Difference between revisions of "42Q-MES0164 Auto Routing Creation"

(Created page with " <small>42Q Home > Administration > Auto Routing Creation</small><br/> 130px|Sanmina logo.png <p style="t...") |

|||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | <small>[[42Q_Cloud-Based_MES/MOMS|42Q Home]] > [[Administration|Administration]] > Auto Routing Creation</small><br/> | + | <small>[[42Q_Cloud-Based_MES/MOMS|42Q Home]] > [[Administration|Administration]] > Auto Routing Creation</small><br/> |

| − | <p style="text-align: center;">''' '''<br/> <br/> <br/> <br/> '''Administration'''</p> <p style="text-align: center;">'''Auto Routing Creation'''</p> <p style="text-align: center;">'''Version MES15.68 ''' | + | <p style="text-align: center;">''' '''<br/> <br/> <br/> <br/> '''Administration'''</p> <p style="text-align: center;">'''Auto Routing Creation'''</p> <p style="text-align: center;">'''Version MES15.68'''</p> <p style="text-align: center;">'''Revision A1'''<br/> <br/> <br/> <br/> <br/> </p> |

| − | + | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction </span></span></span></span></span> = | |

| − | |||

| − | < | ||

| − | |||

| − | = <span class="mw-headline" id="Introduction">Introduction </span> = | ||

<br/> '''Auto Routing Creation '''works by using a pattern-matching technique to compare the operation sequence list that is being pushed into 42Q MES from ERP routing with existing routes in the system. If there are no matches found, the automated system will then check to see if some of the work centers match the locations in 42Q and organize them accordingly to create new routes. | <br/> '''Auto Routing Creation '''works by using a pattern-matching technique to compare the operation sequence list that is being pushed into 42Q MES from ERP routing with existing routes in the system. If there are no matches found, the automated system will then check to see if some of the work centers match the locations in 42Q and organize them accordingly to create new routes. | ||

| Line 18: | Line 14: | ||

| | ||

| − | == <span class="mw-headline" id="Auto_Routing_functionality_in_42Q">Auto Routing functionality in 42Q</span> == | + | |

| + | |||

| + | == <span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q"><span class="mw-headline" id="Auto_Routing_functionality_in_42Q">Auto Routing functionality in 42Q</span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span></span> == | ||

| | ||

| − | *A route is created when releasing a Shop Order into 42Q, the AutoRt generic attribute is enabled and the user has the ability to check the option for the | + | *A route is created when releasing a Shop Order into 42Q, the AutoRt generic attribute is enabled and the user has the ability to check the option for the '''AutoRoute Creation'''. |

*A route could already exist that has the same operation sequence steps, therefore a new route would not be created every time. Attempting to use an existing route should be initially checked before a new route is created. | *A route could already exist that has the same operation sequence steps, therefore a new route would not be created every time. Attempting to use an existing route should be initially checked before a new route is created. | ||

*The main route will be created using Subroutes only. | *The main route will be created using Subroutes only. | ||

| Line 28: | Line 26: | ||

**Only SETUP and RUN resources will be considered to create the location. This is the format used to create the locations and processes: | **Only SETUP and RUN resources will be considered to create the location. This is the format used to create the locations and processes: | ||

***Location: | ***Location: | ||

| − | ****4 char loc (Algorithm)+ empty space + '''Work Center (XML)''' + empty space + OP (Constant) + Occurrence (XML) + empty space + SETUP/RUN | + | ****<span style="color:#2980b9;">4 char loc (Algorithm)</span>+ empty space + '''Work Center (XML)''' + empty space + <span style="color:#27ae60;">OP (Constant)</span> + <span style="color:#f39c12;">Occurrence (XML)</span> + empty space + <span style="color:#8e44ad;">SETUP/RUN</span> |

| − | *****E.g: Location: AAJE'''M996''' | + | *****E.g: Location: <span style="color:#2980b9;">AAJE</span>'''M996''' <span style="color:#27ae60;">OP</span><span style="color:#f39c12;">1</span> <span style="color:#8e44ad;">RUN</span> |

***'''Process:''' | ***'''Process:''' | ||

| − | ****'''Work center (XML) + '''empty space'''+ OP (Constant) + Occurrence (XML) + empty space + SETUP/RUN:''' | + | ****'''Work center (XML) + '''empty space'''+ <span style="color:#27ae60;">OP (Constant)</span> + <span style="color:#f39c12;">Occurrence (XML)</span> + empty space + <span style="color:#f39c12;">SETUP/RUN</span>:''' |

| − | *****E.g: Process: '''M996''' | + | *****E.g: Process: '''M996''' <span style="color:#27ae60;">OP</span><span style="color:#f39c12;">1</span> <span style="color:#8e44ad;">RUN</span> |

*As part of the route creation, the operation sequences will be mapped to the locations for WIP move transactions. The part number will be assigned to the new route. | *As part of the route creation, the operation sequences will be mapped to the locations for WIP move transactions. The part number will be assigned to the new route. | ||

| Line 55: | Line 53: | ||

| | ||

| − | == <span class="mw-headline" id="Auto_Routing">Auto Routing</span> == | + | == <span class="mw-headline" id="Auto_Routing"><span class="mw-headline" id="Auto_Routing"><span class="mw-headline" id="Auto_Routing"><span class="mw-headline" id="Auto_Routing"><span class="mw-headline" id="Auto_Routing">Auto Routing</span></span></span></span></span> == |

'''Auto Routing Creation '''provides the users the ability to create routes and locations automatically. During configuration, the system will be able to alternatively automatically create locations and sub-routes that are prerequisites to a new route and map it to the Shop Order at release time. | '''Auto Routing Creation '''provides the users the ability to create routes and locations automatically. During configuration, the system will be able to alternatively automatically create locations and sub-routes that are prerequisites to a new route and map it to the Shop Order at release time. | ||

| Line 61: | Line 59: | ||

| | ||

| − | === <span class="mw-headline" id="autort">autort</span> === | + | === <span class="mw-headline" id="autort"><span class="mw-headline" id="autort"><span class="mw-headline" id="autort"><span class="mw-headline" id="autort"><span class="mw-headline" id="autort">autort</span></span></span></span></span> === |

The '''autort '''is the new generic attribute option to resolve (create or reuse) a manufacturing route based on the order’s operation sequences. | The '''autort '''is the new generic attribute option to resolve (create or reuse) a manufacturing route based on the order’s operation sequences. | ||

| Line 94: | Line 92: | ||

| | ||

| − | === <span class="mw-headline" id="Adding_Generic_Attributes">Adding Generic Attributes</span> === | + | === <span class="mw-headline" id="Adding_Generic_Attributes"><span class="mw-headline" id="Adding_Generic_Attributes"><span class="mw-headline" id="Adding_Generic_Attributes"><span class="mw-headline" id="Adding_Generic_Attributes"><span class="mw-headline" id="Adding_Generic_Attributes">Adding Generic Attributes</span></span></span></span></span> === |

| | ||

| Line 124: | Line 122: | ||

| | ||

| − | == <span class="mw-headline" id="New_Genetic_Attributes_for_Auto_Routing_Creation">New Genetic Attributes for Auto Routing Creation</span> == | + | == <span class="mw-headline" id="New_Genetic_Attributes_for_Auto_Routing_Creation"><span class="mw-headline" id="New_Genetic_Attributes_for_Auto_Routing_Creation"><span class="mw-headline" id="New_Genetic_Attributes_for_Auto_Routing_Creation"><span class="mw-headline" id="New_Genetic_Attributes_for_Auto_Routing_Creation"><span class="mw-headline" id="New_Genetic_Attributes_for_Auto_Routing_Creation">New Genetic Attributes for Auto Routing Creation</span></span></span></span></span> == |

| | ||

| − | === <span class="mw-headline" id="Enable.2FDisable_Generic_Attributes">Enable/Disable Generic Attributes</span> === | + | === <span class="mw-headline" id="Enable.2FDisable_Generic_Attributes"><span class="mw-headline" id="Enable.2FDisable_Generic_Attributes"><span class="mw-headline" id="Enable.2FDisable_Generic_Attributes"><span class="mw-headline" id="Enable.2FDisable_Generic_Attributes"><span class="mw-headline" id="Enable.2FDisable_Generic_Attributes">Enable/Disable Generic Attributes</span></span></span></span></span> === |

'''autort '''= enable | yes | y | true | t | on [text] | '''autort '''= enable | yes | y | true | t | on [text] | ||

| Line 148: | Line 146: | ||

| | ||

| − | === <span class="mw-headline" id="Configuration">Configuration</span> === | + | === <span class="mw-headline" id="Configuration"><span class="mw-headline" id="Configuration"><span class="mw-headline" id="Configuration"><span class="mw-headline" id="Configuration"><span class="mw-headline" id="Configuration">Configuration</span></span></span></span></span> === |

'''autort_route_name_algorithm '''= <algorithm_number> [numeric] | '''autort_route_name_algorithm '''= <algorithm_number> [numeric] | ||

| Line 208: | Line 206: | ||

| | ||

| − | === <span class="mw-headline" id="Editing_Generic_Attributes">Editing Generic Attributes</span> === | + | === <span class="mw-headline" id="Editing_Generic_Attributes"><span class="mw-headline" id="Editing_Generic_Attributes"><span class="mw-headline" id="Editing_Generic_Attributes"><span class="mw-headline" id="Editing_Generic_Attributes"><span class="mw-headline" id="Editing_Generic_Attributes">Editing Generic Attributes</span></span></span></span></span> === |

Once the attribute is added, users can continue throughout the process or choose to edit the generic attribute by '''clicking''' on the checkbox corresponding to the item on the list and then '''clicking''' Edit Generic Attribute. | Once the attribute is added, users can continue throughout the process or choose to edit the generic attribute by '''clicking''' on the checkbox corresponding to the item on the list and then '''clicking''' Edit Generic Attribute. | ||

| Line 228: | Line 226: | ||

| | ||

| − | == <span class="mw-headline" id="Work_Center_Device_Mapping">Work Center Device Mapping </span> == | + | == <span class="mw-headline" id="Work_Center_Device_Mapping"><span class="mw-headline" id="Work_Center_Device_Mapping"><span class="mw-headline" id="Work_Center_Device_Mapping"><span class="mw-headline" id="Work_Center_Device_Mapping"><span class="mw-headline" id="Work_Center_Device_Mapping">Work Center Device Mapping </span></span></span></span></span> == |

<br/> '''The Work Center Mapping i'''s configured in the Route Level. This mapping is used to find the Subroutes for the main route. Users can configure this mapping in advance or if the Subroutes were automatically created, the Work Center Mapping will be created as well. The mapping will also be done in a 1:1 relationship. | <br/> '''The Work Center Mapping i'''s configured in the Route Level. This mapping is used to find the Subroutes for the main route. Users can configure this mapping in advance or if the Subroutes were automatically created, the Work Center Mapping will be created as well. The mapping will also be done in a 1:1 relationship. | ||

| Line 238: | Line 236: | ||

<br/> '''<u>Note</u>: '''This feature will only be available only if the Auto Routing option is '''enabled. ''' | <br/> '''<u>Note</u>: '''This feature will only be available only if the Auto Routing option is '''enabled. ''' | ||

| − | <br/> <br/> To access the Route Form for Work Center Mapping, navigate to'''Shop Floor Control > Configuration > Shop Floor Configuration.''' | + | <br/> <br/> To access the Route Form for Work Center Mapping, navigate to '''Shop Floor Control > Configuration > Shop Floor Configuration.''' |

<br/> '''Figure 6: Shop Floor Configuration''' | <br/> '''Figure 6: Shop Floor Configuration''' | ||

| Line 299: | Line 297: | ||

| | ||

| − | == <span class="mw-headline" id="Shop_Order_Single_Release">Shop Order Single Release</span> == | + | == <span class="mw-headline" id="Shop_Order_Single_Release"><span class="mw-headline" id="Shop_Order_Single_Release"><span class="mw-headline" id="Shop_Order_Single_Release"><span class="mw-headline" id="Shop_Order_Single_Release"><span class="mw-headline" id="Shop_Order_Single_Release">Shop Order Single Release</span></span></span></span></span> == |

<br/> Once the subroutes have been resolved, the process will look for an exact matching “primary” route composed of all subroutes, if not found a new one will be created. | <br/> Once the subroutes have been resolved, the process will look for an exact matching “primary” route composed of all subroutes, if not found a new one will be created. | ||

| Line 313: | Line 311: | ||

| | ||

| − | There is an | + | There is an AutoRoute Creation option for ‘Single Release’ Shop Orders. Navigate to this option, go to '''Shop Floor Control > Production Control > Shop Floor Control.''' |

<br/> '''Click''' on Shop Order Release. | <br/> '''Click''' on Shop Order Release. | ||

| Line 321: | Line 319: | ||

[[File:ShopOrderRelease.png|700px|ShopOrderRelease.png]] | [[File:ShopOrderRelease.png|700px|ShopOrderRelease.png]] | ||

| − | <br/> As stated before, there is an “'''Auto Route Creation'''” option. This option will only be displayed'''IF '''the autort is enabled. Once selected, the generic attribute for this option will be automatically checked. | + | <br/> As stated before, there is an “'''Auto Route Creation'''” option. This option will only be displayed '''IF '''the autort is enabled. Once selected, the generic attribute for this option will be automatically checked. |

<br/> '''Figure 13: Shop Order Number Filter''' | <br/> '''Figure 13: Shop Order Number Filter''' | ||

| Line 351: | Line 349: | ||

<br/> '''Select''' Auto Route Creation for the release and '''click''' Next. | <br/> '''Select''' Auto Route Creation for the release and '''click''' Next. | ||

| − | <br/> '''<u>Note</u>: '''If the | + | <br/> '''<u>Note</u>: '''If the AutoRoute is selected, a Shop Floor ID must be selected.''' ''' |

<br/> <br/> '''Click '''Next'''. '''<br/> <br/> <br/> '''Figure 16: Shop Floor ID''' | <br/> <br/> '''Click '''Next'''. '''<br/> <br/> <br/> '''Figure 16: Shop Floor ID''' | ||

| Line 371: | Line 369: | ||

Once accepted, the resolved route will be created (reuse in case an exact route already exists) as part of the release process and assigned to the new serial numbers. <br/> | Once accepted, the resolved route will be created (reuse in case an exact route already exists) as part of the release process and assigned to the new serial numbers. <br/> | ||

| − | Once the system finds a match, the Auto-Route resolution page will appear and display primary information concerning steps, work center information, and subroutes that were found. There is also information provided for users to be aware of concerning | + | Once the system finds a match, the Auto-Route resolution page will appear and display primary information concerning steps, work center information, and subroutes that were found. There is also information provided for users to be aware of concerning autoroutes that were assigned automatically to serial numbers. |

<br/> '''<u>Note</u>: '''If an item is red, it indicates that a particular step will not be considered. A message will also be provided to help users understand the reason it is not being considered.<br/> <br/> <br/> '''Click '''Next'''.'''<br/> | <br/> '''<u>Note</u>: '''If an item is red, it indicates that a particular step will not be considered. A message will also be provided to help users understand the reason it is not being considered.<br/> <br/> <br/> '''Click '''Next'''.'''<br/> | ||

| Line 424: | Line 422: | ||

| | ||

| − | == <span class="mw-headline" id="Multiple_Shop_Order_Release_Rule_.28Release_of_Shop_Order.29">Multiple Shop Order Release Rule (Release of Shop Order)</span> == | + | == <span class="mw-headline" id="Multiple_Shop_Order_Release_Rule_.28Release_of_Shop_Order.29"><span class="mw-headline" id="Multiple_Shop_Order_Release_Rule_.28Release_of_Shop_Order.29"><span class="mw-headline" id="Multiple_Shop_Order_Release_Rule_.28Release_of_Shop_Order.29"><span class="mw-headline" id="Multiple_Shop_Order_Release_Rule_.28Release_of_Shop_Order.29"><span class="mw-headline" id="Multiple_Shop_Order_Release_Rule_.28Release_of_Shop_Order.29">Multiple Shop Order Release Rule (Release of Shop Order)</span></span></span></span></span> == |

<br/> For the Multiple Shop Order Release, users can select more than one Shop Order listed at the same time (no matter the part number nor if it is ERP) and they can all be released at the same time. | <br/> For the Multiple Shop Order Release, users can select more than one Shop Order listed at the same time (no matter the part number nor if it is ERP) and they can all be released at the same time. | ||

| Line 470: | Line 468: | ||

| | ||

| − | '''<u>Note:</u> '''It is a common behavior of the Multiple Shop Order Release if the Shop Order fails and presents an Error. The system will just error out those shop orders that failed and removed them from the list. If the | + | '''<u>Note:</u> '''It is a common behavior of the Multiple Shop Order Release if the Shop Order fails and presents an Error. The system will just error out those shop orders that failed and removed them from the list. If the AutoRoute is selected and fails, it will result in a hard stop. |

'''Click '''Next.''' ''' | '''Click '''Next.''' ''' | ||

| Line 531: | Line 529: | ||

<br/> For more information on email notifications for Shop Orders, please refer to [https://42qrpt1.42-q.com/mes_wiki/index.php/SOP-5-I-MES0038-C_RA1_Notification_&_Escalataion Notification & Escalation] | <br/> For more information on email notifications for Shop Orders, please refer to [https://42qrpt1.42-q.com/mes_wiki/index.php/SOP-5-I-MES0038-C_RA1_Notification_&_Escalataion Notification & Escalation] | ||

| − | + | ---- | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | ||

| − | |||

| − | |||

Latest revision as of 17:23, 5 October 2021

42Q Home > Administration > Auto Routing Creation

Administration

Auto Routing Creation

Version MES15.68

Revision A1

Contents

Introduction

Auto Routing Creation works by using a pattern-matching technique to compare the operation sequence list that is being pushed into 42Q MES from ERP routing with existing routes in the system. If there are no matches found, the automated system will then check to see if some of the work centers match the locations in 42Q and organize them accordingly to create new routes.

There are Generic Attributes that are pre-configured in order to help the users know if the Auto Routes are allowed to run or not using valued labels such as: Enabled or Disabled. The system will also be able to alternatively automatically create locations and sub-routes that are prerequisites to a new route and map it to the Shop Order at release time. Note: Algorithms are used to generate the Route Names.

Note: Algorithms are used to generate the Route Names.

Auto Routing functionality in 42Q

- A route is created when releasing a Shop Order into 42Q, the AutoRt generic attribute is enabled and the user has the ability to check the option for the AutoRoute Creation.

- A route could already exist that has the same operation sequence steps, therefore a new route would not be created every time. Attempting to use an existing route should be initially checked before a new route is created.

- The main route will be created using Subroutes only.

- If the aurort_subroute is enabled, the system will create the subroutes and locations in accordance with the ROUTING_OPERATIONS in the XML file.

- Only SETUP and RUN resources will be considered to create the location. This is the format used to create the locations and processes:

- Location:

- 4 char loc (Algorithm)+ empty space + Work Center (XML) + empty space + OP (Constant) + Occurrence (XML) + empty space + SETUP/RUN

- E.g: Location: AAJEM996 OP1 RUN

- 4 char loc (Algorithm)+ empty space + Work Center (XML) + empty space + OP (Constant) + Occurrence (XML) + empty space + SETUP/RUN

- Process:

- Work center (XML) + empty space+ OP (Constant) + Occurrence (XML) + empty space + SETUP/RUN:

- E.g: Process: M996 OP1 RUN

- Work center (XML) + empty space+ OP (Constant) + Occurrence (XML) + empty space + SETUP/RUN:

- Location:

- As part of the route creation, the operation sequences will be mapped to the locations for WIP move transactions. The part number will be assigned to the new route.

Note: In order to use Auto Mapping, processes should have the Flex Field "ERP OP" setup and its value should be "YES". e.g: ERP OP = YES.

- If a route already exists that has the same operation sequences, then a new route would not be created. Existing operation sequence mapping would also be used.

- Route by the process would still be enabled to ensure that if there are multiple locations for the same process, the route will work for all locations.

- Subroute will be used to create the parent route, particularly when the auto-create location/subroute attribute are not enabled.

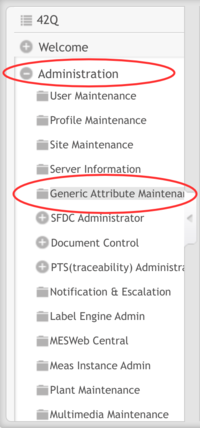

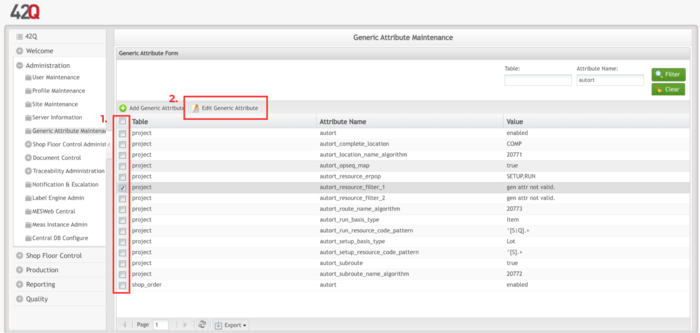

To set-up, Auto Routing Creation, from the 42-Q portal navigate to Administration > Generic Attribute Maintenance.

Figure 1: Generic Attribute Maintenance

The next sections will give details on how Auto Routing Creation works.

Auto Routing

Auto Routing Creation provides the users the ability to create routes and locations automatically. During configuration, the system will be able to alternatively automatically create locations and sub-routes that are prerequisites to a new route and map it to the Shop Order at release time.

autort

The autort is the new generic attribute option to resolve (create or reuse) a manufacturing route based on the order’s operation sequences.

When users release a Shop Order in 42Q and autort is enabled, the route will be composed of subroutes only, each representing one work center operation/step (work center + appearance/repeat index).

The auto-route creation process will look for existing subroutes (considering the last created one if multiple are found) for each ERP route step (work center + appearance/repeat index).

In case there are no matching subroutes the following Generic Attributes :

- autort_subroute is disabled the ERP route step (work center + appearance/repeat index) will be disregarded.

- autort_subroute is enabled and corresponding SETUP or RUN resources are available for the ERP route step, then a new location or locations will be created.

Note: For users, locations and sub-routes are not always created for every Work Order created. Otherwise, locations and routes will contain non-manufacturing steps.

Additionally, only if the generic attribute autort_opseq_map is enabled, the Process FlexField in ERP OP will be considered for Auto Mapping. The user will not “create” locations and subroutes for every Work Order created. Otherwise, locations and routes will contain non-manufacturing steps.

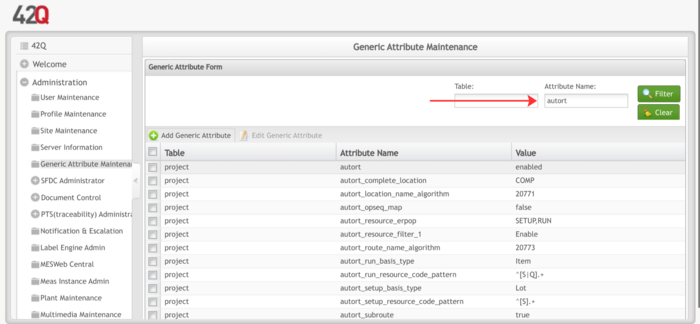

Preconfigured sub-routes are available and can be filtered out to make them easier to find by using the Filter option in the top right-hand corner.

In order to filter out options of sub-routes for Auto Routing, users must type in the Attribute Name “autort” and selectFilter.

Figure 2: AutoRt Search

Routes will only be created based upon the information received in the Work Order created transaction from the ERP system. Additional operations and steps, such as rework, repair, and other exception processes would have to be manually added to the automatically created route.

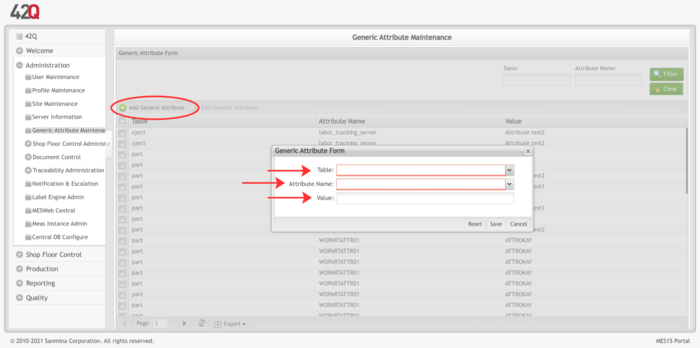

Note: When a generic attribute that is needed does not exist, there is an option to add one using the Add Generic Attribute button.

Adding Generic Attributes

1. To add a Generic Attribute, users must select the Add Generic Attribute from the Generic Attribute Maintenance screen.

Figure 3: Adding Generic Attribute

The Generic Attribute form is displayed.

2. The following fields are available to edit :

- Table

- Attribute Name

- Value (choose to Enable or Disable that specific attribute)

3. Once the form is filled, users can then click save, to save it to the list of other attributes.

Note: Users can use the Filter option to filter out a search to find a specific attribute name. For example, typing in AutoRt will filter out a list of attributes involving Auto Routes.

New Genetic Attributes for Auto Routing Creation

Enable/Disable Generic Attributes

autort = enable | yes | y | true | t | on [text]

If enabled an option to create a manufacturing route based on the order's ERP operation sequences (and resources) will be presented at release time. Disabled by default.

autort_subroute = enable | yes | y | true | t | on | [text]

If enabled the auto-route creation process will create a subroute for work centers with corresponding SETUP or RUN resources. Disabled by default.

autort_opseq_map = enable | yes | y | true | t | on | [text]

If enabled the auto-route creation process will add/override the order’s operation sequence map as the resolved subroute. Enabled by default.

Configuration

autort_route_name_algorithm = <algorithm_number> [numeric]

Defines the algorithm that will be used to generate the auto-created route name.

autort_location_name_algorithm = <algorithm_number> [numeric]

Defines the algorithm that will be used to generate the auto-created location name.

autort_subroute_name_algorithm = <algorithm_number> [numeric]

Defines the algorithm that will be used to generate the auto-created subroute name.

autort_setup_basis_type = <basis_type> [text]

Defines the basis type of SETUP resource (default Lot). It’s used in combination with autort_setup_resource_code_pattern in order to look for a “setup-type” resource.

autort_setup_resource_code_pattern = <resource_code_pattern> [text]

Defines the regex (regular expression) pattern of SETUP resource codes (default ^S.+). It’s used in combination with autort_setup_basis_type in order to remove “setup-type” resources that do not match the pattern.

autort_run_basis_type = <basis_type> [text]

Defines the basis type of RUN resource (default Item). It’s used in combination with autort_run_resource_code_pattern in order to look for a “run-type” resource.

autort_run_resource_code_pattern = <resource_code_pattern> [text]

Defines the regex (regular expression) pattern of RUN resource codes (default ^[S|Q].+). It’s used in combination with autort_run_basis_type in order to remove “run-type” resources that match the pattern.

autort_complete_location = <location_name> [text] (4 character name)

Defines the complete (status 30) location to be used for auto-created routes.

autort_resource_erpop = SETUP,RUN | RUN | SETUP

Defines if the newly created (when needed) processes for SETUP, RUN (or both) resources will be configured with the ERP OP flex field.

Note: For further information concerning Generic Attributes, please refer to SOP Generic Attribute Maintenance documentation.

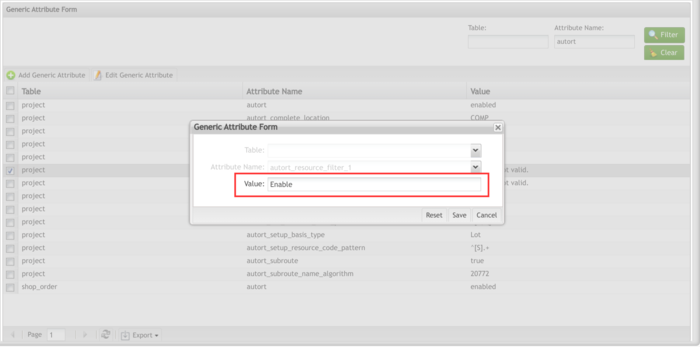

Editing Generic Attributes

Once the attribute is added, users can continue throughout the process or choose to edit the generic attribute by clicking on the checkbox corresponding to the item on the list and then clicking Edit Generic Attribute.

Figure 4: Edit Generic Attributes

Once you add the attribute, the functionality can not be removed. Users can only then Enable or Disable them. To turn the functionality off, users must input “Disabled” into the value box.

This functionality allows the user to be able to set a value of enabling or disabling a Generic Attribute.

Note: Auto Releasing is a functionality that is available but not advocated for routes in 42Q. This is to avoid confusion in the plants that desire to release multiple work orders in one release but do not want to make them available for production in that same time period.

Figure 5: Enable/Disable Value Box

Work Center Device Mapping

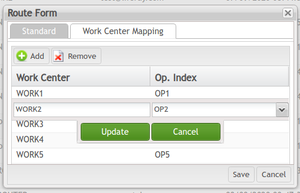

The Work Center Mapping is configured in the Route Level. This mapping is used to find the Subroutes for the main route. Users can configure this mapping in advance or if the Subroutes were automatically created, the Work Center Mapping will be created as well. The mapping will also be done in a 1:1 relationship.

The Work Center Device Mapping is another thing. We configure this in the Target Maintenance: workcenter_device_mapping and this is used to assign the route locations to existing devices in accordance with the Work Center.

Note: This feature will only be available only if the Auto Routing option is enabled.

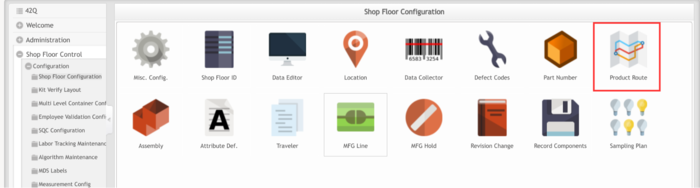

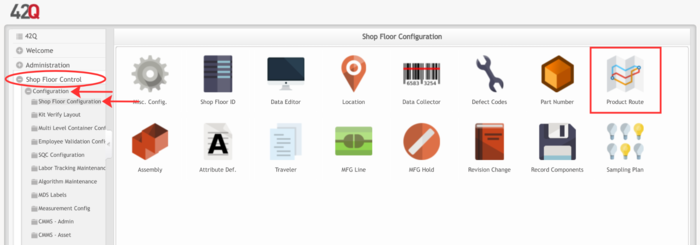

To access the Route Form for Work Center Mapping, navigate to Shop Floor Control > Configuration > Shop Floor Configuration.

Figure 6: Shop Floor Configuration

Click on the option Product Route.

Figure 7: Shop Floor Configuration - Product Route

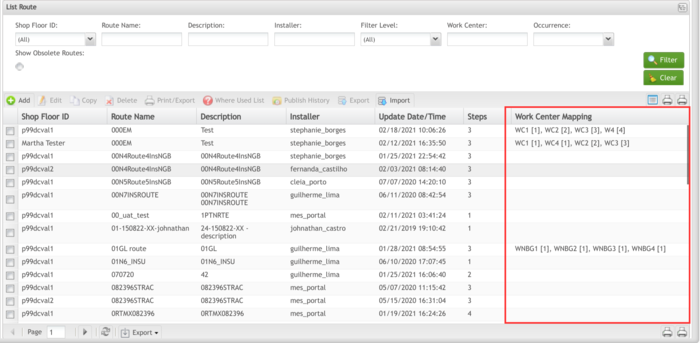

The List Route screen will appear.

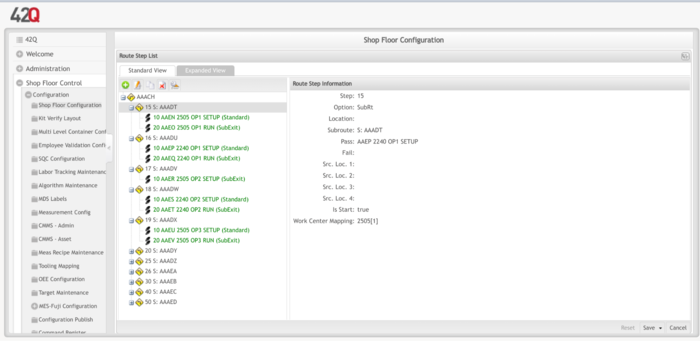

Figure 8: Work Center Mapping

Note: Work Center Mapping is available in the table to provide users information concerning Work Centers for the Shop Floor.

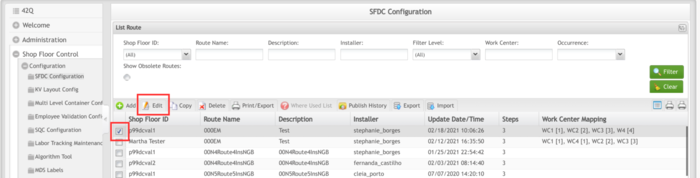

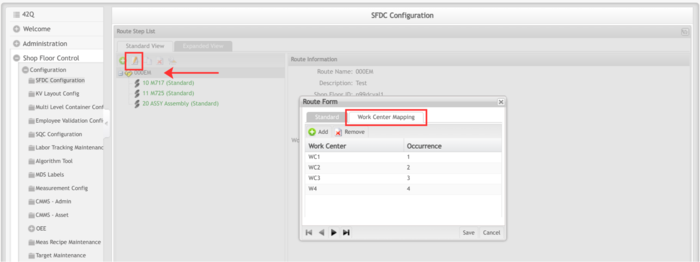

Users can see more details concerning Work Centers by clicking on the Shop Floor ID desired and clicking the edit button. It is possible to also see the Work Center Mapping for all the Subroutes within the Route Information panel.

Figure 9: Work Center

Note: In case a user does not want to use a particular auto-route, the user can create the sub-routes in advance and map the Work Centers manually.

Figure 10: Work Center Mapping

When releasing a shop order in 42Q and autort is enabled, a new option to resolve (create or reuse) a manufacturing route based on the order’s operation sequences will be available. The route will be composed of subroutes only, each representing one work center operation/step (work center + appearance/repeat index).

Figure 11: Route Form

The Auto Routing Creation process will look for existing subroutes (considering the last created one if multiple are found) for each ERP route step (work center + appearance/repeat index).

In case there are no matching subroutes and ...

- autort_subroute is disabled the ERP route step (work center + appearance/repeat index) will be disregarded.

- autort_subroute is enabled and corresponding SETUP or RUN resources are available for the ERP route step then

Note: Only one route can be assigned to an ERP Route step (work center + appearance/repeat index).

Shop Order Single Release

Once the subroutes have been resolved, the process will look for an exact matching “primary” route composed of all subroutes, if not found a new one will be created.

- Route name will be the next value of autort_route_name_algorithm.

- Route step = operation sequence number.

- The first step will be flagged as the start.

- The previous step passes to the first step’s location of the next route unless it’s the last step, in this case, it passes to autort_complete_location.

- The route will be automatically published to Conduit

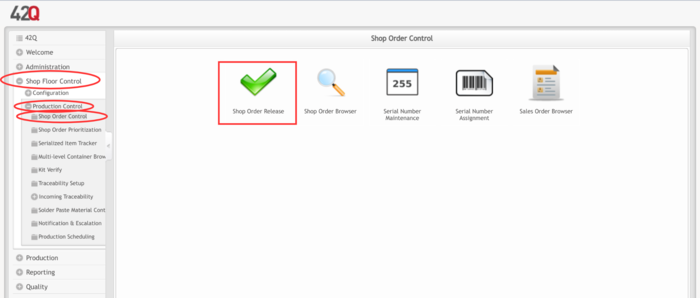

There is an AutoRoute Creation option for ‘Single Release’ Shop Orders. Navigate to this option, go to Shop Floor Control > Production Control > Shop Floor Control.

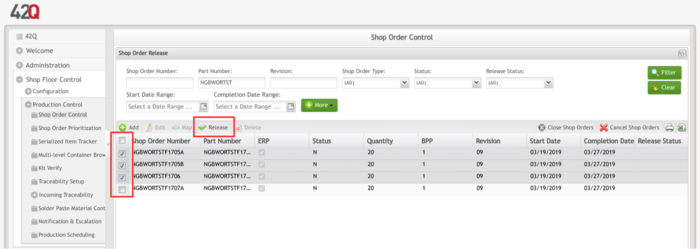

Click on Shop Order Release.

Figure 12: Shop Order Release

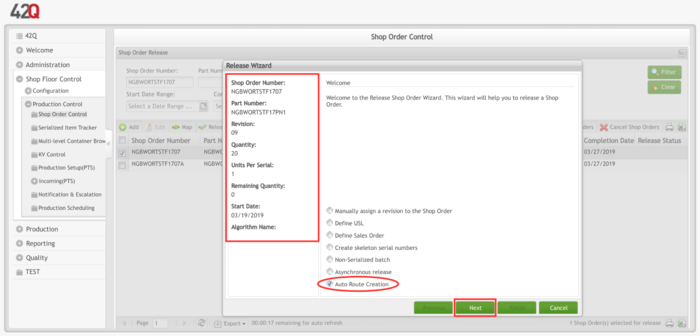

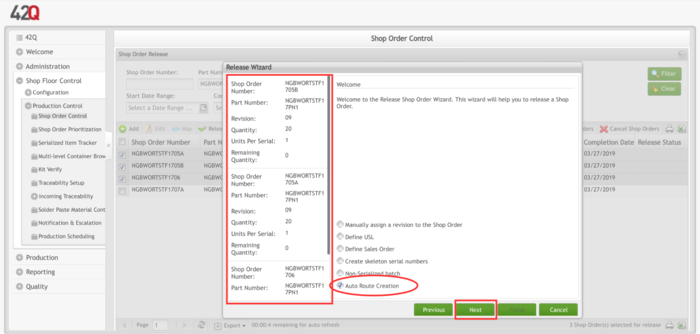

As stated before, there is an “Auto Route Creation” option. This option will only be displayed IF the autort is enabled. Once selected, the generic attribute for this option will be automatically checked.

Figure 13: Shop Order Number Filter

Filter out the search by either inputting the Shop Order Number, Part Number, or Revision Number.

Click Filter.

Figure 14: Shop Order Release

Once the Shop Order is found, select the item by putting a checkmark in the corresponding box and click release.

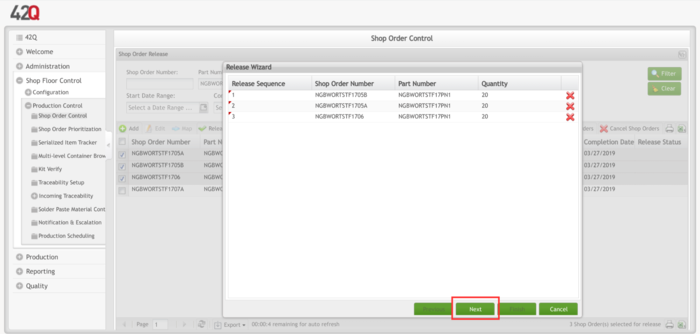

Figure 15: Shop Order Release Wizard

A Release Wizard pop-up box will appear and users will find on the left-hand side information concerning the Shop Order item that was selected.

Select Auto Route Creation for the release and click Next.

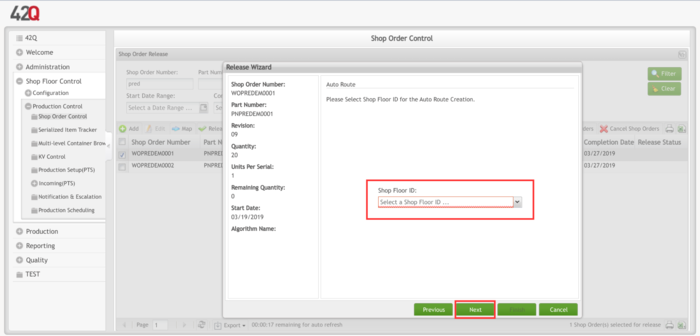

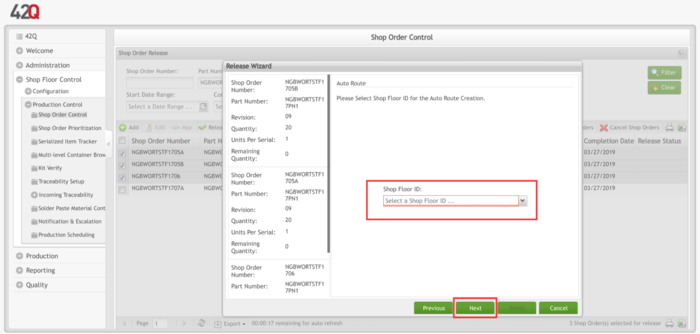

Note: If the AutoRoute is selected, a Shop Floor ID must be selected.

Click Next.

Figure 16: Shop Floor ID

Note: If the site only has one Shop Floor ID, this step will be skipped and it will be auto-selected.

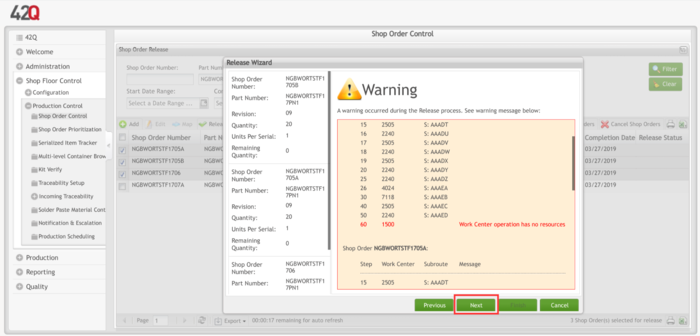

A new step in the release wizard will display a verbose summary of the route resolution, including whether or not an existing matching route was found and in case a new route needs to be created, which steps could be resolved/considered.

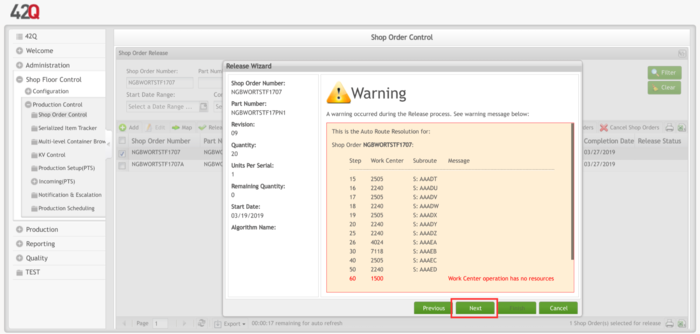

Figure 17: Shop Order Release Warning

Once accepted, the resolved route will be created (reuse in case an exact route already exists) as part of the release process and assigned to the new serial numbers.

Once the system finds a match, the Auto-Route resolution page will appear and display primary information concerning steps, work center information, and subroutes that were found. There is also information provided for users to be aware of concerning autoroutes that were assigned automatically to serial numbers.

Note: If an item is red, it indicates that a particular step will not be considered. A message will also be provided to help users understand the reason it is not being considered.

Click Next.

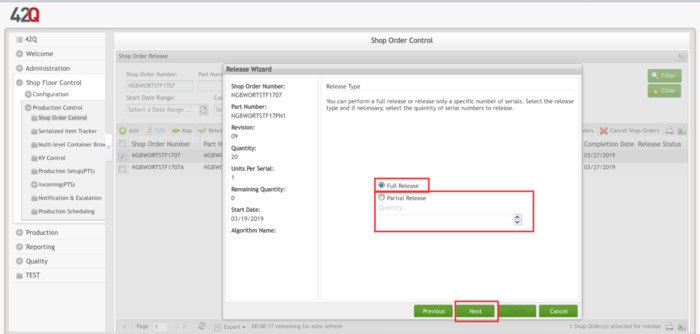

Figure 18: Full/Partial Release

Users must choose between releasing the Shop Order in a Full Release or a Partial Release. Depending on the quantity of the Shop Order and how much the user desires to release will help determine which release is the best fit.

For Example :

- If a user uses a Shop Order that contains a quantity number of 20 and would like to release all 20 as well, the user will choose a “Full Release”.

- If a user uses a Shop Order that contains a quantity number of 10 but would not like to release all but only partial, the user will select “Partial Release” and input the quantity that is desired.

Click Next to Confirm.

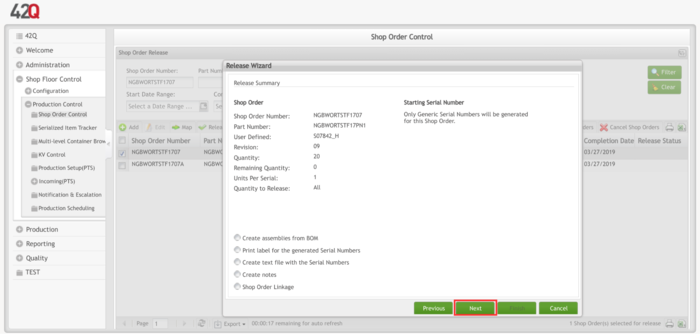

Figure 19: Release Summary

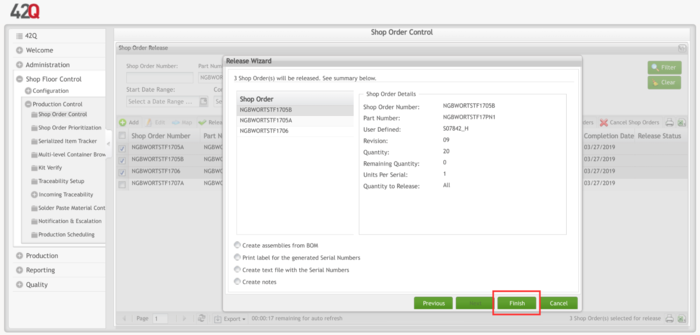

Once confirmed, a Release Summary page will appear giving information about the Shop Order for the users to get a final overview before releasing.

Click Next.

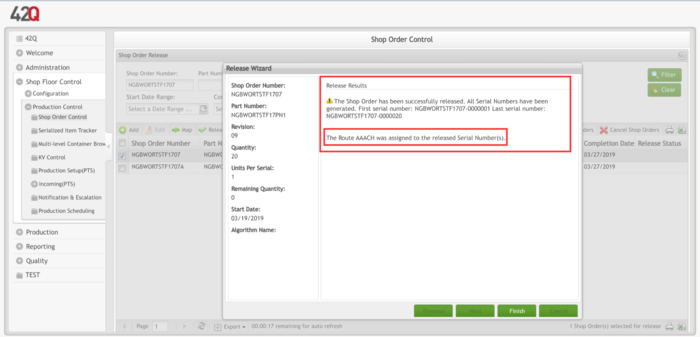

Figure 20: Release Results Successful

A Release Results page will appear if the Shop Order was successfully released. The system will inform users on the route name that was created and assigned to the released Serial Number(s).

Click Finish.

To look for that specific route that was assigned to a released serial number, go to Shop Floor Control > Configuration > Shop Floor Configuration > Product Route.

Figure 21: Product Route

Once the user has found the route in the search box labeled Route Name, users can then check the corresponding box beside the Route Name and click edit and a pop-up screen will appear demonstrating the route steps summarized for the Auto Mapping.

Figure 22: Route Step List

Click Save.

Multiple Shop Order Release Rule (Release of Shop Order)

For the Multiple Shop Order Release, users can select more than one Shop Order listed at the same time (no matter the part number nor if it is ERP) and they can all be released at the same time.

Figure 23: Multiple Shop Order Releases

Click Next.

Figure 24: Multiple Shop Order Releases List

The next warning screen will present the user’s information based upon which Shop Orders were removed and also provide a preview for the other Shop Orders.

Note: When a certain Shop Order(s) is red, it indicates that step will not be considered. There will also be a message displayed providing information on why that step is not being considered.

Users then have the option to cancel the Shop Orders before clicking Next.

Figure 25: Multiple Shop Order - Release Wizard

Select Shop Floor ID and click Next.

Figure 26: Multiple Shop Order - Shop Floor ID

Note: It is a common behavior of the Multiple Shop Order Release if the Shop Order fails and presents an Error. The system will just error out those shop orders that failed and removed them from the list. If the AutoRoute is selected and fails, it will result in a hard stop.

Click Next.

Figure 27: Multiple Shop Order Release - Warning

As for the same with Single Shop Order Releases, once the Shop Floor ID is selected, the release wizard will then generate a page with information concerning all the Shop Order(s) selected.

Any item messages in red are steps that will not be considered and will also be skipped.

Click Next.

Figure 28: Multiple Shop Order Summary

Once confirmed, a Release Summary page will appear providing a final overview of the information about the Shop Order(s) the user selected.

Click Finish.

Note: When executing Multiple Shop Orders, an email notification will be sent to the user if the ‘Create Text File with the Serial Numbers’ is checked and the Siren rule is properly configured.

Once the release task process is completed, the system will send a status mail to the configured recipient. The body template can be changed in accordance to the user's needs, except for the parameters.

- On Success - the email with the following release information has been sent.

- Rule ID: multiple_release_notification_rule_id generic attribute

- Module: Shop Order Control

- Body Template example:

- Part Number: {&part_number}

- Shop Order: {&shop_order_number}

- Revision: {&revision}

- Serial Number: {&serial_numbers}

- 'On Failure - the email with the following error message has been sent.

- Rule ID: multiple_release_error_notification_rule_id generic attribute

- Module: Shop Order Control

- Body Template example:

- The shop order {&shop_order} release get failed due to the following reason {&error_message}

- On Print Failure - the email with the following error message has been sent.

- Rule ID: multiple_release_print_error_notification_rule_id generic attribute

- Module: Shop Order Control

- Body Template example:

- Print Label Failed due to the following error(s):

For more information on email notifications for Shop Orders, please refer to Notification & Escalation