Difference between revisions of "42Q-MES0167 SAP Adapter"

| (64 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | <small>[[42Q_Cloud-Based_MES/MOMS|42Q Home]] > [[Tools|Tools]] > SAP Adapter</small> | + | <small>[[42Q_Cloud-Based_MES/MOMS|42Q Home]] > [[Tools|Tools]] > [[42Q_SAP_Adapter|42Q SAP Adapter]] > SAP Adapter</small> |

| | ||

| Line 7: | Line 7: | ||

| | ||

| − | <center>'''Tools'''</center> <center>'''SAP Adapter'''</center> <center>''' Version | + | <center>'''Tools'''</center> <center>'''SAP Adapter'''</center> <center>''' Version MES15.79'''</center> <center>'''Revision G1'''</center> |

| | ||

| − | + | <center> </center> <center style="text-align: left;"> </center> | |

| − | | + | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| − | |||

| − | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span> = | ||

<center style="text-align: left;"> | <center style="text-align: left;"> | ||

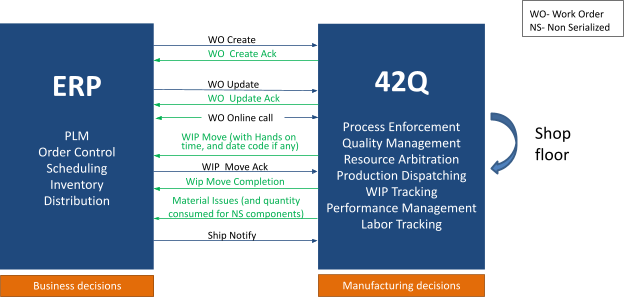

The '''SAP Adapter''' is a middleware software that has been developed for customers to seamlessly integrate their SAP systems with 42Q. This adapter can be installed in the customer’s SAP system in order to allow SAP users to monitor and iterate with 42Q. | The '''SAP Adapter''' is a middleware software that has been developed for customers to seamlessly integrate their SAP systems with 42Q. This adapter can be installed in the customer’s SAP system in order to allow SAP users to monitor and iterate with 42Q. | ||

| Line 38: | Line 36: | ||

| | ||

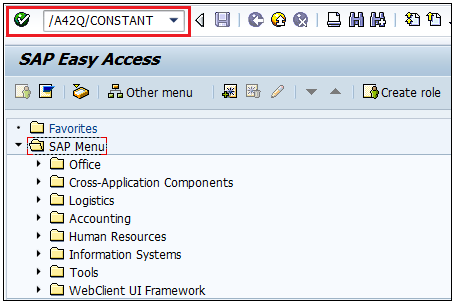

<ol start="2"> | <ol start="2"> | ||

| − | <li>On the new window, set up the '''Org. Id''' (Organization code) and the Customer (Customer code).</li> | + | <li>On the new window, set up the '''Org. Id''' (Organization code) and the '''Customer''' (Customer code).</li> |

</ol> | </ol> | ||

| Line 46: | Line 44: | ||

<ol start="3"> | <ol start="3"> | ||

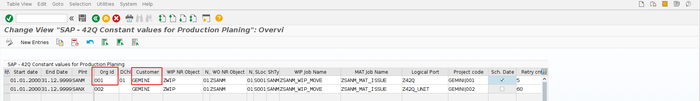

<li>Now it’s time to set up the '''BOM’s''' information, enter the next command: '''CS02''', and then press '''Enter'''.</li> | <li>Now it’s time to set up the '''BOM’s''' information, enter the next command: '''CS02''', and then press '''Enter'''.</li> | ||

| − | <li>Click on the Header icon: [[File:SA Header Icon.png|30x30px|SA Header Icon.png]]</li> | + | <li>Click on the '''Header''' icon: [[File:SA Header Icon.png|30x30px|SA Header Icon.png]]</li> |

<li>Click on the '''SAP-42Q Interface''' tab.</li> | <li>Click on the '''SAP-42Q Interface''' tab.</li> | ||

</ol> | </ol> | ||

| Line 56: | Line 54: | ||

| | ||

<ol start="6"> | <ol start="6"> | ||

| − | <li>In the SFDC System field, click on the | + | <li>In the '''SFDC System''' field, click on the icon: [[File:SA Search Icon.png|30x30px|SA Search Icon.png]], select the value '''MES''' and then click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

| − | <li>In the Interface Type field, click on the icon [ | + | <li>In the '''Interface Type''' field, click on the icon: [[File:SA Search Icon.png|30x30px|SA Search Icon.png]], select one of the following values:</li> |

| + | </ol> | ||

| + | |||

| + | *'''DEFAULT:''' Use this value if you want to send '''WO Header''', '''WO Route''', '''Flex field''', or '''ATO Details''' (if applicable) to 42Q. | ||

| + | *'''SYS-BUILD:''' Use this value if you want to send '''WO Header''', '''WO Route''', or '''BOM''' to 42Q. | ||

| + | <ol start="8"> | ||

| + | <li>Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> | ||

</ol> | </ol> | ||

| − | + | '''<u>Note</u>:''' In the previous step 2, users set up the Organization code and Customer code, the purpose of these fields is to determine how the adapter will perform for each plant. | |

| − | + | | |

| − | + | | |

| + | </center> | ||

| + | = <span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order">Create a Work Order</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | ||

| − | + | | |

| − | + | ||

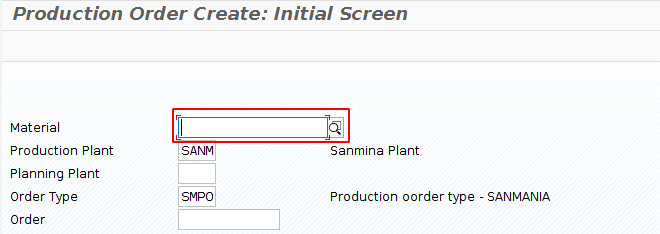

| − | + | #Enter the next command: '''CO01''', and then press '''Enter'''. | |

| − | + | #In the '''Material''' field, enter a '''Part Number'''. | |

| + | #Enter the '''Production Plant'''. | ||

| + | #Enter the '''Planning Plant'''. | ||

| + | #Enter the '''Order Type'''. | ||

| + | #Press '''Enter'''. | ||

| + | |||

| + | | ||

| + | |||

| + | '''Figure 5: Production Order Create''' | ||

| − | + | [[File:SA Production Order Create.png|SA Production Order Create.png]] | |

| − | < | + | <center style="text-align: left;"> </center> <center style="text-align: left;"> <ol start="7"> |

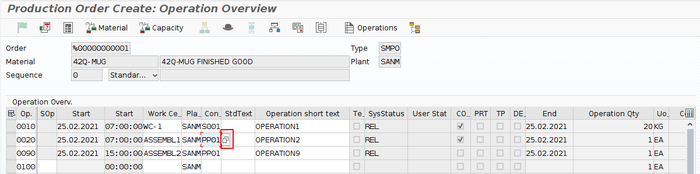

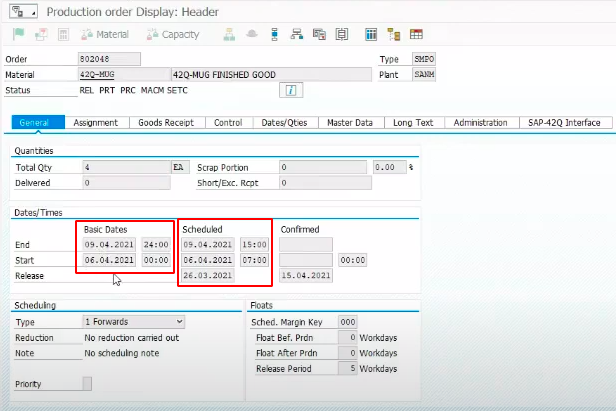

| − | < | + | <li>Set the '''Total Qty''', '''Start Date''', and '''End date'''.</li> |

| − | |||

| − | </li> | ||

</ol> | </ol> | ||

| | ||

| − | + | | |

| − | + | '''Figure 6: Work Order Creation''' | |

| − | + | [[File:SA Work Order Creation.png|700px|SA Work Order Creation.png]] | |

| + | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="8"> | ||

| + | <li>Click on the icon: [[File:SA Release Order Icon.png|30x30px|SA Release Order Icon.png]] to release the '''Work Order'''.</li> | ||

| + | <li>Click on the '''Save''' icon to save the Work Order. The work order will be sent to 42Q. The work order will be sent to 42Q. The order will be available on 42Q under Shop Order Control with ‘ERP’ status as checked.</li> | ||

| + | </ol> | ||

| − | + | Based on correct setups Work Order XML will include the following information: | |

| − | + | *WO Header | |

| + | *WO Production Version | ||

| + | *WO Routing and standard times for each operation (For sending standard time setup should be done correctly, see section nn for that) | ||

| + | *WO Component | ||

| − | + | | |

| − | + | | |

| − | + | | |

| − | + | = <span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation">Mapping an Operation</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | |

| − | + | Mapping of operation happens on 42Q when we map the operation/routing received from SAP to the process/routing on 42Q. If users want to map a particular operation to a location in the 42Q site | |

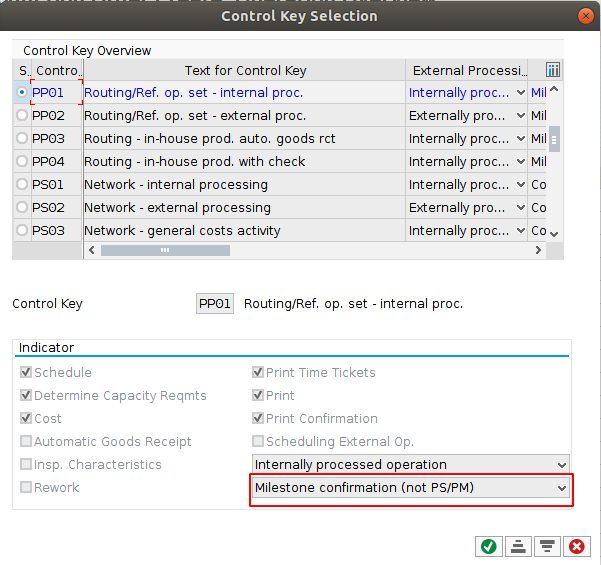

| − | # | + | #Enter the next command: '''CO01''' and then press '''Enter'''. |

| + | #Click on the '''Operation Overview''' icon: [[File:SA Operation Overview Icon.png|30x30px|SA Operation Overview Icon.png]] | ||

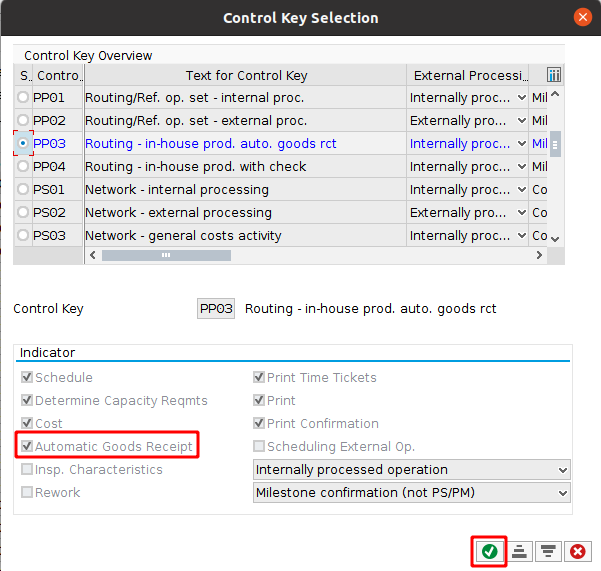

| + | #A new list of operations will be displayed, choose one operation and hover the mouse cursor over its corresponding '''Control Key''' field, when a hover icon appears next to this field, click on it. | ||

| − | + | | |

| − | Figure | + | |

| − | + | ||

| − | <li> | + | '''Figure 7: Component Overview''' |

| + | |||

| + | [[File:SA Component Overview.png|700px|SA Component Overview.png]] | ||

| + | <center style="text-align: left;"> <ol start="4"> | ||

| + | <li>A new pop-up window will appear, then in the last field in the lower right corner select the '''Milestone confirmation (not PS/PM)''' option.</li> | ||

| + | <li>Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] to save changes.</li> | ||

</ol> | </ol> | ||

| − | | + | |

| − | <ol start=" | + | |

| − | <li>Click on the icon [ | + | |

| − | <li>Click on the Save icon to save | + | |

| + | '''Figure 8: Control Key Selection''' | ||

| + | [[File:SA Control Key Selection.png|SA Control Key Selection.png]]</center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="6"> | ||

| + | <li>Click on the icon: [[File:SA Back Icon.png|30x30px|SA Back Icon.png]] to go back to the '''Production Order Create: Header'''.</li> | ||

| + | <li>Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]], then select '''Yes''' to save it, or select '''No''' or '''Cancel''' to abort.</li> | ||

| + | <li>A pop-up window will be displayed to show you the information of the recently mapped operation, finally, click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] to close the window.</li> | ||

</ol> | </ol> | ||

| + | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> | ||

| + | | ||

| − | | + | = <span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates">Monitor SAP updates</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| + | |||

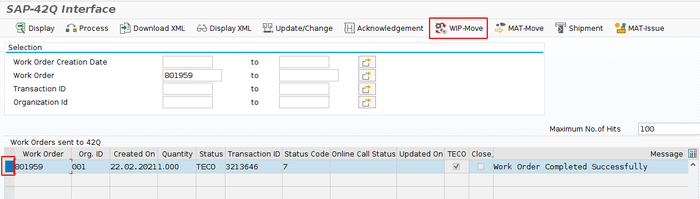

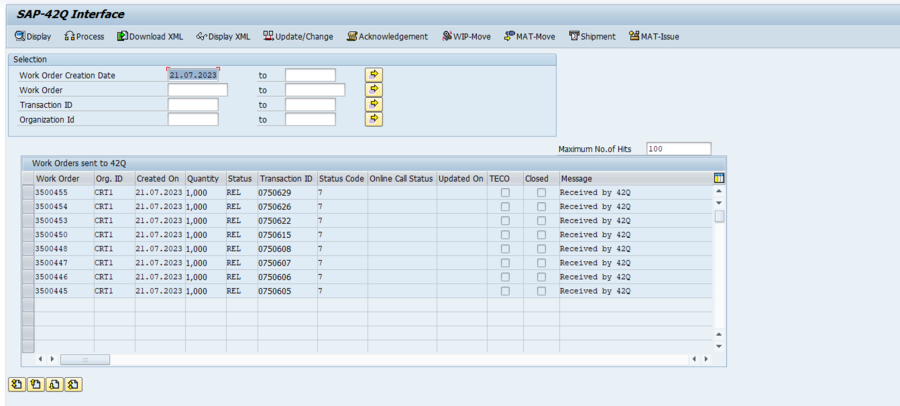

| + | If the users want to see all transactions between SAP and 42Q, such as '''Acknowledgement''', '''WIP-Move''', '''MAT-Move''', '''Shipment''', and '''MAP-Issue''', follow the next steps: | ||

| + | |||

| + | #Enter the next command: '''/A42Q/PROCESS '''(or '''ZQWO_PROCESS''', '''ZWO_PROCESS'''), and then press '''Enter'''. | ||

| + | #Users can see in the '''Message''' column if the information was received successfully by 42Q. | ||

| + | |||

| + | | ||

| + | |||

| + | | ||

| + | |||

| + | '''Figure 9: Work Order Transactions''' | ||

| − | + | [[File:SA Work Order Transactions.png|700px|SA Work Order Transactions.png]] | |

| − | + | | |

| − | + | == <span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change">Update / Change</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | |

| − | + | Users can view updates or changes made to a Work Order (e. g. changes in quantity) by following the next steps: | |

| − | + | #Click on the '''Update/Change''' button. | |

| + | #In the new window that will appear, users can see the data that was updated as well as a confirmation message, notifying that 42Q received the update successfully. | ||

| − | + | | |

| − | + | <br/> '''Figure 10: Work Order Updates-Changes''' | |

| − | + | [[File:SA Work Order Updates-Changes.png|700px|SA Work Order Updates-Changes.png]] | |

| − | < | + | <center style="text-align: left;"> |

| − | < | + | == <span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move">WIP-Move</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

| − | = <span class="mw-headline" id=" | + | |

| − | </ | + | When a unit is moved from one location to another in 42Q, a WIP move transaction is sent to SAP for the mapped locations, or status change. |

| − | </ | ||

| − | + | #Incremental wip moves (based on SAP operation mapping wit 42Q route) | |

| + | #Status change wip moves (rework status 25, 29 / scrap status 50, 55) | ||

| + | #Completion wip move (unit status 30) | ||

| − | + | | |

| − | + | Users can view Work Order '''WIP-Moves''' by following the next steps: | |

| − | # | + | #Select a row. |

| + | #Click on the '''WIP-Move''' button. | ||

| − | + | | |

| − | + | <br/> '''Figure 11: View WIP-Moves''' | |

| − | + | [[File:SA View WIP-Moves.png|700px|SA View WIP-Moves.png]] | |

| − | | + | |

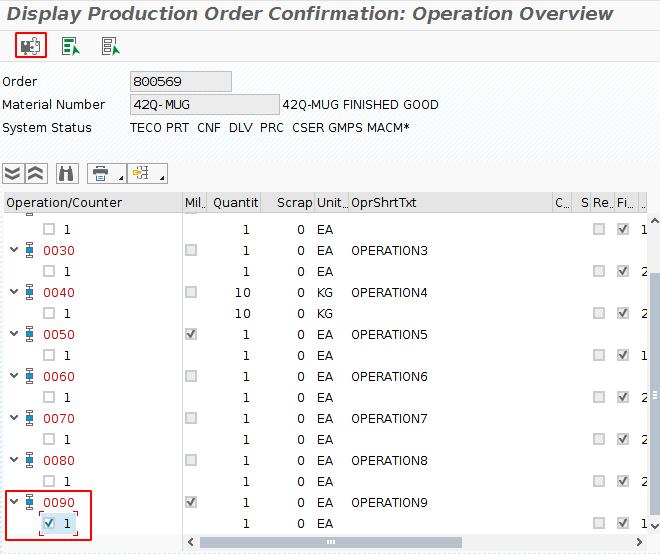

| − | <ol start=" | + | <ol start="3"> |

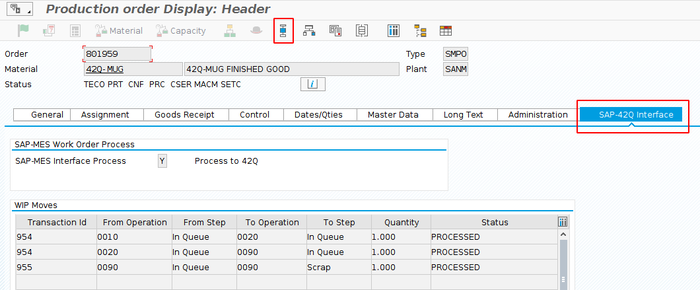

| − | <li>A new | + | <li>A new window will appear, users can see all WIP-Moves belonging to that specific Work Order, as well as all detailed information. To see the Production Order information from a specific WIP-Move, click on the Work Order number.</li> |

| − | |||

</ol> | </ol> | ||

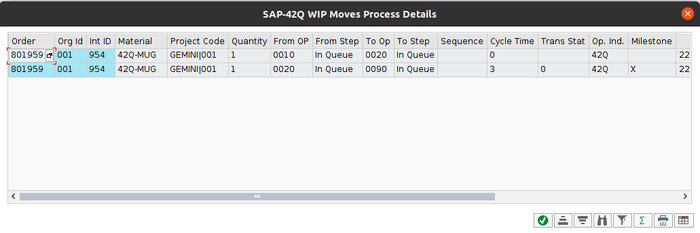

| − | + | <br/> '''Figure 12: Work Order WIP-Moves''' | |

| − | <ol start=" | + | [[File:SA Work Order WIP-Moves.png|700px|SA Work Order WIP-Moves.png]]<br/> <br/> <ol start="4"> |

| − | <li> | + | <li>To see the WIP-Moves transactions, click on the '''SAP-42Q Interface''' tab.</li> |

| − | + | <li>To see the overview of each operation, click on the '''Operation Overview''' button.</li> | |

| − | <li> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | </li> | ||

</ol> | </ol> | ||

| − | + | <br/> <br/> '''Figure 13: WIP-Moves Transactions''' | |

| − | + | | |

| − | + | [[File:SA WIP-Moves Transactions.png|700px|SA WIP-Moves Transactions.png]] | |

| − | + | | |

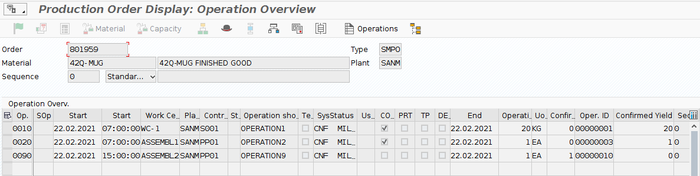

| − | + | <br/> '''Figure 14: WIP-Moves Operation Overview''' | |

| − | | + | [[File:SA WIP-Moves Operation Overview.png|700px|SA WIP-Moves Operation Overview.png]] |

| + | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> <ol start="6"> | ||

| + | <li>Users can also view each individual WIP-Move, as well as their details. In this view, it is easier to identify in what WIP-Move an error occurred by looking at the '''Message''' column. To see this view, click on the Display button.</li> | ||

| + | </ol> | ||

| − | + | | |

| − | + | | |

| − | + | '''Figure 15: Display WIP-Moves Process Details''' | |

| − | + | [[File:SA Display WIP-Moves Process Details.png|700px|SA Display WIP-Moves Process Details.png]] | |

| − | + | | |

| − | + | <br/> '''Figure 16: WIP-Moves Process Details''' | |

| − | + | [[File:SA WIP-Moves Process Details.png|700px|SA WIP-Moves Process Details.png]] | |

| − | < | + | '''<u>Note</u>:''' If there is one milestone operation in the Routing, then WIP Move confirmations only happen when a WIP Move is received for the milestone operation, all the non-milestone operations will be confirmed with that WIP Move. If there are no milestone operations in the routing, then confirmations happen when the WIP moves of respective operations are received. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | | |

| − | + | | |

| − | + | | |

| − | + | == <span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move">MAT-Move</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | |

| − | + | To get a material issue from 42Q the component/ BOM item should be set as PUSH type in SAP. If it is PULL type material standard backflush will happen for that BOM item. | |

| − | + | An assembly definition should be created for that component on 42Q. 42Q sends WIP moves when the assembly is either Standard, Unique, Custom, Consume from NSB or Non Tracked with Quantity. | |

| − | |||

| − | |||

| − | |||

| − | + | | |

| − | |||

| − | |||

| − | |||

| − | |||

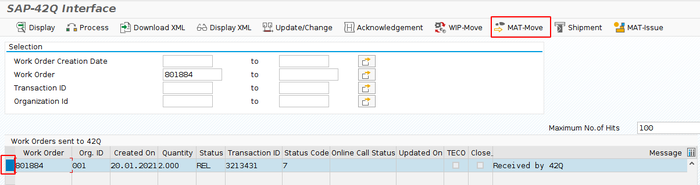

| − | + | Users can view Work Order MAT-Moves (Material Movements) by following the next steps: | |

| − | |||

| − | |||

| − | |||

| − | + | #Select a row. | |

| + | #Click on the '''MAT-Move''' button. | ||

| − | + | <br/> <br/> '''Figure 17: View MAT-Moves''' | |

| − | |||

| − | < | ||

| − | |||

| − | |||

| − | |||

| − | + | [[File:SA View MAT-Moves.png|700px|SA View MAT-Moves.png]] | |

| − | + | | |

| − | + | '''Figure 18: Work Order MAT-Moves''' | |

| − | + | [[File:SA Work Order MAT-Moves.png|700px|SA Work Order MAT-Moves.png]] | |

| − | + | | |

| + | <ol start="3"> | ||

| + | <li>A new window will appear, users can see all MAT-Moves belonging to that specific Work Order, as well as all detailed information.</li> | ||

| + | </ol> | ||

| − | + | | |

| − | < | + | <span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""> </span></span></span></span></span></span></span> |

| − | < | ||

| − | < | ||

| − | |||

| − | |||

| − | < | ||

| − | == <span class="mw-headline" id=" | ||

| − | </ | ||

| − | </ | ||

| − | + | == <span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue">MAT-Issue</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | |

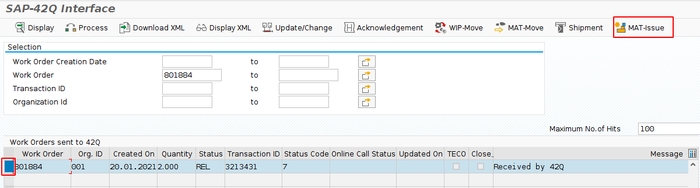

| − | + | Users can view Work Order '''MAT-Issues''' (Material Issues) by following the next steps: | |

| − | Select a row. | + | #Select a row. |

| + | #Click on the '''MAT-Issue''' button. | ||

| − | + | <br/> <br/> '''Figure 19: View MAT-Issues'''<br/> [[File:SA View MAT-Issues.png|700px|SA View MAT-Issues.png]] | |

| − | + | | |

| − | + | | |

| − | |||

| − | |||

| − | |||

| − | + | '''Figure 20: Work Order MAT-Issues''' | |

| − | < | + | [[File:SA Work Order MAT-Issues.png|700px|SA Work Order MAT-Issues.png]] </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="4"> |

| − | < | + | <li>A new window will appear, users can see all MAT-Issues belonging to that specific Work Order, as well as all detailed information.</li> |

| − | |||

| − | </li> | ||

</ol> | </ol> | ||

| − | SAP Adapter allows users to send work order changes to 42Q in the form of Work Order Update Transaction. | + | <br/> '''<u>Note</u>:''' When you receive a Work Order from SAP (or ERP) to 42Q, this Work Order '''Status''' will be set as '''N''' (Not released) in the 42Q system, if you want to release it, you must do it using 42Q. Figure 21: Work Order Received by 42Q. |

| + | </center> <center style="text-align: left;"> </center> <center style="text-align: left;">'''Figure 21: Work Order Received by 42Q'''</center> <center style="text-align: left;"> </center> <center style="text-align: left;">[[File:SA Work Order received by 42Q.png|700px|SA Work Order received by 42Q.png]]</center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> | ||

| + | | ||

| + | |||

| + | = <span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order">Update Work Order</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | ||

| + | <center style="text-align: left;"> | ||

| + | SAP Adapter allows users to send work order changes to 42Q in the form of Work Order Update Transaction. | ||

Following are the common WO updates from the ERP sent to 42Q: | Following are the common WO updates from the ERP sent to 42Q: | ||

| − | # | + | #'''Work Order Header''' |

| − | + | *Status change: | |

| + | **Unreleased to Released -- Send the entire work order details to 42Q | ||

| + | **On Hold | ||

| + | **Closed | ||

| + | **Canceled - Online call directly to 42Q to allow or not allow this change | ||

| + | **Complete - No Charges -Online call directly to 42Q to allow or not allow this change | ||

| − | + | | |

| − | |||

| − | + | *Scheduled Start Date change | |

| + | *Scheduled Completion Date | ||

| + | *Start Quantity | ||

| + | **Increase | ||

| + | **Decrease - Online call directly to 42Q to allow or not allow this change | ||

| − | + | | |

| − | + | <ol start="2"> | |

| − | + | <li>'''Work Order Routing/ Production Version/ Component Change''' </li> | |

| + | </ol> | ||

| − | + | | |

| − | + | '''<u>Note</u>:''' The routing and component change will only happen if the work order is in status ‘'''N'''’ on 42Q. In order to update a Work Order, users must follow the next steps: | |

| − | |||

| − | |||

| − | + | | |

| − | # | + | #Enter the next command in SAP: '''CO02'''. |

| − | ## | + | #Enter the Work Order number in the field '''Order'''. |

| − | ## | + | #Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] |

| + | #Once the new window is open, modify the data you want to change. | ||

| + | #Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]] | ||

| + | #Select '''Yes''' to save it, or select '''No''' or '''Cancel''' to abort. | ||

| + | #Finally, a pop-up window will appear which shows the information changed, to close the window click on the green icon. | ||

| − | + | | |

| − | + | | |

| − | + | </center> | |

| − | + | | |

| − | + | | |

| − | + | = <span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors">Checking Transaction Errors</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | |

| − | |||

| − | |||

| − | + | | |

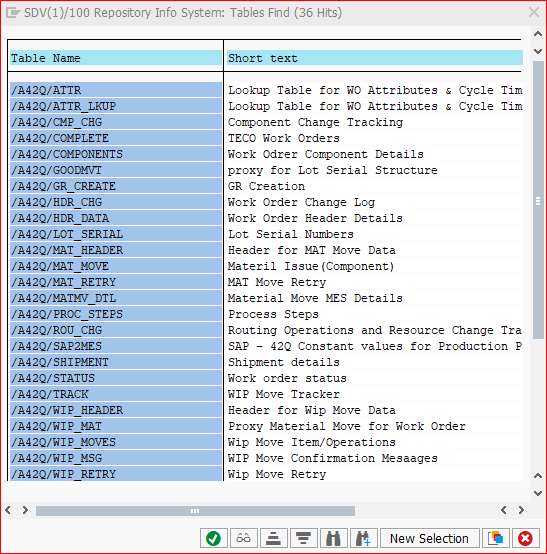

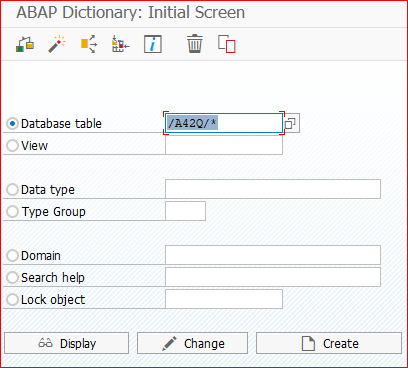

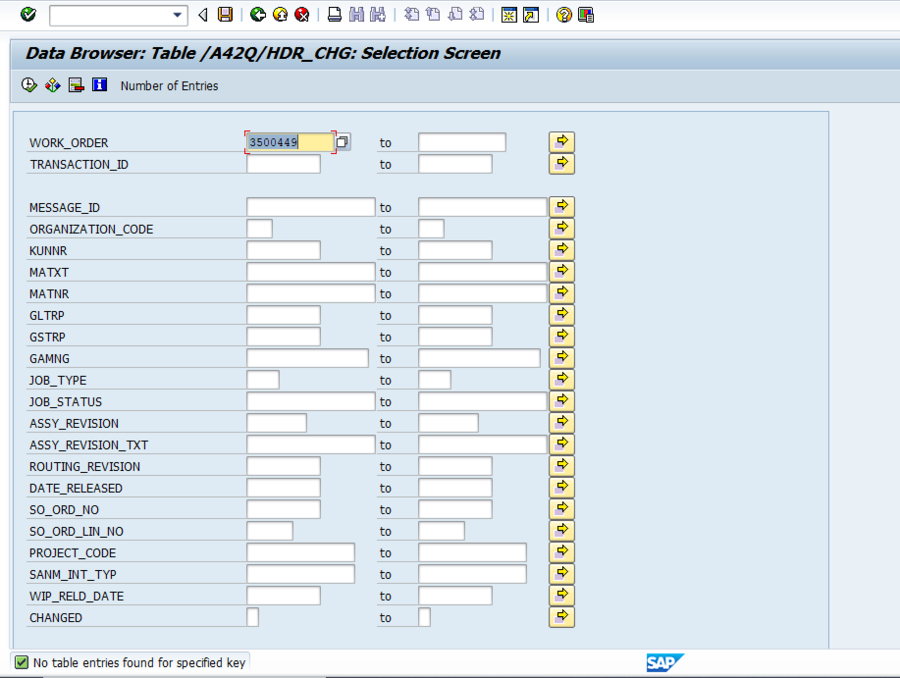

| − | # | + | #Enter the next command in SAP: '''SE11'''. |

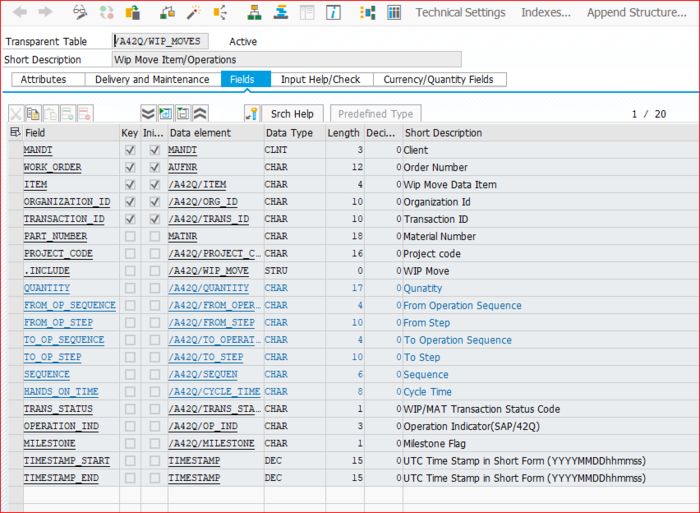

| − | # | + | #In the field of the '''Database table''', enter '''/A42Q/*''' (or '''ZQWO_*''', '''ZWO_*'''), and click on the icon: [[File:SA Search Icon.png|30x30px|SA Search Icon.png]] to display all types of transactions. |

| + | #A pop-up window will appear, select one value from the '''Table Name''' column, and click on the accept button. | ||

| − | + | | |

| − | + | | |

| − | |||

| − | + | '''Figure 22: Table Name Values''' | |

| − | + | [[File:SA Table Name Values.png|SA Table Name Values.png]] | |

| − | |||

| − | + | | |

| + | <ol start="4"> | ||

| + | <li>Click on the '''Display''' button.</li> | ||

| + | </ol> | ||

| − | + | <br/> '''Figure 23: Display Transaction Errors''' | |

| − | |||

| − | |||

| − | + | [[File:SA Display Transaction Errors.png|SA Display Transaction Errors.png]] | |

| − | + | | |

| − | + | <ol start="5"> | |

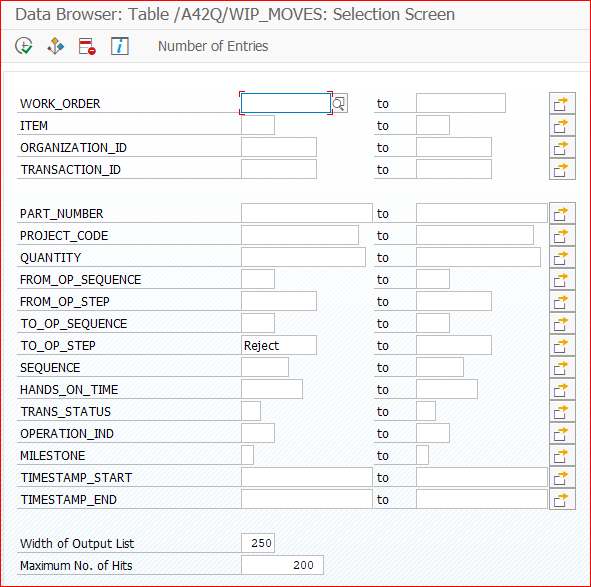

| − | + | <li>To search for specific information, click on the '''Contents''' button.</li> | |

| − | |||

| − | |||

| − | |||

| − | <li> | ||

</ol> | </ol> | ||

| − | + | | |

| − | + | | |

| − | + | '''Figure 24: View Contents''' | |

| − | + | [[File:SA View Content.png|700px|SA View Content.png]] | |

| + | <center style="text-align: left;"> <ol start="6"> | ||

| + | <li>Enter the information you want to look for. The next image will look for rejected WIP-Moves.</li> | ||

| + | <li>Click the '''Execute''' button.</li> | ||

| + | </ol> | ||

| − | + | | |

| − | + | | |

| − | + | '''Figure 25: Search For Rejected WIP-Moves''' | |

| − | + | [[File:SA Search For Rejected WIP-Moves.png|SA Search For Rejected WIP-Moves.png]] | |

| − | + | | |

| − | + | | |

| − | + | '''Figure 26: Rejected WIP-Moves Found''' | |

| − | + | [[File:SA Rejected WIP Moves Found.png|700px|SA Rejected WIP Moves Found.png]] | |

| − | + | | |

| − | + | | |

| + | </center> | ||

| + | = <span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_Ship_Notification_From_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q">Send Ship Notification From SAP to 42Q</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = | ||

| − | + | | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | ||

| − | # | + | == <span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order">Create a Sales Order</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

| + | |||

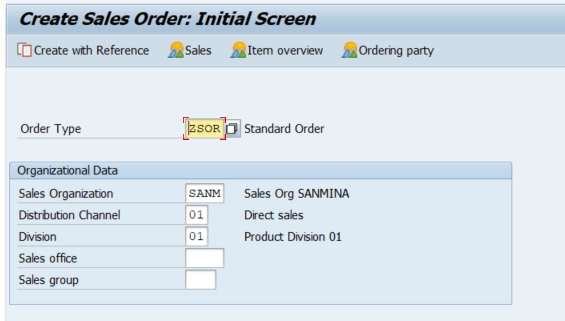

| + | #Enter the next command in SAP: '''VA01'''. | ||

| + | #In the field '''Order Type''', enter the value '''ZSOR''' and click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] | ||

| − | + | | |

| − | + | | |

| − | + | '''Figure 27: Create Sales Order Initial Screen''' | |

| − | + | [[File:SA Create Sales Order Initial Screen.png|SA Create Sales Order Initial Screen.png]] | |

| − | + | | |

| − | | + | |

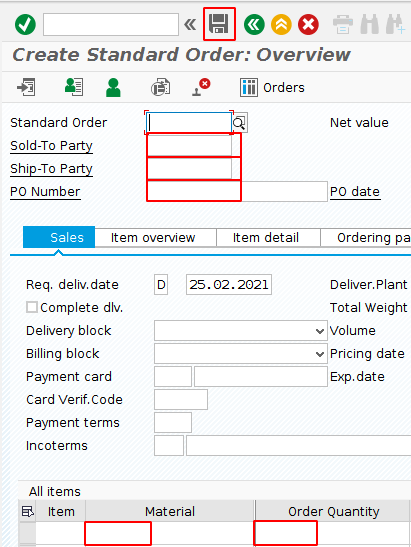

| − | + | <ol start="3"> | |

| − | <li> | + | <li>Enter the corresponding information for '''Sold-To Party''', '''PO Number''', '''Material''', '''Order Quantity'''.</li> |

</ol> | </ol> | ||

| − | <br/> | + | <br/> |

| − | | + | |

| − | + | '''Figure 28: Filling out Sales Order Data''' | |

| − | |||

| − | + | [[File:SA Filling out Sales Order Data.png|SA Filling out Sales Order Data.png]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | | + | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | ||

| + | <ol start="4"> | ||

| + | <li>Click on the '''Save''' icon. In the lower-left corner, users will see the '''Standard Order Number''' generated.</li> | ||

| + | </ol> | ||

| − | + | <br/> <br/> <br/> <br/> '''Figure 29: Standard Order Number Generated''' | |

| − | + | [[File:SA Standard Order Number Generated.png|700x700px|SA Standard Order Number Generated.png]] | |

| − | + | | |

| + | <ol start="5"> | ||

| + | <li>After creating a '''Sales Order''', the next step is to create an '''Outbound Delivery'''.</li> | ||

| + | </ol> | ||

| + | <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> | ||

| + | == <span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery">Create an Outbound Delivery</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | ||

| − | Enter the next command in SAP: | + | #Enter the next command in SAP: '''VL01N'''. |

| + | #Enter the '''Shipping point''' value '''1000''' (Sanmina Shipping Point) and '''Order number''', then press '''Enter'''. | ||

| − | + | <br/> <br/> '''Figure 30: Create Outbound Delivery Initial Screen''' | |

| − | + | [[File:SA Create Outbound Delivery Initial Screen.png|700px|SA Create Outbound Delivery Initial Screen.png]] | |

| − | | + | |

| − | |||

| − | |||

| − | |||

| − | < | + | |

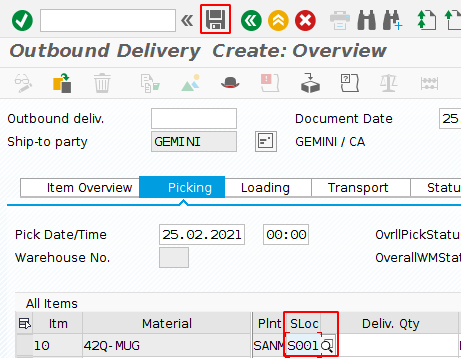

| − | + | <ol start="3"> | |

| − | <li>Click on the Save icon. | + | <li>Since we already had a Sales Order created, SAP will take the corresponding data automatically. Click on the '''Picking''' tab.</li> |

| + | <li>In the '''SLocation''' field, enter the value '''S001''' (Finished goods).</li> | ||

| + | <li>Click on the '''Save''' icon.</li> | ||

| + | <li>Select '''Yes''' to save it, or select '''No''' or '''Cancel''' to abort.</li> | ||

</ol> | </ol> | ||

| − | + | | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | ||

| − | + | '''Figure 31: Filling out Outbound Delivery Data''' | |

| + | |||

| + | [[File:SA Filling out Outbound Delivery Data.png|SA Filling out Outbound Delivery Data.png]] | ||

| + | <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="7"> | ||

| + | <li>After creating an '''Outbound Delivery''', the next step is to create a '''Transfer Order'''.</li> | ||

| + | </ol> | ||

| − | + | | |

| − | + | | |

| − | + | | |

| − | < | + | == <span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order">Create Transfer Order</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == |

| − | |||

| − | < | ||

| − | < | ||

| − | < | ||

| − | < | ||

| − | </ | ||

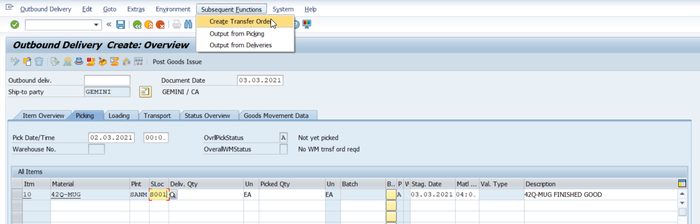

| − | + | #On the menu bar, click on the '''Subsequent Functions''' option. | |

| − | + | #Select the option '''Create Transfer Order'''. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | ||

| − | + | | |

| − | + | '''Figure 32: Create Transfer Order''' | |

| − | + | [[File:SA Create Transfer Order.png|700px|SA Create Transfer Order.png]] | |

| − | + | | |

| − | |||

| − | | ||

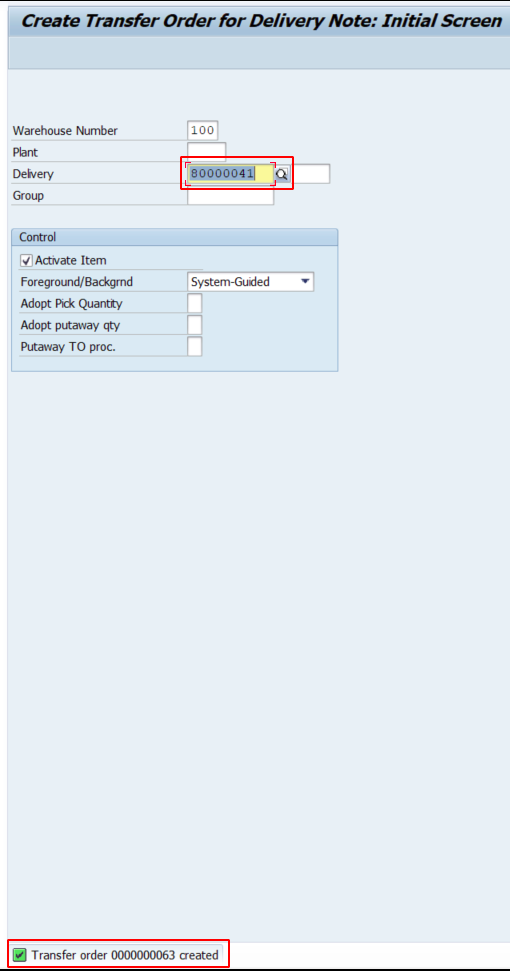

<ol start="3"> | <ol start="3"> | ||

| − | <li>A new window will be displayed, you will notice that in the lower left corner will appear the Outbound Delivery number generated, make sure that number is entered in the Delivery field, then click on the icon | + | <li>A new window will be displayed, you will notice that in the lower-left corner will appear the Outbound Delivery number generated, make sure that number is entered in the '''Delivery''' field, then click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

</ol> | </ol> | ||

| − | <br/> <br/> | + | <br/> <br/> '''Figure 33: Outbound Delivery Number Generated''' |

| + | |||

| + | [[File:SA Outbound Delivery Number Generated.png|x700px|SA Outbound Delivery Number Generated.png]] | ||

| + | |||

| + | | ||

| + | |||

| + | | ||

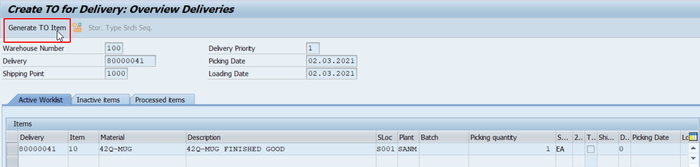

<ol start="4"> | <ol start="4"> | ||

| − | <li>Click on the Generate TO Item button.</li> | + | <li>Click on the '''Generate TO Item''' button.</li> |

| − | <li>Click on the Save icon | + | <li>Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]]</li> |

</ol> | </ol> | ||

| − | <br/> <br/> | + | <br/> <br/> '''Figure 34: Generate TO Item''' |

| − | <ol start="6"> | + | |

| − | <li>In the lower left corner you will see the Transfer Order number generated. Copy the value from the field Delivery.</li> | + | '''[[File:SA Generate TO Item.png|700px|SA Generate TO Item.png]]''' |

| + | |||

| + | | ||

| + | <ol start="6"> | ||

| + | <li>In the lower-left corner you will see the Transfer Order number generated. Copy the value from the field '''Delivery'''.</li> | ||

</ol> | </ol> | ||

| − | <br/> <br/> | + | <br/> <br/> '''Figure 35: Transfer Order Number Generated''' |

| − | + | ||

| − | <li>Enter the next command in SAP: VL02N.</li> | + | '''[[File:SA Transfer Order Number Generated.png|SA Transfer Order Number Generated.png]]''' |

| − | <li>A new window will be displayed. Click on the icon | + | |

| + | | ||

| + | <ol start="7"> | ||

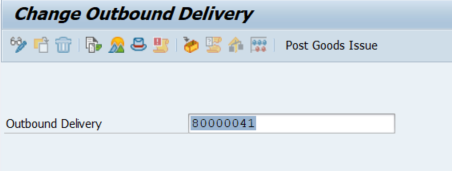

| + | <li>Enter the next command in SAP: '''VL02N'''.</li> | ||

| + | <li>A new window will be displayed. Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> | ||

</ol> | </ol> | ||

| − | <br/> <br/> | + | <br/> <br/> '''Figure 36: Change Outbound Delivery Initial Screen''' |

| − | + | ||

| − | <li>On the menu bar, click on the Extras option.</li> | + | '''[[File:SA Change Outbound Delivery Initial Screen.png|SA Change Outbound Delivery Initial Screen.png]]''' |

| − | <li>Select Serial Numbers.</li> | + | |

| + | | ||

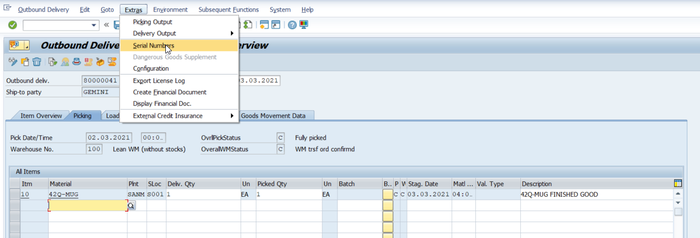

| + | <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="9"> | ||

| + | <li>On the menu bar, click on the '''Extras''' option.</li> | ||

| + | <li>Select '''Serial Numbers'''.</li> | ||

</ol> | </ol> | ||

| − | Figure 37: Extras Options | + | |

| − | <ol start="11"> | + | |

| − | <li>Click on the button Create serial number automatically.</li> | + | |

| + | |||

| + | '''Figure 37: Extras Options''' | ||

| + | |||

| + | '''[[File:SA Extras Options.png|700px|SA Extras Options.png]]''' | ||

| + | </center> <center style="text-align: left;"> <ol start="11"> | ||

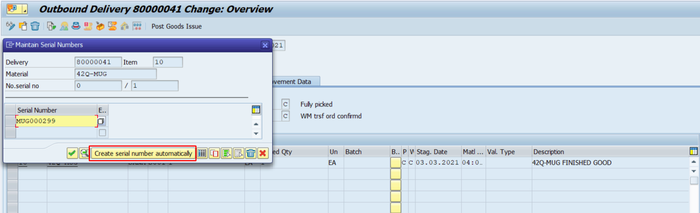

| + | <li>Click on the button '''Create serial number automatically'''.</li> | ||

</ol> | </ol> | ||

| − | <br/> <br/> | + | <br/> <br/> '''Figure 38: Maintain Serial Numbers''' |

| − | <ol start="12"> | + | |

| + | '''[[File:SA Maintain Serial Numbers.png|700px|SA Maintain Serial Numbers.png]]''' | ||

| + | </center> <center style="text-align: left;"> <ol start="12"> | ||

<li>A new pop-up window will appear, check the boxes of the Order Numbers you want.</li> | <li>A new pop-up window will appear, check the boxes of the Order Numbers you want.</li> | ||

| − | <li>Click on the Copy icon | + | <li>Click on the '''Copy''' icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

| − | <li>Then click on the Continue button | + | <li>Then click on the '''Continue''' button: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

<li>Select a specific row.</li> | <li>Select a specific row.</li> | ||

| − | <li>Click on the icon [ | + | <li>Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] to execute.</li> |

| − | <li>Click on the Post Goods Issues button.</li> | + | <li>Click on the '''Post Goods Issues''' button.</li> |

</ol> | </ol> | ||

| − | | + | |

| − | |||

| − | |||

| − | |||

| − | + | | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''Figure 39: Outbound Delivery Change Overview''' | |

| − | + | '''[[File:SA Outbound Delivery Change Overview.png|700px|SA Outbound Delivery Change Overview.png]]''' | |

| + | </center> <center style="text-align: left;"> <ol start="18"> | ||

| + | <li>Users will notice in the lower-left corner that the Outbound Delivery number was generated.</li> | ||

| + | </ol> | ||

| − | + | <br/> <br/> '''Figure 40: Outbound Delivery Number Generated''' | |

| − | + | | |

| + | </center> <center style="text-align: left;"> <ol start="19"> | ||

| + | <li>The next step is to create a '''Shipment'''.</li> | ||

| + | </ol> | ||

| − | + | | |

| + | </center> | ||

| + | == <span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment">Create a Shipment</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | ||

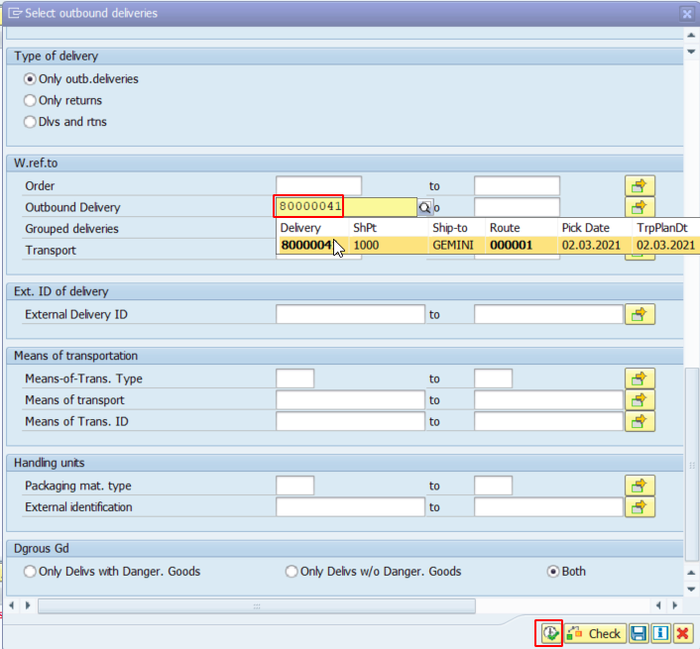

| − | Once the new window is displayed, scroll down to the section W.ref.to, in the field Outbound Delivery, enter the Outbound Delivery number that was just created. | + | #Enter the next command: '''VT01N''' and press '''Enter'''. |

| + | #Click on the '''Deliveries''' button. | ||

| + | #Once the new window is displayed, scroll down to the section '''W.ref.to''', in the field '''Outbound Delivery''', enter the Outbound Delivery number that was just created. | ||

| + | #In the '''Delivery Status''' section, in case you don’t need the '''Total GDS mvt stat'''. or '''Trms.plan.status''', simply delete their multiple values. | ||

| + | #Click on the '''Execute''' button. | ||

| − | + | | |

| − | + | | |

| − | |||

| − | |||

| − | + | '''Figure 41: Selecting Outbound Deliveries''' | |

| − | + | [[File:SA Selecting Outbound Deliveries.png|700x700px|SA Selecting Outbound Deliveries.png]] | |

| − | + | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="6"> | |

<li>Users will notice the Number of Deliveries found.</li> | <li>Users will notice the Number of Deliveries found.</li> | ||

</ol> | </ol> | ||

| − | <br/> <br/> | + | <br/> <br/> '''Figure 42: Number of Deliveries Found''' |

| − | <ol start="7"> | + | |

| + | '''[[File:SA Number of Deliveries Found.png|700x700px|SA Number of Deliveries Found.png]]''' | ||

| + | </center> <center style="text-align: left;"> <ol start="7"> | ||

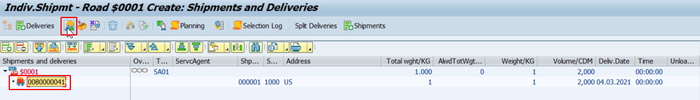

<li>Select the shipment number that you just created.</li> | <li>Select the shipment number that you just created.</li> | ||

| − | <li>Click on the button Overview of Current Shipment.</li> | + | <li>Click on the button '''Overview of Current Shipment'''.</li> |

</ol> | </ol> | ||

| − | Figure 43: Selecting Shipment Number | + | |

| + | |||

| + | | ||

| + | |||

| + | '''Figure 43: Selecting Shipment Number''' | ||

| + | |||

| + | '''[[File:SA Selecting Shipment Number.png|700px|SA Selecting Shipment Number.png]]''' | ||

| + | |||

| + | | ||

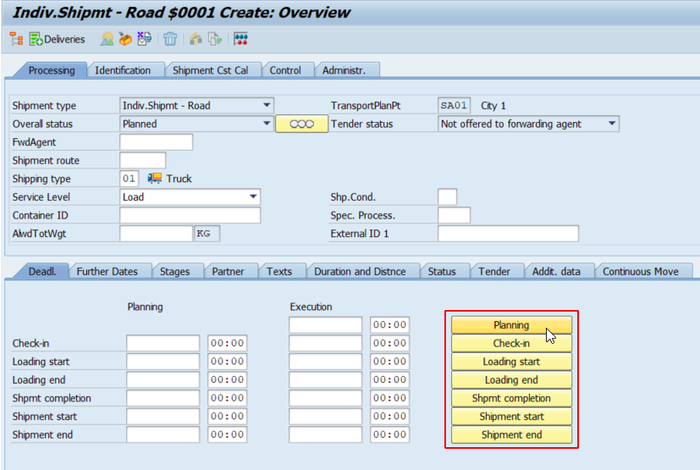

<ol start="9"> | <ol start="9"> | ||

| − | <li>In the lower right corner, you must select all the options (Planning, Check-in, Loading start, Shipmt. Completion, Shipment start, and Shipment end).</li> | + | <li>In the lower right corner, you must select all the options ('''Planning''', '''Check-in''', '''Loading start''', '''Shipmt. Completion''', '''Shipment start''', and '''Shipment end''').</li> |

</ol> | </ol> | ||

| − | <br/> <br/> <br/> | + | <br/> <br/> <br/> '''Figure 44: Selecting Shipment Steps''' |

| + | |||

| + | '''[[File:SA Selecting Shipment Steps.png|700x700px|SA Selecting Shipment Steps.png]]''' | ||

| + | |||

| + | | ||

| + | |||

| + | | ||

<ol start="10"> | <ol start="10"> | ||

| − | <li>Click on the Save icon | + | <li>Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]]</li> |

</ol> | </ol> | ||

| | ||

| − | = < | + | |

| − | < | + | |

| − | < | + | |

| − | = <span class="mw-headline" id=" | + | |

| − | </ | + | = <span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs"><span class="mw-headline" id="Key_Value_Pairs">Key Value Pairs</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> = |

| − | </ | + | |

| + | '''Key Value Pairs''' (Custom Attributes) allow users to send custom fields or native fields, which are not part of the standard adapter from ERP to 42Q. | ||

| + | |||

| + | Key value pairs can be sent from the following 4 ERP levels: | ||

| + | |||

| + | #'''Work Order (shop order):''' ‘WO_ATTRIBUTE’ tag in WO Create. | ||

| + | #'''Work Order Assembly (shop order part number):''' ‘WO_PART_ATTRIBUTE’ tag in WO Create. | ||

| + | #'''BOM Item (shop order BOM component part):''' ‘COMPONENT_PART_ATTRIBUTE’ tag in WO Create. | ||

| + | #'''Work Order BOM Item (specific to work order):''' ‘WO_BOM_ATTRIBUTE’ XML tag in WO Create. | ||

| + | |||

| + | | ||

| + | |||

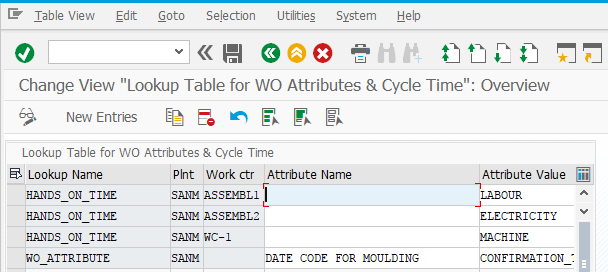

| + | To send these custom attributes, users need to follow the next steps: | ||

| + | |||

| + | #Enter the '''Lookup Name''', which is composed of the suffix: '''‘DYN_’''' and then, add the Key Value Pairs Tag, e.g., '''‘DYN_WO_ATTRIBUTE’'''. | ||

| + | #Enter the '''Plant'''. | ||

| + | #Enter the '''Sequence Number''' (Work ctr). | ||

| + | #Enter the '''Attribute Name''' (Attribute Name sent to 42Q) . | ||

| + | #Enter the '''Attribute Value''' (field name in SAP). | ||

| + | |||

| + | | ||

| + | |||

| + | '''Figure 45: Lookup Table for WO Attributes and Cycle Time''' | ||

| − | + | [[File:SA Lookup Table for WO Attributes and Cycle Time.png|700px|SA Lookup Table for WO Attributes and Cycle Time.png]] | |

| − | + | | |

| − | + | | |

| − | + | | |