Difference between revisions of "Release Notes"

| Line 19: | Line 19: | ||

| | ||

| + | |||

| Line 89: | Line 90: | ||

| | ||

| − | '''Business Systems Connectivity - Tinmon v1.4. | + | '''Business Systems Connectivity - Tinmon v1.4.6''' |

Improvements | Improvements | ||

| Line 379: | Line 380: | ||

*Portlet manage_shop_order_serials function, used by the Shop Order portlet, updated to replace the units on a shop order with a skeleton serial. | *Portlet manage_shop_order_serials function, used by the Shop Order portlet, updated to replace the units on a shop order with a skeleton serial. | ||

| − | |||

*ERP Shop Order enhanced to allow users to have not only the “Internal” revisions but the serial numbers and/or labels with their revisions as well. | *ERP Shop Order enhanced to allow users to have not only the “Internal” revisions but the serial numbers and/or labels with their revisions as well. | ||

Revision as of 14:56, 21 July 2020

42Q Home > 42Q Release Notes

Introduction

The following release notes were created to communicate with external customers the details of changes or enhancements made to the 42Q portal. The release notes are organized by date, with the most recent appearing first. All medically validated versions are denoted with asterisks and appear in blue font (Ex. ***April 2016***). All versions prior to a medically validated version are included in the medically validated packages.

15.64 Non-Medical Deployment

Version: 15.64 Non-Medical

Environment: Non-Medical Production HA Environment

Asset Performance - OEE v2.6.0

Improvements

- The Part Number in OEE was changed from Optional to Mandatory as well as the Shop Order, changed from Mandatory to Optional, to allow the user to configure the Target UPH.

- OEE renamed the Menu in the 42Q portal to:

- Shop Floor Control → Configuration → (OEE replaced by OEE Configuration), in order to keep the consistency, the tab needs to change from OEE to OEE Configuration as the menu.

- Production → (OEE Data Collection replaced by Manual OEE Workbench), it needs to change the portlet name to fit for the new menu structure.

- OEE fuji-host interface improvement to increase more computation capability for more machines to connect to the system.

Business Intelligence - MESWeb Execution v4.7.7

Improvements

- The existing Yield & Defect report logic has been updated in order to properly accommodate panels and single units to have a new MESWeb report that will provide an accurate yield report for panels by counting the defective boards (reference designator).

- Timeout connection was added to the DataBase server to avoid the server to reconnect non stop.MU

- Yield Serials Report upgraded to display the data properly with Y&D Report upgrades.

- Yield and Defect reports improvement to calculate excel percentage correctly when exported.

- Reports updated to define the work week period are from Sunday to Saturday in OEE.

Business Intelligence - Operation Dashboard v1.1.1

Improvements

- “Part_Key“ option field was removed and the “Product” column field was renamed to be labeled as “Part_Number” for Operation Dashboard.

Business Intelligence - SPC v1.2.25

Improvements

- For monitor creation, enhance attribute group validation through MES101 rather than by attribute name alike.

- SPC server structure was refactored to support the dynamic of adding/removing instances and the ability to use the same program with different configurations within all plant sites.

- Enhancement to ensure LCL = 0, if the calculation of LCL < 0, for R chart and S chart only.

- Remove no longer used parameters named "#of active thread" in the SPC System Parameter Maintenance page.

Business Intelligence - Vision (ePanel) v1.1.1

Improvements

- The SPC Dashboard was enhanced to allow the users to transfer one more parameter name ‘shopFloorId’ when calling the SPC API.

Business Systems Connectivity - ERP Interface

Improvements

- 42Q ERP interface updated to allow completions on “unreleased” shop orders.

Business Systems Connectivity - Tinmon v1.4.6

Improvements

- A new configuration per site needs to be configured to determine the customer_codes that the customer_part_revision will be used as default to release ERP Shop Orders:

- Table: shop_order

- Attribute Name: default_customer_revision_by_customer_code

- Table: shop_order

- For Roboship, mark child containers as ‘Sent’ for FTP and XML.

- 42Q ERP interface updated to allow completions on “unreleased” shop orders.

- Wip Move Ack updated to add email alerts for missing data, including wip move ack status and time that is processed in tables.

CMMS - CMMS v2.6.1

New Features

- Add Downtime Resolution Cycle Time Report to sort out Downtime events and related Repair Work Order records.

- CMMS provides a new API for Production Scheduling to get the PM Calendar.

Improvements

- CMMS has the following new Calibration History enhancements:

- Place control and standards for calibration input status workflow.

- Timezone verification to show calibration history in site timezone rather than UTC.

- Enhancements for Work Request module to improve the following:

- "My Requests" changed to “My Requested”.

- "Category Des" changed to "Category Description".

- When opening a work request module the first time, it will be duplicated with buttons. Users have to refresh the page to make it show properly.

- Backend change does not occur when WR approval is done.

- Performance improvements in the following backend services/jobs.

- Calibration, PM and WO escalation, PM email notification, WO & Checklist.

- CMMS cron job to support H/A.

- Asset Dashboard improved to show as Asset ID rather than Asset Name with configurable width and height.

- Tooling load quantity was enhanced to conform to the mapped quantity and showing the milestone display.

IIOT - Measurement v3.2.0.3

Improvements

- Sensor Capture Parser (IIoT) was adjusted to support client_id (new SPC API’s requirement).

- The improvements in the Parser include:

- Add the Client_ID info in the requests made to SPC API.

- Dynamic Configuration cleanup in order to remove configuration switches no longer used as well as to rename misleading ones:

- Implemented a way to make the Parser configurable to stick to the pre-existing infinite loop (while(true)) or to follow Core’s standard polling cycle.

- The improvements in the Parser include:

Production Scheduling v1.0.2

New Features

- Main Production Scheduling screen includes:

- A calendar that includes the ability to select different views daily, weekly, monthly, and yearly.

- Ability to preview a list of shop orders with status unscheduled.

- Shop Order updated to allow the ability to schedule a shop order by dragging the selected order from the list and onto the calendar.

- Enabled Shop Order list and filters to appear in grid view to enable faster searching.

- Within the calendar view, a detailed scheduled Shop Order list is provided within the block representing each scheduled Shop Order for a given mfg line/machine.

- Shop Order system enhanced to allow the ability to let the planners add extra comments to the scheduled Shop Orders.

- Shop Order system allows the ability to cancel a scheduled Shop Order by simply right-clicking and canceling, or by moving the Shop Order into the trash icon.

- Shop Order system enhanced to prevent Shop Orders from being scheduled within past dates.

- Shop Order system allows the user to see the current 42Q MFG shift configuration within the calendar.

- Shop Order system allows the ability to collapse all panels to maximize the calendar display.

- Shop Order system allows the ability to split a scheduled Shop Order into different lines and time slots.

- Access to production schedule module from Production control.

MES 101 - Appgarden v2.0.6

New Features

- Custom keyboard added on Appgarden for users to easily input the host and allow the ability to select the host by clicking the “H” button.

MES 101 - Conduit v1.10.1

New Features

- Conduit /Production Workbench enhanced to allow the ability to scan boards for PTS mapped locations.

- Pre-split behavior implemented during the scanning of panel serial numbers within Conduit.

- When a panel serial number is scanned in conduit (whether conduit creates the panel or the panel already existed) conduit will:

- Lookup extended panel configuration for the panel in the SDE.

- If pre-split is enabled conduit will :

- Generate panel quantity serial number values using either the algorithm engine or an incrementing suffix

- Generate panel quantity “positions” using either ROWS/COLS or a separate algorithm

- Create a serial record for each generated serial number value. and add as a tracked component to the panel serial number at the generated board position reference designator.

- When a panel serial number is scanned in conduit (whether conduit creates the panel or the panel already existed) conduit will:

- Pre-split operations (SplitPanel, SplitPanelAlgorithm, and SplitEntirePanel) updated in order to match a provided split serial number with a specific panel position.

- Update Record Defect to take the optional new field.

- Record defect has been altered to take a new optional field: component_position

- When this value is provided the Record Defect will include the following behavior:

- Attempt to find an unremoved, tracked serial number at a reference designator matching the component_position

- If present, the operation will record what amounts to duplicate defect on the component serial number’

- The original defect and the component defect will be linked together using the LinkDefect operation.

- When this value is provided the Record Defect will include the following behavior:

- Repair defect code updated to allow the ability for operators to repair any and all child defects linked to the one being explicitly repaired.

- Support added for CONDUIT_PANEL lines to allow for extended attributes in relation to pre-splitting.

- Production Workbench error message updated to provide users with location names instead of location keys when an error message occurs.

Improvements

- Enhancement to allow the capability for Conduit to support custom algorithms in commands.

MES 101 - Configuration Publish v2.1.10

Improvements

- Configuration Publish improved to only show three months of data in the Configuration Publish portal.

MES 101 - Label Engine v2.5.1

New Features

- Label Engine was enhanced to support EPL script language upload and usage within the Label Engine process.

Improvement

- Label Engine is adding a new and flexible mode "Other Template" with no rules, no upload validations, no custom modifications.

MES 101 - MES-API v1.16.1

New Features

- New MES_API endpoint to allow the ability to change the status of the container, all units in that container, and all containers and units assigned at any level below that container.

- MES-API is now able to receive the entire defective child component hierarchy of a given serial number recursively.

Improvements

- Improvement of unit comment API to prevent the database results from returning all factors.

- New end-point in MES-API created to retrieve all configurations set in generic attributes.

- API enhancement to export the valid containers and display a message concerning which containers were exported and which containers were not expected.

MES 101 - Server Information Portlet v1.12.49

New Features

- Support multimedia-API connection info in Server Information.

MES 101 - Plant Maintenance Portlet v1.12.43

Improvements

- Support Brazil/East UTC time zone at Plant configuration.

MES 101 - Multi-Level Container Configuration v2.5.0

Improvements

- Container level greater than 100 Mask supported in Conduit containerization / Multi Container Portlet.

- Enhancement to add the new Container Mask in the report for Level >100.

- Multi-Level Containerization Browser enhancement to improve list - Export Container options.

- Multi Containerization Browser -> Export Multiple Container - Includes successfully exported containers.

MES 101 - Multi-Level Container Maintenance v2.17.0

New Features

- Multi Container Browser Portlet enhanced to allow the capability to change serial numbers to status 40 in 42Q.

MES 101 - Multimedia API & Multimedia Admin v1.2.2

New Features

- Retention Policy for Multimedia Elements enhanced to fulfill the goal of keeping storage time spans as minimal as possible with high retrieving speed and lower cost.

- Tenant Management enhancement to achieve configuration to use Multimedia API through a web application.

- Enhancement to support querying daily media elements records such as tenant Name, identifier, tag name, file name, mime type, file size, created date, status.

- Integrate with 42Q IAM as user authentication to allow 42Q admin to log in to the Multimedia Admin web application via Sanmina SecureAuth.

MES 101 - PCB APK v2.22.2

New Features

- PCB APK Secure Document Access Implementation

MES 101 - Production Workbench v1.9.3

New Features

- Production Workbench now supports pictures to be captured and linked to attributes

- When the user clicks on the camera icon a model panel should be displayed, this modal panel will contain:

- Camera: Support capturing images using the device camera.

- Tab for Preview

- Tab for Device Camera.

- “Take Picture” button enhanced to have the following behavior:

- If the Retake button is pressed, the tab to take a photo will display again and the user will be able to take a new picture.

- If the Take another photo button is pressed, it will allow the user to take an additional photo.

- Icon to delete files will be shown when the user drags and drops some files.

- General preview display will allow the user to see all the photos taken, delete selected files, or take more photos if the user uploads or cancels the picture.

- Enhancement to allow the ability to replace an image that was previously captured by a new one.

- Updated Responsive Layout screen in PWB when using a full screen on a mobile device.

- Panel update to delete selected pictures taken previously.

- New stations endpoints to consult the information about station ids and respective devices from the MESportal database.

- The operator will have the ability to upload files when clicks on or selects a small upload file icon:

- Once is clicking the upload file icon on the prompt that will let the user select the files and the other one is if the user drag and drop files into the prompt.

- Once the user selects the files or drags and drops one or more photos, the files are going to be added at the bottom of the prompt and are going to be attached to the attribute, component, assemblies, or any command until the commands are executed on Conduit.

- The limit to upload files is 50 maximum per each media attribute.

- Allow users to see all existing files in order to select the files or drag and drop one or more files to attach to the attribute, component, assemblies, or any command until the commands are executed on Conduit.

- Integrate into Production Workbench the compatibility to interact with clients (Production Workbench), Conduit, and Multimedia API, sending some POST transactions with the normal payload and including the media identifier.

- Interact with the Record media command to save information in the Activity table.

- Link media command to save information to the Activity media table.

- Generic attribute to add the capability to restrict the type of file to be uploaded.

- Small image preview is shown when users add pictures to an attribute.

Improvements

- Wrapper with a display style ‘inline-block’ was added on the configured questions and an extra button was added to expand the panel.

- Answers are marked as expired when QCP is enabled/approved.

- Part Number description limit enhanced to support a large number of characters.

MES 101 - QCP Configuration v1.0.2

Improvements

- QCP checklist answers are marked as expired when the checklist is enabled/approved.

- Hidden Fields in QCP Configuration Portlet updated to become available to users.

MES 101 - Reprocessing Defect v1.1.0

New Features

- A message added to indicate the iteration number is needed in the summary within the troubleshooting section.

- Remedy Section updated so that if NCMR is selected, iteration number is added next to the RRID in the Remedy sections’ system phase.

Improvements

- Formatted the logs in the system-log-portlet to improve the ability to debug, avoid redundancy, and improve log solutions.

MES 101 - Roboship

Improvements

- Roboship enhancement to mark child containers as ‘Sent’ in FTP and XML.

MES 101 - SFDC Portlet v1.14.43

Improvements

- Document mapping improvements to improve the searching performance of Agile documents. enhancement of the Next & Sync Agile logic.

MES 101 - System Log Portlet v1.11.8

Improvements

- Logs in the System-Log-Portlet were reformed for users to improve the ability to debug, avoid redundancy, and generally improve user log solutions displayed in the Kibana system.

MES 101 - Shop Order Control v2.22.1

New Features

- Portlet manage_shop_order_serials function, used by the Shop Order portlet, updated to replace the units on a shop order with a skeleton serial.

- ERP Shop Order enhanced to allow users to have not only the “Internal” revisions but the serial numbers and/or labels with their revisions as well.

Improvements

- Fractional quantities from ERP updated to set BOM Information quantity field to 15 decimal digit precision rather than 2 decimal digit precisions.

MES+ - Kit Verify Control v2.16.0

New Features

- Kit Verify shop order rules enhanced to support process closed shop order (RMA).

- Enabled ‘Replace Components’ functionality button for Standard.

MES+ - MES-Connector v2.1.1

Improvements

- MES-Connector auto-refresh JWT token in order to increase communication security between MES-Connector portlet and Web Service.

- MES-Connector log file enhanced in order to fit the new H/A structure.

- Non-Ajax Service supports Portlet with and without ajax header.

- MES-Connector stores JWT Public Key to AWS S3.

- FUJI_MES Host interface time-out enhancement in Mes-Connector.

MES+ - PTS Portlet v2.1.2

New Features

- PTS Scanning Flow Control enhancement to help prevent the PTS board from missing scanning issues.

- PTS label API provided to update the remaining material quantity to reprint the label with the updated remaining quantity.

MES+ - PTS Solder Paste

New Features

- AUT Solder Paste configuration at PTS System Setting.

- In order to make the solder paste more flexible for the plant user, it should be highly configurable as follows:

- Add ‘Solder Paste Control’ switch in PTS System Setting function.

- Add ‘Solder Paste Refrigeration Process’ and ‘Solder Paste Thaw Process’ two switches in the PTS System Setting function.

- Add the “Stirring Solder-Paste” switch at the PTS System Setting.

- In order to make the solder paste more flexible for the plant user, it should be highly configurable as follows:

- AUT Solder Paste Control by MPN configuration enhancement to provide users the ability to key in different MPN parameters.

- AUT Solder Paste Refrigerator asset creation feature to create the refrigerator.

- New solder paste refrigeration in GUI.

- New solder paste refrigeration out GUI.

- The system provides the new solder paste thaw start GUI, then the operator will perform the process when they start the solder paste thawing.

- The system provides the new solder paste thaw end GUI, then the operator will perform the process when they end the solder paste thawing.

- In order to pass the solder paste thaw process, then the operator needs to stir the solder paste during the solder paste thaw process.

This stirring time process is optional based on the PTS system setting :

- ‘Employee Number’ item can not be empty.

- ‘Solder Paste Material SN’ item can not be empty.

- If the stirring time is less or larger than the predefined max./min stirring time, then the system will prompt the warning message "The stirring time is over or less than the predefined stirring time."

- The system provides the open jar GUI, then the operator will perform the process when they open a solder paste jar.

The system needs to meet the following requirements.

- ‘Employee Number’ item can not be empty.

- ‘Solder Paste Material Serial Number’ item can not be empty.

- The ‘Reference Work Order’ item can be empty.

- The ‘Reference Work Order’ item is related to part configured in ‘Solder Paste MPN Control’ function.

- If the previous step has already mapped ‘Solder-Paste Material Serial Number and ‘Reference Work Order’ then the

- The value of ‘Reference Work Order’ will display automatically after the user completes inputting the ‘Solder Paste Material Serial Number’ item.

- If the value of ‘Employee Number’ does not exist the system will prompt ‘Incorrect User’.

- If the value of ‘Solder Paste Material Serial Number’ does not exist the system will prompt ‘Incorrect Solder Paste Material’.

- If the value of ‘Reference Work Order’ does not exist the system will prompt ‘Incorrect Work Order’.

- If the shelf time of current solder paste material is more than ‘Shelf-Life’ configured in function ‘Solder Paste MPN Control’ then the system will prompt ‘Shelf Time Expired’.

- The load solder process verification will be via the PTS load material GUI, the operator loads the solder paste to the PTS and the PTS treat it as load the solder paste to the stencil.

- The unload solder process will be via the PTS unload material GUI and the system will update the solder paste status accordingly.

The current PTS unloading material function/logic needs to be improved as follows:

- The status of current solder paste material must be ‘Load Solder-Paste to Stencil’ status (otherwise system prompt warning msg).

- If the unloading material operation is successful the status of current solder material needs to be changed to ‘Unload Solder-Paste from Stencil’ status and write related process operation data to related DB new process operation table.

- The system provides the new scrap process GUI and the operator can perform the scrap process when solder paste floor life expires.

The new scrap process needs to meet the following requirements.

- ‘Employee Number’ item can not be empty.

- ‘Solder Paste Material Serial Number’ item can not be empty.

- If the value of ‘Employee Number’ does not exist the system will prompt ‘Incorrect User’.

- If the value of ‘Solder Paste Material Serial Number’ does not exist the system will prompt ‘Incorrect Solder Paste Material’.

- If any step of all above solder paste control steps prompt ‘Warning Message’ or ‘Error Message’ then system prompt ‘Do you want to scrap current solder-paste material?’ at the same time.

- The system provides the Solder Paste Status Report and the requirements will be as follows:

- Supply query condition items ‘Solder Paste Part Number’, ‘Solder Paste S/N’, ‘Solder Paste Status’, ‘Start Date’, ‘End Date’ on the report.

- Supply displays data items ‘Solder Paste Part Number’, ‘Solder Paste Serial Number’, ‘Solder Paste Status’, ‘Status Changed By’, ‘Status Changed Date time’ on the report.

- The system provides the Solder Paste Process Tracking Report and the requirements will be as follows.

- Supply query condition items ‘Solder Paste Part Number’, ‘Solder Paste Serial Number’, ‘Process’, ‘Step’, ‘Start Date’, ‘End Date’ on the report.

- Supply displays data items ‘Solder Paste P/N’, ‘Solder Paste Serial Number’, ‘Process’, ‘Step By’, ‘Step Datetime’ on the report.

NOTE: Some of the menus in the 42Q Portal and Portlet Names are subject to change for release 15.64.

Please refer to the below table for detailed information.

42Q Menu Changes

| As Is | To Be |

|---|---|

| PTS | Traceability |

| SFDC Configuration | Shop Floor Configuration |

| KV Layout | Kit Verify Layout |

| KV Control | Kit Verify |

| Algorithm Tool | Algorithm Maintenance |

| OEE | OEE Configuration |

| Shop Order Sequencing | Shop Order Prioritization |

| Enable/Diasble AML | Approved Manufacturer List |

| Virtual RT | Virtual Receipt |

| Reset Qty to Zero | Reset Material Qty |

| Batch/Lot Process Control | OEE Workbench |

| OEE Data Collection | Manual OEE Workbench |

| CMMS Calibration/Preventative Maintenance/Spare Parts/Work Orders/Work Request | CMMS Folder |

| SFDC Administrator | Shop Floor Control Administration |

15.63 Non-Medical Deployment

Version: 15.63 Non-Medical

Environment: Non-Medical Production HA Environment

Business Intelligence - MESWEb Central v3.7.0

Improvements

- The Drill Down and Widget Drill Down items now have an option that removes the report drill down.

- MESWeb Central now displays “loading” when a filter is saved on the Central application.

- Http/Https attribute is now included within the MESWeb central application.

Business Intelligence - MESWeb Execution v4.6.6

New Features

- QCP Configuration Module was added to MESWeb Execution.

- MES Web Multimedia displays support for unit history.

Improvements

- The lot number and the quantity for the non-serialized components will be reported in the Unit History report.

- Non-Serialized Component Types: Quantity Consumed are now available in Unit History.

Business Intelligence - MESWeb MES Web Service v1.6.0

New Features

- Dashboard Packets are available for users in MESWeb MES Web Service via manual push.

-The users are able to navigate to the 42Q Dashboard and find several pre-loaded/saved snapshots, with each focusing on either Production, Quality, or OEE widgets, also they are now able to adjust and configure parameters to customize the widgets to display information pertaining to specific lines, with their particular processes and products being produced. This new feature allows visualizing data in a more out-of-the-box setup, requiring less configuration time and effort.

Business Intelligence - Operation Dashboard v3.5.0

New Features

- Dashboard Packets are available for users in Operation Dashboard via manual push.

-The users are able to navigate to the 42Q Dashboard and find several pre-loaded/saved snapshots, with each focusing on either Production, Quality, or OEE widgets, also they are now able to adjust and configure parameters to customize the widgets to display information pertaining to specific lines, with their particular processes and products being produced. This new feature allows visualizing data in a more out-of-the-box setup, requiring less configuration time and effort.

Business Intelligence - Operation Dashboard Portlet v1.1.0

New Features

- Dashboard Packets are available for users in the Operation Dashboard Portlet via manual push. The users are able to navigate to the 42Q Dashboard and find several pre-loaded/saved snapshots, with each focusing on either Production, Quality, or OEE widgets, also they are now able to adjust and configure parameters to customize the widgets to display information pertaining to specific lines, with their particular processes and products being produced. This new feature allows visualizing data in a more out-of-the-box setup, requiring less configuration time and effort.

'Business Intelligence'- PSI APK v2.21.5

Improvements

- PSI was enhanced to display a language drop-down box for users to select ‘Chinese Characters’

- APK was enhanced to allow the user to add a permission to access photos, media, and files on their prompt box; the users easier to operate using the search button (magnifying glass icon), allowing the user to open any of the Images/Blueprints documents for the first time, and showing a dialog pop-up asking for permission to access photos, media, and files in the device. Users would be able to click the following two options:

- Always Allow

- Deny

When the user clicks Always Allow, the related document will be open directly and show up the user documents directly, but if the option Deny is clicked, the blueprint/image documents won’t be open on the PSI.

- Enhancement to allow users to input the upper case of the host and change to lowercase automatically to improve the PSI performance.

- Improvement to disable the built-In keyboard in PSI after users input the text field.

- An Esc button was added on the PSI keyboard.

- PSI changed the web service connection from HTTP to SFTP to improve the performance of the loading image/stack up.

Business Intelligence - SPC Server v1.3.2

New Features

- The SPC Portlets now has a new feature that allows the user to create and edit monitors in batch, that will reduce user workload, users will be able to do the following operations:

Allow users to create monitors in batches.

- Support creates multi-part numbers/Family id with one location/process/location family or multi-location/process/location family with one part numbers/Family ID.

- Allow users to export all the related attributes when creating a monitor.

- If selected part numbers have attributes, the attributes selection box in the new monitor>Data Collection Strategy page will only allow the common attributes.

- Creating monitors in a batch should fill a batch id. This batch id will help users to do the operation of search or edit monitors.

Allow users to edit monitors in batches.

Allow users to delete monitors in batches.

- SPC now supports Dot Line Charts.

- SPC added a sampling function on continuous charts: The sampling rules can be customized by the user, this sampling method can be divided into two:

- Time Period Sampling.

- Quantity Sampling.

Improvements

- Monitor list in SPC is enhanced and the following tasks were added:

- Support research monitors by batch ID.

- Add batch id/ Update By in Revision page

- Add batch id/ Update By/Update Time in the monitor list page.

- Two grouping functions were added to SPC, the user now will able to:

- Set the number of groups, use the same BAR value used for the next data analysis.

Business Intelligence - SPC Portlet v1.2.23

Improvements

- P-Chart enhancement, the user will be able to see the number of Defective / Inspected.

Business Systems Connectivity - Oracle Adapter

New Features

- Columns for MDS order_line table and "flex" fields in the sales order XML from ERP, were added to Oracle Adapter.

- Users will be able to include the original Serial Number when the Serial Number is removed from the Shop Order.

Business Systems Connectivity - Tinmon v1.3.3

New Features

- The Multiple Shop Order Release module now allows Multiple Shop Orders to be released in the same operation.

With the following functionalities:

- Ability to order the Shop Order sequence to be released/ Capability to remove Shop Orders after to choose and before to be released.

- Shop Order now displays a summary screen with the information about each Shop Order selected.

- Select the Starting Serial Number, display the information into the panel grouped by Algorithm.

- Select the Revision, ability to select a different revision by Part number, Shop Order panel should be grouped by part number.

- Unit Started Location, this option should be configured in the Part Number Maintenance, we can select the Unit Started Location, the information in the Shop Order panel should be grouped by part number.

- The user can select a different configuration for each part number to print labels.

- The user can now create a text file with the Serial Numbers and the information will be sent by email.

Business Systems Connectivity - WipMoves v3.2.8

New Features

- WipMove is now able to replicate tables so that they can be replicated from the MDS Wip moves report.

Improvements

- 42Q ERP WipmMoves for status 25 move to status 20 at unmapped location/process for In Queue step value setup.

CMMS - CMMS Portlet v2.5.0

New Features

- CMMS now allows bulk load in Tooling Mapping and Import Tooling Mapping data, in four simple steps:

- CMMS provides .csv file templates for users to input fields: Shop Floor ID, Part Number, Process, Location, Asset Type, Qty, Panel Qty, Control Mode.

- After the user fills in the .csv file, they will have the option to validate the fields is valid in MES system: Shop Floor ID, Part Number, Process, Location, Asset Type, Qty, Panel Qty, Control Mode and show the wrong field to prompt the user to revise.

- Import data into the Tooling mapping module with the updated user and updated time is shown at the Tooling Mapping list. If there's already a record for the same Shop Floor ID + Part Number + Location + Asset Type (criteria as one unique record ), then update the existing record.

- After tooling mapping imported, the control mode is by Part Number, Place MFG hold.

CMMS - CMMS Web Service v2.5.2

New Features

- CMMS now allows bulk load in Tooling Mapping and Import Tooling Mapping data, in four simple steps:

- CMMS provides .csv file templates for users to input fields: Shop Floor ID, Part Number, Process, Location, Asset Type, Qty, Panel Qty, Control Mode.

- After the user fills in the .csv file, they will have the option to validate the fields is valid in MES system: Shop Floor ID, Part Number, Process, Location, Asset Type, Qty, Panel Qty, Control Mode and show the wrong field to prompt the user to revise.

- Import data into the Tooling mapping module with the updated user and updated time is shown at the Tooling Mapping list.If there's already a record for the same Shop Floor ID + Part Number + Location + Asset Type (criteria as one unique record ), then update the existing record.

- After tooling mapping imported, the control mode is by Part Number, Place MFG hold.

- Device ID / Location list dropdown and data validation were added in Asset Mapping.

- CMMS WS upgrade to Django3.0.

Improvements

- Support insensitive case searches for Asset ID in query fields within Load/Unload Tooling/Mapping/Tooling.

- Asset ID in CMMS is not case sensitive in query fields at Load/Unload Tooling/Mapping/Tooling where used in a report.

- CMMS is now able to give all lists of the required jig according to Tooling Mapping. A reference window was added to show current locations tooling mapping information: Pin number, process, location, asset type, quantity, panel quantity, control mode.

- The Old Usage Times Column added at Manual Update Usage portlet to easily show the user the original usage times before manual update. This improvement will also show the updated times that will distinguish the current usage times field at Tooling Load to avoid confusion.

- The CMMS Site management page can read the existing OEE source_type value and the users are now able to edit the source_type at the GUI.

- CMMS Site ID was enhanced in the Report Asset Downtime & Report Work page.

- The asset upload limit has been enhanced.

- An "All" option in the drop-down list was added to the work order inquiry.

- The spare parts Part Number data field database setting was modified to prevent users from having length restriction in CMMS Admin Page.

MES 101 - Conduit v1.9.3

New Features

- Conduit has a new command that allows setting shipped containers and its lower-level containers.

- Conduit has a new command named Store Media it allows it to act as an upload mechanism to persist in media content via the generic Multimedia API.

- Conduit has a new command named Render Label to invoke the LE local-print endpoint and write the downloaded content to a local temp file.

- Conduit created a new mfghold for employees to prevent scanning.

- Conduit now provides split quantity data for batches and panels.

- PWB update to allow users to export a container to Oracle after closing it on their discretion using a Conduit command.

- Conduit now has a Global option to update Serial number location.

- Conduit now allows the serial location to reflect the current location/process when scanned to match, as cycle time data collection is being started.

MES 101 - Label Engine v2.4.7

New Features

- Label Engine now has a plant configurable option to allow preventing duplicate labels.

- Label Engine now has the option to 'Test Print'.

Improvements

- Label Engine label audit log was enhanced to identify who printed a label using the Shop Order browser.

- Labe Engine now has a user-configurable mandatory violation message to allow label designers to provide custom messages on screen.

- Combo box displays a special function that sorts the in_key order list (at the database) alphabetically.

- Log enhancement to add the database and site information to track logging during printing.

- Label Engine modified to extract the time zone information using the currently supported methods.

- Label Engine standardized the column names in the exported file.

- After filling in all fields in the filter option and clicking on the clear button, the ‘Failures Field’ will be cleared as well.

- Label Engine has incremented the time in the validation messages displayed, so is possible to read all information, the pop-up will open when it is necessary.

- Label Engine Labels, Add/Edit Label, Element Creation, and Database have improved the screen size.

- The version for log4j used by Label Engine from log4j-1.2.16 was updated to log4j-1.2.17.

- Label Engine implemented MES-cache-management.

- Label Engine implemented Palindrome Authentication.

- Label Engine implemented Swagger to generate Restful API Documentation.

- Label Engine has refactoring Restful PrintingResource for the following:

Changes are required to:

- Palindrome Authentication.

- Swagger Documentation.

- Get Host/Database configuration from MES-cache-management based on a client ID.

- Unit Tests.

- Label Engine Print History screen was improved by adding the phrases "of this label" and "approved".

- Label Engine Labels has improvements in the following sections:

- The Data after: hh:mm:ss. has been removed.

- A border in red color for the Reprint Reason field was added.

- The rendered screen was expanded and displays the scroll just when necessary.

- The button and screen name to Print/Reprint name was changed.

- The spaces between the buttons were standardized.

- The Custom Mandatory Message field stays positioned as a fixed screen when positioning the cursor.

- Label Engine Admin - Application Configuration Improvements for the following:

- The Duplicate Serial Number - Label Printing Prevention section was renamed.

- Enable duplicate printing prevention feature was updated to only allow an Entry to be printed once per label.

- Label Engine Print and Reprint controls were added.

- Label Engine db_function blocks generate the custom message to become dynamic and not a static custom message saved with the block.

MES 101 - Label Engine Web Service v2.4.7

New Features

- Label Engine Web Service has improved the existing Printing Client Web Services (delimiter).

- Label Engine Web Service now provides different options to the user such as:

- A new web service method which will allow the user to print a label by using a URL with two methods: GET and POST.

- The new web service(s) will return data back to the caller regarding the status of the prints (+ same error messages that are logged in audit in the event of failure).

- Print Labels WS Parameters (subject to change at design time):

- Label name

- Print queue name

- Token value

- User/operator name

- EntryValue = array

- A new web service method which will allow the user to print a label by using a URL with two methods: GET and POST.

- Reprint Labels WS params ( (subject to change at design time), same as print labels +.

- Reason for reprint.

- Approver (free form - name / employee #?)

- Reprint Notes (free form to capture any notes the plant wishes)

- A web service to return the file(s) associated with a previous print job was created in Label Engine Web Service.

- Multi-Level Container Maintenance, Serialized Item Tracker, and Shop Order Control updated to call the new lbleng-webservice to get Label Engine print queues and labels.

Improvements

- Web Service enhancements to send back dynamic, meaningful messages with web service calls.

- LE Web Services Calls - Enhance logging.

- Identify the caller (by name) so that reverse lookup of the token isn't needed when inspecting logs

- Include the full list of parameters received by the web service call.

- LE Web Service -> Local/Print/Reprint - now has the same Validation message form the portal: ”An exception occurred while trying to print the label. Exception: CSP-0102-001: The label does not have any 'printable' files (templates or fonts)... can't print this label!.

- Response Content-Type is JSON instead of textHTMLl

MES 101 - MES-API v1.13.1

New Features

- Ship Notify Web Service change to set containers to status 40.

Improvements

- MES-API users are now able to configure a maximum date range to avoid issues like single API consuming on the API call functionality.

MES 101 - Movesntonextso

New Features

- Functions that replace units on a Shop Order with a skeleton unit (3.2.4. Skeletons), to put the replaced serial number in the action 0 (Create Unit) activity.a1 field has been modified.

MES 101 - Multi-Level Containerization Configuration v2.4.0

New Features

- Multi-Level Container now allows the user to define a mask for any level.

MES 101 - Multi-Level Containerization Maintenance v2.16.1

New Features

- Multi-Level Container Maintenance added the capability to Roboship to handle Multi-level Containers.

Improvements

- 42Q outermost container info (Top level) number will populate the parent container and the outermost container elements.

MES 101 - Palindrome Web Admin v1.0.5

New Features

- Palindrome Web Admin provides the persistence in the credentials and permissions in order to validate system access between applications.

MES 101 - Production Workbench v1.8.2

New Features

- Production Workbench now has QCP (Quality Control Process):

- Show the activity option for displaying QCP information only if it was mapped /saved in a process/location.

- Each process/location has different QCP information(QCP activity).

- When clicking in the QCP activity, expand the data table with the next information:

- QCP Checklist name:

- Part number (optional)

- Revision (optional)

- Time Stamp

- Operator

- Location/Process

- And the items list.

- QCP Checklist name:

- Production Workbench now uses CCR service to store and get the QCP data, including mfg_hold for employees.

- The sfdcdnld core command was changed to ignore the new type of mfg_holds for employees.

- Production Workbench QCP CheckList is now available in the following languages:

- Spanish

- Portuguese

- Chinese

Improvements

- Auto-populate in the container information is now available in Production Workbench.

- The command configured on the Generic Attribute ‘ps_container_command’ will be automatically prompted when a container is created.

- Production Workbench now has the capability to print automatically or prompt the operator when finishing the container.

- A new validation was added to check if the process name is empty before creating a request to Conduit.

- The option to close the container and adding the ID after is the container is complete is now automatic.

- A new button was added on the container panel in order to remove all the units of the scanned container.

- A new limit was established in Production Workbench commands so the user can select from a drop-down list can add or remove serials from the container.

- A new validation was added to display the 42Q logo on the top left corner of the fullscreen layout.

- Production Workbench was modified to display users with the correct error messages when something goes wrong.

- The ‘Mask Fail’ message was modified and the missing (“) has been added.

- A new layout on the configuration for full-screen within the portal and is responsive to mobiles was added.

- Production Workbench now has a new module that was modified to manage PDF documents.

- The call to queryAlfrescoInfo.action was removed, and the alfresco_host and the portalHostDB are loaded from the environment variables ALFRESCO_HOST and DB_HOST.

- Auto Print option in the label program added to configure label printing.

MES 101 - Android Device Maintenance Portlet v1.12.16

Improvements

- Android Device Maintenance now prevents users from adding more than one asset number for one device.

MES 101 - Appgarden v2.05

Improvements

- Appgarden was enhanced for better operation with the following features:

- A downloaded size to indicate the downloading process on the Appgarden screen was added so users know how close they are to having the file downloaded, and if the download is finished, it will show the APK name +download finished as the second screenshot.

- Add the Service Host information, that indicates the Appgarden connection to which portal server.

- Asset Number will indicate the Appgarden to which the Asset Number registers with the portal.

- The latest network time, it indicates the Appgarden whether connecting to the network normally, if the time is updated every 15 seconds, while, it means the

- The network connection is normal, it will try to get the “Download“ & “Remove“ task from the portal every 15 seconds.

- Latest Heartbeat Time, it indicates whether the Appgarden is running healthy, if the time is updated every 2 seconds, while, the Appgarden heartbeat time is running normally. it will try to judge the Appgarden whether have installed/removed the APK, and check the md5, if no, then it will install/remove the APK and return the status to portal every 2 seconds after getting the portal’s task to submit.

- Download Task, it indicates whether you have any tasks to download from the portal. such as: if the portal has submitted an APK to install, PSI 2.20, then it shows install PSI 2.20.

- Remove Task, it indicates whether users have any tasks to remove from the portal, such as, if the portal has submitted an APK to remove PSI 2.20, then it shows remove PSI 2.20.

- The Server time, it indicates the MES portal server pushes the device time to the Appgarden. The Server time & Execution time & Please wait for information will only show up when users submit the task in a future time.

- Execution time indicates the time of tasks submitted in the portal(Android device maintenance module).

- Please wait, it indicates the execution time > the server time.

- PSI Download finished, it indicates the APK is downloaded on Appgarden waiting for installation.

- Add a scan button for the Host and asset No. it saves users' time to register the host and asset No. as the fourth screenshot.

- Add an H icon to read the host service txt. file as the second screenshot, it allows users to select a host when users click the H icon, which it’s more convenient for users no need to input the host manually as the second screenshot, but this H function is only for Zebra devices because the host service configuration files will be installed in the stage now, and users no need to install the configuration files to the tablet manually.

- Modify Appgarden style according to different mobile devices, such as Zebra, Android mobile, tablets with different brands Huawei, Samsung, have different resolutions, the App garden will adjust automatically according to the devices' resolution, such as it will have a scroll bar on the right side.

- Modify the Host can support HTTPs.

- Appgarden enhancement to allow users to use Air - deployment function upgraded for Appgarden.

- Stream updates and configure the installation to tablet applications flexibly.

- Control the Asset No. registration on Appgarden.

MES 101 - Roboship

New Features

- A ‘Shipped Container Status’ was added to Roboship form a Sanmina Container, to provide the user with the visibility if the container has been shipped.

- Roboship now has an optional function to send information about the container automatically when the user closes it in 42Q.

- Roboship now has the capability to send more than one container per transaction from 42Q to Oracle.

- A new procedure was added to Roboship to analyze Oracle web service endpoint to consume Roboship XML.

MES 101 - Serialized Item Tracker v2.7.0

New Features

- Refactoring Portlets now can call the lbleng-webservice.

MES 101 - SFDC Portlet v1.14.42

Improvements

- SFDC Portlet now allows the user to go to the document mapping module and map the Engineering notes based on the Tool/Cam number.

- Engineering notes appear in the PSI and the notes have been added into the portal.

MES 101 - SFDC Configuration v2.14.1

New Features

- SFDC configuration provides the tags to enable users to group similar part numbers at the Part Maintenance and to allow flexibility.

MES 101 - Shop Order Control Portlet v2.20.2

New Features

- The Shop Order Release module now allows Multiple Shop Orders to be released in the same operation.

With the following functionalities:

- Ability to order the Shop Order sequence to be released/ Capability to remove Shop Orders after to choose and before to be released.

- Shop Order now displays a summary screen with the information about each Shop Order selected.

- Select the Starting Serial Number, display the information into the panel grouped by Algorithm.

- Select the Revision, ability to select a different revision by Part number, Shop Order panel should be grouped by part number.

- Unit Started Location, this option should be configured in the Part Number Maintenance, we can select the Unit Started Location, the information in the Shop Order panel should be grouped by part number.

- The user can select a different configuration for each part number to print labels.

- The user can now create a text file with the Serial Numbers and the information will be sent by email.

- Shop Order Scheduling is now available in the following languages:

- Spanish

- Portuguese

- Chinese

- A new filter for Release Status for the Shop Order based on Multiple Shop Order Release was added:

Release Status:

- Failed Release

- Releasing

- Waiting Release

New Column in the panel:

- Mouse over the user can see a tooltip with the error message if the Release status is Failed Release.

Print/Export Filtered:

- Also was added the new column to the report.

- The Shop Order grid is refreshed after every second, based on the configured Generic Attribute value and if the value is empty or not a number then the system will consider the default value as 0.5.

Generic attributeauto_refresh_shop_order_release_list = time in minutes

- Shop Order now sends a notification to the user when the release task process is completed.

Improvements

- Shop Order now has the ability to “batch” release Work Orders.

- A new button called ‘Release Transfer Hold’ is now available in the Shop Order Information -> ERP information panel when:

- ERP transfer is on hold for the Shop Order.

- The user has permission.

- The release operation is enabled for that site.

MES 101 - Target Maintenance v2.5.0

Improvements

- Target Maintenance now allows the users to export and import in the ‘Filter’ list.

- Target Maintenance now allows the users to import, replace, and export a target from the ‘Filter’ list.

MES 101 - QCP Configuration v1.0.0

New Features

- QCP is a new application in the 42Q portal.

The QCP Configuration form was created to allow the user to create and edit checklists and content such as:

Configuration items:

- Checklist content (checkbox, text,etc)

- Process/Location Mapping

- Part Number Change (should be optional)

- Revision Change (should be optional)

- Frequency Configuration (shift, login, time, etc.).

MES+ - EDHR

New Features

- A second level of validation was added in EDHR before releasing the serial number (and its parametric data collected) to the next station.

- A new feature was added to record changes on the parametric data previously collected (RedLine).

- A new feature was added to allow manual test log to work with recipes with boolean steps.

- An input mask was added for a test step to save the different entries in the Manual Test Log module.

MES+ - Multimedia API v1.1.9

New Features

- Considering security and privacy, Internet browsing needs to be blocked to visit S3 file storage systems.

- Multimedia API performance improvement that tenant configuration information is cached.

- End users are now able to delete pieces of the Multimedia Elements and have the actual elements saved.

- The Multimedia API now supports the storage of Multimedia Elements at Customer, Plan or Site level.

- Registration for Tenants by DataBase Script.

- Multimedia API supports both Palindrome Authentication and Apigee Gateway (only supports Palindrome in this phase).

MES+ - PTS HA v3.1.16

New Features

- The PTS scanning board quantity calculation is saved at the cache and the currently available board quantity will be updated.

- The current PTS web service will define the plant code with the database connection at the local db.property configuration file.

- PTS OWMS and PrintQ Interface have been enhanced in order to fit the new API interface.

- PrintQ shares storage to find out the correct plant and DataBase server/DataBase connection.

- The MES-Interface application connects to share storage to find out the correct plant and DataBase server/DataBase configuration.

- MES-Connector connects to the shared storage to find the correct plant & DB server/DB configuration.

- PTS HA now connects to the shared storage to find the correct plant and database server/database configuration.

- Printer local configuration is moved to the shared storage/place so that both instances can find out the PTS label printer information and print out the label.

- PTS has enhanced the image uploading to save all the orientation feature images at the local DB server folder.

- The PTS label template file has been saved at the PTS database local directory. Customized label template files will save at the shared storage and the different PTS instances can retrieve the plant label template during the label printing.

- Ezpicklist enhancement to improve SMT picklist conversion performance.

- Web Service/Interface security enhancement to improve PTS web service and PPC interface security to prevent important data from being exposed to end-users.

MES+ - PTS Portlet v2.0.9

New Features

- PTS label is now able to print the BIN code at the PTS side.

The following configuration steps allow users to be able to print the BIN Code.

- Set the main switch to turn on the LED BIN Code feature and the BIN Code field will display at the label printing/reprint/split portlet.

- Add the new field at the PN Extra Info portlet based on the PN, so that the user can define the specific PN with the LED BIN Code option, then the user needs to enter the BIN Code for this specific P/N during the label printing.

- Add the BIN Code field at the PTS Label reprint, so that the label will show the BIN Code field.

- Add the BIn Code field at the PTS split label, the new split label will have the same BIN Code with the original label.

- The PTS MES-Interface (Fujitrax-PTS Interface) has the following features in order to sync the BIN Code to the specific Fujitrax data field.

- The BIN Code data field needs to be added to the synchronization script.

- BIN Code value needs to insert this into the Fujitrax ‘Lighting Class’ data field.

- The PTS rework function changed in order to show the Bin Code.

- A change in the PTS Report and the PTS Label was made in order to show the LED Bin Code to the PTS related reports and label.

- In order to sync the LED BIN Code to the Fujitrax DB, the PTS-Fuji interface adds the LED BIN Code field.

- Add the BIN Code field at the MES-Interface.

- Sync the BIN Code value to the Fujitrax database and insert it into the Fujitrax database ‘Lighting Class’ field.

- The BOM variant was increased to become more configurable and flexible to allow users to define their variants.

Improvements

- The current JSON parameter was improved with the process of including special characters ‘%’ and ‘+’ cases.

- The current ‘Upload AML’ function was improved to check the file column name.

- The current ‘Upload Picture’ function has been improved to display from the current style to base 64 styles.

- The MSD values were improved to update the Fuji database.

MES+ - PTS Web Service v2.2.14

New Features

- These are the following required features for the PTS web service to accommodate for the WMS-PTS interface code change:

- The PTS Label web service needs to add the new field to receive the BIN_CODE to receive the OWMS BIN Code.

- The PTS database schema needs to create the new data fields to save this new BIN Code data as well.

Improvements

- Improvement to allow Non-HA PTS WS to match with the latest PTS portal version.

15.62 Non-Medical Deployment

Version: 15.62 Non-Medical

Environment: Non-Medical Production HA Environment

Business Intelligence - 42Q-Live Configuration Portlet v1.8.0

New Features

- New IIoT layer is available in 42Q Live.

Improvements

- 42Q Live IIoT layer sensor was improved.

Business Intelligence - 42Q-Live Monitor v1.7.0

Improvements

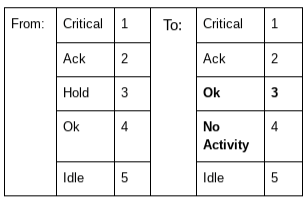

Two 42Q Live Priority and Status changes:

- Rename “On Hold” status to “No Activity”.

- Change the priority settings.

Business Intelligence - MESWeb Central v3.6.0

Improvements

- The widget configuration in MESWeb Central changed to display the filter configuration window as follows:

- Name

- Parameter Name

- Data Source Type

- Report

- Delete button

- The publish predefined reports window now has available locations components to easily sort information.

Business Intelligence - MESWeb Execution v4.5.0

Improvements

- Sort data source field items on the MESWeb Execution application.

- MESWeb Execution Yield & Defect improved so the user is able to see the following:

- The dialog window is aligned properly in the middle of the screen.

- If the process does not have defects recorded the option to open the dialog window will be disabled.

- Impersonate function now available in MESWeb.

- Cycle Time reports now show records of individual activity for all the serials and operators to improve time calculations in the overall efficiency, it shows the record of:

- Serial Number

- Employee Number

- Hands-on Time

- Cycle Time

- Unattended time

- Wait Time

- At the end of the report provides the total, minimum, maximum, average and qty of serials for all the times(hands-on time, unattended time, cycle time and wait time)

Business Intelligence - Operation Dashboard v3.4.0

Improvements

- The Dashboard monitor is triggered in a new window with the 9 default Yield/TP widgets sorted alphabetically.

Business Intelligence - SPC Portlet v1.2.21

Improvements

- Edit and delete buttons in monitors with manual types are now available.

Business Intelligence - SPC Server v1.3.0.1

Improvements

- SPC now uses the reporting database (fine-tuned for heavy queries while also preventing disruptions in the transactional database).

Business Systems Connectivity - ProcessWipMoves v1.0.3

New Features

- Support was added to include various attribute data in XML. When a serial goes to complete, send configured attribute data if it exists:

- Gen_attr_def is table_name = wip_movement, attr_name = so_attribute, gen_attr record has name of attribute in attr_data field.

Improvements

- ProcessWipMoves is configured to quit when one SendWipMove fails and delays other wip moves from processing to other servers. This can also result in skipped processes for other projects/databases if one SendWipMove task is failed.

CMMS - CMMS Portlet v2.4.0

Improvements

- AJAX security enhancements.

CMMS - CMMS Web Service v2.4.3

Improvements

- The company information is now arranged by the following order: Address, City, State, ZIP Code, Country according to conventions.

- OEE manual data collection user interface improvements.

- Tooling Control mapping, load and unload user interface improvements.

- CMMS single or multiple tenant support in a single instance.

- CalibrationHistory displays records for all of the calibration status changes rather than only the final status of a calibration record.

- System error messages improvement.

- Support multiple MES instances for tooling mapping/load/unload.

MES 101 - Android Device Maintenance v1.12.14

Improvements

- More log-Android Device Maintenance added to Android Device Maintenance Portlet.

- More log-Android Package Maintenance was added to Android Device Maintenance Portlet.

MES 101 - Conduit v1.8.0

Improvement

- Add capability for conduit to support custom algorithms in commands.

MES 101 - MES-API v1.12.0

New Features

- MES-API enhanced with the ability to add functionality to PCB 42Q to increase productivity, efficiencies and cost savings such as:

- Create Engineering notes that all parts can see by adding the notes based on the tool/cam number, even if a user has not yet been added to 42Q.

- Auto-populate the component item attribute fields in 42Q from actual material issue transactions in Oracle.

- Displays an error message when the user searches for a specific flex field for a given Part Number if it doesn't exist.

MES 101 - Production Workbench v1.7.9

New Features

- Access Control: Production Workbench is now exclusively accessible inside the portal.

- The user should launch Production Workbench when filling the login information and select the site. The site, plant and portal information should be pulled from the user context already logged in.

Improvements

- Tooltip was changed to add information for Serial Number quantity.

- Production Workbench command list will only allow users to select one finisher command.

- The validation message for Hold Non-Serialized was changed, to make it more clear that container configuration is missing.

- A new button was added to the command list in order to complete the command.

- The default value in the “Add Non-Serialized to Container” command was removed to optimize functions.

- Containers performance improvements:

- Add pagination of the results.

- Group by non-serialized items.

- Async calls to do commit when existing auto_commit tag on the conduit commands.

- The warning message was changed from location to error message.

- The error message during the removal of a Non-Serialized item from a container was changed to be more understandable for the user.

- An information message was added after completing the container capacity so the operator easily knows that the container was closed.

- Auto submits assembly steps were added.

- Message when the user tries to select more than one finisher command.

- Validate the Part Number when adding a non serialized unit to the container.

MES 101 - SFDC Portlet v1.14.40 (Document Control portlet)

Improvements

- A pop-up warning message will show when users input a wrong tool_cam_number format.

- "By Engineering Notes” function was removed to improve the document mapping module.

- An export function was added to export the AVP record from documents that are saved into files then records are imported into another document. This means exporting the current mapping and importing the mapping, which would allow users to make mass changes much quicker.

- Agile document download server improved for better performance.

- More logs provided for download & service and log-eManual Lite for better support.

- Chinese characters for Engineering Notes added for better customer experience.

- An import function was added to export the AVP record from documents that are saved into the file then records are imported into another document. This means exporting the current mapping and importing the mapping, which would allow users to make mass changes much quicker.

MES 101 - SFDC Web Service v1.12.19

Improvements

- The batch process was changed to “download” to connect to the MDS Host to download shop orders.

MES 101 - Shop Order Control v2.18.2

New Features

- New features applied to Shop Order Portlet, Shop Order Release, and Shop Order Browser:

- A new button (+) will be added to allow the user to include more filter fields. When pressing the (+) Button, the options will be displayed:

- Shop Order extra fields (that are not included on the filter yet).

- Generic Attribute definitions for Shop Order.

- Part Number extra fields (that are not included on the filter yet).

- Generic Attribute definitions for Part Number.

- Functionalities

- It will be possible to select more than one value or deselect a value that has already been inserted.

- It will be possible to filter the items.

- The filter fields will be updated with the currently selected values.

- A new button (+) will be added to allow the user to include more filter fields. When pressing the (+) Button, the options will be displayed:

MES+ MES-Interface v2.1.1

New Feature

- MSL Level WMS-PTS enhancements to run a server to sync the label from PTS database to Fuji database.

15.61 Non-Medical Deployment

Business Intelligence - MESWeb

Improvements

- Labels are printed with the “Null” legend when “project_preffix” is null on database.

- Unit History now displays the Custom message when there is no customer or route provided.

- Whole project reads environment variables for Configuration otherwise reads from properties files.

- Messweb response time was improved.

- Date Format is the same for exporting files and web application.

Business Intelligence - PTS & PTSR DB Schema

Improvements

- Report function response time was highly improved.

CMMS - CMMS Web Services

Improvements

- UI/UX enhancement for CMMS - Calibration List:

- Extra space between titles and text boxes was removed.

- Labels are now aligned to the right and boxes to the left.

- Search and Clear button is now consistent through the screens.

- Accuracy, grace period, interval and money spent fields are now align to the right.

- Actual calibration date, Calibration due date, last calibration date , planned date and Reschedule date are now align to the center.

- Space between categories was added.

- Headings were adjusted so that all titles are visible.

- UI/UX enhancement for CMMS - Spare Parts - Purchase Request:

- Extra space between titles and text boxes was removed.

- Label “Part #” was changed to “Part Number”.

- Labels are now aligned to the right and boxes to the left

- Search, Clear, Add, Edit and export buttons are now consistent through the screens.

- Code message was removed after Edit button.

- In the grid, Updated Date (Change from Update Date) is now aligned to the center.

- General tab was simplified in order to make the required fields required for PM Work Order and the ones required for Repair Work Order, easily identifiable.

- CMMS group configuration was simplified, The system might bring all those three Category from Group Setting table and add them to the Asset Group Configuration automatically once the user add this specific group to the Asset. (Refer to the Group Category Setting and add automatically)

- Search is now enabled on Press of enter key across CMMS modules.

- Export button to get all assets together is now available.

MES 101 - Android Device Maintenance Portlet

Improvements

- Android device maintenance portlet alfresco account was changed to User Guest account, instead of using Admin to access Alfresco.

MES 101 - Multi-Level Container Configuration

New features

- Dependency mesportal-password-util was updated to 1.0.2 to avoid encryption to add extra spaces.

Improvements

- Assign one or more Operations for each action (Add, Copy, Edit and Delete will be affected.,

- Add Element and/or Close

MES 101 - Multi-Level Container Maintenance Portlet

Improvements

- Dependency mesportal-password-util was updated to 1.0.2 to avoid encryption to add extra spaces.

MES 101 - PCB - Process WIPMoves

Improvements

- For fail to location not in route, get department from fail to location and use for rework dept in wip move.

- Label Engine and MDS labels for traveler are now able to support Chinese characters for printing.

MES 101 - Production Workbench

New features

- Cycle Time:

- Display planned Cycle Time upon initial serial scan.

- Count down from initial Planned Cycle Time.

- Production workbench it's now Accessible only inside the portal.

- Throughput indicator was added in the left vertical bar.

- Reliability on mouse usage was reduced by adding the following:

- The commands with the tag “auto_commit” will be automatically “save/send” to conduit on keypress ENTER.

- Error Message would display right after the prompt input (with Red color), if Command (transaction, validation) fails.

- The current command (prompt) will be removed from the list and one success message (green one) will be displayed.

- If command was executed successfully And if the “repeatable” tag is also present on this command, immediately after sending the command to Conduit a new prompt for that same command will be asked.

- The command with the tag “repeatable” will be automatically prompt at first time on keypress ENTER.

- User will be able to enable (the repeat behavior) for one command without configuring a tag for it.

- On the TextField (prompt) with Mouse Over a new button will be displayed (left side from delete button) to enable or disable this feature.

- The ESC key could be used to display or hide (toggle behavior) the command dropdown list.

- When the Command List is shown, the user can press the Arrows keys (Up and Down) to navigate on the list, and through the command and press ENTER to select it.

- After selecting at least one command on the list, and if none command is focused (with arrows keys) to close the dropdown list, the ENTER key could be pressed.

- PWB is now enabled to interact with the containerization functionality that it was available only in the portlet (Shop Order Control --> Production Control --> Multi-level Container Browse; This functionality is available through a new icon (open box) on the left bar, by clicking on it the content of the container become available; there are several commands that enabled such as :

- Create a container,

- Open container,

- Close container,

- Add the unit to the container,

- Add non-serialized to container

- Remove Unit from the container,

- Remove non-serialized from the container.

MES 101 - PSI

Improvements

- Android data collector is now supported by Android 9

MES 101 - SFDC Configuration Portlet

Improvements

- Mandatory columns are now marked with a “*” character.

- Defect Code is now imported with uppercase.

- SFDC configuration / Assembly Maintenance must support this new component types (Portlet and mes-api).

- “Consume from NSB”

- “Non-tracked with Quantity”

New features

- Dependency mesportal-password-util was updated to 1.0.2 to avoid encryption to add extra spaces.

MES 101 - Shop Order Control

New features

- Dependency mesportal-password-util was updated to 1.0.2 to avoid encryption to add extra spaces.

MES+ - Kit Verify Production Portlet

New features

- Dependency mesportal-password-util was updated to 1.0.2 to avoid encryption to add extra spaces.

MES - API

New features

- SFDC configuration / Assembly Maintenance must support this new component types (Portlet and mes-api).

- “Consume from NSB”

- “Non-tracked with Quantity”

***15.60.3 Medical Deployment***

Business Intelligence - MESWEB

New Features

- The pallet ID is now displayed in the Unit History report.

- The scheduler service will send only one call per application no matter the number of schedules configured.

- Execution application matches schedules with the application being called and limits the number of times that the scheduler application calls the API. Schedules that fail more than 3 times per day are disabled.

Improvements

- Unit history report enhanced with Tooling information coming from cmmr schema.

- Aging Report.

Business Intelligence - 42Q Live

New Features

- Encrypted password.

Improvements

- Portal name was changed from Monocle to 42Q Live and subfolders were removed from it at UAT and Production to match with *Development instance.

- 42Q Live portal layout page at UAT was being displayed in blank, but now is displaying the information properly.

Business Intelligence - Siesense New Features

- All dashboards created for 42Q or Business team are now available through Sisense portlet.

Business Intelligence - SPC

Improvements

- Httpurl template for SPC updated in Database.

- "GO" button at Quality-SPC is now displaying correctly.

- SPC - Portlet wireframe security improved

- Issue that avoided user to see monitors groups on SPC was fixed

CMMS

New Features

- New CMMS/OEE icons for the new portlets.

- For ease of use, Move Company module to CMMS admin as Company information will be used both by Assets and Spare Parts. It’s more like of Admin stuff.

Improvements

- Distinguished Color between valid and invalid PM Reschedule date

- Multi-language supported.

- Accessible modules are shown by user’s permissions.

- UAT CMMS group removal pop up language change to English.

- CMMS system error message improvement

- Client ID enhancements

- 5 Hours shift does not longer cause overlapping.

- Duplicated Locator is not allowed for Subinventory and error messages were replaced to plain language instead of code language.

- Remaining Qty/QOH is now updated after return operation

- Asset ID, Asset Name and Asset Type are now mandatory fields for the complete CMMS Asset record Creation/Editing process.

- Multiple shop order is now supported by jig load.

- New "Overdue" status available for Work Order Status Report.

- OEE Data collection interface improved for Report Asset Down.

- CMMS Overdue filter added to Work order searching drop down list.

- CMMS Checklist timeout update was enhanced

- Quality and Performance data are now retrieved from MES101-OEE MES-API

- Calibration History information is now displayed on the Calibration History tab, rather than just the future calibration date and plant.

- Label Part # was changed to Part Number in Purchase Request

- Labels aligned to the right and boxes to the left.

- Consistent search, clear, add, edit, export button to all modules of CMMS- Spare parts.

- Code message after edit button was removed from Purchase Request and Transaction Log.

- In the grid, Updated Date (Change from Update Date) are aligned to the center at Purchase Request, Transaction Log, Transfer Parts, Cycle Count, Reuse Parts, Scrap Parts, Adjust Parts, Return Parts, Issue Parts, Inventory View and Receive parts.

- Drop-down feature added for Transaction Log

- Headings were adjusted to make titles visible at Inventory View, Reuse Parts, Scrap Parts, Adjust Parts, Transfer Parts and Issue Parts.

- Clean button was changed to Clear at Transaction Log.