Difference between revisions of "42Q-MES0167 SAP Adapter"

| Line 12: | Line 12: | ||

| | ||

<center>This SOP is 42Q's corporate standard.</center> <center> This document is under revision control. The latest revision is located on Intranet.</center> <center> Once printed it is an uncontrolled copy. All alterations to this work instruction require approval.</center> <center> Contact the IT Global Education and Training Department to submit suggested alterations and or updates.</center> <center> </center> <center> </center> <center style="text-align: left;"> </center> | <center>This SOP is 42Q's corporate standard.</center> <center> This document is under revision control. The latest revision is located on Intranet.</center> <center> Once printed it is an uncontrolled copy. All alterations to this work instruction require approval.</center> <center> Contact the IT Global Education and Training Department to submit suggested alterations and or updates.</center> <center> </center> <center> </center> <center style="text-align: left;"> </center> | ||

| − | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction"><span class="mw-headline" id="Introduction">Introduction</span></span></span></span></span></span></span></span></span></span></span> = |

<center style="text-align: left;"> | <center style="text-align: left;"> | ||

The '''SAP Adapter''' is a middleware software that has been developed for customers to seamlessly integrate their SAP systems with 42Q. This adapter can be installed in the customer’s SAP system in order to allow SAP users to monitor and iterate with 42Q. | The '''SAP Adapter''' is a middleware software that has been developed for customers to seamlessly integrate their SAP systems with 42Q. This adapter can be installed in the customer’s SAP system in order to allow SAP users to monitor and iterate with 42Q. | ||

| Line 72: | Line 72: | ||

| | ||

| − | = <span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order">Create a Work Order</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order"><span class="mw-headline" id="Create_a_Work_Order">Create a Work Order</span></span></span></span></span></span></span></span></span></span></span> = |

| | ||

| Line 113: | Line 113: | ||

| | ||

| − | = <span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation">Mapping an Operation</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation"><span class="mw-headline" id="Mapping_an_Operation">Mapping an Operation</span></span></span></span></span></span></span></span></span></span></span> = |

Mapping of operation happens on 42Q when we map the operation/routing received from SAP to the process/routing on 42Q. If users want to map a particular operation to a location in 42Q site | Mapping of operation happens on 42Q when we map the operation/routing received from SAP to the process/routing on 42Q. If users want to map a particular operation to a location in 42Q site | ||

| Line 144: | Line 144: | ||

</ol> | </ol> | ||

</center> <center style="text-align: left;"> </center> <center style="text-align: left;"> | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> | ||

| − | = <span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates">Monitor SAP updates</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates"><span class="mw-headline" id="Monitor_SAP_updates">Monitor SAP updates</span></span></span></span></span></span></span></span></span></span></span> = |

If the users want to see all transactions between SAP and 42Q, such as '''Acknowledgement''', '''WIP-Move''', '''MAT-Move''', '''Shipment''', and '''MAP-Issue''', follow the next steps: | If the users want to see all transactions between SAP and 42Q, such as '''Acknowledgement''', '''WIP-Move''', '''MAT-Move''', '''Shipment''', and '''MAP-Issue''', follow the next steps: | ||

| Line 161: | Line 161: | ||

| | ||

| − | == <span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change">Update / Change</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change"><span class="mw-headline" id="Update_.2F_Change">Update / Change</span></span></span></span></span></span></span></span></span></span></span> == |

Users can view updates or changes made to a Work Order (e. g. changes in quantity) by following the next steps: | Users can view updates or changes made to a Work Order (e. g. changes in quantity) by following the next steps: | ||

| Line 174: | Line 174: | ||

'''[[File:SA Work Order Updates-Changes.png|700x700px|SA Work Order Updates-Changes.png]]''' | '''[[File:SA Work Order Updates-Changes.png|700x700px|SA Work Order Updates-Changes.png]]''' | ||

</center> <center style="text-align: left;"> | </center> <center style="text-align: left;"> | ||

| − | == <span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move">WIP-Move</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move"><span class="mw-headline" id="WIP-Move">WIP-Move</span></span></span></span></span></span></span></span></span></span></span> == |

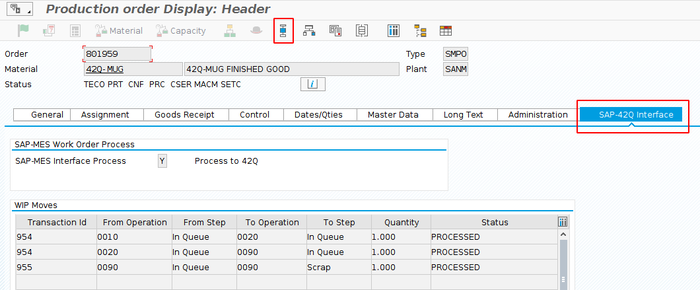

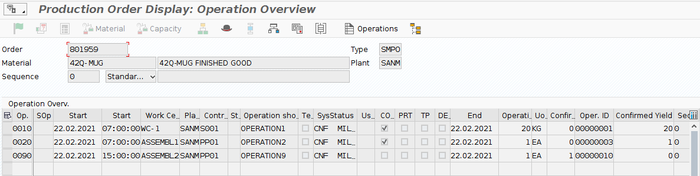

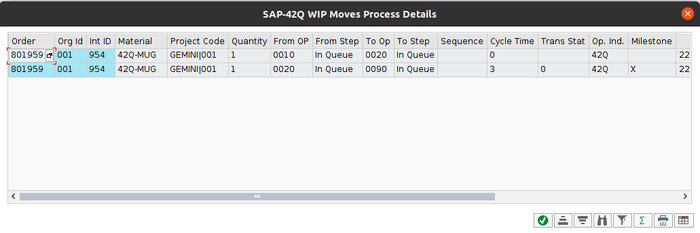

Users can view Work Order '''WIP-Moves''' by following the next steps: | Users can view Work Order '''WIP-Moves''' by following the next steps: | ||

| Line 233: | Line 233: | ||

| | ||

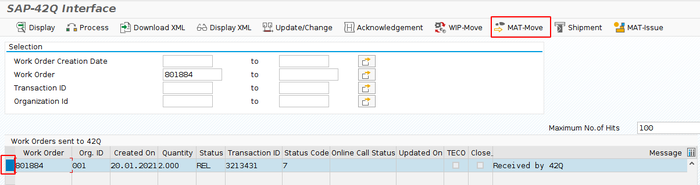

| − | == <span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move">MAT-Move</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move"><span class="mw-headline" id="MAT-Move">MAT-Move</span></span></span></span></span></span></span></span></span></span></span> == |

To get a material issue from 42Q the component/ BOM item should be set as PUSH type in SAP. If it is PULL type material standard backflush will happen for that BOM item | To get a material issue from 42Q the component/ BOM item should be set as PUSH type in SAP. If it is PULL type material standard backflush will happen for that BOM item | ||

| Line 261: | Line 261: | ||

| | ||

| − | == <span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""> </span></span></span></span> == | + | == <span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""><span class="mw-headline" id=""> </span></span></span></span></span> == |

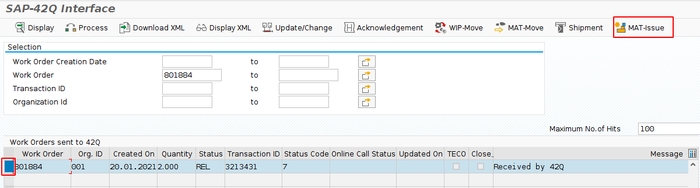

| − | == <span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue">MAT-Issue</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue"><span class="mw-headline" id="MAT-Issue">MAT-Issue</span></span></span></span></span></span></span></span></span></span></span> == |

Users can view Work Order MAT-Issues (Material Issues) by following the next steps: | Users can view Work Order MAT-Issues (Material Issues) by following the next steps: | ||

| Line 283: | Line 283: | ||

<br/> '''<u>Note</u>:''' When you receive a Work Order from SAP (or ERP) to 42Q, this Work Order '''Status''' will be set as '''N''' (Not released) in the 42Q system, if you want to release it, you must do it using 42Q. Figure 21: Work Order Received by 42Q. | <br/> '''<u>Note</u>:''' When you receive a Work Order from SAP (or ERP) to 42Q, this Work Order '''Status''' will be set as '''N''' (Not released) in the 42Q system, if you want to release it, you must do it using 42Q. Figure 21: Work Order Received by 42Q. | ||

</center> <center style="text-align: left;"> </center> <center style="text-align: left;">'''Figure 21: Work Order Received by 42Q'''</center> <center style="text-align: left;"> </center> <center style="text-align: left;">[[File:SA Work Order received by 42Q.png|700x700px|SA Work Order received by 42Q.png]]</center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> | </center> <center style="text-align: left;"> </center> <center style="text-align: left;">'''Figure 21: Work Order Received by 42Q'''</center> <center style="text-align: left;"> </center> <center style="text-align: left;">[[File:SA Work Order received by 42Q.png|700x700px|SA Work Order received by 42Q.png]]</center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> | ||

| − | = <span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order">Update Work Order</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order"><span class="mw-headline" id="Update_Work_Order">Update Work Order</span></span></span></span></span></span></span></span></span></span></span> = |

<center style="text-align: left;"> | <center style="text-align: left;"> | ||

SAP Adapter allows users to send work order changes to 42Q in the form of Work Order Update Transaction. | SAP Adapter allows users to send work order changes to 42Q in the form of Work Order Update Transaction. | ||

| Line 290: | Line 290: | ||

#'''Work Order Header''' <ol start="1" style="list-style-type: lower-alpha;"> | #'''Work Order Header''' <ol start="1" style="list-style-type: lower-alpha;"> | ||

| − | </ol> < | + | </ol> </ol> |

| + | |||

| + | *Status change: <ol start="1" style="list-style-type: lower-roman;"> | ||

<li>Unreleased to Released -- Send the entire work order details to 42Q</li> | <li>Unreleased to Released -- Send the entire work order details to 42Q</li> | ||

<li>On Hold</li> | <li>On Hold</li> | ||

| Line 296: | Line 298: | ||

<li>Canceled - Online call directly to 42Q to allow or not allow this change</li> | <li>Canceled - Online call directly to 42Q to allow or not allow this change</li> | ||

<li>Complete - No Charges -Online call directly to 42Q to allow or not allow this change</li> | <li>Complete - No Charges -Online call directly to 42Q to allow or not allow this change</li> | ||

| − | </ol> | + | </ol> <li>Scheduled Start Date change</li> |

| − | <li>Scheduled Start Date change</li> | ||

<li>Scheduled Completion Date</li> | <li>Scheduled Completion Date</li> | ||

<li>Start Quantity <ol start="1" style="list-style-type: lower-roman;"> | <li>Start Quantity <ol start="1" style="list-style-type: lower-roman;"> | ||

| Line 303: | Line 304: | ||

<li>Decrease - Online call directly to 42Q to allow or not allow this change</li> | <li>Decrease - Online call directly to 42Q to allow or not allow this change</li> | ||

</ol> </li> | </ol> </li> | ||

| − | < | + | <li> <ol start="2"> |

| − | <ol start="2"> | ||

<li>'''Work Order Routing/ Production Version/ Component Change''' </li> | <li>'''Work Order Routing/ Production Version/ Component Change''' </li> | ||

| − | </ol> | + | </ol> |

| − | |||

| | ||

| Line 318: | Line 317: | ||

#Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]] | #Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]] | ||

#Select '''Yes''' to save it, or select '''No''' or '''Cancel''' to abort. | #Select '''Yes''' to save it, or select '''No''' or '''Cancel''' to abort. | ||

| − | #Finally, a pop-up window will appear which shows the information changed, to close the window click on the green icon. | + | #Finally, a pop-up window will appear which shows the information changed, to close the window click on the green icon. |

| − | |||

| | ||

| | ||

| − | = <span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors">Checking Transaction Errors</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors"><span class="mw-headline" id="Checking_Transaction_Errors">Checking Transaction Errors</span></span></span></span></span></span></span></span></span></span></span> = |

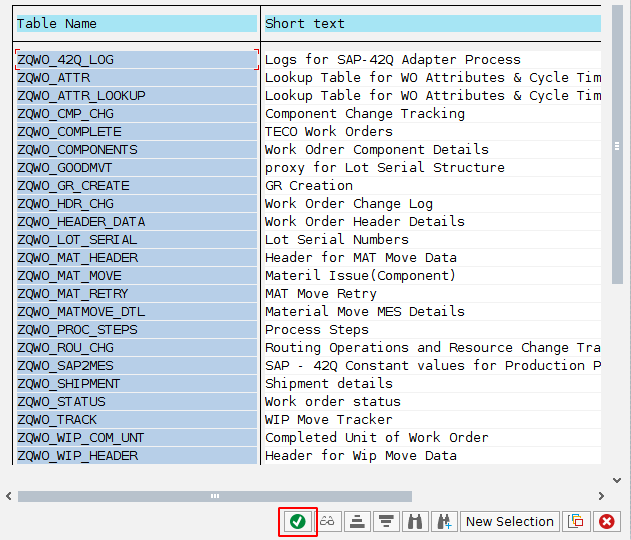

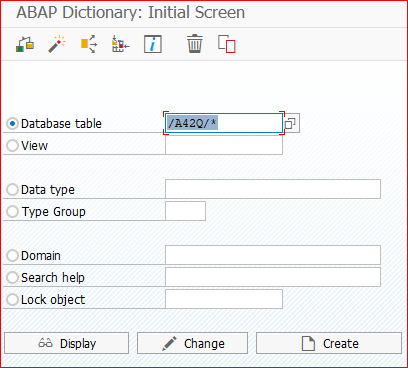

#Enter the next command in SAP: '''SE11'''. | #Enter the next command in SAP: '''SE11'''. | ||

#In the field of '''Database table''', enter '''/A42Q/*''' (or '''ZQWO_*''', '''ZWO_*'''), and click on the icon: [[File:SA Search Icon.png|30x30px|SA Search Icon.png]] to display all types of transactions. | #In the field of '''Database table''', enter '''/A42Q/*''' (or '''ZQWO_*''', '''ZWO_*'''), and click on the icon: [[File:SA Search Icon.png|30x30px|SA Search Icon.png]] to display all types of transactions. | ||

| − | #A pop-up window will appear, select one value from the '''Table Name''' column, and click on the accept button. | + | #A pop-up window will appear, select one value from the '''Table Name''' column, and click on the accept button. |

| − | |||

| | ||

| Line 339: | Line 336: | ||

<ol start="4"> | <ol start="4"> | ||

<li>Click on the '''Display''' button.</li> | <li>Click on the '''Display''' button.</li> | ||

| − | </ol> | + | </ol> |

| − | |||

<br/> '''Figure 23: Display Transaction Errors''' | <br/> '''Figure 23: Display Transaction Errors''' | ||

| Line 346: | Line 342: | ||

<ol start="5"> | <ol start="5"> | ||

<li>To search for specific information, click on the '''Contents''' button.</li> | <li>To search for specific information, click on the '''Contents''' button.</li> | ||

| − | </ol> | + | </ol> |

| − | |||

| | ||

| Line 355: | Line 350: | ||

'''[[File:SA View Contents.png|700x700px|SA View Contents.png]]''' | '''[[File:SA View Contents.png|700x700px|SA View Contents.png]]''' | ||

| + | </li> | ||

| + | </ul> | ||

</center> <center style="text-align: left;"> <ol start="6"> | </center> <center style="text-align: left;"> <ol start="6"> | ||

<li>Enter the information you want to look for. The next image will look for rejected WIP-Moves.</li> | <li>Enter the information you want to look for. The next image will look for rejected WIP-Moves.</li> | ||

| Line 366: | Line 363: | ||

'''Figure 25: Search for Rejected WIP-Moves''' | '''Figure 25: Search for Rejected WIP-Moves''' | ||

| − | '''[[File:SA Search for Rejected WIP-Moves.png]]''' | + | '''[[File:SA Search for Rejected WIP-Moves.png|SA Search for Rejected WIP-Moves.png]]''' |

| | ||

| Line 374: | Line 371: | ||

'''Figure 26: Rejected WIP-Moves Found''' | '''Figure 26: Rejected WIP-Moves Found''' | ||

| − | [[File:SA Rejected WIP-Moves Found.png|700x700px]] | + | [[File:SA Rejected WIP-Moves Found.png|700x700px|SA Rejected WIP-Moves Found.png]] |

| | ||

| Line 380: | Line 377: | ||

| | ||

| − | = <span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q">Send ship notification from SAP to 42Q</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q"><span class="mw-headline" id="Send_ship_notification_from_SAP_to_42Q">Send ship notification from SAP to 42Q</span></span></span></span></span></span></span></span></span></span></span> = |

| | ||

| − | == <span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order">Create a Sales Order</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order"><span class="mw-headline" id="Create_a_Sales_Order">Create a Sales Order</span></span></span></span></span></span></span></span></span></span></span> == |

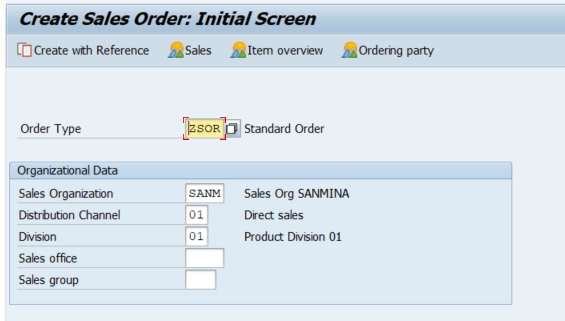

#Enter the next command in SAP: '''VA01'''. | #Enter the next command in SAP: '''VA01'''. | ||

| − | #In the field '''Order Type''', enter the value '''ZSOR''' and click on the icon: [[File:SA Enter Icon.png|30x30px]] | + | #In the field '''Order Type''', enter the value '''ZSOR''' and click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] |

| | ||

| Line 395: | Line 392: | ||

'''Figure 27: Create Sales Order Initial Screen''' | '''Figure 27: Create Sales Order Initial Screen''' | ||

| − | [[File:SA Create Sales Order Initial Screen.png]] | + | [[File:SA Create Sales Order Initial Screen.png|SA Create Sales Order Initial Screen.png]] |

| | ||

| Line 406: | Line 403: | ||

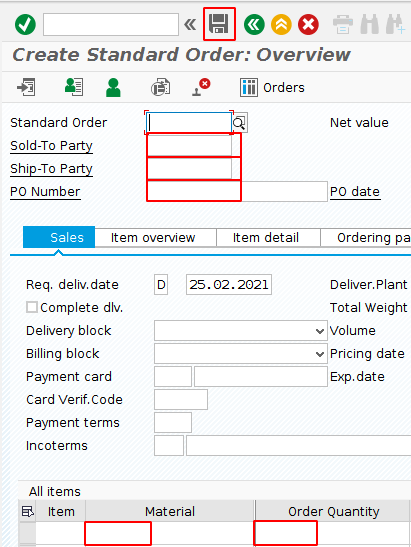

'''Figure 28: Filling out Sales Order Data''' | '''Figure 28: Filling out Sales Order Data''' | ||

| − | [[File:SA Filling out Sales Order Data.png]] | + | [[File:SA Filling out Sales Order Data.png|SA Filling out Sales Order Data.png]] |

| | ||

| Line 415: | Line 412: | ||

<br/> <br/> <br/> <br/> '''Figure 29: Standard Order Number Generated''' | <br/> <br/> <br/> <br/> '''Figure 29: Standard Order Number Generated''' | ||

| − | [[File:SA Standard Order Number Generated.png|700x700px]] | + | [[File:SA Standard Order Number Generated.png|700x700px|SA Standard Order Number Generated.png]] |

<ol start="5"> | <ol start="5"> | ||

<li>After creating a '''Sales Order''', the next step is to create an '''Outbound Delivery'''.</li> | <li>After creating a '''Sales Order''', the next step is to create an '''Outbound Delivery'''.</li> | ||

</ol> | </ol> | ||

</center> <center style="text-align: left;"> </center> <center style="text-align: left;"> | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> | ||

| − | == <span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery">Create an Outbound Delivery</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery"><span class="mw-headline" id="Create_an_Outbound_Delivery">Create an Outbound Delivery</span></span></span></span></span></span></span></span></span></span></span> == |

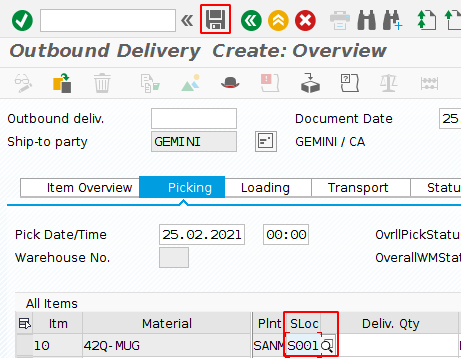

#Enter the next command in SAP: VL01N. | #Enter the next command in SAP: VL01N. | ||

| Line 427: | Line 424: | ||

<br/> <br/> '''Figure 30: Create Outbound Delivery Initial Screen''' | <br/> <br/> '''Figure 30: Create Outbound Delivery Initial Screen''' | ||

| − | [[File:SA Create Outbound Delivery Initial Screen.png|700x700px]] | + | [[File:SA Create Outbound Delivery Initial Screen.png|700x700px|SA Create Outbound Delivery Initial Screen.png]] |

| | ||

| Line 442: | Line 439: | ||

'''Figure 31: Filling out Outbound Delivery Data''' | '''Figure 31: Filling out Outbound Delivery Data''' | ||

| − | [[File:SA Filling out Outbound Delivery Data.png]] </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="7"> | + | [[File:SA Filling out Outbound Delivery Data.png|SA Filling out Outbound Delivery Data.png]] </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="7"> |

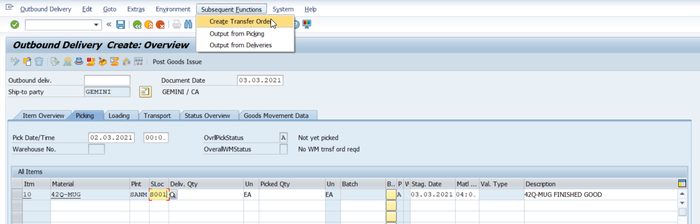

<li>After creating an '''Outbound Delivery''', the next step is to create a '''Transfer Order'''.</li> | <li>After creating an '''Outbound Delivery''', the next step is to create a '''Transfer Order'''.</li> | ||

</ol> | </ol> | ||

| − | < | + | |

| − | == <span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order">Create Transfer Order</span></span></span></span></span></span></span></span></span></span> == | + | |

| + | |||

| + | == <span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order"><span class="mw-headline" id="Create_Transfer_Order">Create Transfer Order</span></span></span></span></span></span></span></span></span></span></span> == | ||

#On the menu bar, click on the '''Subsequent Functions''' option. | #On the menu bar, click on the '''Subsequent Functions''' option. | ||

| Line 457: | Line 456: | ||

'''Figure 32: Create Transfer Order''' | '''Figure 32: Create Transfer Order''' | ||

| − | [[File:SA Create Transfer Order.png|700x700px]] | + | [[File:SA Create Transfer Order.png|700x700px|SA Create Transfer Order.png]] |

| | ||

<ol start="3"> | <ol start="3"> | ||

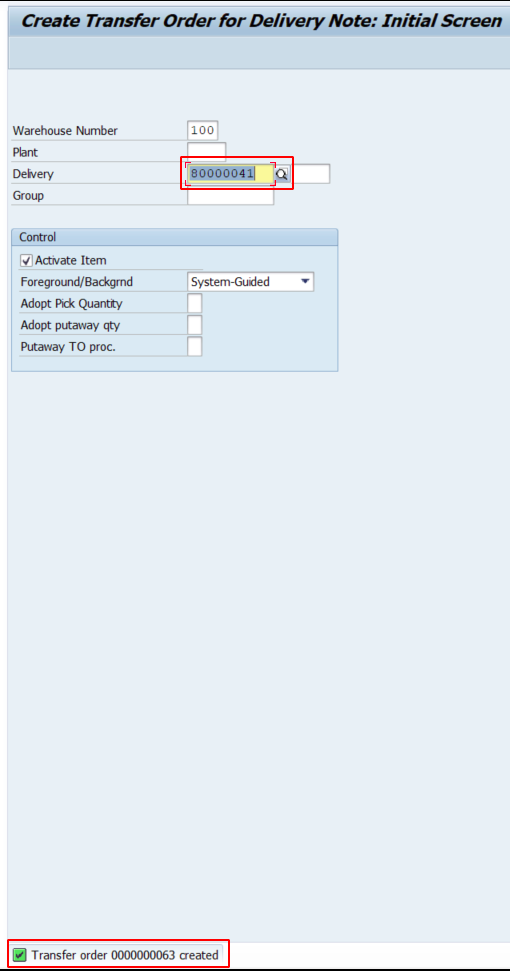

| − | <li>A new window will be displayed, you will notice that in the lower left corner will appear the Outbound Delivery number generated, make sure that number is entered in the '''Delivery''' field, then click on the icon: [[File:SA Enter Icon.png|30x30px]]</li> | + | <li>A new window will be displayed, you will notice that in the lower left corner will appear the Outbound Delivery number generated, make sure that number is entered in the '''Delivery''' field, then click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

</ol> | </ol> | ||

<br/> <br/> '''Figure 33: Outbound Delivery Number Generated''' | <br/> <br/> '''Figure 33: Outbound Delivery Number Generated''' | ||

| − | [[File:SA Outbound Delivery Number Generated.png]] | + | [[File:SA Outbound Delivery Number Generated.png|SA Outbound Delivery Number Generated.png]] |

| | ||

| Line 473: | Line 472: | ||

<ol start="4"> | <ol start="4"> | ||

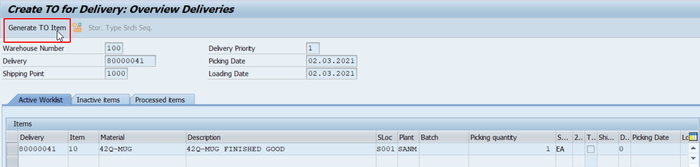

<li>Click on the '''Generate TO Item''' button.</li> | <li>Click on the '''Generate TO Item''' button.</li> | ||

| − | <li>Click on the Save icon: [[File:SA Save Icon.png|30x30px]]</li> | + | <li>Click on the Save icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]]</li> |

</ol> | </ol> | ||

<br/> <br/> '''Figure 34: Generate TO Item''' | <br/> <br/> '''Figure 34: Generate TO Item''' | ||

| − | '''[[File:SA Generate TO Item.png|700x700px]]''' | + | '''[[File:SA Generate TO Item.png|700x700px|SA Generate TO Item.png]]''' |

<ol start="6"> | <ol start="6"> | ||

<li>In the lower left corner you will see the Transfer Order number generated. Copy the value from the field '''Delivery'''.</li> | <li>In the lower left corner you will see the Transfer Order number generated. Copy the value from the field '''Delivery'''.</li> | ||

| Line 485: | Line 484: | ||

<br/> <br/> '''Figure 35: Transfer Order Number Generated''' | <br/> <br/> '''Figure 35: Transfer Order Number Generated''' | ||

| − | '''[[File:SA Transfer Order Number Generated.png]]''' | + | '''[[File:SA Transfer Order Number Generated.png|SA Transfer Order Number Generated.png]]''' |

| − | + | <ol start="7"> | |

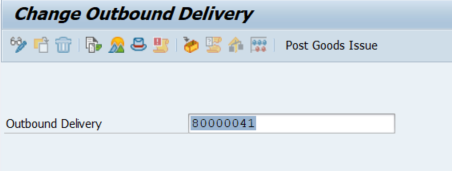

<li>Enter the next command in SAP: '''VL02N'''.</li> | <li>Enter the next command in SAP: '''VL02N'''.</li> | ||

| − | <li>A new window will be displayed. Click on the icon: [[File:SA Enter Icon.png|30x30px]]</li> | + | <li>A new window will be displayed. Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

</ol> | </ol> | ||

<br/> <br/> '''Figure 36: Change Outbound Delivery Initial Screen''' | <br/> <br/> '''Figure 36: Change Outbound Delivery Initial Screen''' | ||

| − | '''[[File:SA Change Outbound Delivery Initial Screen.png]]''' | + | '''[[File:SA Change Outbound Delivery Initial Screen.png|SA Change Outbound Delivery Initial Screen.png]]''' |

</center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="9"> | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="9"> | ||

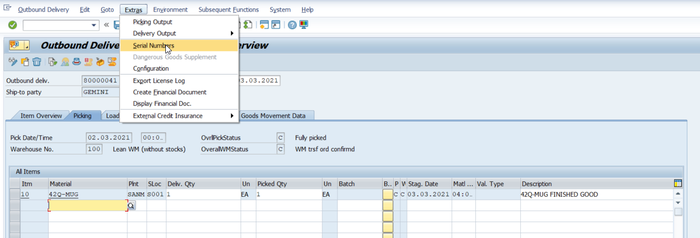

<li>On the menu bar, click on the '''Extras''' option.</li> | <li>On the menu bar, click on the '''Extras''' option.</li> | ||

| Line 505: | Line 504: | ||

'''Figure 37: Extras Options''' | '''Figure 37: Extras Options''' | ||

| − | '''[[File:SA Extras Options.png|700x700px]]''' | + | '''[[File:SA Extras Options.png|700x700px|SA Extras Options.png]]''' |

</center> <center style="text-align: left;"> <ol start="11"> | </center> <center style="text-align: left;"> <ol start="11"> | ||

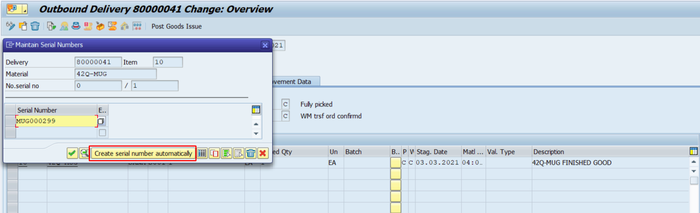

<li>Click on the button '''Create serial number automatically'''.</li> | <li>Click on the button '''Create serial number automatically'''.</li> | ||

| Line 512: | Line 511: | ||

<br/> <br/> '''Figure 38: Maintain Serial Numbers''' | <br/> <br/> '''Figure 38: Maintain Serial Numbers''' | ||

| − | '''[[File:SA Maintain Serial Numbers.png|700x700px]]''' | + | '''[[File:SA Maintain Serial Numbers.png|700x700px|SA Maintain Serial Numbers.png]]''' |

</center> <center style="text-align: left;"> <ol start="12"> | </center> <center style="text-align: left;"> <ol start="12"> | ||

<li>A new pop-up window will appear, check the boxes of the Order Numbers you want.</li> | <li>A new pop-up window will appear, check the boxes of the Order Numbers you want.</li> | ||

| − | <li>Click on the Copy icon: [[File:SA Enter Icon.png|30x30px]]</li> | + | <li>Click on the Copy icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

| − | <li>Then click on the Continue button: [[File:SA Enter Icon.png|30x30px]]</li> | + | <li>Then click on the Continue button: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]]</li> |

<li>Select a specific row.</li> | <li>Select a specific row.</li> | ||

| − | <li>Click on the icon: [[File:SA Enter Icon.png|30x30px]] to execute.</li> | + | <li>Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] to execute.</li> |

<li>Click on the '''Post Goods Issues''' button.</li> | <li>Click on the '''Post Goods Issues''' button.</li> | ||

</ol> | </ol> | ||

| Line 528: | Line 527: | ||

'''Figure 39: Outbound Delivery Change Overview''' | '''Figure 39: Outbound Delivery Change Overview''' | ||

| − | '''[[File:SA Outbound Delivery Change Overview.png|700x700px]]''' | + | '''[[File:SA Outbound Delivery Change Overview.png|700x700px|SA Outbound Delivery Change Overview.png]]''' |

</center> <center style="text-align: left;"> <ol start="18"> | </center> <center style="text-align: left;"> <ol start="18"> | ||

<li>Users will notice in the lower left corner that the Outbound Delivery number was generated.</li> | <li>Users will notice in the lower left corner that the Outbound Delivery number was generated.</li> | ||

| Line 535: | Line 534: | ||

<br/> <br/> '''Figure 40: Outbound Delivery Number Generated''' | <br/> <br/> '''Figure 40: Outbound Delivery Number Generated''' | ||

| − | '''[[File:SA Outbound Delivery Number Generated.png]]''' | + | '''[[File:SA Outbound Delivery Number Generated.png|SA Outbound Delivery Number Generated.png]]''' |

</center> <center style="text-align: left;"> <ol start="19"> | </center> <center style="text-align: left;"> <ol start="19"> | ||

<li>The next step is to create a '''Shipment'''.</li> | <li>The next step is to create a '''Shipment'''.</li> | ||

</ol> | </ol> | ||

| − | < | + | |

| − | == <span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment">Create a Shipment</span></span></span></span></span></span></span></span></span></span> == | + | |

| + | |||

| + | == <span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment"><span class="mw-headline" id="Create_a_Shipment">Create a Shipment</span></span></span></span></span></span></span></span></span></span></span> == | ||

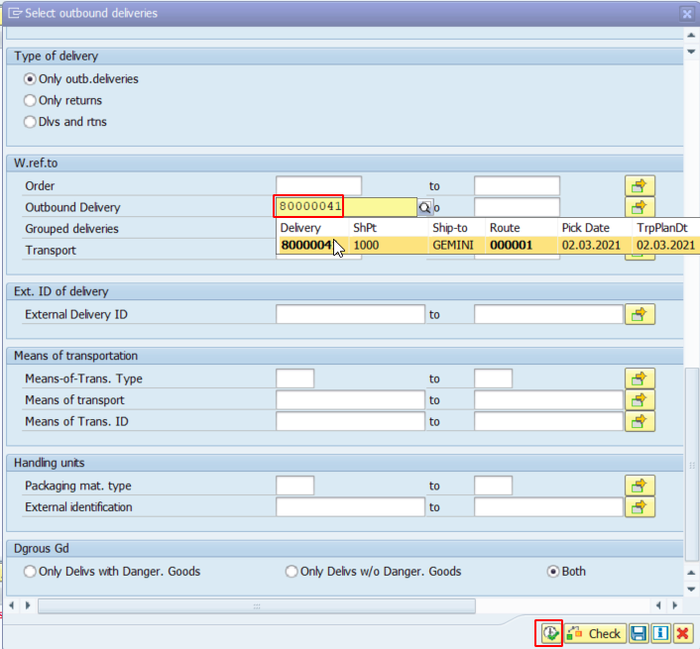

#Enter the next command: '''VT01N''' and press '''Enter'''. | #Enter the next command: '''VT01N''' and press '''Enter'''. | ||

| Line 554: | Line 555: | ||

'''Figure 41: Selecting Outbound Deliveries''' | '''Figure 41: Selecting Outbound Deliveries''' | ||

| − | [[File:SA Selecting Outbound Deliveries.png|700x700px]] | + | [[File:SA Selecting Outbound Deliveries.png|700x700px|SA Selecting Outbound Deliveries.png]] |

</center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="6"> | </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="6"> | ||

<li>Users will notice the Number of Deliveries found.</li> | <li>Users will notice the Number of Deliveries found.</li> | ||

| Line 561: | Line 562: | ||

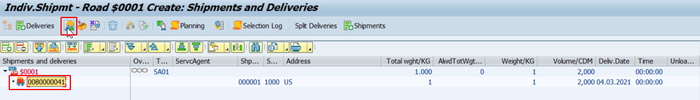

<br/> <br/> '''Figure 42: Number of Deliveries Found''' | <br/> <br/> '''Figure 42: Number of Deliveries Found''' | ||

| − | '''[[File:SA Number of Deliveries Found.png|700x700px]]''' | + | '''[[File:SA Number of Deliveries Found.png|700x700px|SA Number of Deliveries Found.png]]''' |

</center> <center style="text-align: left;"> <ol start="7"> | </center> <center style="text-align: left;"> <ol start="7"> | ||

<li>Select the shipment number that you just created.</li> | <li>Select the shipment number that you just created.</li> | ||

| Line 573: | Line 574: | ||

'''Figure 43: Selecting Shipment Number''' | '''Figure 43: Selecting Shipment Number''' | ||

| − | '''[[File:SA Selecting Shipment Number.png|700x700px]]''' | + | '''[[File:SA Selecting Shipment Number.png|700x700px|SA Selecting Shipment Number.png]]''' |

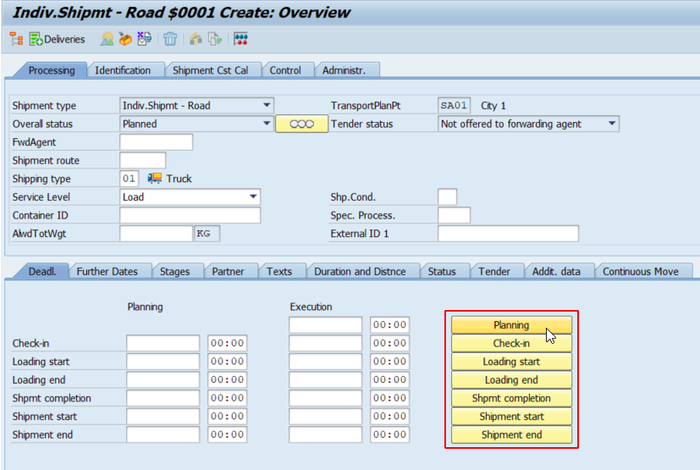

| | ||

| Line 582: | Line 583: | ||

<br/> <br/> <br/> <br/> '''Figure 44: Selecting Shipment Steps''' | <br/> <br/> <br/> <br/> '''Figure 44: Selecting Shipment Steps''' | ||

| − | '''[[File:SA Selecting Shipment Steps.png|700x700px]]''' | + | '''[[File:SA Selecting Shipment Steps.png|700x700px|SA Selecting Shipment Steps.png]]''' |

| | ||

| Line 588: | Line 589: | ||

| | ||

<ol start="10"> | <ol start="10"> | ||

| − | <li>Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px]]</li> | + | <li>Click on the '''Save''' icon: [[File:SA Save Icon.png|30x30px|SA Save Icon.png]]</li> |

</ol> | </ol> | ||

| Line 595: | Line 596: | ||

| | ||

| − | = <span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time">Standard Cycle Time and Hands on Time</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time"><span class="mw-headline" id="Standard_Cycle_Time_and_Hands_on_Time">Standard Cycle Time and Hands on Time</span></span></span></span></span></span></span></span></span></span></span> = |

'''<u>Note</u>:''' Part of 42Q 15.66 update. | '''<u>Note</u>:''' Part of 42Q 15.66 update. | ||

| Line 601: | Line 602: | ||

| | ||

| − | == <span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup">Hands on Time Setup</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup"><span class="mw-headline" id="Hands_on_Time_Setup">Hands on Time Setup</span></span></span></span></span></span></span></span></span></span></span> == |

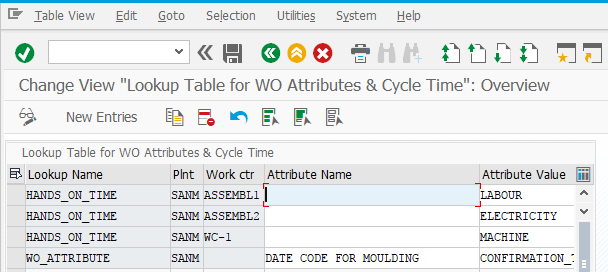

To configure Hands on Time on SAP, users must follow the next steps: | To configure Hands on Time on SAP, users must follow the next steps: | ||

| Line 631: | Line 632: | ||

'''Figure 45: Lookup Table''' | '''Figure 45: Lookup Table''' | ||

| − | '''[[File:SA Lookup Table.png]]'''<br/> <br/> <br/> Users can verify the Hands on Time and Cycle Time by navigating to: '''Reporting > MESWeb > Default Reports > Cycle Time Details Report''', filling out the information users are looking for, and press the '''Go''' button. | + | '''[[File:SA Lookup Table.png|SA Lookup Table.png]]'''<br/> <br/> <br/> Users can verify the Hands on Time and Cycle Time by navigating to: '''Reporting > MESWeb > Default Reports > Cycle Time Details Report''', filling out the information users are looking for, and press the '''Go''' button. |

| | ||

| Line 637: | Line 638: | ||

'''Figure 46: Cycle Time Details Report''' | '''Figure 46: Cycle Time Details Report''' | ||

| − | '''[[File:SA Cycle Time Details Report.png|700x700px]]''' | + | '''[[File:SA Cycle Time Details Report.png|700x700px|SA Cycle Time Details Report.png]]''' |

| | ||

| Line 643: | Line 644: | ||

| | ||

| − | == <span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values">Check Hands on Time Values</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values"><span class="mw-headline" id="Check_Hands_on_Time_Values">Check Hands on Time Values</span></span></span></span></span></span></span></span></span></span></span> == |

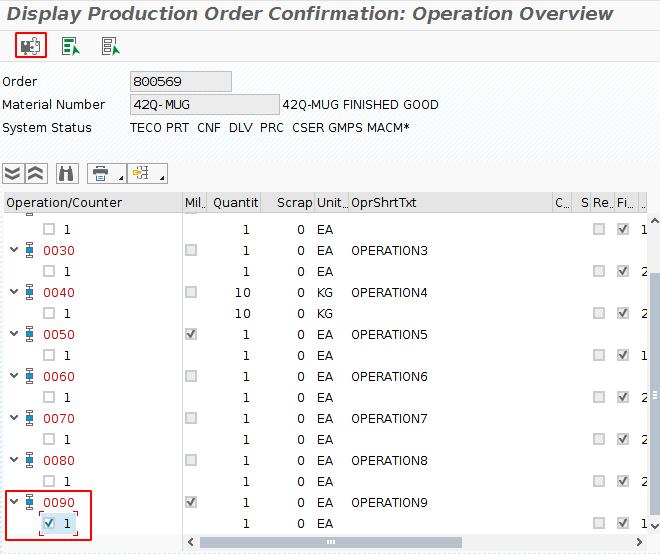

To check the HANDS_ON_TIME values on SAP, users must follow the next steps: | To check the HANDS_ON_TIME values on SAP, users must follow the next steps: | ||

| Line 652: | Line 653: | ||

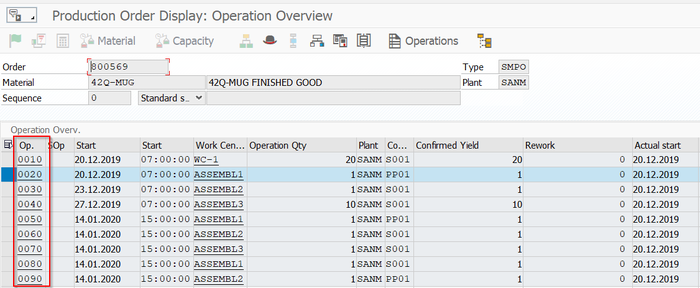

<br/> <br/> '''Figure 47: Production Order Display''' | <br/> <br/> '''Figure 47: Production Order Display''' | ||

| − | [[File:SA Production Order Display.png|700x700px]] | + | [[File:SA Production Order Display.png|700x700px|SA Production Order Display.png]] |

| | ||

| Line 667: | Line 668: | ||

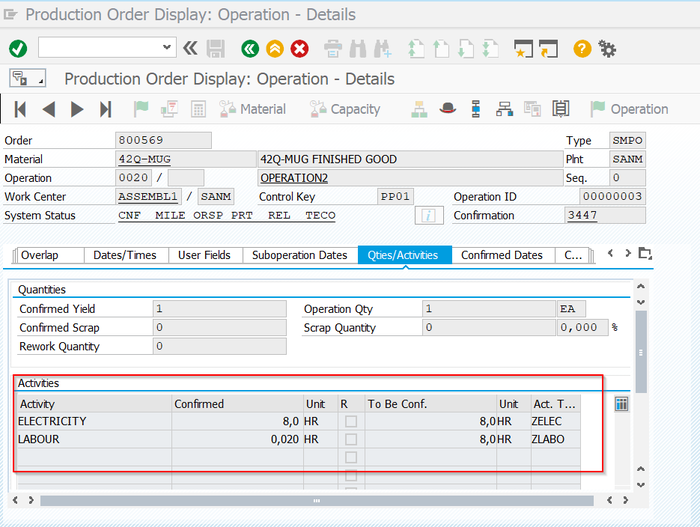

'''Figure 48: Selecting Operation Value''' | '''Figure 48: Selecting Operation Value''' | ||

| − | [[File:SA Selecting Operation Value.png|700x700px]] | + | [[File:SA Selecting Operation Value.png|700x700px|SA Selecting Operation Value.png]] |

| | ||

| Line 678: | Line 679: | ||

<br/> <br/> '''Figure 49: Displaying More Options''' | <br/> <br/> '''Figure 49: Displaying More Options''' | ||

| − | '''[[File:SA Displaying More Options.png|700x700px]]'''<br/> <br/> <br/> '''Figure 50: Qties-Activities Tab''' | + | '''[[File:SA Displaying More Options.png|700x700px|SA Displaying More Options.png]]'''<br/> <br/> <br/> '''Figure 50: Qties-Activities Tab''' |

| − | '''[[File:SA Qties-Activities Tab.png|700x700px]]''' | + | '''[[File:SA Qties-Activities Tab.png|700x700px|SA Qties-Activities Tab.png]]''' |

</center> <center style="text-align: left;"> | </center> <center style="text-align: left;"> | ||

| − | == <span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup">Standard Cycle Time Setup</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup"><span class="mw-headline" id="Standard_Cycle_Time_Setup">Standard Cycle Time Setup</span></span></span></span></span></span></span></span></span></span></span> == |

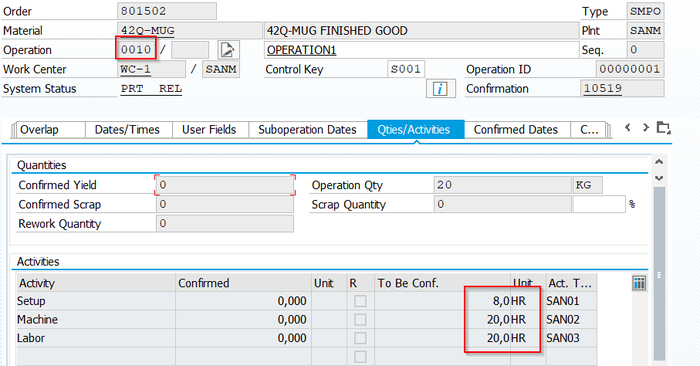

To configure Standard Cycle Time on SAP, users must follow the next steps: | To configure Standard Cycle Time on SAP, users must follow the next steps: | ||

| Line 691: | Line 692: | ||

<br/> <br/> '''Figure 51: Attributes from Lookup Table''' | <br/> <br/> '''Figure 51: Attributes from Lookup Table''' | ||

| − | '''[[File:SA Attributes from Lookup Table.png|700x700px]]''' | + | '''[[File:SA Attributes from Lookup Table.png|700x700px|SA Attributes from Lookup Table.png]]''' |

'''<u>Note</u>:''' For reference see the different attribute values that exist: | '''<u>Note</u>:''' For reference see the different attribute values that exist: | ||

| Line 705: | Line 706: | ||

'''Figure 52: Operation Value''' | '''Figure 52: Operation Value''' | ||

| − | '''[[File:SA Operation Value.png|700x700px]]''' | + | '''[[File:SA Operation Value.png|700x700px|SA Operation Value.png]]''' |

| | ||

| Line 715: | Line 716: | ||

'''Figure 53: Operation Value in Work Order Creation Code''' | '''Figure 53: Operation Value in Work Order Creation Code''' | ||

| − | '''[[File:SA Operation Value in Work Order Creation Code.png|700x700px]]''' | + | '''[[File:SA Operation Value in Work Order Creation Code.png|700x700px|SA Operation Value in Work Order Creation Code.png]]''' |

| − | < | + | |

| − | + | = <span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order"><span class="mw-headline" id="Standard_Cycle_Time_from_Work_Order">Standard Cycle Time from Work Order</span></span></span></span></span></span></span></span></span></span></span> = | |

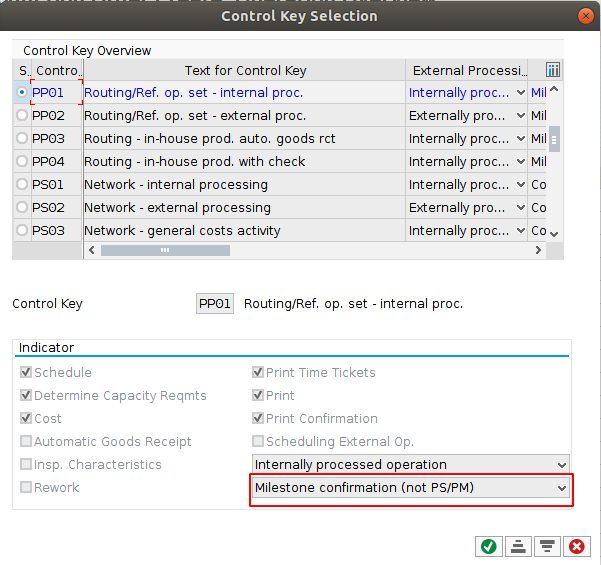

To send resource information such as setup time, machine time for operations from WO Level, users must select the ‘Ord lv Stf’ flag in '''/A42Q/CONSTANT''' (or '''ZQWO_CONSTANT''', '''ZWO_CONSTANT''') form. | To send resource information such as setup time, machine time for operations from WO Level, users must select the ‘Ord lv Stf’ flag in '''/A42Q/CONSTANT''' (or '''ZQWO_CONSTANT''', '''ZWO_CONSTANT''') form. | ||

| Line 727: | Line 728: | ||

'''Figure 54: Select ‘Ord lv Stf’ Flag''' | '''Figure 54: Select ‘Ord lv Stf’ Flag''' | ||

| − | '''[[File:SA Select ‘Ord lv Stf’ Flag.png|700x700px]]''' | + | '''[[File:SA Select ‘Ord lv Stf’ Flag.png|700x700px|SA Select ‘Ord lv Stf’ Flag.png]]''' |

| | ||

| Line 739: | Line 740: | ||

| | ||

| − | = <span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup">Date Code Setup</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup"><span class="mw-headline" id="Date_Code_Setup">Date Code Setup</span></span></span></span></span></span></span></span></span></span></span> = |

To configure Data Code on SAP, users must follow the next steps: | To configure Data Code on SAP, users must follow the next steps: | ||

| Line 760: | Line 761: | ||

<br/> When 42Q records '''DATE CODE FOR MOULDING''' attribute. The recorded value is sent to SAP.<br/> <br/> <br/> '''Figure 55: Recorded Value Received by 42Q''' | <br/> When 42Q records '''DATE CODE FOR MOULDING''' attribute. The recorded value is sent to SAP.<br/> <br/> <br/> '''Figure 55: Recorded Value Received by 42Q''' | ||

| − | [[File:SA Recorded Value Received by 42Q.png|700x700px]] | + | [[File:SA Recorded Value Received by 42Q.png|700x700px|SA Recorded Value Received by 42Q.png]] |

| | ||

| Line 766: | Line 767: | ||

| | ||

| − | == <span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code">Check Data Code</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code"><span class="mw-headline" id="Check_Data_Code">Check Data Code</span></span></span></span></span></span></span></span></span></span></span> == |

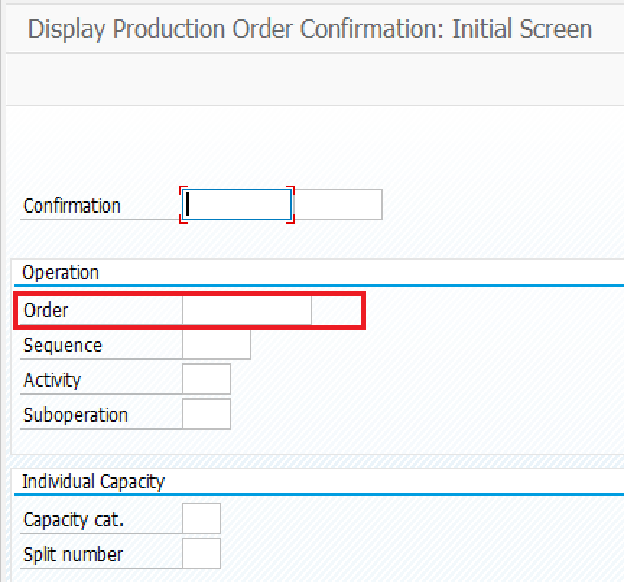

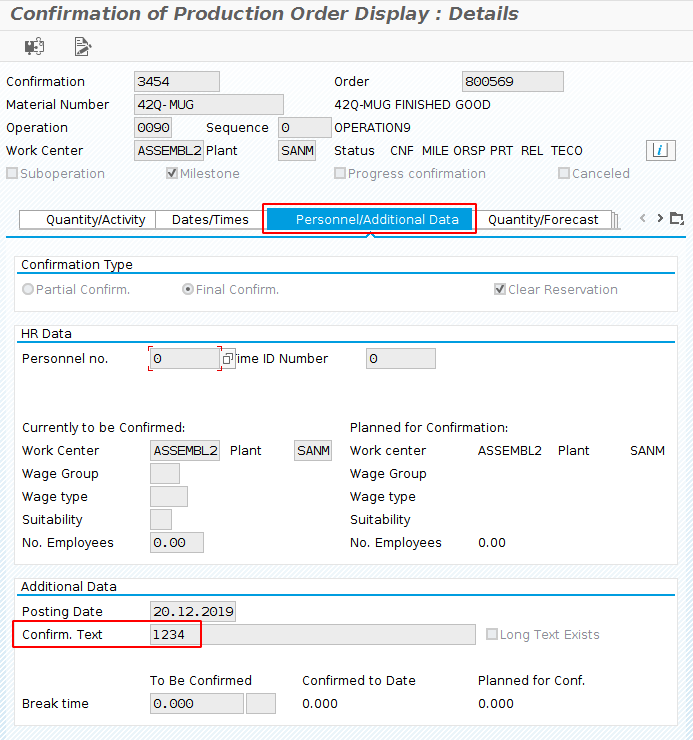

To check the Data Code on SAP, users must follow the next steps: | To check the Data Code on SAP, users must follow the next steps: | ||

| Line 775: | Line 776: | ||

<br/> '''Figure 56: Entering Work Order''' | <br/> '''Figure 56: Entering Work Order''' | ||

| − | [[File:SA Entering Work Order.png]] | + | [[File:SA Entering Work Order.png|SA Entering Work Order.png]] |

| | ||

| Line 790: | Line 791: | ||

'''Figure 57: Selecting Final Confirmation''' | '''Figure 57: Selecting Final Confirmation''' | ||

| − | [[File:SA Selecting Final Confirmation.png]] </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="5"> | + | [[File:SA Selecting Final Confirmation.png|SA Selecting Final Confirmation.png]] </center> <center style="text-align: left;"> </center> <center style="text-align: left;"> </center> <center style="text-align: left;"><ol start="5"> |

<li>Select the '''Personnel/Additional Data''' tab.</li> | <li>Select the '''Personnel/Additional Data''' tab.</li> | ||

<li>Users will see that the '''Date Code''' is available in the Confirmation text field.</li> | <li>Users will see that the '''Date Code''' is available in the Confirmation text field.</li> | ||

| Line 798: | Line 799: | ||

<br/> '''Figure 58: Data Code''' | <br/> '''Figure 58: Data Code''' | ||

| − | [[File:SA Data Code.png]]</center> <center style="text-align: left;">< | + | [[File:SA Data Code.png|SA Data Code.png]]</center> <center style="text-align: left;"> |

| − | + | = <span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR"><span class="mw-headline" id="Perform_GR">Perform GR</span></span></span></span></span></span></span></span></span></span></span> = | |

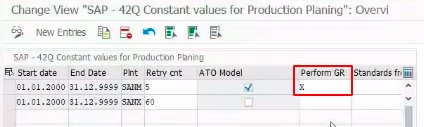

First of all, users must do two different types of configuration, Automatic GR Configuration and Enable Perform GR Flag: | First of all, users must do two different types of configuration, Automatic GR Configuration and Enable Perform GR Flag: | ||

| Line 805: | Line 806: | ||

| | ||

| − | == | + | == <span class="mw-headline" id=".E2.80.8B.E2.80.8B.E2.80.8B.E2.80.8B.E2.80.8B.E2.80.8B.E2.80.8BEnable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag"><span class="mw-headline" id="Enable_Perform_GR_Flag">Enable Perform GR Flag</span></span></span></span></span></span></span></span></span></span></span> == |

This function allows users to use the adapter to do the delivery manually at a later stage: | This function allows users to use the adapter to do the delivery manually at a later stage: | ||

| Line 818: | Line 819: | ||

'''Figure 59: Constant Table Window''' | '''Figure 59: Constant Table Window''' | ||

| − | '''[[File:SA Constant Table Window.png]]''' | + | '''[[File:SA Constant Table Window.png|SA Constant Table Window.png]]''' |

| − | < | + | |

| − | == <span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration">Automatic GR Configuration</span></span></span></span></span></span></span></span></span></span> == | + | == <span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration"><span class="mw-headline" id="Automatic_GR_Configuration">Automatic GR Configuration</span></span></span></span></span></span></span></span></span></span></span> == |

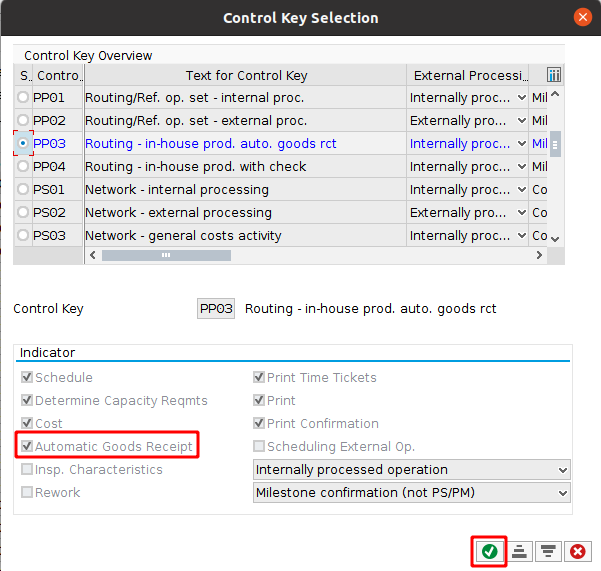

In order to do this configuration, users must follow the next steps: | In order to do this configuration, users must follow the next steps: | ||

| Line 826: | Line 827: | ||

#Enter the next command in SAP: '''CO02'''. | #Enter the next command in SAP: '''CO02'''. | ||

#Enter the Work Order number in the field '''Order'''. | #Enter the Work Order number in the field '''Order'''. | ||

| − | #Click on the icon: [[File:SA Enter Icon.png|30x30px]] | + | #Click on the icon: [[File:SA Enter Icon.png|30x30px|SA Enter Icon.png]] |

| − | #Click on the '''Operation Overview''' icon: [[File:SA Operation Overview Icon.png|30x30px]] | + | #Click on the '''Operation Overview''' icon: [[File:SA Operation Overview Icon.png|30x30px|SA Operation Overview Icon.png]] |

#A new list of operations will be displayed, choose one operation and hover the mouse cursor over its corresponding '''Control Key''' field, when a hover icon appears next to this field, click on it. | #A new list of operations will be displayed, choose one operation and hover the mouse cursor over its corresponding '''Control Key''' field, when a hover icon appears next to this field, click on it. | ||

| Line 836: | Line 837: | ||

'''Figure 60: Control Key Icon''' | '''Figure 60: Control Key Icon''' | ||

| − | '''[[File:SA Control Key Icon.png|700x700px]]''' | + | '''[[File:SA Control Key Icon.png|700x700px|SA Control Key Icon.png]]''' |

</center> <center style="text-align: left;"> <ol start="6"> | </center> <center style="text-align: left;"> <ol start="6"> | ||

<li>Mark the'''Automatic Goods Receipt''' checkbox and click on the green '''Continue''' button.</li> | <li>Mark the'''Automatic Goods Receipt''' checkbox and click on the green '''Continue''' button.</li> | ||

| Line 847: | Line 848: | ||

'''Figure 61: Automatic Goods Receipt Option''' | '''Figure 61: Automatic Goods Receipt Option''' | ||

| − | [[File:SA Automatic Goods Receipt Option.png]] | + | [[File:SA Automatic Goods Receipt Option.png|SA Automatic Goods Receipt Option.png]] |

| | ||

| Line 853: | Line 854: | ||

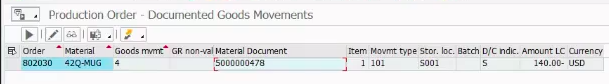

'''<u>Note</u>:''' If the information or the final operation sequence are done, then the adapter will prevent users from marking the Automatic GR (Goods Receipt) option. On the other hand, if the Automatic GR is enabled the SAP system will take it forward but the adapter will not bate if the Automatic GR is successfully processed or not, if the Automatic GR fails, the delivered quantity will have an impact, so the delivered quantity will not be available and if it’s not available, users won’t be able to change the status to TECO as in Figure 62.<br/> <br/> <br/> '''Figure 62: Production Order Status''' | '''<u>Note</u>:''' If the information or the final operation sequence are done, then the adapter will prevent users from marking the Automatic GR (Goods Receipt) option. On the other hand, if the Automatic GR is enabled the SAP system will take it forward but the adapter will not bate if the Automatic GR is successfully processed or not, if the Automatic GR fails, the delivered quantity will have an impact, so the delivered quantity will not be available and if it’s not available, users won’t be able to change the status to TECO as in Figure 62.<br/> <br/> <br/> '''Figure 62: Production Order Status''' | ||

| − | '''[[File:SA Production Order Status.png|700x700px]]''' | + | '''[[File:SA Production Order Status.png|700x700px|SA Production Order Status.png]]''' |

| | ||

| Line 869: | Line 870: | ||

'''Figure 63: Documented Goods Movements Window''' | '''Figure 63: Documented Goods Movements Window''' | ||

| − | '''[[File:SA Documented Goods Movements Window.png]]''' | + | '''[[File:SA Documented Goods Movements Window.png|SA Documented Goods Movements Window.png]]''' |

| | ||

| Line 876: | Line 877: | ||

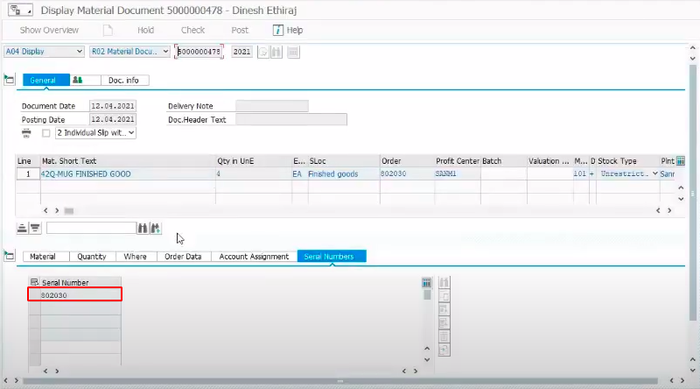

Users will be able to pass the serial number only if it was not configured with the Automatic GR option in Control Key.<br/> <br/> <br/> '''Figure 64: Material Document Window''' | Users will be able to pass the serial number only if it was not configured with the Automatic GR option in Control Key.<br/> <br/> <br/> '''Figure 64: Material Document Window''' | ||

| + | |||

| + | [[File:SA Material Document WIndow.png|700x700px]] | ||

| + | <br/> | ||

| + | = <span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag"><span class="mw-headline" id="Scheduled_Start_and_End_Time_Flag">Scheduled Start and End Time Flag</span></span></span></span></span></span></span></span></span></span></span> = | ||

| + | |||

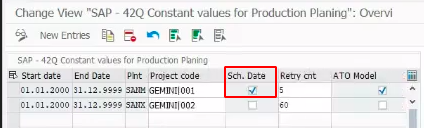

| + | This flag will allow the users to select between the two dates at the work order level. | ||

| + | |||

| + | If this flag is enabled at the constant table, the adapter will pick the dates from the Scheduled start date and end date column, but if it is disabled, users will pick the dates between the Basic start date and End date. | ||

| + | |||

| + | | ||

| | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''Figure 65: Scheduled Date Flag''' | |

| − | + | '''[[File:SA Scheduled Date Flag.png]]'''<br/> <br/> | |

| − | + | '''Figure 66: WO Basic and Scheduled Date''' | |

| − | [ | + | '''[[File:SA WO Basic and Scheduled Date.png]]''' |

| − | + | | |

| − | + | | |

| − | + | ||

| − | + | = <span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag"><span class="mw-headline" id="TECO_Flag">TECO Flag</span></span></span></span></span></span></span></span></span></span></span> = | |

| − | </ | ||

| − | + | In the command field, enter the following command: /A42Q/PROCESS (or ZQWO_PROCESS, ZWO_PROCESS) (process table), press Enter and enable the TECO flag as in Figure 67. | |

After the TECO flag is enabled at the process table, any updates to the work order will not be sent to 42Q. | After the TECO flag is enabled at the process table, any updates to the work order will not be sent to 42Q. | ||

| Line 908: | Line 913: | ||

<br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <ol start="14"> | <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <ol start="14"> | ||

<li> | <li> | ||

| − | = <span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change">WIP Confirmation Change </span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change"><span class="mw-headline" id="WIP_Confirmation_Change">WIP Confirmation Change </span></span></span></span></span></span></span></span></span></span></span> = |

</li> | </li> | ||

</ol> | </ol> | ||

| Line 931: | Line 936: | ||

<br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <ol start="15"> | <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <br/> <ol start="15"> | ||

<li> | <li> | ||

| − | = <span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP">'''Common Issues on SAP'''</span></span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP"><span class="mw-headline" id="Common_Issues_on_SAP">'''Common Issues on SAP'''</span></span></span></span></span></span></span></span></span></span></span> = |

</li> | </li> | ||

</ol> | </ol> | ||

| Line 937: | Line 942: | ||

'''Figure 69: Common Issues on SAP''' | '''Figure 69: Common Issues on SAP''' | ||

| − | = <span class="mw-headline" id="_3"><span class="mw-headline" id="_3"><span class="mw-headline" id="_3"><span class="mw-headline" id="_3"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"> </span></span></span></span></span></span></span></span></span> = | + | = <span class="mw-headline" id="_2"><span class="mw-headline" id="_3"><span class="mw-headline" id="_3"><span class="mw-headline" id="_3"><span class="mw-headline" id="_3"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"><span class="mw-headline" id="_2"> </span></span></span></span></span></span></span></span></span></span> = |

</center> | </center> | ||

Revision as of 18:18, 14 July 2021

42Q Home > Tools > SAP Adapter

Contents

- 1 Introduction

- 2 Create a Work Order

- 3 Mapping an Operation

- 4 Monitor SAP updates

- 5 Update Work Order

- 6 Checking Transaction Errors

- 7 Send ship notification from SAP to 42Q

- 8 Standard Cycle Time and Hands on Time

- 9 Standard Cycle Time from Work Order

- 10 Date Code Setup

- 11 Perform GR

- 12 Scheduled Start and End Time Flag

- 13 TECO Flag

- 14 WIP Confirmation Change

- 15 Common Issues on SAP

- 16

Introduction

The SAP Adapter is a middleware software that has been developed for customers to seamlessly integrate their SAP systems with 42Q. This adapter can be installed in the customer’s SAP system in order to allow SAP users to monitor and iterate with 42Q.

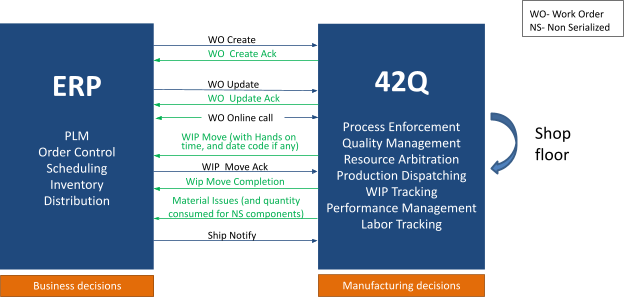

The below diagram explains the capabilities provided by these SAP Adapters:

Figure 1: SAP Diagram

The SAP adapter requires an initial setup for new customers.

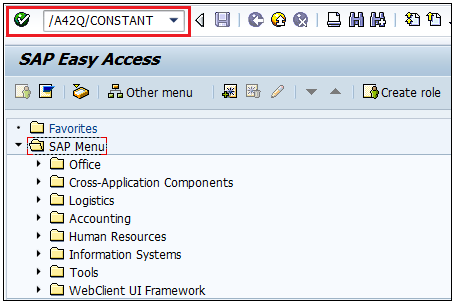

- In the command field, enter the following command: /A42Q/CONSTANT (or ZQWO_CONSTANT, ZWO_CONSTANT), and then press Enter.

Figure 2: Command Field

- On the new window, set up the Org. Id (Organization code) and the Customer (Customer code).

Figure 3: Initial Set Up

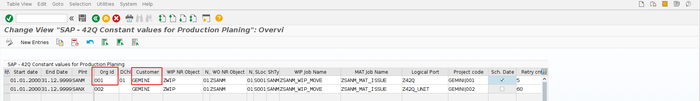

- Now it’s time to set up the BOM’s information, enter the next command: CS02, and then press Enter.

- Click on the Header icon:

- Click on the SAP-42Q Interface tab.

Figure 4: 42Q Interface

- In the SFDC System field, click on the icon:

, select the value MES and then click on the icon:

, select the value MES and then click on the icon:

- In the Interface Type field, click on the icon:

, select one of the following values:

, select one of the following values:

- DEFAULT: Use this value if you want to send WO Header, WO Route, Flex field, or ATO Details (if applicable) to 42Q.

- SYS-BUILD: Use this value if you want to send WO Header, WO Route, or BOM to 42Q.

Note: In the previous step 2, users set up the Organization code and Customer code, the purpose of these fields is determine how the adapter will perform for each plant.

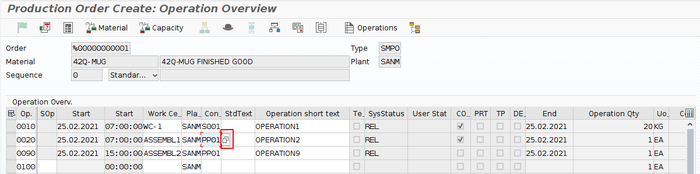

Create a Work Order

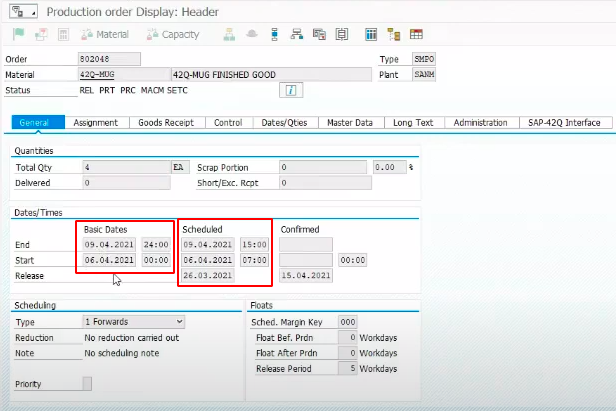

- Enter the next command: CO01, and then press Enter.

- In the Material field, enter a Part Number.

- Enter the Production Plant.

- Enter the Planning Plant.

- Enter the Order Type.

- Press Enter.

Figure 5: Production Order Create

- Set the Total Qty, Start date, and End date.

Figure 6: Work Order Creation

- Click on the icon:

to release the Work Order.

to release the Work Order. - Click on the Save icon to save the Work Order. The work order will be sent to 42Q.

Based on correct setups Work Order XML will include the following information:

- WO Header

- WO Production Version

- WO Routing and standard times for each operation (For sending standard time setup should be done correctly, see section nn for that)

- WO Component

Mapping an Operation

Mapping of operation happens on 42Q when we map the operation/routing received from SAP to the process/routing on 42Q. If users want to map a particular operation to a location in 42Q site

- Enter the next command: CO01 and then press Enter.

- Click on the Operation Overview icon:

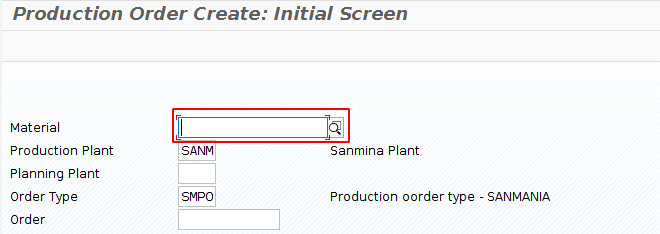

- A new list of operations will be displayed, choose one operation and hover the mouse cursor over its corresponding Control Key field, when a hover icon appears next to this field, click on it.

Figure 7: Component Overview

- A new pop-up window will appear, then in the last field in the lower right corner select the Milestone confirmation (not PS/PM) option.

- Click on the icon:

to save changes.

to save changes.

Figure 8: Control Key Selection

- Click on the icon:

to go back to the Production Order Create: Header.

to go back to the Production Order Create: Header. - Click on the Save icon:

, then select Yes to save it, or select No or Cancel to abort.

, then select Yes to save it, or select No or Cancel to abort. - A pop-up window will be displayed to show you the information of the recently mapped operation, finally, click on the icon:

to close the window.

to close the window.

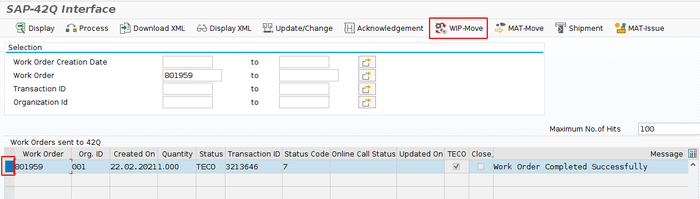

Monitor SAP updates

If the users want to see all transactions between SAP and 42Q, such as Acknowledgement, WIP-Move, MAT-Move, Shipment, and MAP-Issue, follow the next steps:

- Enter the next command: /A42Q/PROCESS (or ZQWO_PROCESS, ZWO_PROCESS), and then press Enter.

- Users can see in the Message column if the information was received successfully by 42Q.

Figure 9: Work Order Transactions

Update / Change