Difference between revisions of "SOP-42Q-MES0041 100 Traceability"

Dane parker (talk | contribs) |

|||

| Line 5: | Line 5: | ||

<br> | <br> | ||

<center>This Work Instruction is Sanmina's corporate standard.</center> <center>This document is under revision control. The latest revision is located on SanminaNet.</center> <center>Once printed it is an uncontrolled copy. All alterations to this work instruction require approval.</center> <center>Contact the IT Global Education and Training Department to submit suggested alterations and or updates.</center> | <center>This Work Instruction is Sanmina's corporate standard.</center> <center>This document is under revision control. The latest revision is located on SanminaNet.</center> <center>Once printed it is an uncontrolled copy. All alterations to this work instruction require approval.</center> <center>Contact the IT Global Education and Training Department to submit suggested alterations and or updates.</center> | ||

| − | ''This edition applies to MES15 Portal 1.0 Application and all subsequent releases and modifications until otherwise indicated in new revisions. | + | ''This edition applies to MES15 Portal 1.0 Application and all subsequent releases and modifications until otherwise indicated in new revisions.'' |

= Production = | = Production = | ||

| − | + | The Parts Traceability System (PTS) is one of the applications within the MES suite of tools. It was developed to meet the demands of customers to provide component level traceability as well as to provide quality controls. This system plays a very important role in automating the production lines and raising productivity as well as enforcing rigorous product quality control. It has been implemented to many Sanmina plants across the globe. This application and the features it provides continue to evolve, as the changing technologies used for the SMT process equipment tools become more detailed and rich in functionality. <br> | |

| − | |||

| − | The Parts Traceability System (PTS) is one of the applications within the MES suite of tools. It was developed to meet the demands of customers to provide component level traceability as well as to provide | ||

== 100% Traceability == | == 100% Traceability == | ||

| Line 18: | Line 16: | ||

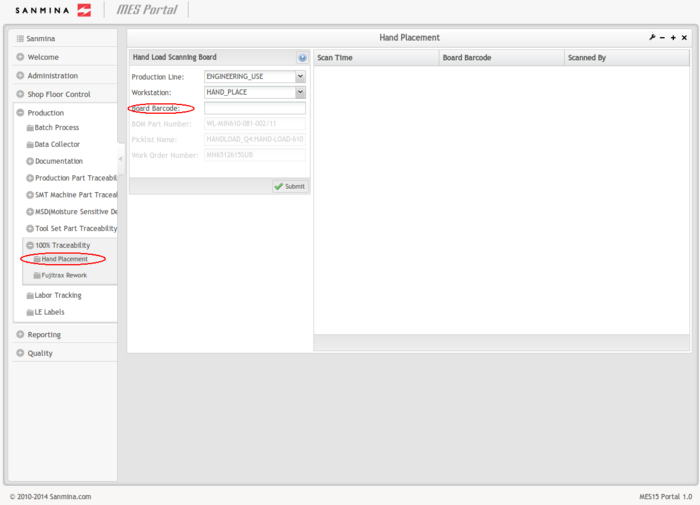

1. To access the Hand Placement page, navigate to '''Production <nowiki>></nowiki> 100% Traceability <nowiki>></nowiki> Hand placement.''' | 1. To access the Hand Placement page, navigate to '''Production <nowiki>></nowiki> 100% Traceability <nowiki>></nowiki> Hand placement.''' | ||

| + | |||

'''Figure 1: Hand Placement''' | '''Figure 1: Hand Placement''' | ||

| − | [[Image: | + | [[Image:01 100T Hand placement-main.png|left|700px|01 100T Hand placement-main.png]]<br> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

2. Choose the Production Line and Workstation, then enter the Board Barcode and select '''Submit'''. If the material is sufficient a "Successful" message will display in the right section of the Portlet. This section will also display the '''Scan Time''', '''Board Barcode''', and the '''Scanned By '''information. | 2. Choose the Production Line and Workstation, then enter the Board Barcode and select '''Submit'''. If the material is sufficient a "Successful" message will display in the right section of the Portlet. This section will also display the '''Scan Time''', '''Board Barcode''', and the '''Scanned By '''information. | ||

| Line 67: | Line 66: | ||

3. If material is not sufficient an "Error-Workstation material has run out when scan!" message will display. This is because some things need to be verified before using 100% traceability hand placement function. | 3. If material is not sufficient an "Error-Workstation material has run out when scan!" message will display. This is because some things need to be verified before using 100% traceability hand placement function. | ||

| − | + | NOTE: | |

*First, the chosen Production Line must be on line. Also, you can add a Production Line and Workstation at other Portlets in PTS, and then set it on line. | *First, the chosen Production Line must be on line. Also, you can add a Production Line and Workstation at other Portlets in PTS, and then set it on line. | ||

*Second, the Part Number must set 100% Traceability at "PN Extra Info" page. | *Second, the Part Number must set 100% Traceability at "PN Extra Info" page. | ||

| − | *When hint Error, the user must load material of the same Part Number for scanning. The user can select the '''Load Material''' Portlet to load material to a workstation. After this the user can repeat the actions: Choose Production Line, Workstation, and input a Board Barcode for scanning. A dialog box will display. The user can choose the Old Component and New Component from the corresponding Designator. | + | *When hint Error, the user must load material of the same Part Number for scanning. The user can select the '''Load Material''' Portlet to load material to a workstation. After this the user can repeat the actions: Choose Production Line, Workstation, and input a Board Barcode for scanning. A dialog box will display. The user can choose the Old Component and New Component from the corresponding Designator. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | '''Figure 2: Hand Placement: P/N Extra Information''' | ||

| + | [[Image:02 100T Hand placement-PN Extra info.png|left|700px|02 100T Hand placement-PN Extra info.png]]<br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

=== Fujitrax Rework === | === Fujitrax Rework === | ||

| Line 122: | Line 122: | ||

'''Figure 3: Fujitrax Rework''' | '''Figure 3: Fujitrax Rework''' | ||

| − | [[Image: | + | [[Image:03 100T FujiTrax Rework.png|left|700px|03 100T FujiTrax Rework.png]]<br> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

1. Enterthe '''Board''' '''S/N''', and '''Designator'''. The old component and lot code will display. | 1. Enterthe '''Board''' '''S/N''', and '''Designator'''. The old component and lot code will display. | ||

| Line 170: | Line 170: | ||

3. Select '''Submit.''' | 3. Select '''Submit.''' | ||

| + | <br> | ||

== Document Revision History == | == Document Revision History == | ||

Revision as of 14:42, 12 March 2014

This edition applies to MES15 Portal 1.0 Application and all subsequent releases and modifications until otherwise indicated in new revisions.

Contents

Production

The Parts Traceability System (PTS) is one of the applications within the MES suite of tools. It was developed to meet the demands of customers to provide component level traceability as well as to provide quality controls. This system plays a very important role in automating the production lines and raising productivity as well as enforcing rigorous product quality control. It has been implemented to many Sanmina plants across the globe. This application and the features it provides continue to evolve, as the changing technologies used for the SMT process equipment tools become more detailed and rich in functionality.

100% Traceability

Hand Placement

1. To access the Hand Placement page, navigate to Production > 100% Traceability > Hand placement.

Figure 1: Hand Placement

2. Choose the Production Line and Workstation, then enter the Board Barcode and select Submit. If the material is sufficient a "Successful" message will display in the right section of the Portlet. This section will also display the Scan Time, Board Barcode, and the Scanned By information.

3. If material is not sufficient an "Error-Workstation material has run out when scan!" message will display. This is because some things need to be verified before using 100% traceability hand placement function.

NOTE:

- First, the chosen Production Line must be on line. Also, you can add a Production Line and Workstation at other Portlets in PTS, and then set it on line.

- Second, the Part Number must set 100% Traceability at "PN Extra Info" page.

- When hint Error, the user must load material of the same Part Number for scanning. The user can select the Load Material Portlet to load material to a workstation. After this the user can repeat the actions: Choose Production Line, Workstation, and input a Board Barcode for scanning. A dialog box will display. The user can choose the Old Component and New Component from the corresponding Designator.

Figure 2: Hand Placement: P/N Extra Information

Fujitrax Rework

Figure 3: Fujitrax Rework

1. Enterthe Board S/N, and Designator. The old component and lot code will display.

2. Enter the New Component and Remark.

3. Select Submit.

Document Revision History

| Date | Author | Title | Version | Change Reference |

| 08/01/13 | Helena Wang | Technical Writer | 1.0 | Initial SO Work Instruction |

| 02/17/14 | Ashley Martin | Technical Writer | 1.0 | Review and Format |

| 02/28/14 | Elaine Fonaro | Technical Writer | 1.0 | Format for WIKI |