Difference between revisions of "42Q-MES0161 Material Allocation"

| (One intermediate revision by the same user not shown) | |||

| Line 12: | Line 12: | ||

| | ||

| − | |||

| − | '''Material Allocation''' is a functionality that provides users with the ability to create lots, allocate materials, and track the material by the location assigned to an MFG Line in specific locations. | + | = <span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation_.3F"><span class="mw-headline" id="What_Is_Material_Allocation"><span class="mw-headline" id="What_Is_Material_Allocation">What Is Material Allocation?</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| − | + | ||

| + | '''Material Allocation''' is a functionality that provides users with the ability to create lots, allocate materials, and track the material by the location assigned to an MFG Line in specific locations.[[File:Lot tracking Material Allocation.png|700px|Lot tracking Material Allocation.png]] | ||

| + | |||

Material allocation plays an important role in the initial stage of production planning. Without a good allocation of available material to order, companies might face a large amount of tardiness penalty associated with late completion, affecting customer satisfaction. | Material allocation plays an important role in the initial stage of production planning. Without a good allocation of available material to order, companies might face a large amount of tardiness penalty associated with late completion, affecting customer satisfaction. | ||

| − | |||

| − | |||

| | ||

| Line 66: | Line 65: | ||

| | ||

| − | |||

| − | Material Allocating is very important in the case of failures or recalls. For example, if an airplane fails and/or crashes, the pieces are found and the parts are put together to find out what could have possibly malfunctioned. Lot number identifies the parts of ingredients, as well as, labor and equipment records involved in the manufacturing of those parts. Inability to track important parts and/part numbers can be very crucial to a manufacturing business. Demonstrated below are some good key questions to ask when in the event of needing to know information concerning a part. | + | = <span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation"><span class="mw-headline" id="Example_of_Material_Allocation:"><span class="mw-headline" id="Example_of_Material_Allocation:"><span class="mw-headline" id="Example_of_Material_Allocation:"><span class="mw-headline" id="Example_of_Material_Allocation:"><span class="mw-headline" id="Example_of_Material_Allocation:"><span class="mw-headline" id="Example_of_Material_Allocation:"><span class="mw-headline" id="Example_of_Material_Allocation:">Example of Material Allocation</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| − | + | ||

| − | | + | Material Allocating is very important in the case of failures or recalls. For example, if an airplane fails and/or crashes, the pieces are found and the parts are put together to find out what could have possibly malfunctioned. Lot number identifies the parts of ingredients, as well as, labor and equipment records involved in the manufacturing of those parts. Inability to track important parts and/part numbers can be very crucial to a manufacturing business. Demonstrated below are some good key questions to ask when in the event of needing to know information concerning a part. [[File:Example of Material Allocation.png|700px|Example of Material Allocation.png]]<br/> |

| | ||

Latest revision as of 14:35, 3 August 2021

Material Allocation

Factories are complex, busy places with a lot of systems, machinery, and processes in place. Technology plays a key part in the manufacturing world. We see the benefits of it clearly through lot traceability — you can streamline your supply chain and have confidence in all of the steps along the way.

The inventory management system allocates a specific quantity of materials, as determined by purchasing workers, to meet customer demand. Allocating material to a sales order does not remove the quantity from inventory. The allocation creates a projection of the amount of material the company will need to meet the current demand or sales orders.

Contents

What Is Material Allocation?

Material Allocation is a functionality that provides users with the ability to create lots, allocate materials, and track the material by the location assigned to an MFG Line in specific locations.![]()

Material allocation plays an important role in the initial stage of production planning. Without a good allocation of available material to order, companies might face a large amount of tardiness penalty associated with late completion, affecting customer satisfaction.

Benefits of Material Allocation

- Improve material allocation efficiency: Maximize the utilization of materials to meet the company’s objective in the material allocation

- Reduce material storage cost: Minimize the costs of storage with material arrival date estimation for a just-in-time strategy

- A clear picture on inventory status: Decrease the load on bottleneck production units by utilizing available material

How Material Allocation Operates within 42Q

Please refer to the Production Shop Order Prioritization documentation for information concerning Material Allocation and how it is used within the 42Q portal.

How can Material Allocation Help Your Business?

Inventory Control

With Material Allocation, you can have stronger inventory control processes in your manufacturing facilities. You can track which materials are being used and in what products easily. You can identify which raw materials need to be used if there is an expiration threat as well. If there is a problem in one of the groups, material allocation makes identifying the problem lot significantly smoother. This means your inventory control processes will be tighter and transparent.

Visibility

Material Allocation provides enhanced visibility over multiple levels of a product. You can trace items being shipped into your manufacturing facility and through its journey, making suppliers more accountable than ever. With this visibility, you can also compile fast analyses to show you what’s going on at the ground level. This digital visibility reduces the margin of human error.

Better Support with Suppliers

There is a much greater insight into the quality of your final products. Since you’ve tracked raw materials from each of the suppliers, you can use this information to assess which suppliers yielded higher quality. You can build relationships with your preferred suppliers, fine-tune orders, put in special requests and negotiate better deals when you have the information to support your decisions.

Inventory Management

Attempting to track your lots manually is a futile effort that takes a lot of time and runs a greater risk of human error. Automate material allocation with online inventory management software so that everything is managed in real-time. With inventory software, you can enter information like barcodes and lot numbers and it will populate across every single item in the lot so that there are fewer chances of duplicating or missing information; everything in the system is accurate and trustworthy.

Having a good sufficient tracking system plays a vital role in material allocation to allow the ability to set controls in place in the event that something does happen or goes wrong. Within the ERP system, keeping track of part numbers is automated through the use of a lot or serial numbers, and barcoding and scanning information for better quality control in inventory management.

Example of Material Allocation

Material Allocating is very important in the case of failures or recalls. For example, if an airplane fails and/or crashes, the pieces are found and the parts are put together to find out what could have possibly malfunctioned. Lot number identifies the parts of ingredients, as well as, labor and equipment records involved in the manufacturing of those parts. Inability to track important parts and/part numbers can be very crucial to a manufacturing business. Demonstrated below are some good key questions to ask when in the event of needing to know information concerning a part.

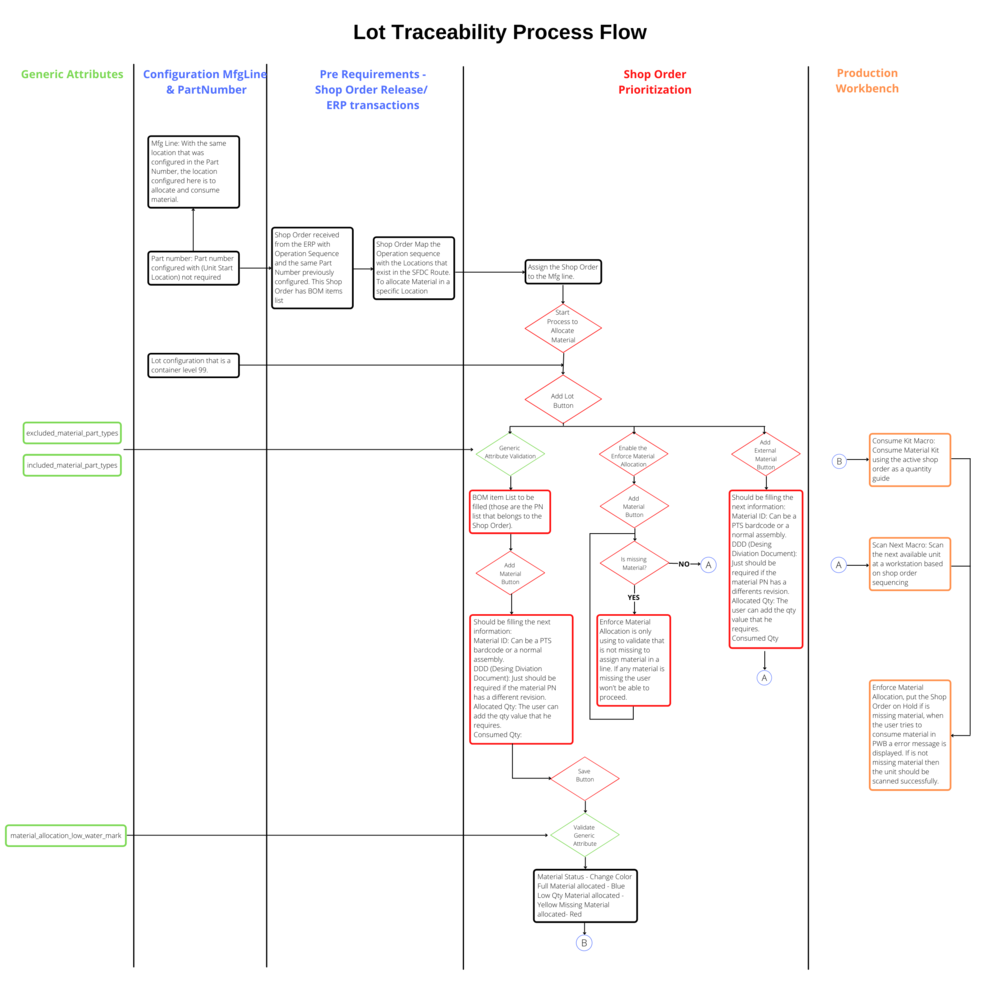

Material Allocation & Lot Traceability -- Process Flow

This is the general process flow for Material Allocation for Shop Order Prioritization.