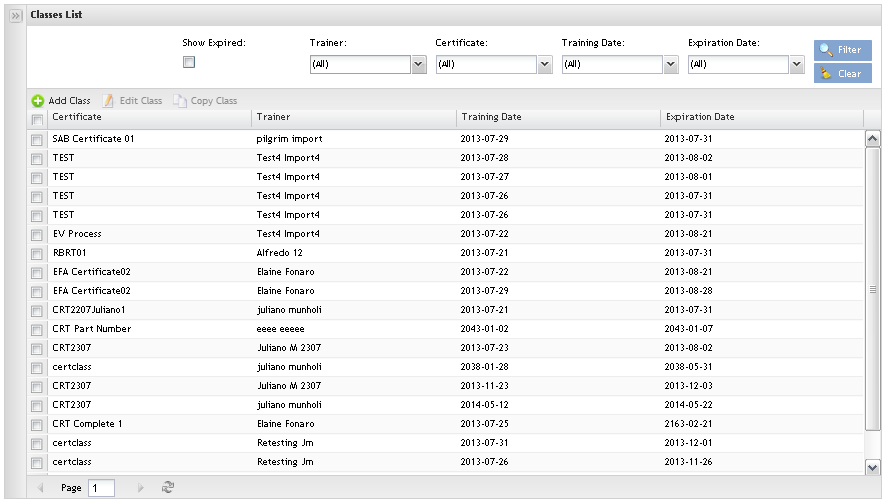

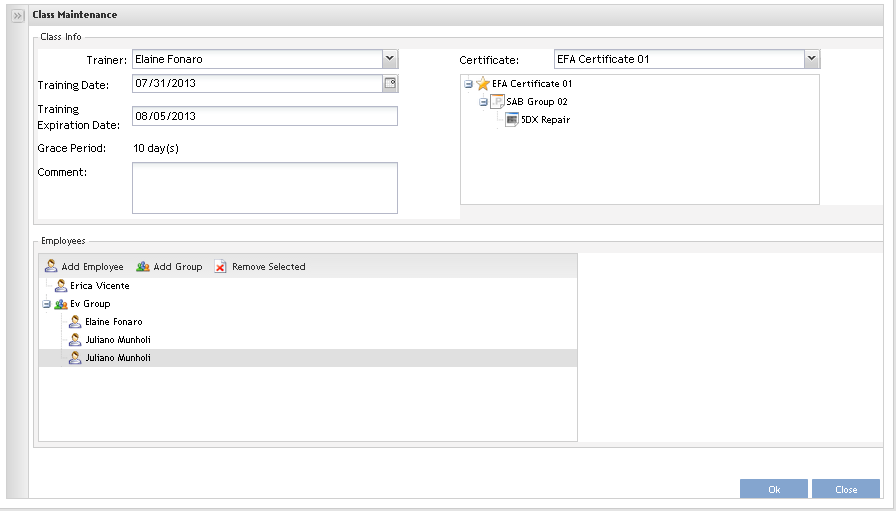

Class Maintenance

Toaccess theClass Maintenance, click on Class Maintenance option. The Class Maintenance main page is displayed:

Figure 38: Class Maintenance

The user is able to add, copy or edit classes and perform searches from the main class page.

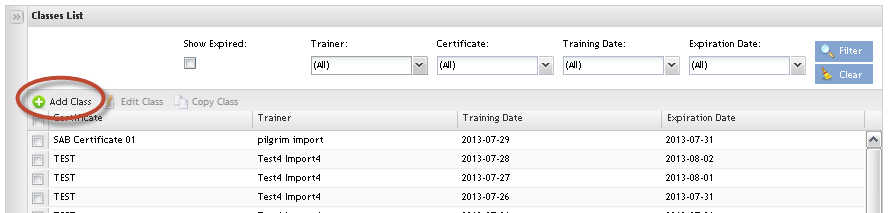

Adding Classes

Figure 39: Add Class

1. Click on Add Class in the Menu bar.

The Class Maintenance page displays:

Figure 40: Class Maintenance

1. Select the trainer, the certificate and the date for training from the drop down list. Selecting the certificate, the Grace Period and Training Expiration Date will be automatically filled.

2. Go to Employees maintenance and add the employees who have taken the class, by clicking on the Add Employee button.

NOTE: The class must have at least one associated certificate.

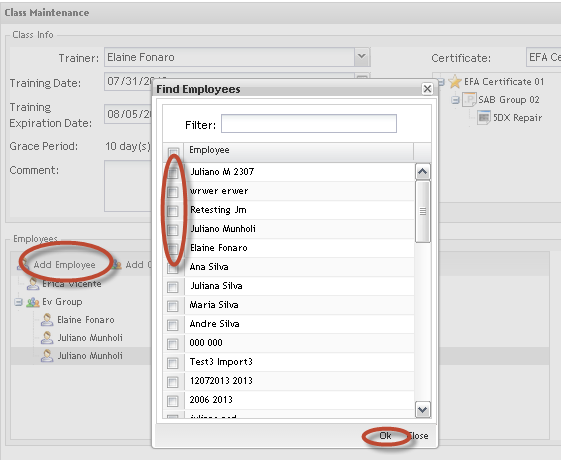

Figure 41: Add Employees

1. Add the Employees clicking on Add Employee.

The Find Employees popup displays to find Employees.

2. Select the Employee (s) and click on OK to commit the inclusion.

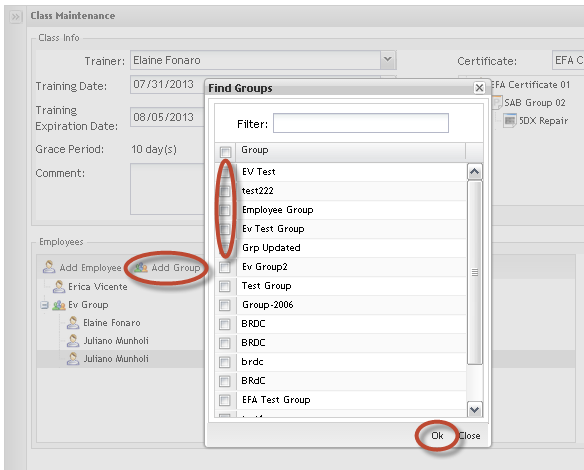

To add employee groups:

Figure 42: Add Employees Groups

1. Click on Add Group.

The Find Groups popup displays to find Groups.

2. Select the Group (s) and click on OK to commit the inclusion.

Both, groups or employees are displayed in the Employees list.

NOTE: The add Employees by group is a way to make adding employees fast and EV does not store group information, i.e. if the selected group has a new employee added in the future, he/she won’t be added to the class.

Editing Classes

To Edit Classes, select the class to be edited and click on Edit icon. Follow the same steps performed to add classes. Click on Ok button to commit the changes.

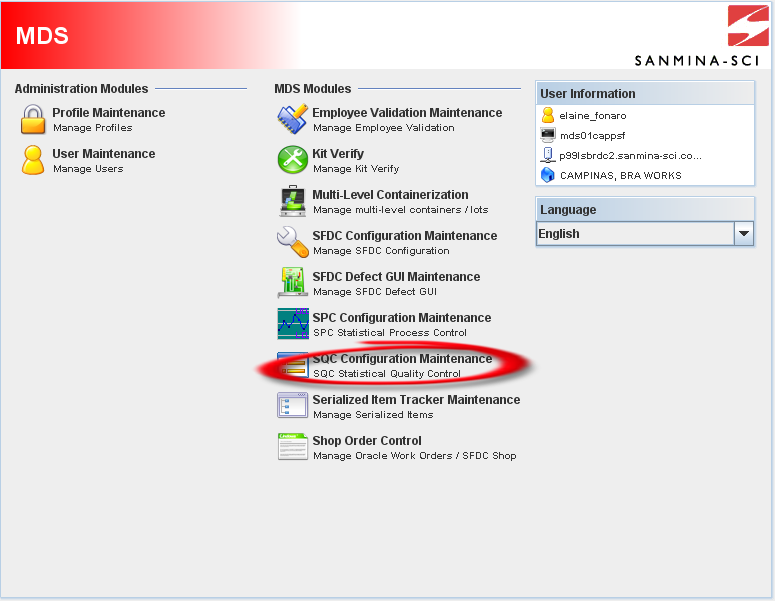

SQC Configuration

Introduction

The SQC module was developed to store baseline and static data only. It is used for comparison against actual data collected by SFDC/MDS. The data can be imported from a spreadsheet, or data is manually entered. The data can be previously calculated cycle time data for processes and can also be the manufacturing time from Oracle for a particular part number. Regardless of how the data is entered into the module, it is simply reference data. The data is not automatically updated; therefore any changes must be done manually.

See below some important definitions for the user:

- HPU (Hour Per Unit) - It measures how long time Operators take to produce a unit.

- Cycle Time

Process cycle times:

- Short cycle times: the user logs in and “starts” a serial number, leaving the data collector location at the “Menu Selection” prompt while the process is being performed;

- Medium to Long cycle times: the user starts a process and then the serial number will be released, or not remain at the Menu Selection prompt. This is also true of where a process consists of multiple test stations being run by a single operator, at a single data collector location. In this instance, units are started at different times, hence the need to “start” a unit, but free up the data collector location for the next unit starting on the next tester. As units complete the process, they are rescanned and passed or failed to the next location/process.

NOTE: Calculation of cycle time would be different between a short cycle time and medium to long cycle time processes. Medium to long cycle time processes would most likely include situations where shift changes, breaks, lunches, etc. are included. The cycle time calculations would need to take these times into account.

Statistic Quality Control Setup

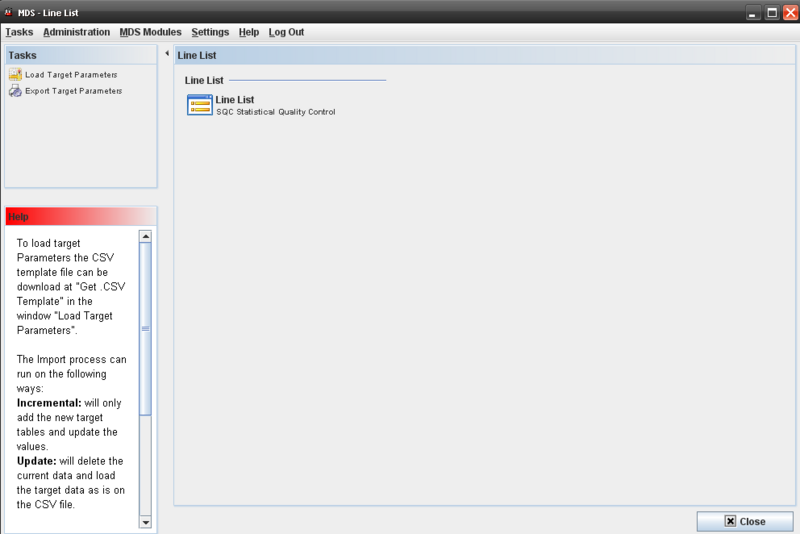

To access SQC module, click onSQC Configuration Maintenance in the main MDS window.

Figure 1: MDS Client Main Window – SQC

The SQC Maintenance window is displayed as follow:

Figure 2: SQC Main Page

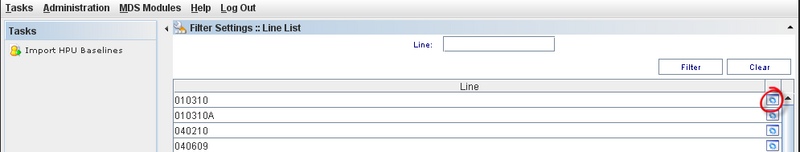

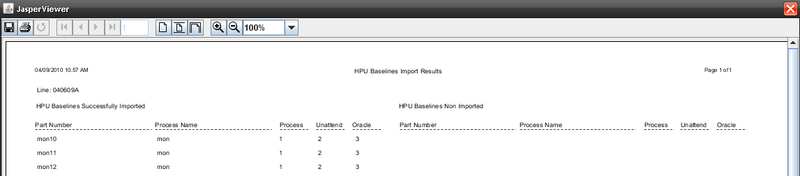

TheMDS Line List screendisplays all available lines’ names and allows filtering data by entering data in the Line field. To clear the field content, click on Clear button and start a new filter.

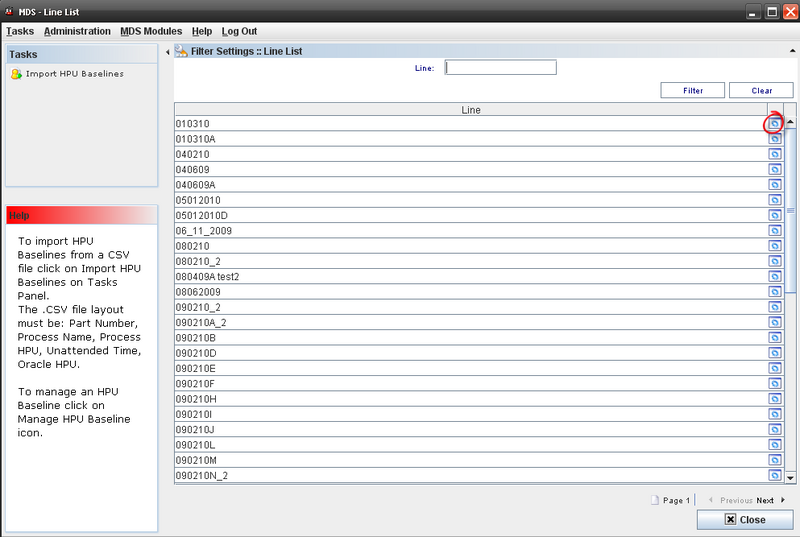

SQC – Line List Functionalities

There is just one available action to be executed from the Line List screen: Manage HPU Lines. See the next topics for further information.

Managing HPU Lines

Figure 3: SQC Line List

Click on Manage HPU Baselines icon in the list. The HPU manage screen is displayed.

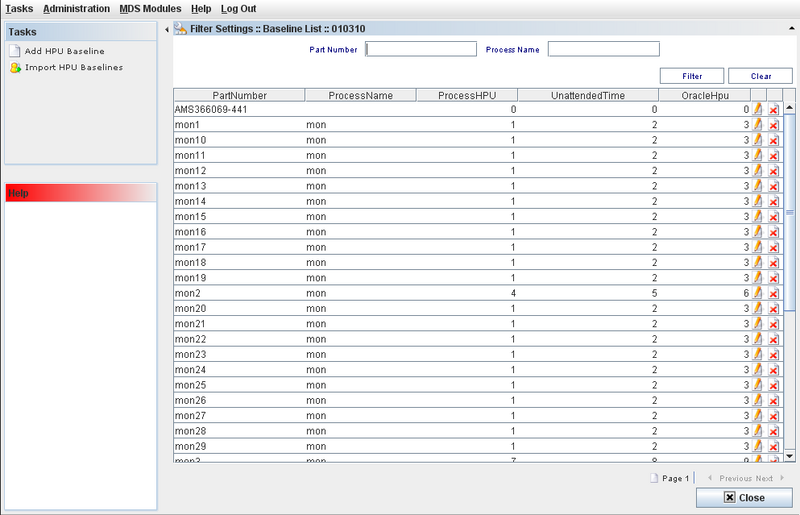

Figure 4: HPU Baselines Manage Screen

This screen allows the user to:

- Add HPU Baselines;

- Import HPU Baselines;

- Edit HPU Baselines;

- Delete HPU Baselines;

There is a general filter by Part Number or Process Name. To execute the filter, enter the data and click on Filter.

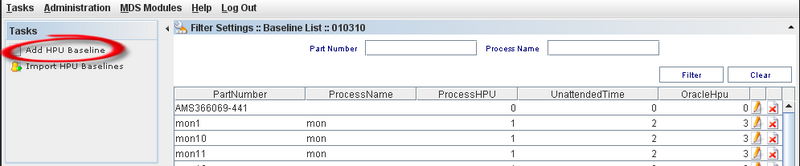

Adding HPU Baselines

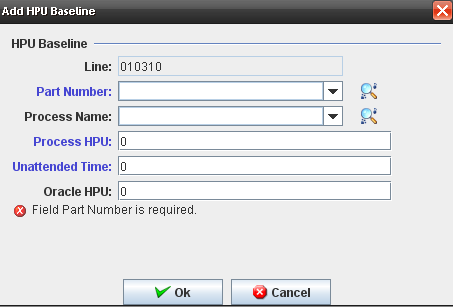

To add an HPU Baseline, follow the steps below:

1) Click on "Manage HPU Baselines" icon and click on "Add HPU Baseline" on the tasks panel.

Figure 5: Add HPU - Task Panel

A pop up to Add HPU Baselines is displayed:

Figure 6: Add HPU Baseline

The following fields are displayed and the user must enter data for the mandatory fields in blue:

* Line (Combo Box disabled) automatically selected, due to is the same line selected in the list.

* Part Number (Combo Box)

* Process Name (Combo Box)

* Process HPU (Text Field)

* Unattended Time (Text Field)

* Oracle HPU (Text Field)

ThePart Number and the Process Name are displayed in the drop down list from database.

Click on "OK" button after enter the mandatory fields to conclude.

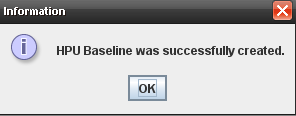

The application displays the following message:

Figure 7: Successful Message

The created HPU Baseline is displayed on the List screen.

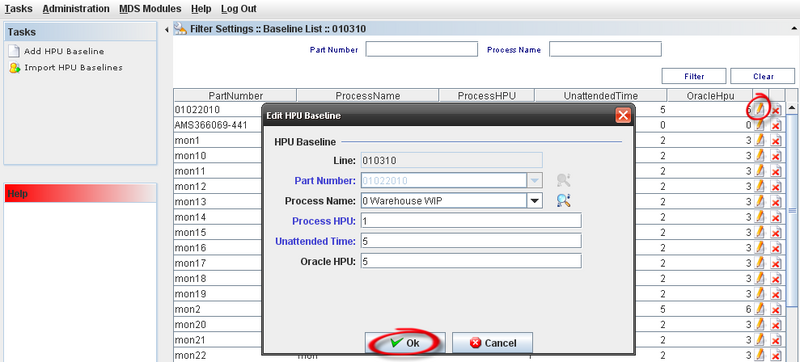

Editing HPU Baselines

To Edit an HPU baseline, the user must select an existing HPU line from the list and click onEdit icon.

The HPU Baseline window displays with the Baseline information. The process to edit is the same as to add baselines.

Figure 8: Edit HPU Baseline

Note: TheLine and Part Number fields can not be updated:

Click on "OK" button to conclude.

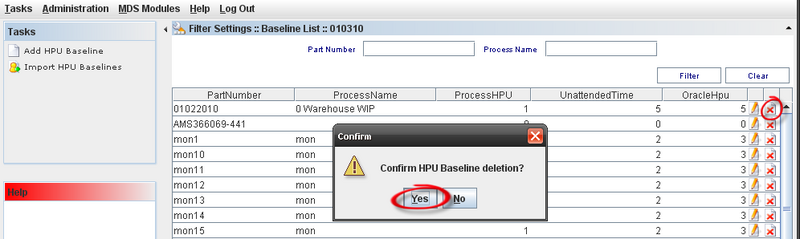

Deleting HPU Baselines

1) On the Baseline List, select an existing HPU Baseline and click on Delete Icon

Figure 9: Deleting HPU

Click on "OK" button;

A confirmation message displays. Click on Yes to conclude.

Importing HPU Lines

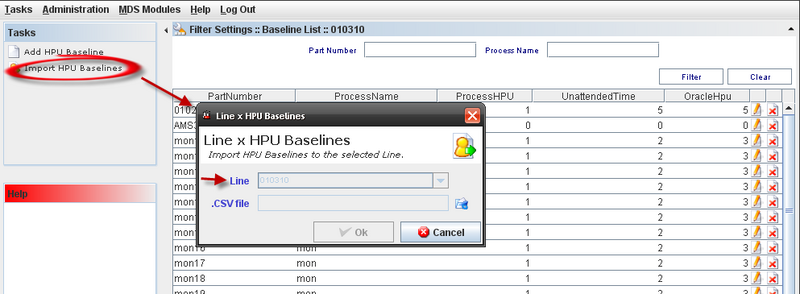

Go toSQC Configuration Maintenance. The user can import HPU data directly form this screen by clicking on Import HPU Baselines in the Task Panel or click on "Manage HPU Baselines" icon.

Figure 10: Manage HPU Baseline

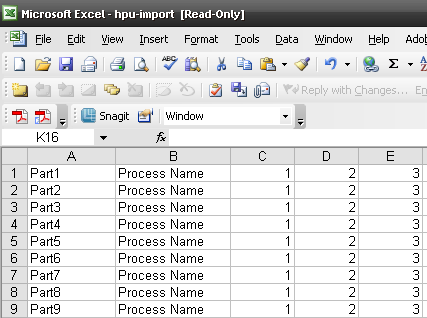

Figure 11: .CSV File Model

The .CSV file layout must be: Part Number, Process Name, Process HPU, Unattended Time and Oracle HPU.

Figure 12: Import HPU Baselines

2) Click on "Import HPU Baselines" on the task on panel. The screen to import Baselines for Line is displayed with the following fields:

* Line (Combo Box disabled)

*.CSV File (Open Browser button displayed beside this field to select the path where the file is located in).

3) Click on "Open Browser" icon and select the .CSV file and click on "OK".

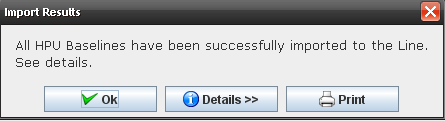

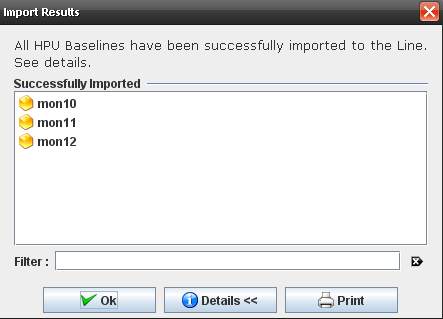

The "Report Results" screen is displayed with the following message: "All HPU Baselines have been imported to the line successfully. See Details"

Figure 13: Report Result

To see the message details, click on "Details" button.

Figure 14: Import Details

All part numbers are listed as "Successfully Imported" and all the HPU Baselines are displayed in the Baseline's list with exactly the same data from the .CSV file.

Printing HPU Lines

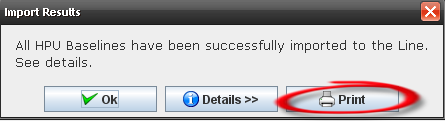

To print HPU Lines, go to MDS Client > SQC Configuration Maintenance and click on "Manage HPU Baselines" icon for the line.

1) Click on "Import HPU Baselines" on the task panel and click on "Open Browser" icon and select the .CSV file. Click "OK".

2) Click on "Print" button.

Figure 15: Print HPU Baselines

A report is generated:

Figure 16: Generated Report

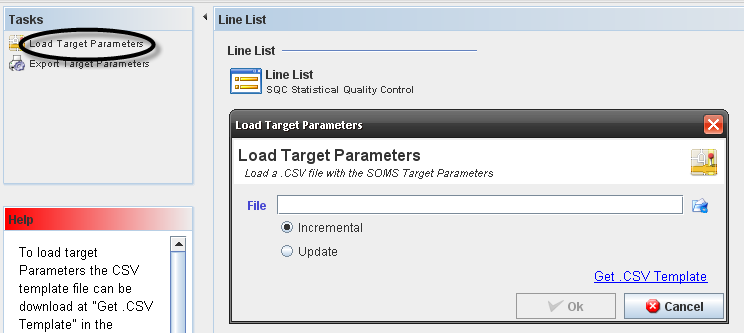

Load Target Parameters

To Load Target Parameters, go to MDS Client > SQC Configuration Maintenance and click on "Load Target Parameter" in the Tasks panel.

Figure 17: Load Target Parameters

To load target Parameters, the CSV template file can be download at "Get .CSV Template" in the "Load Target Parameters" pop up.

The Import process can run on the following ways:

- Incremental: will only add the new target tables and update the values.

- Update: will delete the current data and load the target data as is on the CSV file.

Following the .CSV file template:

Part Number,Family,Process,Process

Group,TargetYield,TargetTPhr,TargetDPMO,TargetCycleTime,TargetHPU,ResourceHr

STRING(50)x,STRING(50)x,STRING(30)x,STRING(50)x,DECIMAL(999.99)+,INTEGER(2147483647)+,DECIMAL(99999.99)+,

DECIMAL(99999.99)+,DECIMAL(99999.99)+,DECIMALDECIMAL(99999.999999)+

First line: field name

Second line: field type ("x" means at least one must be filled out by line - the key, "+" means one or more fields must be filled out - the targets)

Third to last line: target values - consumed from the higher level to deeper, ex:

1) If a target is set only for a Mfg Line, only the "key" column Mfg Line must be filled out and the target values

2) If a targets is set for a Process on a specific Mfg Line only the "key" columns Mfg Line and Process must be filled out and the target values

If there are more than one target configuration for a specific "key" the data will be loaded but the reports can use both - please avoid that with a good organization on the CSV file.

The Import task does not validate if the data is correct on the CSV file, i.e. if the Part Numbers or Mfg Line exists on the MDS tables - please make sure all data set is already configured on MDS tables.

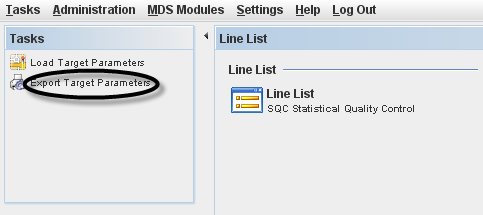

Export Target Parameters

The Export Target Parameters will export the previous loaded .CSV file tha contain the project parameters. This file is generated fro Nagios system.

Figure 18: Export Target Parameter

These parameters are loaded to MDS Client and will be handled in the MESR.

To export target parameters, click on Export Target Parameters in the Tasks panel, select the .CSV file and the path to save de file and click on Save.

Labor Tracking Maintenance

Labor Tracking Introduction

A new module was developed to allow users login labor and absence hours. It is used to control the employees work and when the employee is not working. A report can be generated with the result.

- Labor Tracking: allow users to Clock In and Clock Out labor or absence hours

- Labor Tracking Maintenance: only Supervisors can access and change employee entries

- New commands to clock in and clock out labor: “!!2clockin” and “!!2clockout”

Labor Tracking Functionalities

This chapter teaches how the user manages the Labor Tracking module. It displays all functionalities and actions that can be performed by users and supervisors.

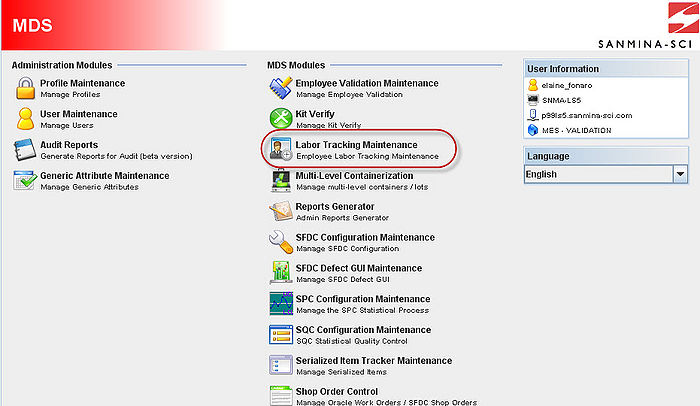

To access the Labor Tracking access the MDS Client and click on Labor Tracking Maintenance in the MDS Modules list.

Figure 1: MDS Client Modules

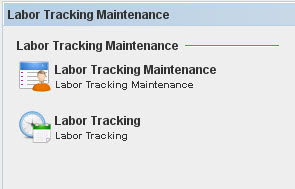

The Labor Tracking Maintenance main screen is displayed:

Figure 2: Labor Tracking Sub-modules

Select a Labor Tracking sub-module to maintain.There is an integration with the SFDC system that allows users to use !! commands.

NOTE: Just Supervisor users have access to Labor Tracking Maintenance.

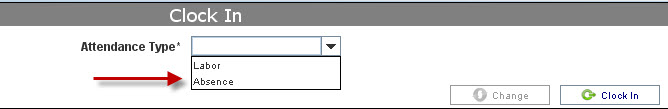

Labor Tracking

This screen allows the user to log the worked hours and absences. Follow the steps below to Clock In.

1. Click on Labor Tracking Sub-module;

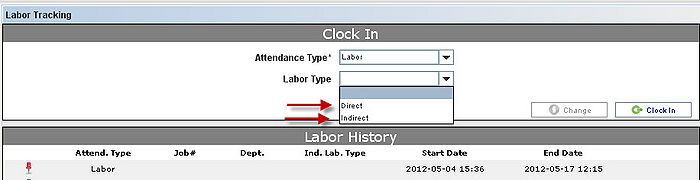

2. Select the Attendance Type:

Figure 3: Attendance Type

A) Absence: to log the labor absence hours.B) Labor: to log the employee worked hours.

3. Selecting Labor, select the Labor Type:

Figure 4: Labor Type

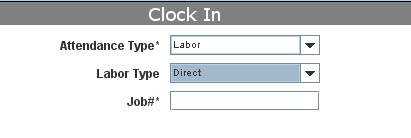

- Direct Attendance: for specific activity. For this labor type, enter the job# (work order for example);

Figure 5: Direct Labor Type

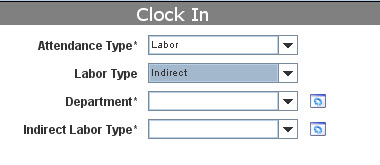

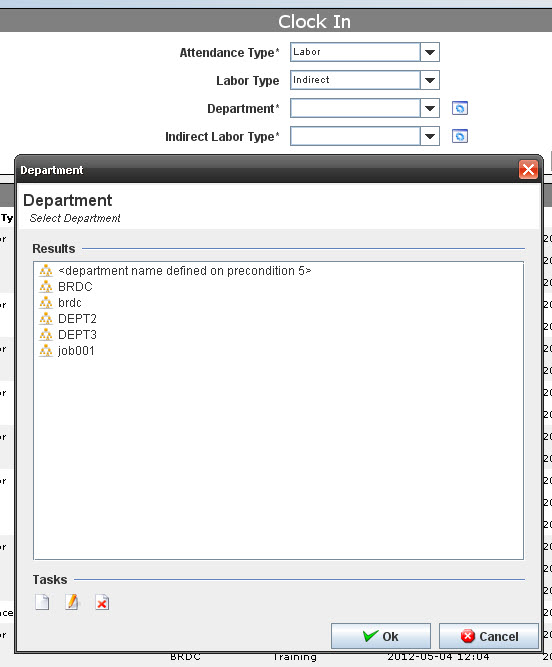

B) Indirect Attendance: for generic activity. For this labor type, select the Department and the Indirect Labor Type from the drop-down list;

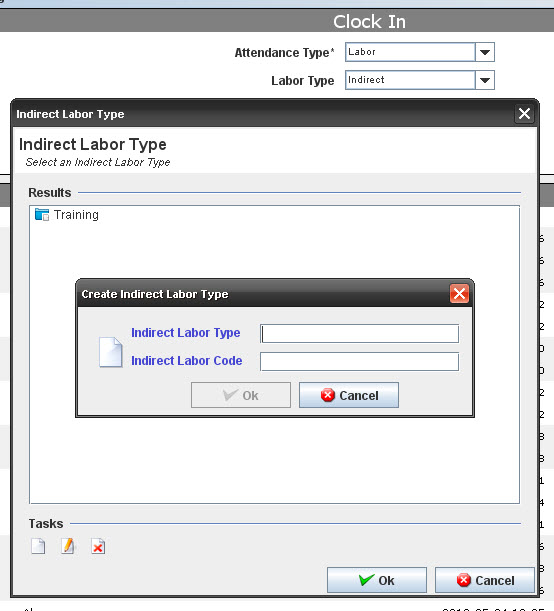

Figure 6: Indirect Labor Type

Selecting Indirect Attendance, select the Department and Indirect Labor Type from drop down list. It is possible to create, edit or delete Department and Indirect Labor Type clicking on Manage icon.

Figure 7: Managing Department

Managing Department and Indirect Labor Type:

Figure 8: Indirect Labor Type

To manage the Indirect Labor Type (Add, Edit or Delete), click on the respective icons, fill the mandatory fields and click on OK.

4- Click on Clock In button. The select data will be displayed in the Labor History. If you need to change any value, select the value and click on Change button.

5- Click on Clock Out when you stop to work.

Labor Tracking Maintenance

This screen allows managing employee, adding labor and executing different filters in the Labor History.

Filter

To filter, the user needs to fill the available mandatory fields and click on Filter.

Figure 9: Filter Settings

The results are displayed in the Labor History.

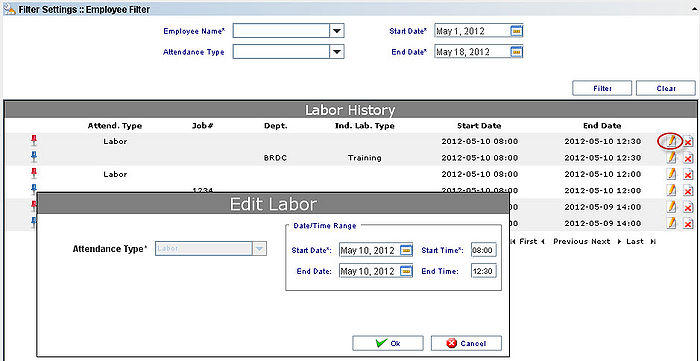

It is possible to Edit or Delete the Labor Entered by clicking on the Delete/Edit icons:

Figure 10: Edit Labor

The supervisor is able to update just the Data/Time range. It is not allowed to update the Attendance Type.

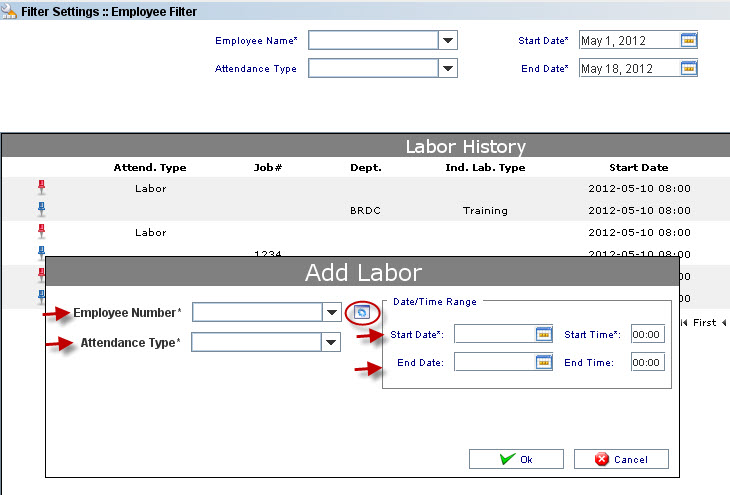

Add Labor

This screen allows the supervisor log the work hours to the employee. In addiction it is possible to maintain the Employee#, Department and Indirect Labor Type if Indirect Attendance were chosen.

Click on Cancel to cancel the action.

To Add Labor, click on Add Labor task in the Tasks panel. The screen to add Labor is displayed:

Figure 11: Add Labor

Update the necessary data and click on Ok button.

Click on the maintenance icon to manage employee numbers if necessary.

The difference between Add LDAP and Non LDAP user is that the LDAP user is fetching in the Sanmina database, so it is necessary to fill the HR Number.

After enter the Data to add the labor, the result is displayed in the Labor History.

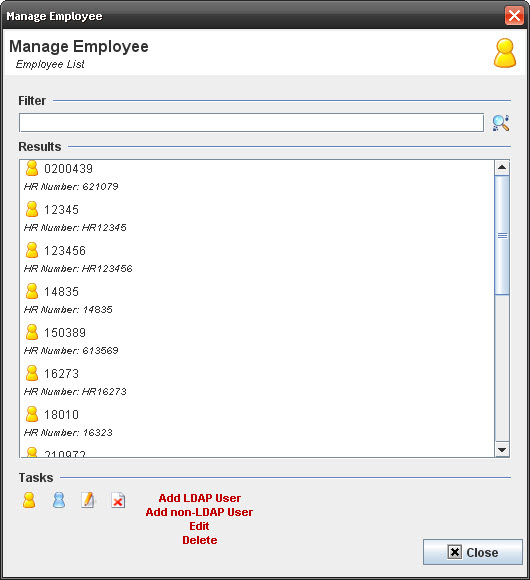

Manage Employee

Figure 12: Manage Employee

From this screen the supervisor is able to Add LDAP and non-LDAP users edit and delete users.1. To add an employee from web service, just select the user and click on Ok button.2. To add a non LDAP user, click on Add non LDAP User icon, enter the employee# and click on Ok button.3. To edit an user, select the user, click on Edit icon, update the employee# and click on Ok button;4. To delete a user, select the user and click on Delete icon. Click on Yes to complete the action.

Labor Tracking – Using SFDC Commands

The clockin command is run at a data collector at any time after the operator logs in.

It is run as a !!2 command, which means that it is entered at the Serial Number prompt.

If an operator is already clocked in, running the command again will automatically end the previous labor record, and begin a new record.

The format of the command is:

!!2clockin.labor_type.labor_data

labor_type labor_data

1 (direct labor) job_number (shop order)

2 (indirect labor) partment

For example, to start a labor record for Shop Order 100501, scan:

!!2clockin.1.100501

The clockout command is run at a data collector at any time after the operator logs in when there is an open labor record.

It is run as a !!2 command, which means that it is entered at the Serial Number prompt.

The format of the command is:

!!2clockout

Algorithm Tool

Introduction

The Shop Floor Data Collection System (SFDC) communicates interactively with the Customer Order Processing System (COPS), and Statistical Process Control/Statistical Quality Control (SPC/SQC). The Manufacturing Data System (MDS) makes the communication between these systems possible.

SFDC provides real-time information used by SPC/SQC and MESWeb to create quality control reports. The data configuration for SFDC PC is handled within the Manufacturing Data System (MDS), which is a complete factory automation system. The SFDC System uses barcode scanning, both manual and automated, to monitor and control a single product line or an entire plant. SFDC Configuration collects data, provides analysis, maintains unit histories, and controls product movement on the manufacturing floor.

The system provides Access Control between the modules of the application, including the functionalities of each screen. The current version has an SFDC Configuration page which provides access to all sub modules pages and its functionalities (view, add, edit, delete, print and generate output file.

Set up SFDC Configuration

1. To access the SFDC Configuration, click on SFDC Configuration in the menu. The main SFDC Configuration and sub modules page is displayed:

Figure 1: MDS Portal – SFDC Configuration Sub modules

NOTE: A user only has access to the modules assigned to his/her profile.

Algorithm Tool

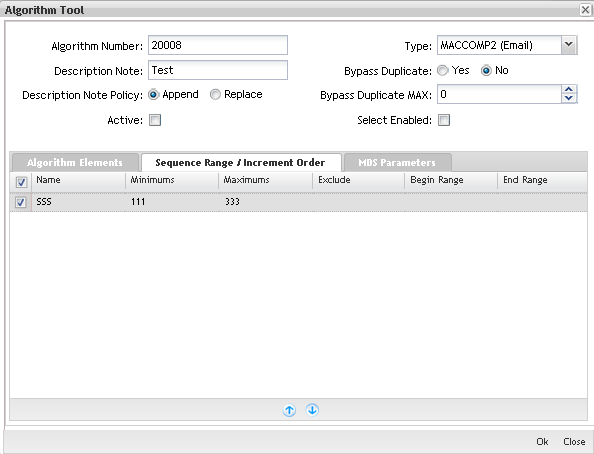

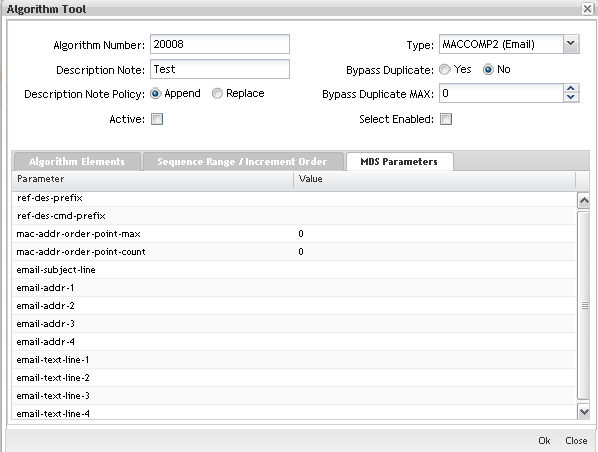

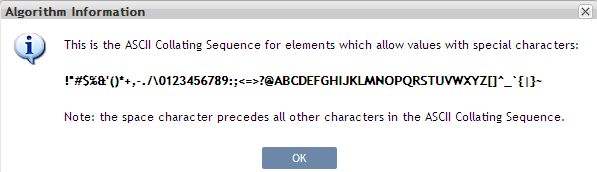

The Algorithm Tool provides the ability to create and modify serial number algorithms. The Algorithm Tool adheres to the format used by Sanmina customers and engineers when writing specifications for serial number algorithms. It is an integrated with the SFDC and generates serial numbers (Shop Order and Containerization modules) and MAC Addresses.

The main Algorithm Tool functionality is to trigger actions according to MDS parameters.

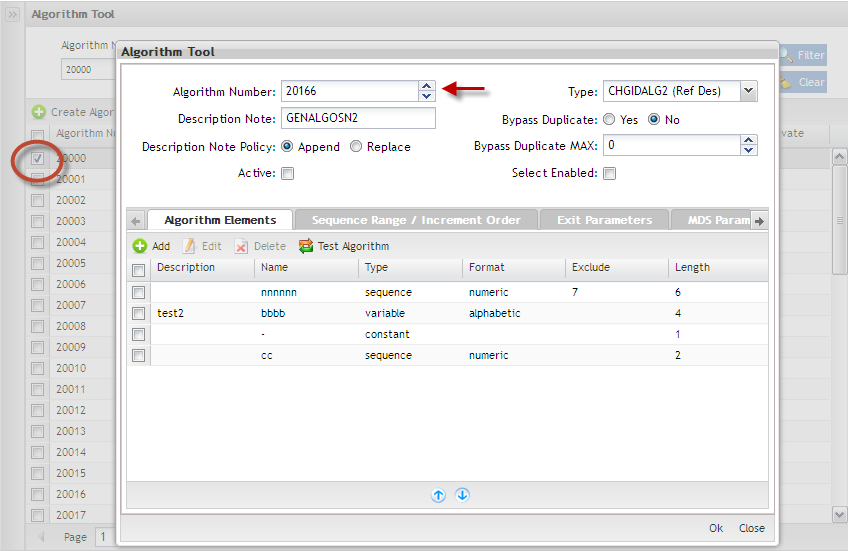

Algorithm Tool Main Page

To access the Algorithm Tool, click on Algorithm Tool in the SFDC Configuration Maintenance menu. The Algorithm Browser displays:

Figure 2: Algorithm Tool Browser

This Algorithm main page displays all defined algorithms. The user is able toCreate Edit, Copy, Delete, Import and Export andView the file or View Customcode record. See the next topics for further information.

The filter feature allows filtering results by algorithm number range, description and active status. When Type displays All it means that algorithms not created by the tool are displayed in the list. Enter the desired filter criteria and click on Filter. Click on Clear to clear the filter fields.

Creating Algorithms

Note: As a general rule, when creating customer defined serial number algorithms, see customer serialization documentation to ensure correct algorithm format and functionality. This avoids the risk of generation and use of incorrect serialization formats.

1- To create algorithms, click on Create Algorithm on main menu.

Figure 3: Create Algorithm

The Algorithm maintenance window displays:

Figure 4: Algorithm Maintenance

2- The Algorithm Number available at database is displayed. If necessary, it is possible to enter a special algorithm number.

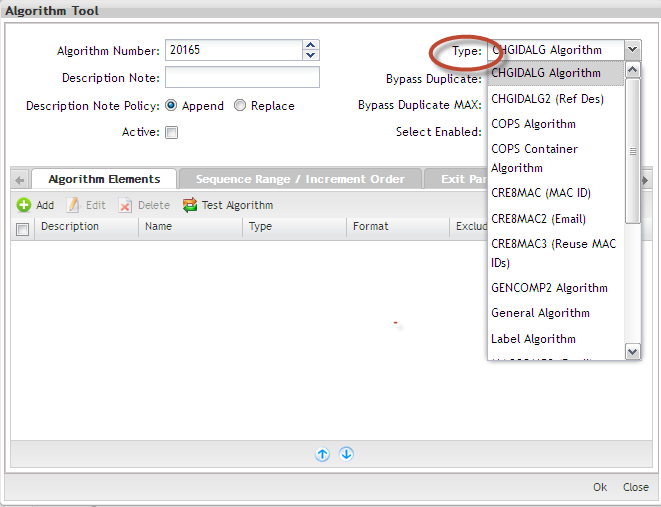

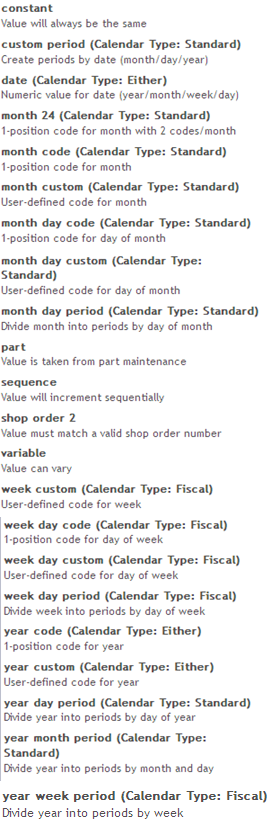

3- Choose the algorithm type that determines how the algorithm will be used in production by selecting the algorithm type in the Type drop down list;

Figure 5: Algorithm Types

The Algorithm Tool currently supports the following algorithm types:

- Shop Order Algorithm - This algorithm type is used to generate serial numbers from the SFDC Shop Order Release screen in MDS.

- SFDC Container Algorithm - This algorithm type is used to generate serial numbers from the SFDC Container menus in MDS.

- COPS Algorithm - This algorithm type is used to generate serial numbers from the COPS menus in MDS.

- GENCOMP2 Algorithm - This algorithm type is used to generate serial numbers using the GENCOMP2 command from SFDC.

- CRE8MAC (MAC ID) Algorithm - This algorithm type is used to generate serial numbers using the CRE8MAC command from SFDC.

- Label Algorithm - This algorithm type is used to generate serial numbers for labels. The Label algorithm type requires that a particular label be programmed by IT to call the specific serial number algorithm using this algorithm type.

- Non Serial Nbr Algorithm - This algorithm type is used when no serial is generated.

- CRE8MAC2 - sends e-mails alerting the user when the MAC ADDRESS quantity is low.

- General - created for general purposes.

- Skeleton Algorithm - to be used in the release process in the Shop Order Module.

- CHGIDALG Algorithm - This algorithm type is used to generate serial numbers using the CHGIDALG command from SFDC.

- CHGIDALG2 (Ref Des) - This algorithm type is used to generate serial numbers using the CHGIDALG2 command from SFDC. The reference designator parameter is passed to the CHGIDALG2 command from the MDS Parameters in the Algorithm Tool.

- COPS Container Algorithm - This algorithm type is used to generate serial numbers from the COPS Container menus in MDS.

- CRE8MAC3 (Reuse Mac IDs) - This algorithm type is used to generate serial numbers using the CRE8MAC3 command from SFDC. The CRE8MAC3 command sends e-mails alerting the user when the MAC ADDRESS quantity is low. The CRE8MAC3 command also seeks out ranges of serial numbers that have not yet been generated and assigned.

- MACCOMP2 (Email) - This algorithm type is used to generate serial numbers using the MACCOMP2 command from SFDC. The MACCOMP2 command sends e-mails alerting the user when the MAC ADDRESS quantity is low.

- Send Serial File Algorithm - This algorithm type is used to generate serial numbers using the SENDSERIALFILE command from SFDC. The SENDSERIALFILE command sends a file that lists the generated serial numbers to users. The SENDSERIALFILE command also sends e-mails alerting the user when the serial number quantity is low.

An existing algorithm may not be changed to a different algorithm type under the following conditions:

- If the algorithm has already been used in production. This condition can be overridden by setting the latest serial number to blank in the Latest SN Menu of the Testing Facility.

- If the latest serial number has already been set to a non-blank value in the Latest SN Menu of the Testing Facility. This condition can be overridden by setting the latest serial number to blank in the Latest SN Menu of the Testing Facility.

A Shop Order algorithm type may not be changed to a different algorithm type under the following conditions:

- If the algorithm definition contains an element where the Variable Length attribute is set to "yes".

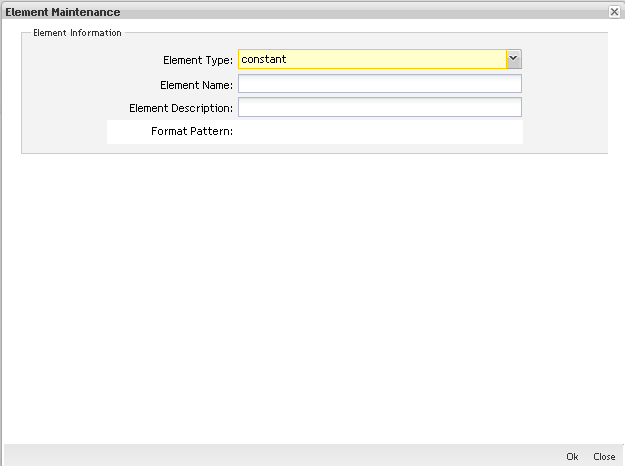

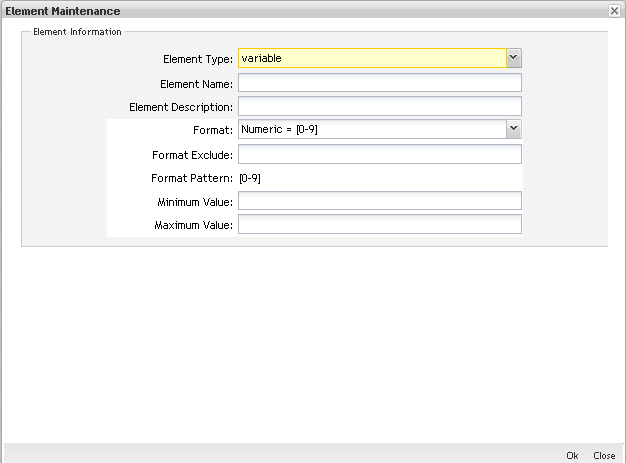

- If the algorithm definition contains an element where the Previous Must Match Current attribute is set to "yes".

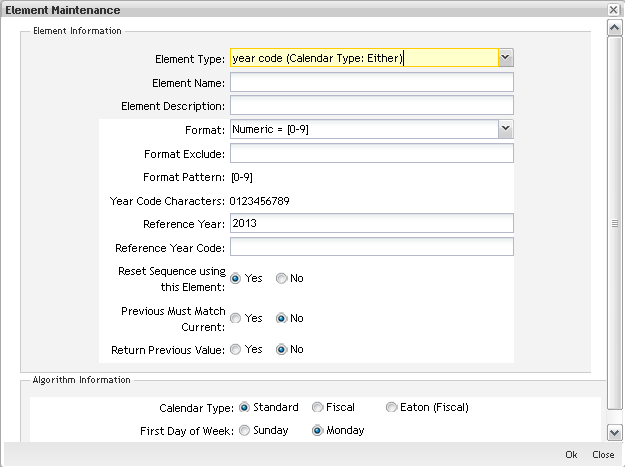

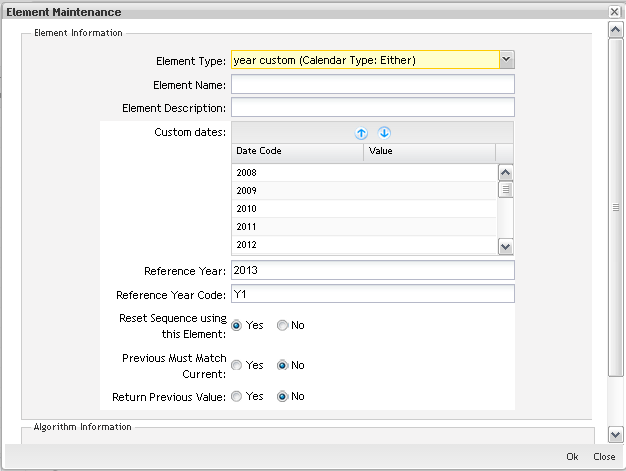

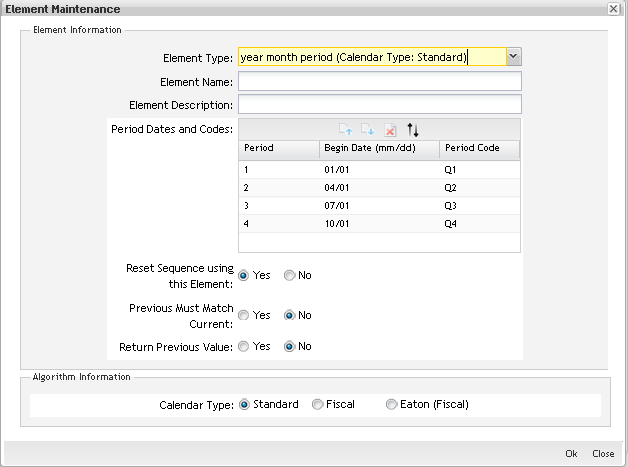

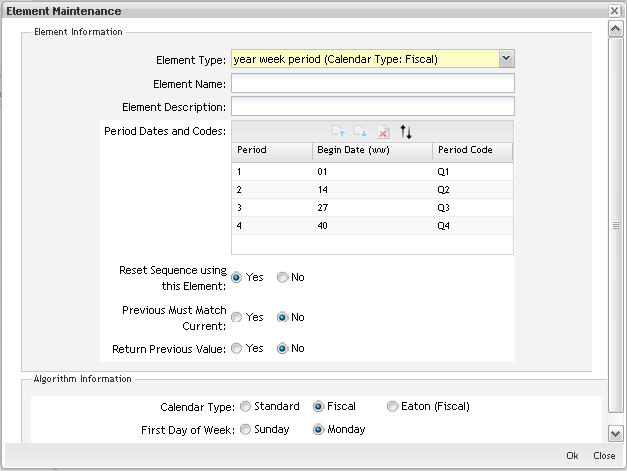

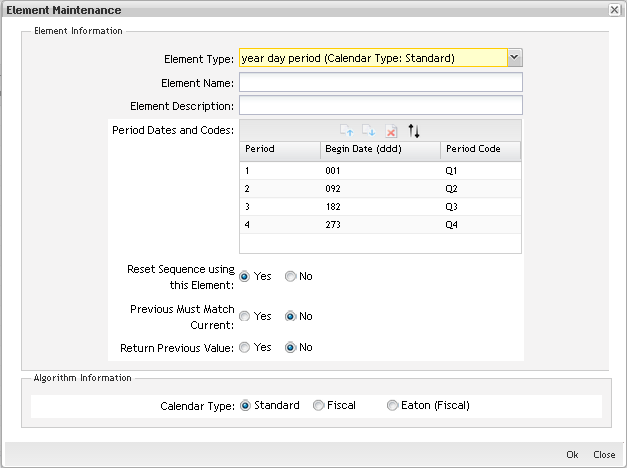

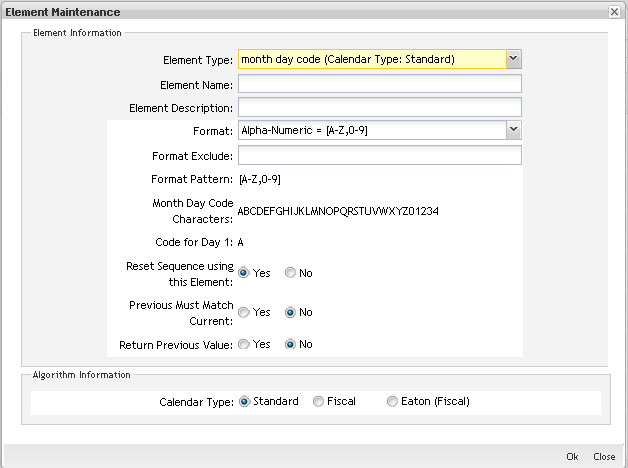

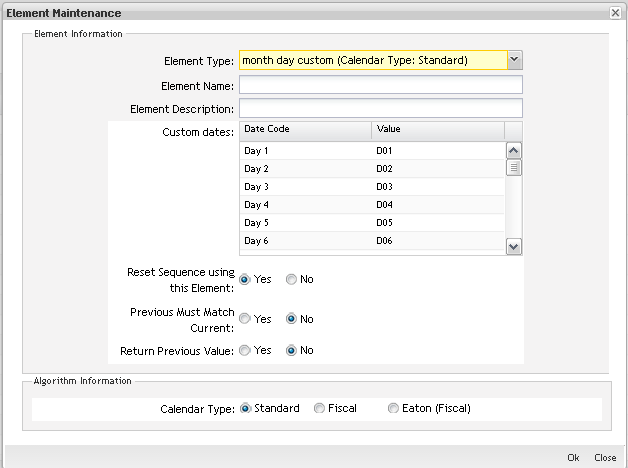

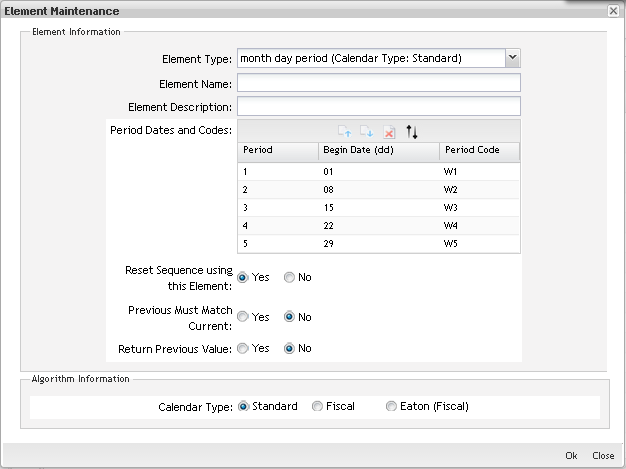

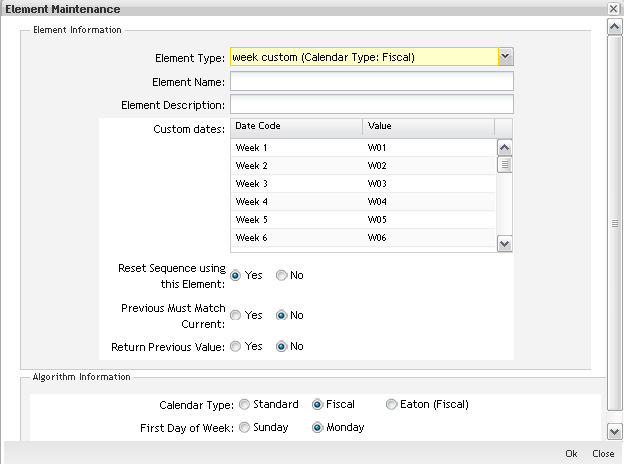

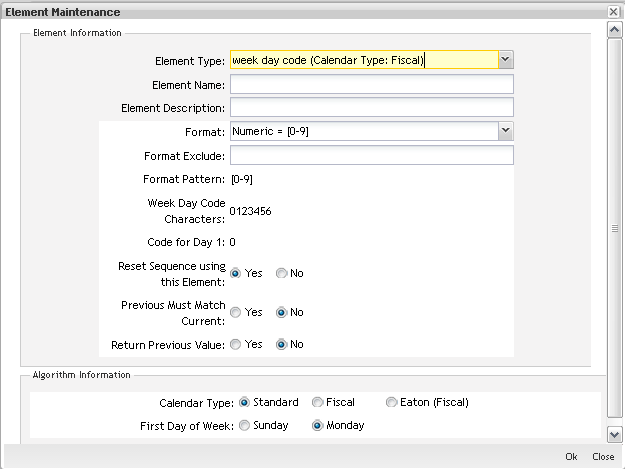

- If the algorithm definition contains an element where the Return Previous Value attribute is set to "yes".