Difference between revisions of "42Q-MES0174-A OEE Workbench"

| Line 35: | Line 35: | ||

| | ||

| − | == <span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration">Machine Integration</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | + | |

| + | == <span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration"><span class="mw-headline" id="Machine_Integration">Machine Integration</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | ||

To set up the machine in CMMS Asset go to '''Shop Floor Control> Configuration> CMMS Asset> Asset'''. | To set up the machine in CMMS Asset go to '''Shop Floor Control> Configuration> CMMS Asset> Asset'''. | ||

| Line 57: | Line 58: | ||

'''Figure 4: Add Asset Information''' | '''Figure 4: Add Asset Information''' | ||

| − | '''[[File:OEEWB AddAssetInformation.png|OEEWB AddAssetInformation.png]]''' | + | '''[[File:OEEWB AddAssetInformation.png|890px|OEEWB AddAssetInformation.png]]''' |

<u>'''Note'''</u>: The following fields are mandatory: '''Asset Id''', '''Asset Name''', and '''Asset Type'''. | <u>'''Note'''</u>: The following fields are mandatory: '''Asset Id''', '''Asset Name''', and '''Asset Type'''. | ||

Revision as of 21:18, 16 November 2022

42Q Home > Production > OEE Workbench

Production

OEE Workbench

Version MES15.72

Revision B1

Contents

Introduction

Batch/Lot Process form is an interface that allows for basic data collection, including location selection, basic defect recording, attribute/assembly data if configured. TAKT time display and OEE basic data recording is available using asset integration through CMMS. All the activities are recorded in Unit History against the serial record.

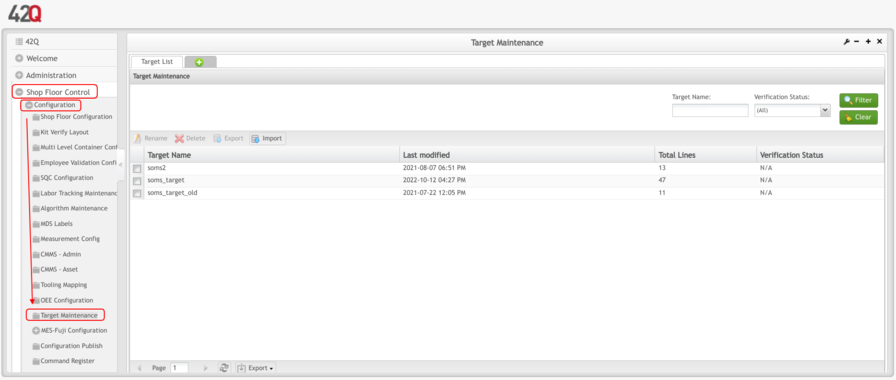

Target Maintenance

To use the Batch/Lot Process Control function, the following items are required:

- A serial (batch in this case) in process status for the location to

- Setup target maintenance with setup time and cycle time for the part number

Go to Shop Floor Control> Configuration> Target maintenance> soms_target

Note: Users have to set up the Target Cycle Time and Setup Time for the part number and process they will be working on using the Create button on the top right.

For more details on target maintenance please refer to Target Maintenance.

Machine Integration

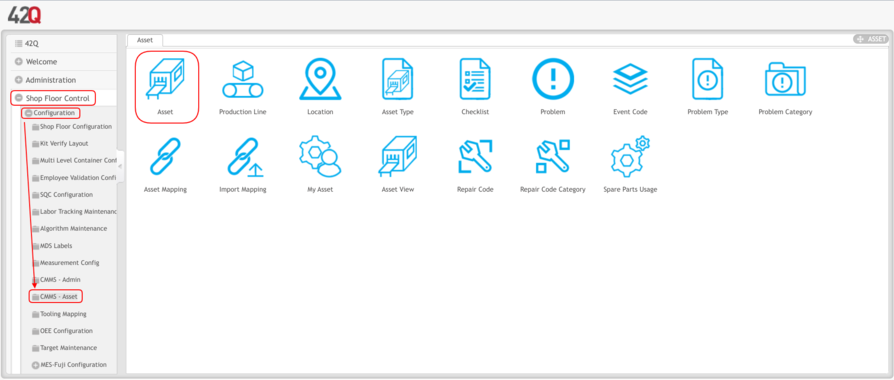

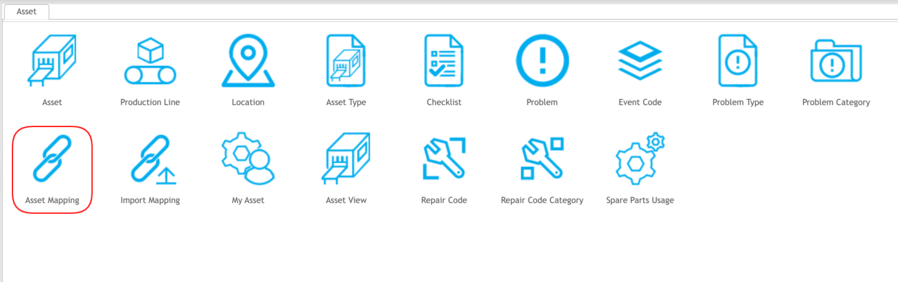

To set up the machine in CMMS Asset go to Shop Floor Control> Configuration> CMMS Asset> Asset.

Figure 2: CMMS-Asset

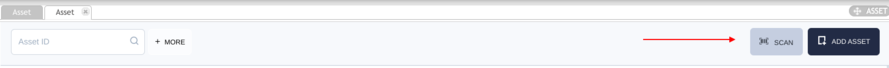

Select the Add button to add a new machine (asset). The Add Asset Window will be displayed to enter the required information.

Figure 3: Scan / Add Asset

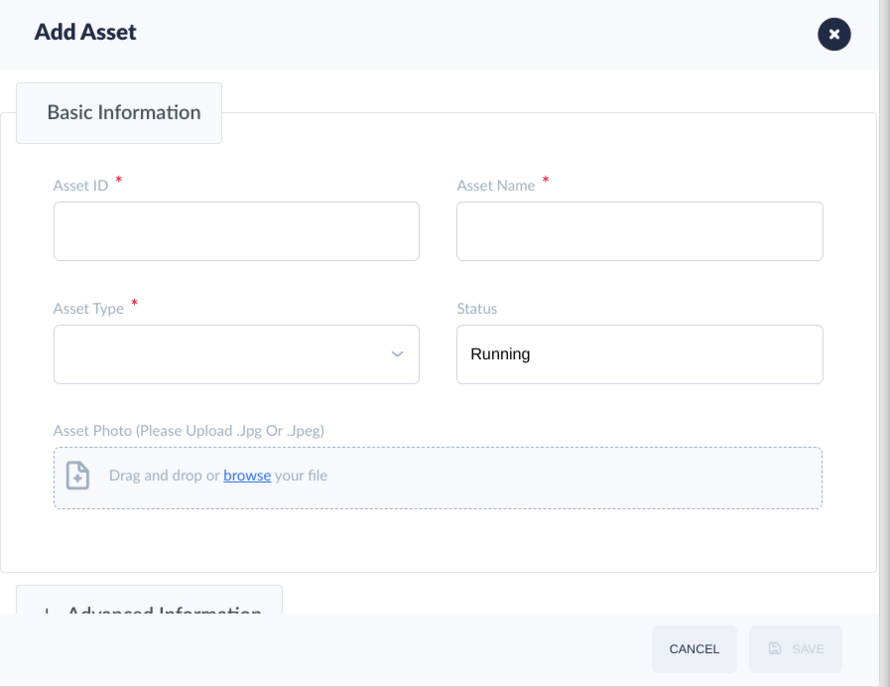

Figure 4: Add Asset Information

Note: The following fields are mandatory: Asset Id, Asset Name, and Asset Type.

Users must map the CMMS Asset to the location operator who will perform the job.

To map the machine to the respective location, go to Shop Floor Control> Configuration> CMMS Asset> Asset Mapping.

Figure 5: Asset Mapping

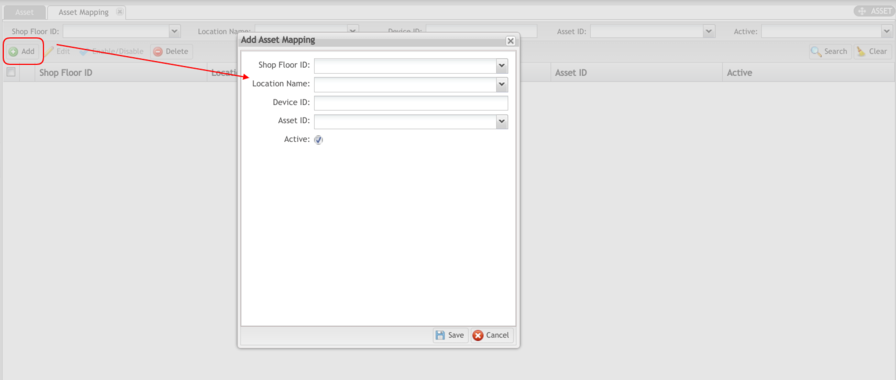

Select Add and fill the form with the Location Name and Machine for mapping as shown in the figure.

Figure 6: Add Asset Mapping

For more details on asset management refer to CMMS Asset.

Users have to set up Problems/ Reasons for the machine. To add the problems in CMMS under Problem, users must have the problem type and problem category created before the problem creation.

Assign the Problem to Asset Type for the assets.

Figure 7: Asset Type

Figure 8: Edit Asset Type

OEE Workbench

Without Asset Integration

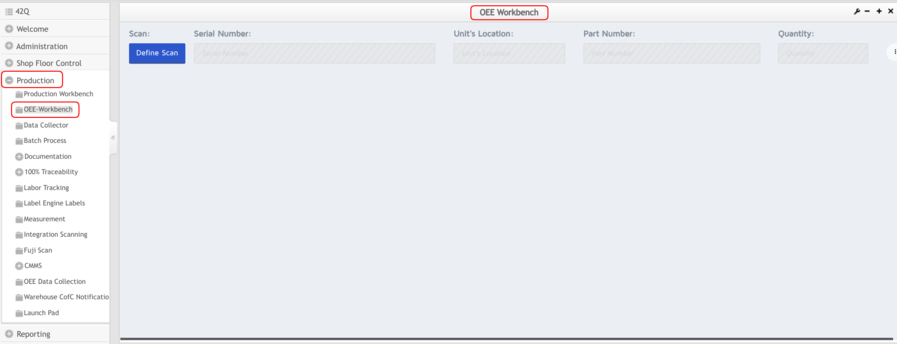

Once all the prerequisites have been set up the users have to access the Batch/Lot Process control form; to do so navigate to Production> OEE Workbench

Figure 9: OEE Workbench

Users have to Scan the Location they want to work on to be able to see all the units that are available to that location.

Figure 10: Select Device or Location

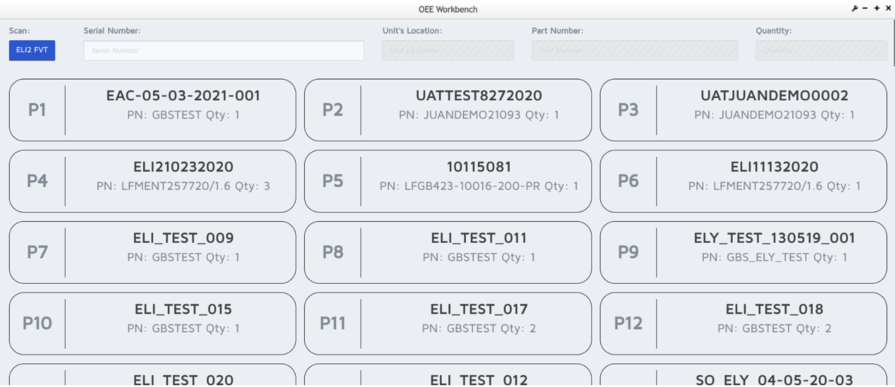

Note: Batch can also be scanned in the serial number text box. The P1, P2 are the priority based on the shop order sequencing. If there is no sequencing/ priority defined the orders appear as the oldest order first.

Figure 9: OEE Workbench Location and Serial Numbers

Users have to select the unit to work on. It will give a summary of the unit, such as part number, unit quantity (can be updated by user), shop order quantity. As there is no machine integration the machine status is N/A.

Figure 10: Unit to Work On Screen

Note: There is a new rule that states that when a location name starts with ‘S’, the operation will not be considered as SETUP (it will not be hard-coded), instead, it will take as reference the setup done in the process_mapping to retrieve the operations. However, if the process_mapping does not contain the ‘S’, or is empty, ‘S’ will be set up by default.

Select START to begin the operation. If there are any prompts (attributes or assembly setups) they must be completed.

Figure 11: Attributes or Assembly Setups

- The clock will start ticking and users will be able to see the time under which the operation starts. This is the Remaining Time (standard time*qty + setup time), Setup Time, and Standard Time based on the SOMS table set up in target maintenance.

- Multiple operations are available for operators, such as Add Comment, Add Defect, and End of the process.

- Once all the activities have been finished, users can select the END button to move the unit to the next step based on the route. All the activities will be recorded in Unit History.

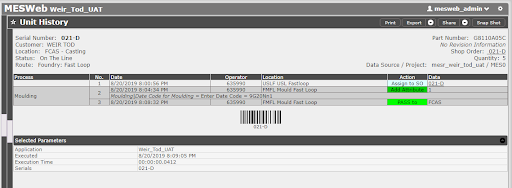

Figure 12: MESWeb Unit history

With Asset Integration

Once all the prerequisites have been set up the users have to access the Batch/Lot Process control form; to do so navigate to Production> OEE Workbench (Figure 7). Users have to Scan the Location they want to work on to see all the units that are available at that location.

Note: Batch can also be scanned in the serial number text box.

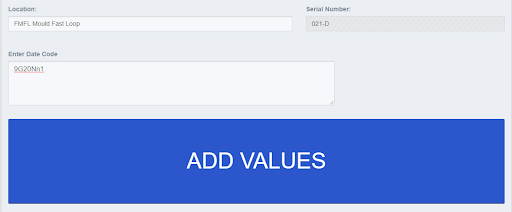

Figure 13: Scanned Location

The next step is to select a unit and quantity on which the operator will work on.

Figure 14: Selected Unit to Work On

To begin the operation, users must select START. Once done, the clock will start ticking and the user will be able to see the start time under the remaining time.

Figure 15: Running Machine Example

Note: The machine status comes from CMMS, if the machine is under maintenance in CMMS, the status of the machine will be down here.

To stop the machine, users must select the STOP button and then, specify a reason for stopping the machine. The reasons are the problems that have been created in CMMS Asset.

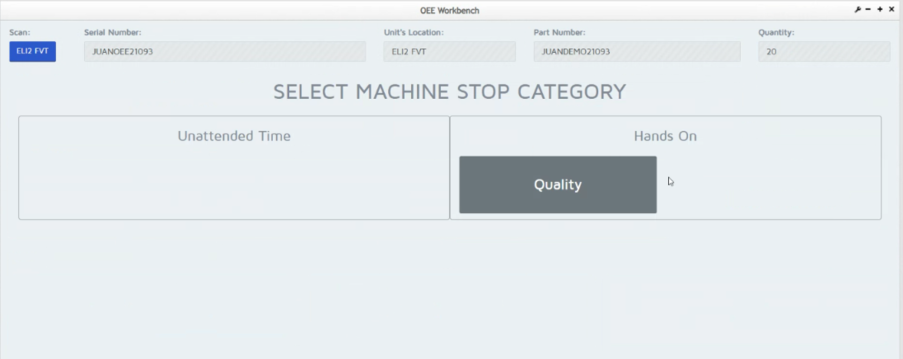

Figure 16: Stop Category

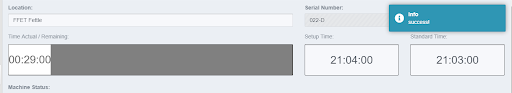

A confirmation message will be displayed asking to proceed or cancel the action. Once confirmed, the problem will be recorded on the machine and a success message will be displayed.

Figure 17: Information Update Message

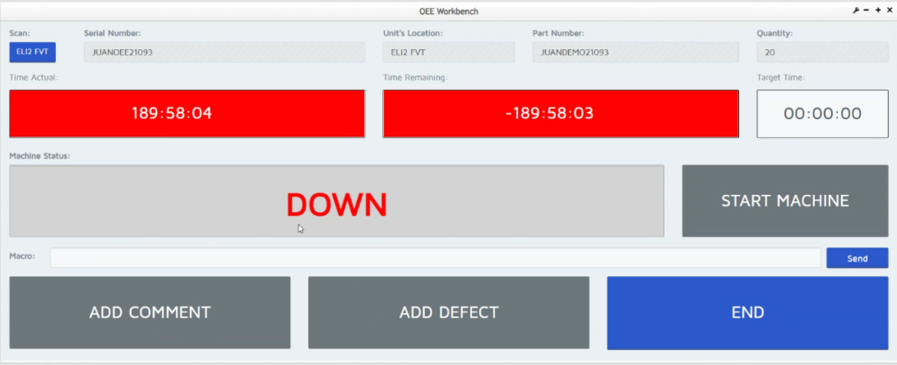

The system will advise that the machine is “DOWN”. Once the problem has been fixed, the operator can select again the Start Machine button and the Machine Status will be changed to “RUNNING”.

Figure 18: Down Machine Example